Rapid analysis method for major elements, minor elements and trace elements in alloy slag charge

A trace element, rapid analysis technology, applied in the field of analysis and testing, can solve the problems of poor representativeness, small sampling amount, easy to pollute the environment, etc., to achieve a good guiding role and reduce detection costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

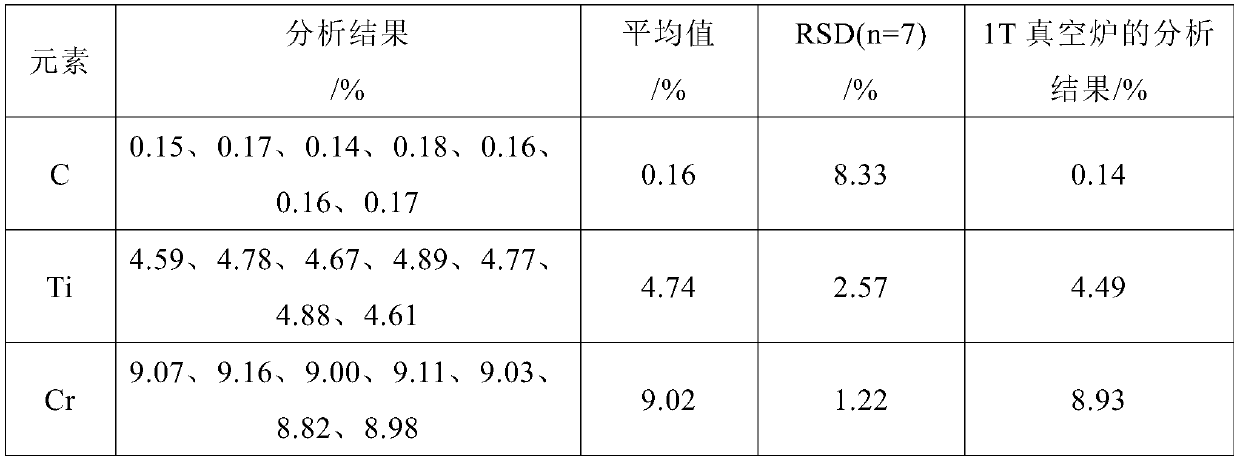

Examples

Embodiment 1

[0023] a. Take about 250g of K417 casting high-temperature alloy blade slag material, with a diameter ranging from 0.5 to 10mm. Put the above-mentioned alloy slag material into the prepared lye, and add potassium hydroxide to every 100g of water. 5g, 18g of sodium hydroxide and 5mL of saturated ammonia water. The lye is heated to 80°C for ultrasonic cleaning for 5 minutes, and then continuously cleaned with pure water. Mix organic reagents with ultrasonic cleaning for 5 minutes and then blow dry. The frequency of ultrasonic waves is 60-100KHz, and the power of ultrasonic waves is 50-1000W;

[0024] b. Put the alloy slag into the copper-based crucible of the MSM20-7 (non-consumable) metal smelting furnace and pile it up into a cone shape. The copper-based crucible is circulated with cooling water to prevent the copper-based crucible from melting. The base crucible has an inner diameter of 25 mm and a depth of 10 mm. After vacuuming the metal melting furnace, it is filled with a...

