Component change prediction method and system for special steel type mixed casting blank

A prediction method and mixed-casting billet technology, applied in the field of iron and steel manufacturing, can solve the problem that the prediction model relies on laboratory numerical simulation calculation or water model experiment, etc., and achieve the effect of accurate starting position and ending position and accurate judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

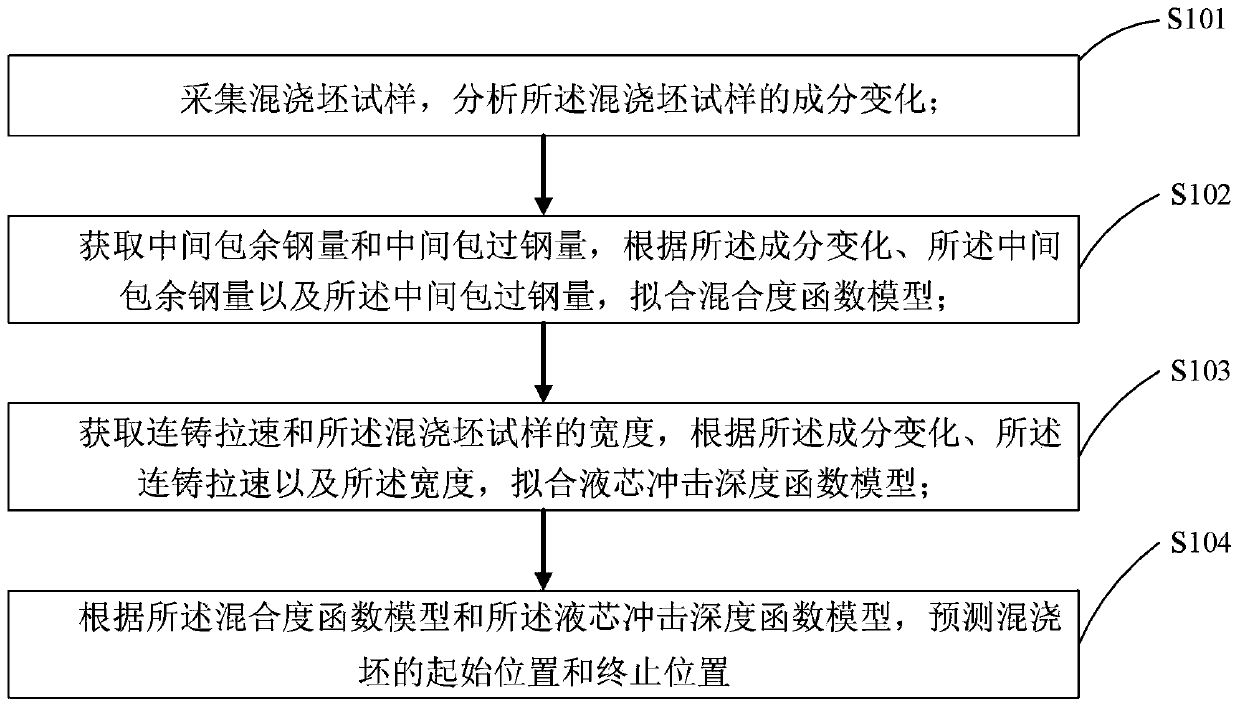

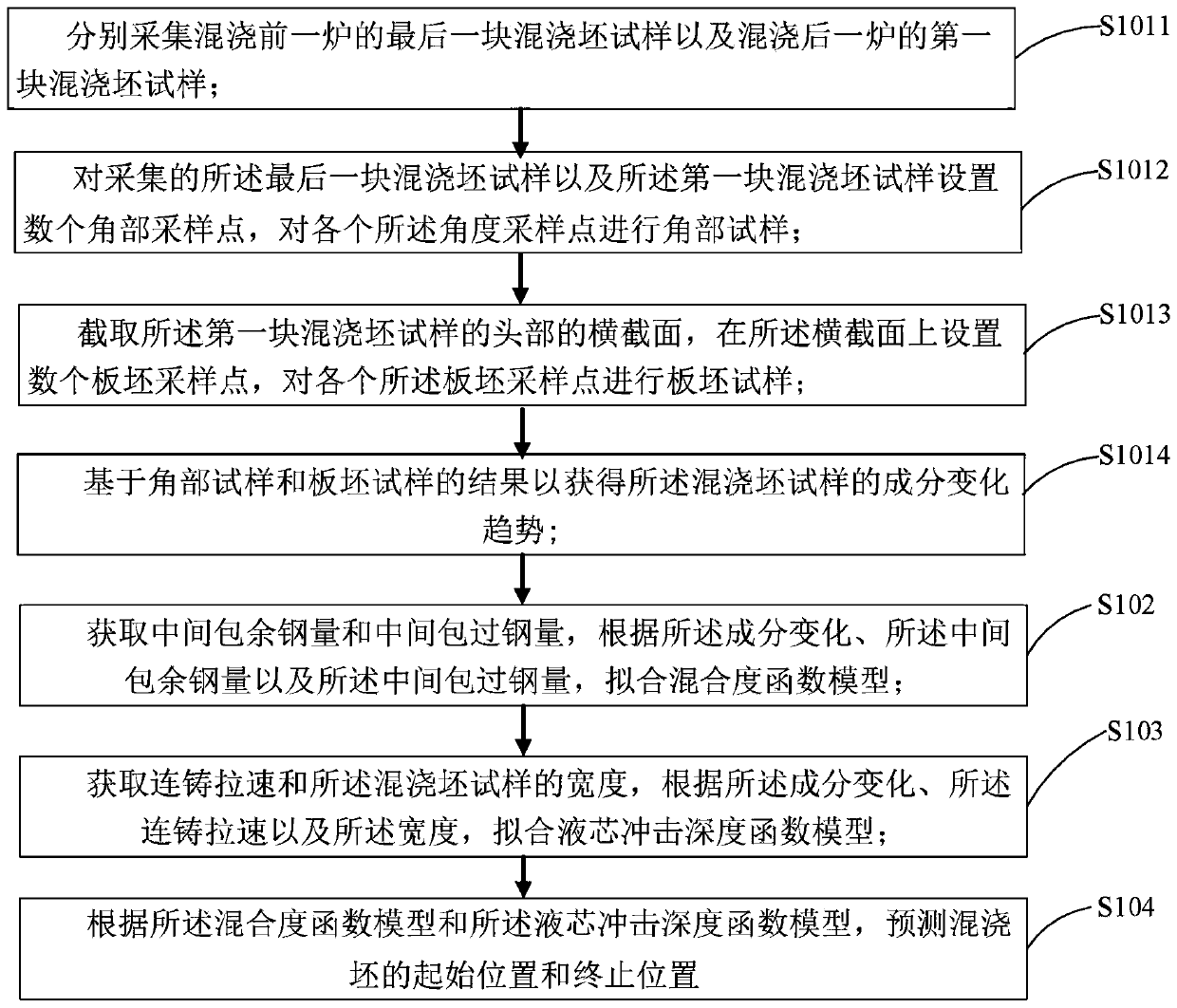

Method used

Image

Examples

specific Embodiment

[0093] S201, mixed pouring of SAPH370 and SAPH440, SAPH370 is the molten steel from the furnace before the mixing, and SAPH440 is the molten steel from the furnace after the mixing; among them, when the molten steel ladle of SAPH440 