non-lamellar sn 2 p 2 s 6 Preparation method of nanosheets and its application in the field of photocatalytic hydrogen evolution

A nanosheet, non-layered technology, applied in the field of inorganic semiconductor nanomaterials, can solve the problems of restricted layered structure, introduction of solvent impurities, long preparation period, etc., and achieve the effects of stable chemical properties, good crystallinity and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

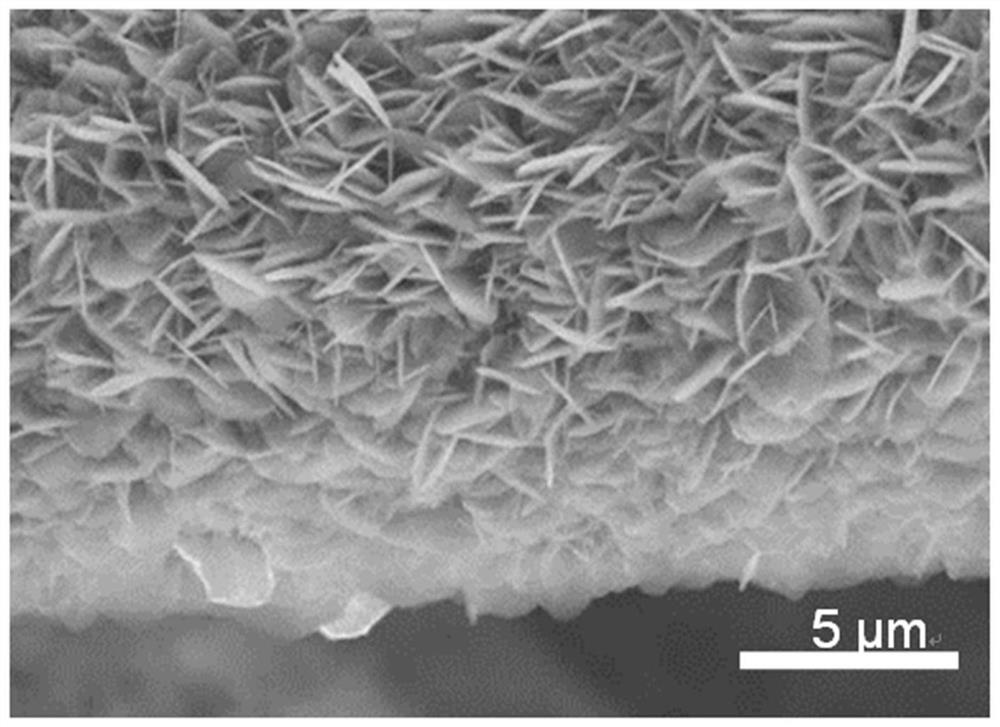

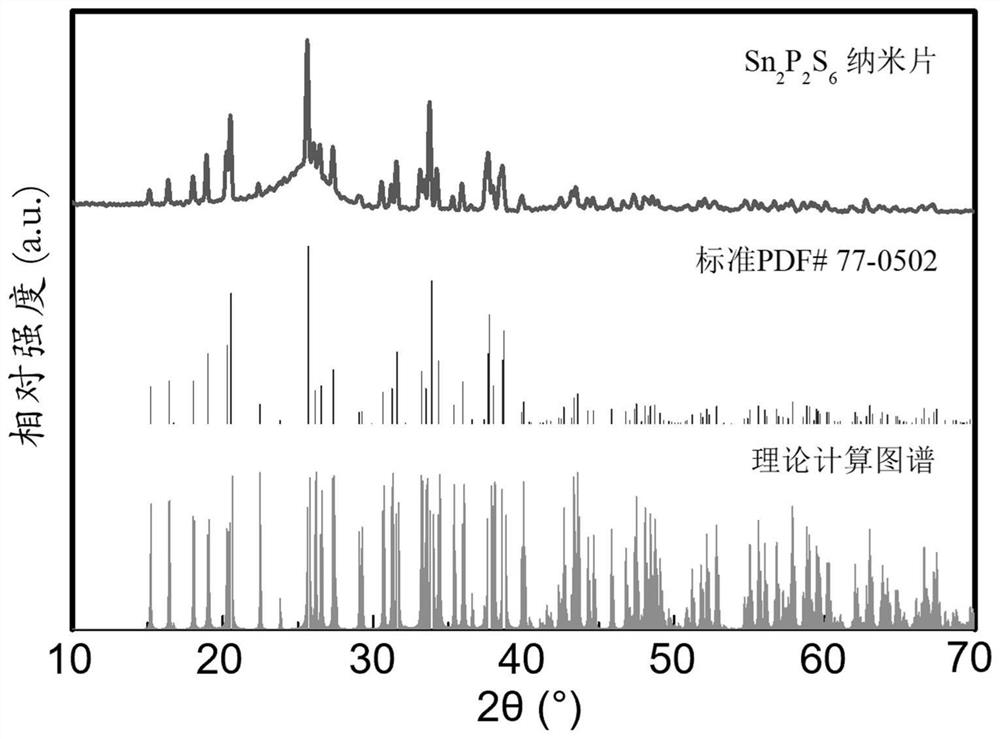

[0040] This embodiment provides a high-quality large-area non-layered Sn 2 P 2 S 6 The preparation method of nanosheets, the specific steps are as follows:

