Method for extracting metal compound particles, method for analyzing metal compound particles, and electrolyte solution used in said methods

一种金属化合物、提取方法的技术,应用在金属化合物粒子的提取、该金属化合物粒子的分析以及在这些中使用的电解液领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] The present invention will be described below through examples. However, the present invention should not be limited to the following examples and interpreted.

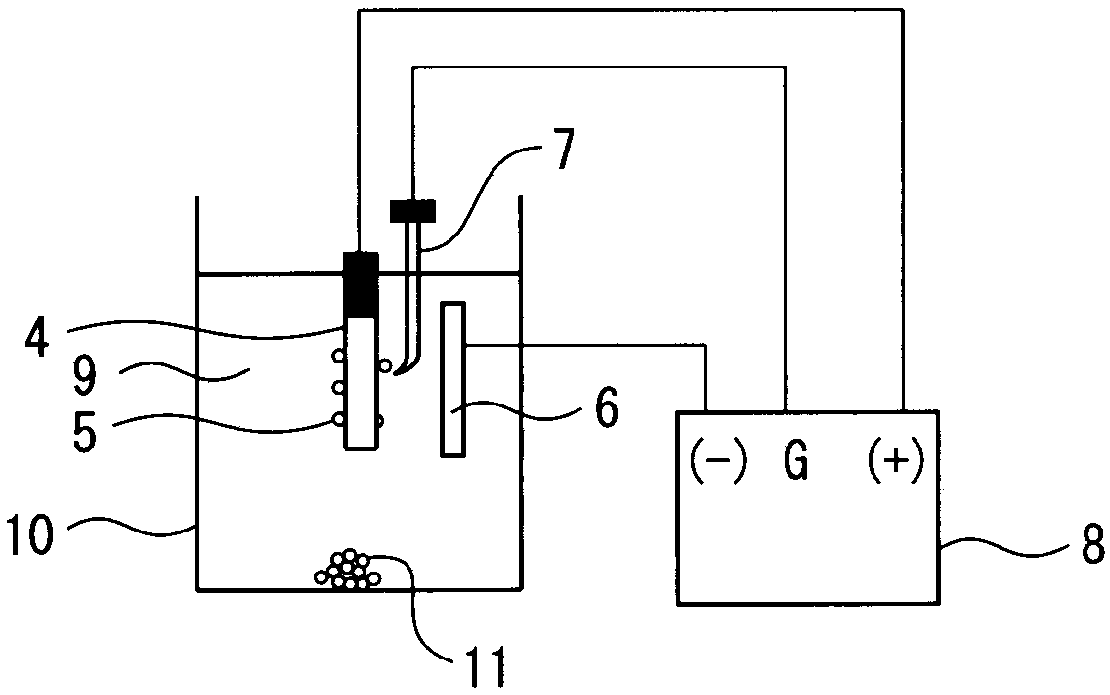

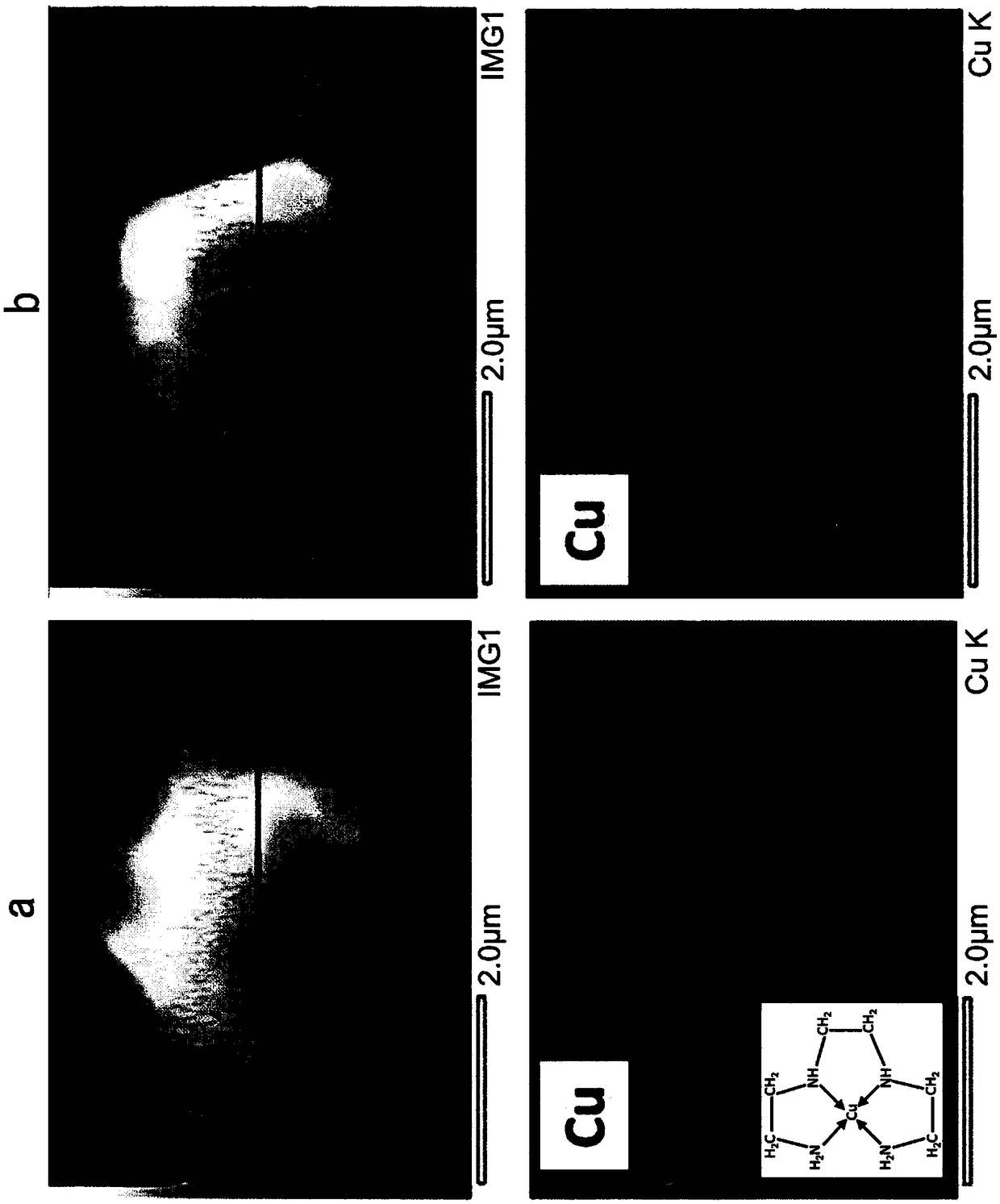

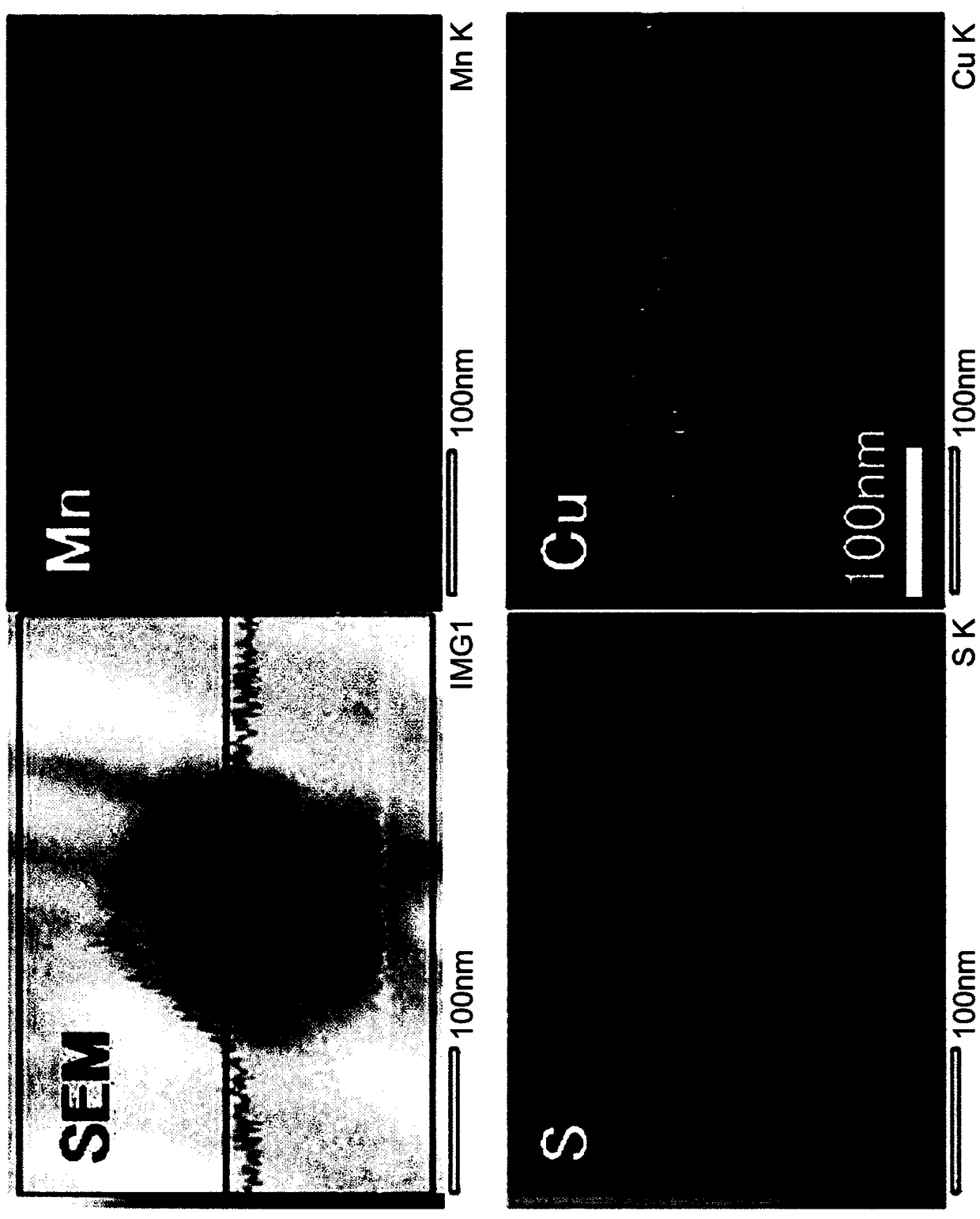

[0157] The inclusions or precipitated phases in the iron and steel samples were observed by using the electrolyte solution and the electrolysis method of the present invention. As a comparative example, a sulfide-based inclusion containing 4% by mass of methyl salicylate + 1% by mass of salicylic