is opened, the remaining steel in the tundish is 55.20t , the main process parameters and predicted values of the mixed casting model are shown in Table 3;

[0094] Table 3 Mixed pouring process parameter list

[0095]

[0096] S202, performing corner samples and cross-section samples on the mixed cast billet respectively;

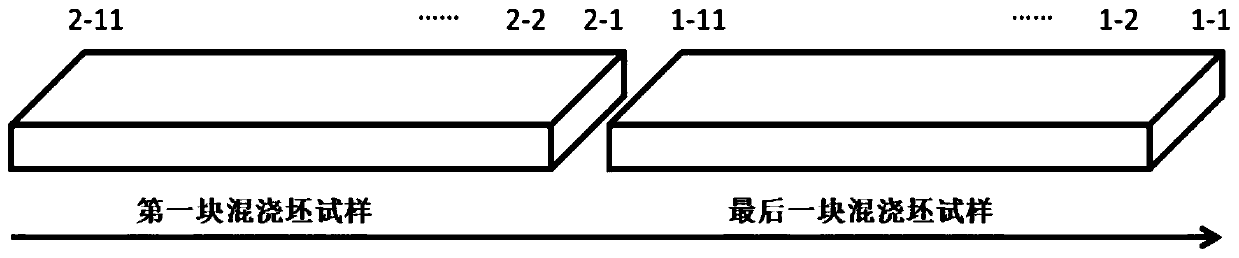

[0097] Collect the last sample of the mixed billet from the heat before the pouring and the first sample of the billet from the heat after the pouring;

[0098] The corner samples were sampled every 1m, and the components at different sampling positions were detected by a spark direct reading spectrometer from the last sample and the first sample.

[0099] Intercept the cross-section of the head of the first mixed cast s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com