[0041] (1) 48.0 mg of thioacetamide (C 2 H 5 NS), 56.0mg tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O) dissolved in 40 mL of isopropanol (C 3 H 8 (2), the solution was transferred to a 50mL polytetrafluoroethylene reactor after 5 minutes of ultrasound, and the carbon cloth fibers with an aspect ratio of 3cm×2cm were leaned in the reactor, and a solvothermal reaction was carried out at 180°C, Incubate for 24 hours, and obtain SnS loaded on carbon cloth fibers after the reaction is completed. 2 Nanocrystalline.

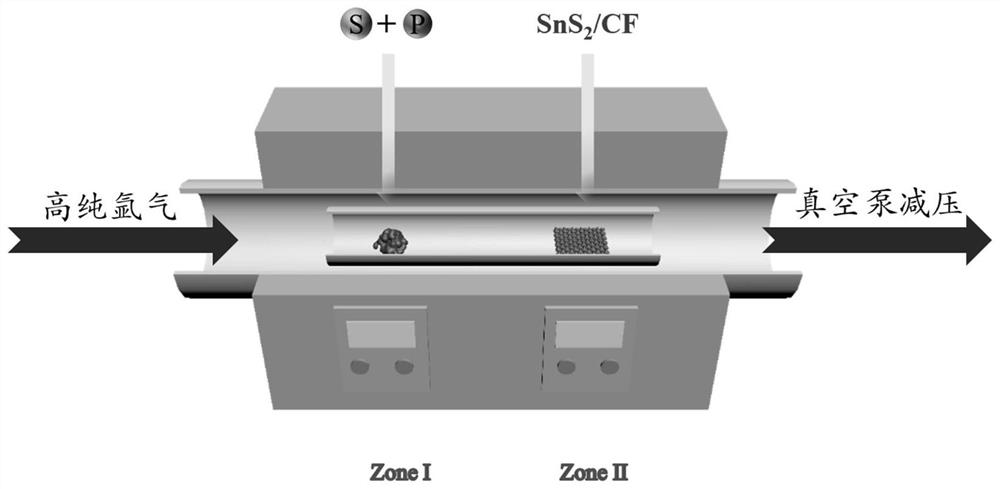

[0042] (2) SnS supported on carbon cloth fibers 2 Nanocrystalline and red phosphorus / sulfur mixed powder were placed on the sealing ends of two quartz sleeves, respectively, and placed in the Zone-II and Zone-I heating zones of the double-temperature zone tube furnace with a distance of 25 cm. The tube...

Embodiment 2

[0052] This embodiment provides a non-layered Sn 2 P 2 S 6 The preparation method of nanosheets, the specific steps are as follows:

[0053] (1) 48.0 mg of thioacetamide (C 2 H 5 NS), 56.0mg tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O) dissolved in 40 mL of isopropanol (C 3 H 8 (2), the solution was transferred to a 50mL polytetrafluoroethylene reactor after ultrasonication for 5 minutes, and the carbon cloth fibers with an aspect ratio of 3cm×2cm were leaned in the reactor, and a solvothermal reaction was carried out at 180°C, Incubate for 24 hours, and obtain SnS loaded on carbon cloth fibers after the reaction is completed. 2 Nanocrystalline.

[0054] (2) SnS supported on carbon cloth fibers 2 Nanocrystalline and red phosphorus / sulfur mixed powder were placed on the sealing ends of two quartz sleeves, respectively, and placed in the Zone-II and Zone-I heating zones of the dual-temperature zone tube furnace, with a distance of 25 cm, and a mechanical pump was us...

Embodiment 3

[0057] This embodiment provides a Sn 2 P 2 S 6 The preparation method, the specific steps are as follows:

[0058] (1) 48.0 mg of thioacetamide (C 2 H 5 NS), 56.0mg tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O) dissolved in 40 mL of isopropanol (C 3 H 8 (2), the solution was transferred to a 50mL polytetrafluoroethylene reactor after ultrasonication for 5 minutes, and the carbon cloth fibers with an aspect ratio of 3cm×2cm were leaned in the reactor, and a solvothermal reaction was carried out at 180°C, Incubate for 24 hours, and obtain SnS loaded on carbon cloth fibers after the reaction is completed. 2 Nanocrystalline.

[0059] (2) SnS supported on carbon cloth fibers 2 Nanocrystalline and red phosphorus / sulfur mixed powder were placed on the sealing ends of two quartz sleeves, respectively, and placed in the Zone-II and Zone-I heating zones of the dual-temperature zone tube furnace, with a distance of 25 cm, and a mechanical pump was used for the heating zone. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com