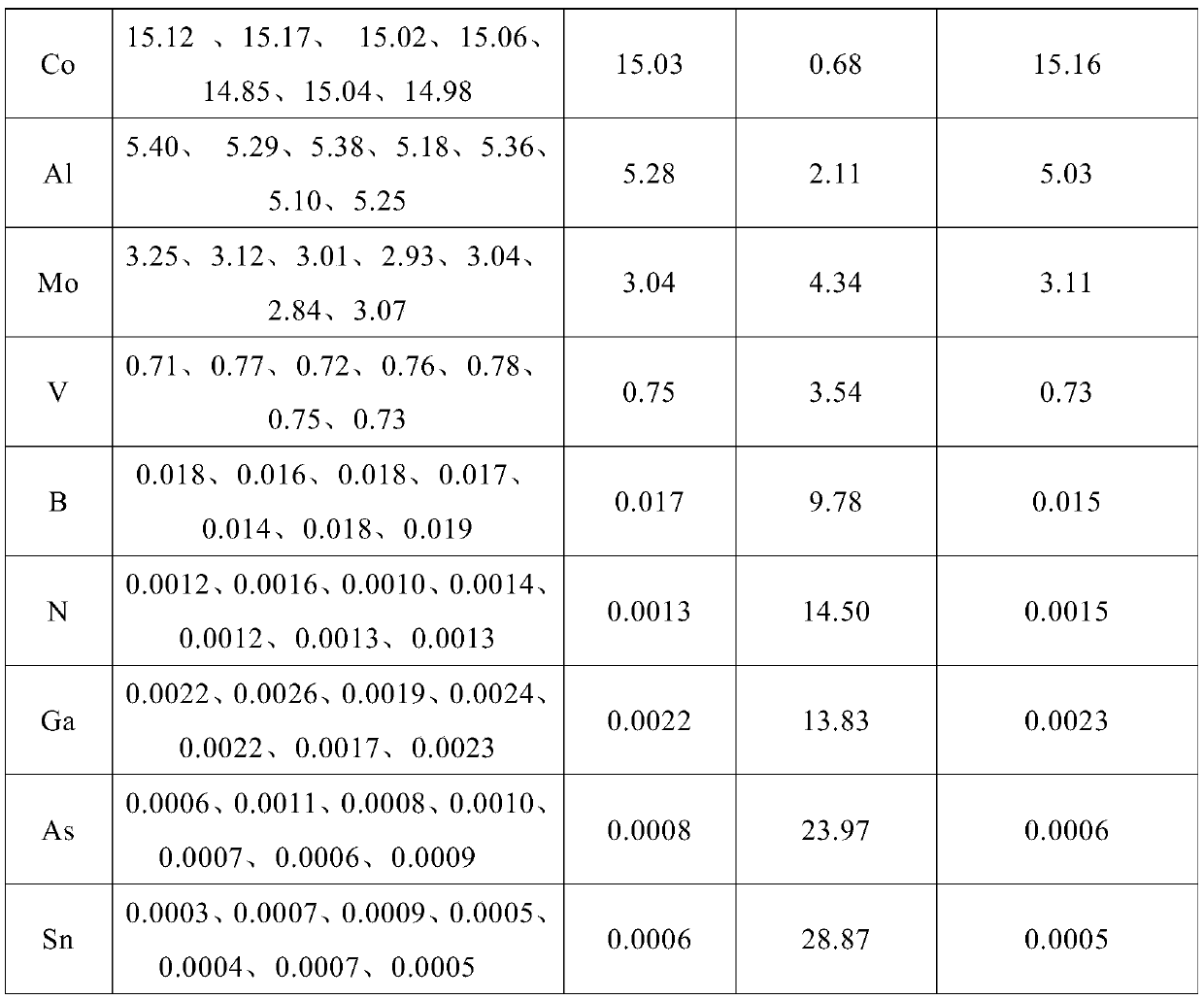

Embodiment 2

[0029] a. Take about 150g of deformed alloy milling material with a length of 0.5-20mm and grade K4169, wash it with pure water and put it into the lye consisting of 8g of potassium hydroxide, 15g of sodium hydroxide and 10mL of saturated ammonia water per 100g of water , heated the lye to 90°C and ultrasonically cleaned for 5 minutes, then continuously washed with pure water for 3 times, ultrasonically cleaned for 5 minutes in an organic reagent mixed with absolute ethanol, acetone and carbon tetrachloride at a volume ratio of 2:1:1, and then dried , the ultrasonic frequency is 60-100KHz, and the ultrasonic power is 50-1000W;

[0030] b. Put the alloy slag into the copper-based crucible of the MSM20-7 (non-consumable) metal smelting furnace and pile it up into a cone shape. The copper-based crucible is circulated with cooling water to prevent the copper-based crucible from melting. The base crucible has an inner diameter of 35 mm and a depth of 15 mm. After vacuuming the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com