High-temperature steam oxidation quenching test device and method for reactor cladding material

A test device and high-temperature steam technology, applied in the field of nuclear safety control, can solve the problems of furnace heat transfer performance, not easy to adjust arbitrarily, lack of cooling process, etc., and achieve the effects of low cost, easy operation, and easy sample temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

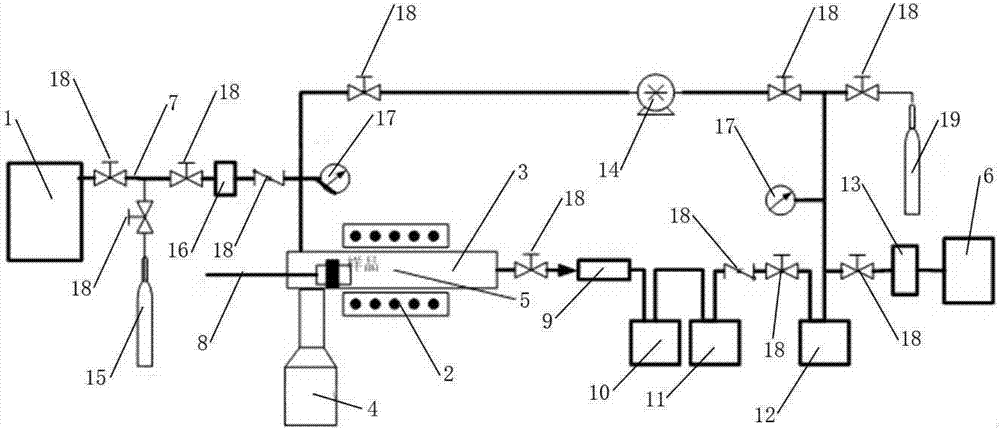

[0035] Exemplary reactor cladding material high temperature steam oxidation quenching test device of the present invention is as figure 1 As shown, it includes steam generator 1, ordinary resistance furnace 2, reaction chamber 3, quenching pool 4, thermocouple 5, hydrogen analyzer 6, connecting pipeline 7, push rod 8, condenser 9, water storage tank 10, cooling Well 11, hydrogen storage cylinder 12, filter 13, vacuum pump 14, inert gas source 15, flow meter 16, pressure gauge 17, valve 18, nitrogen source 19 with carrier.

[0036] The core of the steam generator 1 is a boiler that heats water to generate steam, uses deionized water to replenish water automatically, and provides 0.1-1MPa steam at the outlet. The high-temperature steam provided by the steam generator 1 enters the reaction chamber 3 through the connecting pipeline 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com