Oxidative adsorption experiment system and method for trace amount of hydrogen in oxygen atmosphere

An oxygen atmosphere and experimental system technology, which is applied in the direction of radioactive purification, climate sustainability, and reduction of greenhouse gases, can solve the problems of complex adjustment and calibration of measuring instruments and great influence, and achieve complete development and stability, improve mixing effects, and enhance The effect of experimental precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

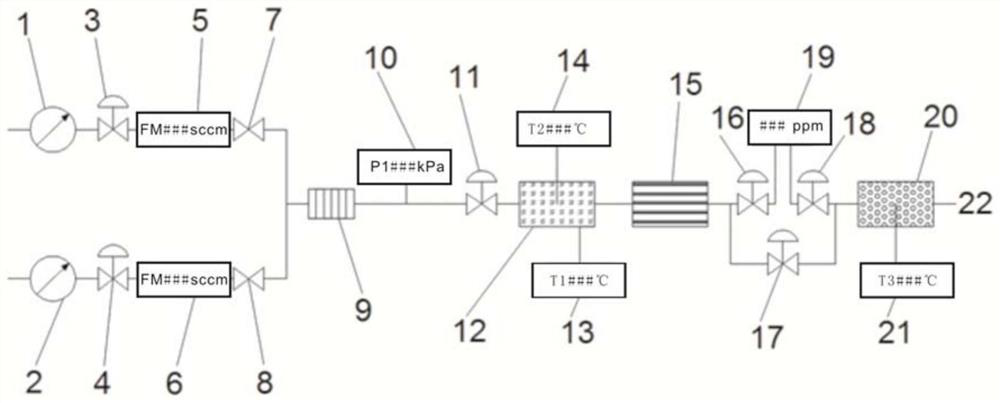

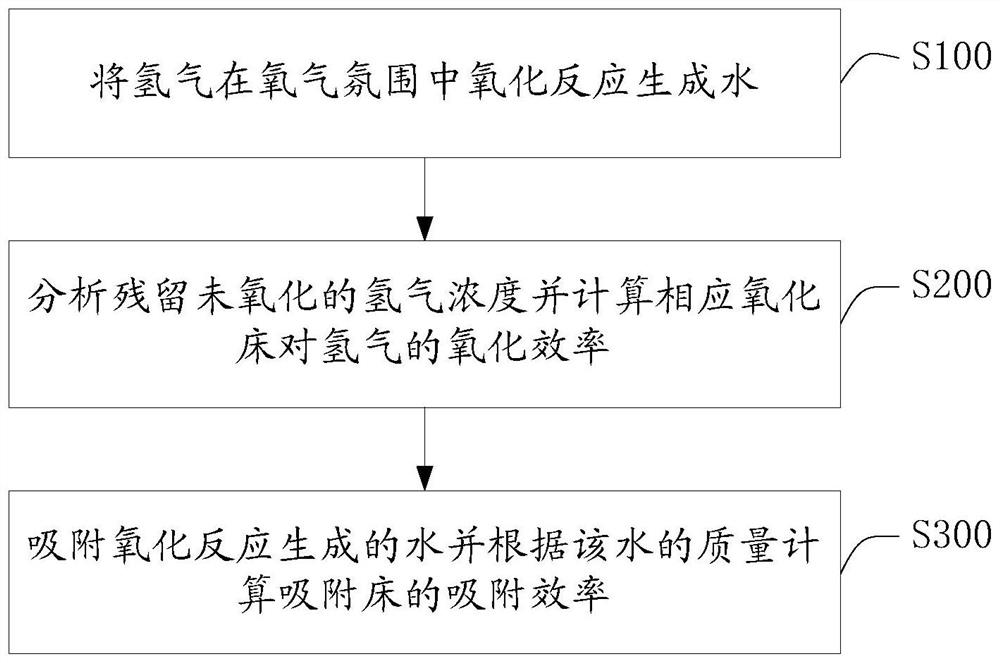

[0029] Such as figure 1 As shown, the present invention provides an oxidative adsorption experimental system for trace hydrogen in an oxygen atmosphere, comprising an oxidation bed, a trace hydrogen analyzer 19 and an adsorption bed connected in sequence; a gas source is connected to the inlet of the oxidation bed; the gas source is connected to the inlet of the oxidation bed; The source includes a hydrogen source and an oxygen source, both of which are connected to the inlet of the oxidation bed through a three-way valve to react in the oxidation bed to generate water; the trace hydrogen analyzer 19 is used to analyze the concentration of residual unoxidized hydrogen; The adsorption bed is used to absorb the water generated by the reaction.

[0030] In this embodiment, the copper oxide bed 12 is used for the oxidation bed, and the molecular sieve be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com