Device for electrolytic etching and method for extracting metal compound particles

A metal compound, electrolytic etching technique used in materials analysis using wave/particle radiation, electrolytic components, electrolytic processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0157] The present invention will be described below through examples. However, the present invention should not be limited to the following examples and interpreted.

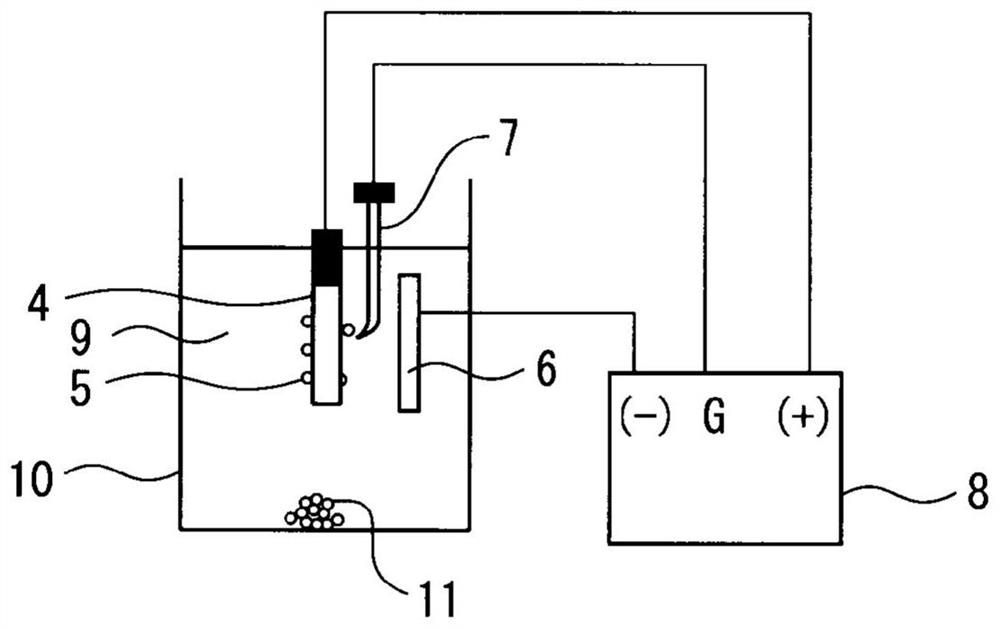

[0158] Quantitative analysis of inclusions or precipitates in steel samples was carried out by electrolysis using the apparatus for electrolytic etching of the present invention. As a comparative example, a comparative example in which electrolysis was performed using a conventional electrolytic solution was prepared.

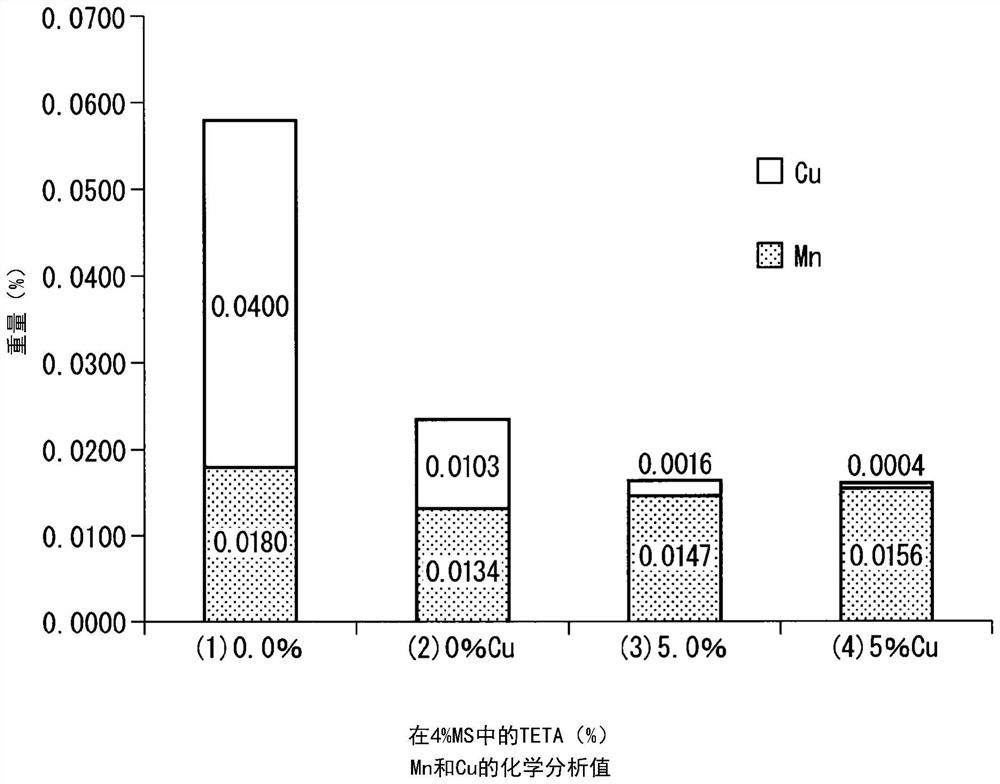

[0159] In this example, as a steel sample, a steel material containing 0.4% by mass of Cu was heat-treated at 1350° C. for 30 min for solid solution, and then rapidly cooled in water.

[0160] The following two types of electrolyte solutions were prepared.

[0161] (1) 4% MS: It has been known for a long time that sulfide-based inclusions can be recovered as a residue, and contains 4% by mass of methyl salicylate + 1% by mass of salicylic acid + 1% by mass of tetramethyl chloride Triammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com