Method for measuring content of trace hydrogen in low alloy steel

A low-alloy steel and hydrogen content technology, applied in the field of analysis and testing, can solve the problems of detecting trace hydrogen content in low-alloy steel, and achieve the effect of improving accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

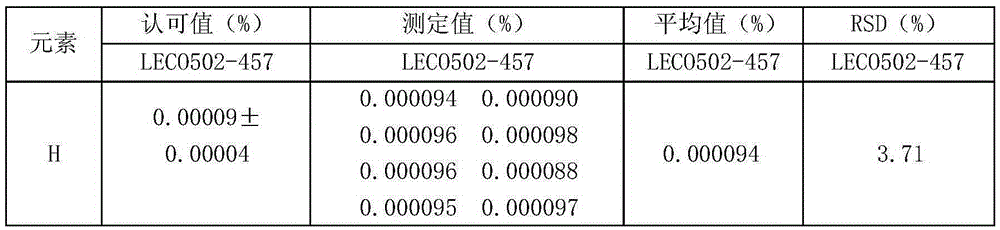

[0030] Embodiment 1: Analysis of hydrogen content standard substance LECO502-457 in steel

[0031] Step 1: Preparation of test conditions

[0032] Sub-step 1.1: Instrument selection

[0033] It is determined that the hydrogen analyzer is a device for detecting trace hydrogen content in the standard substance LECO502-457. The setting parameters of the device are: degassing power 3900W, time: 60s, analysis power 2500W, minimum analysis time: 80s, degassing method: Double degassing, flow rate: 150ml / min, measurement pressure: 15psi, inlet pressure: 40psi.

[0034] Sub-step 1.2: Preparation of main reagents and materials:

[0035] Diethyl ether or acetone: analytically pure,

[0036] Standard substance of hydrogen content in steel:

[0037] American LECO501-529, hydrogen content: 0.00058% ± 0.00008%

[0038] American LECO502-457, hydrogen content: 0.00009% ± 0.00004%

[0039] Graphite crucible: spectrally pure, high temperature crucible;

[0040] Step 2: Preparation of Spec...

Embodiment 2

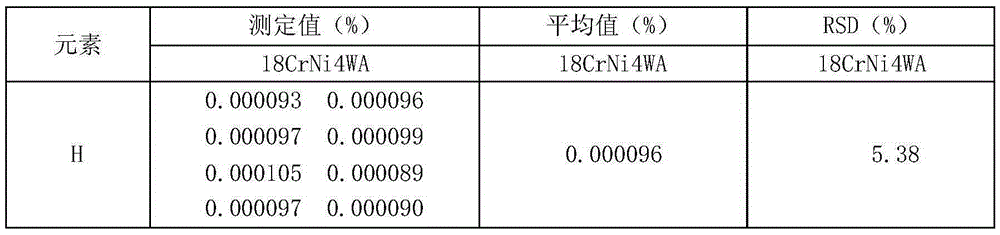

[0051] Embodiment 2: Analysis of hydrogen content in low alloy steel 18Cr2Ni4WA

[0052] Step 1: Preparation of test conditions

[0053] Sub-step 1.1: Instrument selection

[0054] It is determined that the hydrogen analyzer is a device for detecting trace hydrogen content in low alloy steel 18Cr2Ni4WA. The setting parameters of the device are: degassing power 3950W, time: 60s, analysis power 2550W, minimum analysis time: 80s, degassing method: double Degassing, flow rate: 150ml / min, measurement pressure: 15psi, inlet pressure: 40psi.

[0055] Sub-step 1.2: Preparation of main reagents and materials

[0056] Diethyl ether or acetone: analytically pure,

[0057] Standard substance of hydrogen content in steel:

[0058] American LECO501-529, hydrogen content: 0.00058% ± 0.00008%

[0059] American LECO502-457, hydrogen content: 0.00009% ± 0.00004%

[0060] Graphite crucible: spectrally pure, high temperature crucible;

[0061] Step 2: Preparation of Specimen

[0062] Afte...

Embodiment 3

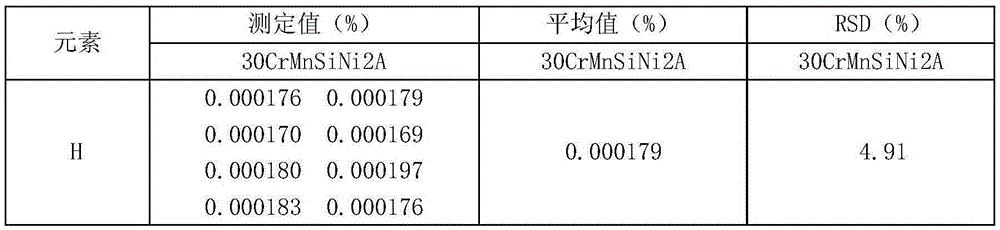

[0072] Embodiment 3: Analysis of hydrogen content in low alloy steel 30CrMnSiNi2A

[0073] Step 1: Preparation of test conditions

[0074] Sub-step 1.1: Instrument selection

[0075] It is determined that the hydrogen analyzer is a device for detecting trace hydrogen content in low alloy steel 30CrMnSiNi2A. The setting parameters of the device are: degassing power 3800W, time: 60s, analysis power 2450W, minimum analysis time: 80s, degassing method: double Degassing, flow rate: 150ml / min, measurement pressure: 15psi, inlet pressure: 40psi.

[0076] Sub-step 1.2: Preparation of main reagents and materials

[0077] Diethyl ether or acetone: analytically pure,

[0078] Standard substance of hydrogen content in steel:

[0079] American LECO501-529, hydrogen content: 0.00058% ± 0.00008%

[0080] American LECO502-457, hydrogen content: 0.00009% ± 0.00004%

[0081] Graphite crucible: spectrally pure, high temperature crucible;

[0082] Step 2: Preparation of Specimen

[0083] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com