Analytical method of nitrogen content in scrap like steel

An analysis method, a technology of nitrogen content, applied in the direction of material thermal conductivity, etc., to achieve the effect of solving the analysis of nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

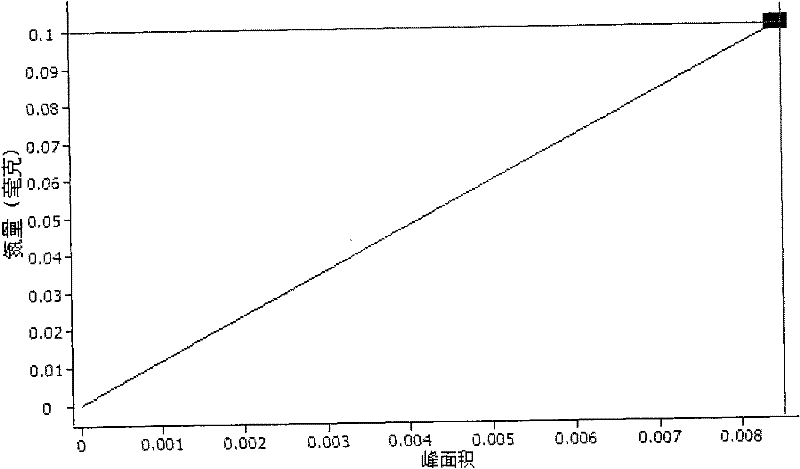

Image

Examples

Embodiment

[0034] 1. Reagents and equipment

[0035] Acetone (analytical pure)

[0036] Ultrasonic cleaner (model KH3200)

[0037] High purity helium (carrier gas)

[0038] Ordinary nitrogen (power gas)

[0039] TCH600 Oxygen, Nitrogen and Hydrogen Analyzer (product of Leco, USA)

[0040] Graphite crucible (special crucible for oxygen, nitrogen and hydrogen analyzer, Leco 776-247)

[0041] Heating furnace (electrode pulse furnace, part of TCH600 oxygen, nitrogen and hydrogen analyzer)

[0042] Gas analyzer (referring to TCH600 oxygen, nitrogen and hydrogen analyzer)

[0043] 2. Working parameters

[0044] Power gas pressure: 40psi;

[0045] Carrier gas pressure: 20psi;

[0046] Degassing time: 35 seconds;

[0047] Degassing power: 5300W;

[0048] Cleaning time before analysis: 80 seconds;

[0049] Analysis power: 4800W;

[0050] Analysis time: 55 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com