Verification device for nitriding furnace ammonia gas decomposition rate and verification method thereof

A verification method and a verification device technology, which are applied in the field of chemical heat treatment, can solve problems such as waste products, affecting product quality, and blocking the tail gas collection pipeline of hydrogen analyzers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

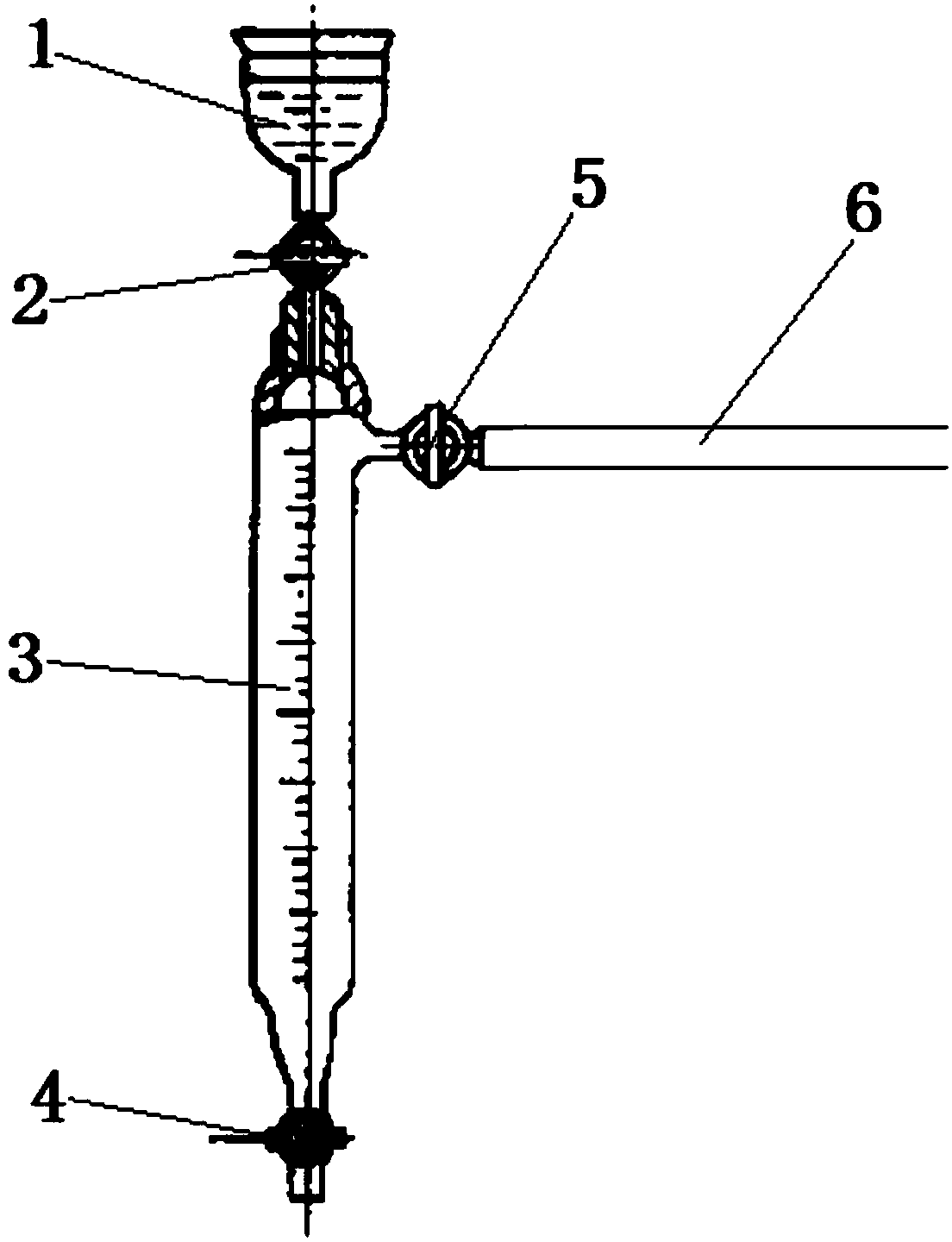

Image

Examples

Embodiment 1

[0040] The verification of the ammonia decomposition rate was carried out under the condition that the temperature of the nitriding furnace was 600°C.

[0041] Firstly, the calibration body of the present invention is communicated with the gas collection pipeline on the nitriding furnace grate pipeline; then the ammonia decomposition rate obtained by the calibration body of the method of the present invention is 80%, and the hydrogen analysis of the nitriding furnace exhaust pipeline is connected The ammonia decomposition rate obtained by the instrument is 80%; it shows that the data of the hydrogen analyzer is correct.

Embodiment 2

[0043] The verification of the ammonia decomposition rate is carried out under the condition that the temperature of the nitriding furnace is 550°C.

[0044] First, the calibration body of the present invention is communicated with the gas collection pipeline on the nitriding grate pipeline; then the ammonia decomposition rate obtained by the calibration body of the method of the present invention is 79.5%, and the hydrogen analysis of the nitriding furnace exhaust pipeline is connected The ammonia decomposition rate obtained by the instrument is 80%; it shows that the data of the hydrogen analyzer is correct.

Embodiment 3

[0046] The ammonia decomposition rate was verified when the temperature of the nitriding furnace was 600°C.

[0047] First, the calibration body of the present invention is communicated with the gas collection pipeline on the nitriding grate pipeline; then the ammonia decomposition rate obtained by the calibration body of the method of the present invention is 60%, and the hydrogen analysis of the nitriding furnace exhaust pipeline is connected The ammonia decomposition rate obtained by the instrument is 63%; it shows that the data of the hydrogen analyzer is wrong, and the hydrogen analyzer needs to be calibrated, and the gas filter of the hydrogen analyzer should be cleaned to clear the impurities in the gas filter, thereby improving Measurement accuracy of hydrogen analyzers.

[0048] By using the device and the verification method of the invention, the measurement results of the hydrogen analyzer can be monitored in real time to ensure that the product quality is monitored...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com