Method for analyzing defect type through scanning electron microscope and microscope

A technology of scanning electron microscopy and defect types, which is applied in the direction of analyzing materials, using wave/particle radiation for material analysis, testing metal components, etc., and can solve problems such as inaccurate determination and inability to find solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

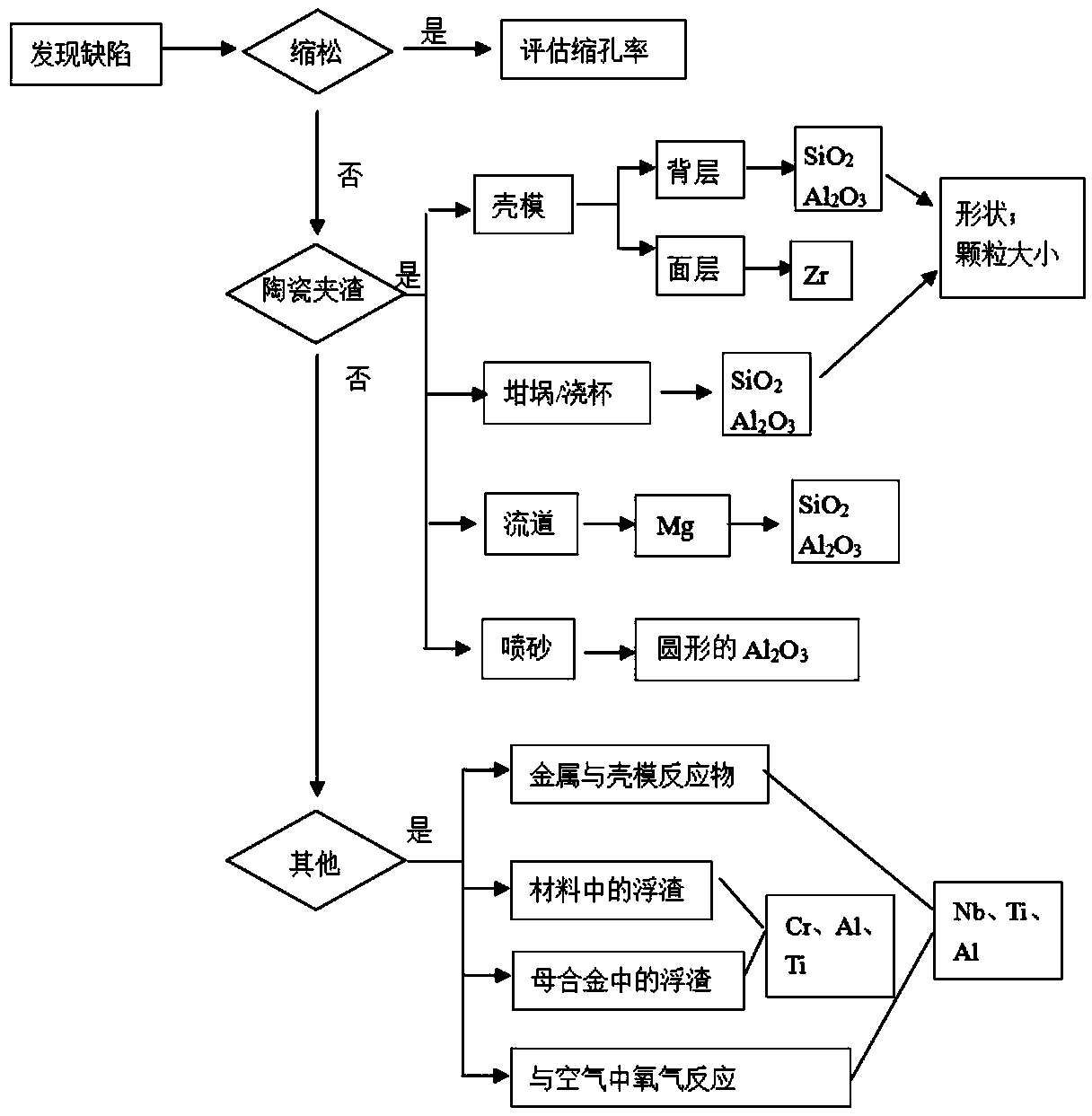

[0056] 1. Preliminary judgment is made on the surface defect of the casting, the defect position is displayed with fluorescence, and the defect position is made into a gold image, such as Figure 8 ;

[0057] 2. Use a scanning electron microscope to observe the tissue morphology at 50-1000 times

[0058] 1) Observe its morphological structure: such as Figure 9 , which has no fixed shape and rough edges, and is preliminarily determined to be oxidized slag inclusions;

[0059] 2) if Figure 10 , it can be found that the composition of the defect area is different from that of the base metal, which is in line with the characteristics of oxidized slag inclusions;

[0060] 3) Surface scanning is enriched at the same position, such as Figure 11 As shown, the defect area mainly contains Al and O elements, and more Cr and Nb elements are also detected in the defect area. The detected elements and percentages are shown in the following table:

[0061]

[0062] 3. Conclusion: Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com