acid + 1% by mass of tetramethylammonium chloride (TMAC) that has been known to recover sulfide-based inclusions as a residue was used. ) of the conventional electrolyte solution (4% MS), using the comparative example of electrolysis, the inclusions or precipitated phases of the same iron and steel samples were observed. As the electrolytic solution of the present invention, an electrolytic solution (5% TETA) of 5% by volume of triethylenetetramine (TETA) + 1% by mass of tetramethylammonium chloride (TMAC) was used. ...

Embodiment 2

[0169] Quantitative analysis of inclusions or precipitates in steel samples was performed by electrolysis using the electrolytic solution of the present invention. As a comparative example, a comparative example in which electrolysis was performed using a conventional electrolytic solution was prepared.

[0170] In this example, as a steel sample, a steel material containing 0.4% by mass of Cu was heat-treated at 1350° C. for 30 min for solid solution, and then rapidly cooled in water.

[0171] The following three types of electrolyte solutions were prepared.

[0172] (1) 4% MS: 4% by mass of methyl salicylate + 1% by mass of salicylic acid + 1% by mass of tetramethylammonium chloride, which has been known to recover sulfide-based inclusions as residues (TMAC) as a control example.

[0173] (2) 4% MS+5% TETA: 5% by volume of triethylenetetramine (TETA), which forms a complex with Cu ions, was added to the 4% MS of (1).

[0174] (3) 5% TETA: an electrolytic solution of triet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| complex stability constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com