High-strength steel member

a high-strength steel and member technology, applied in the field of high-strength steel members, can solve the problems of deterioration in ductility or toughness, cracking after quenching, etc., and achieve the effect of excellent delay in fracture resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0134]Hereinafter, the present disclosure will be more specifically described with reference to Examples. It is noted that the respective Examples are not intended to limit the scope of the present disclosure.

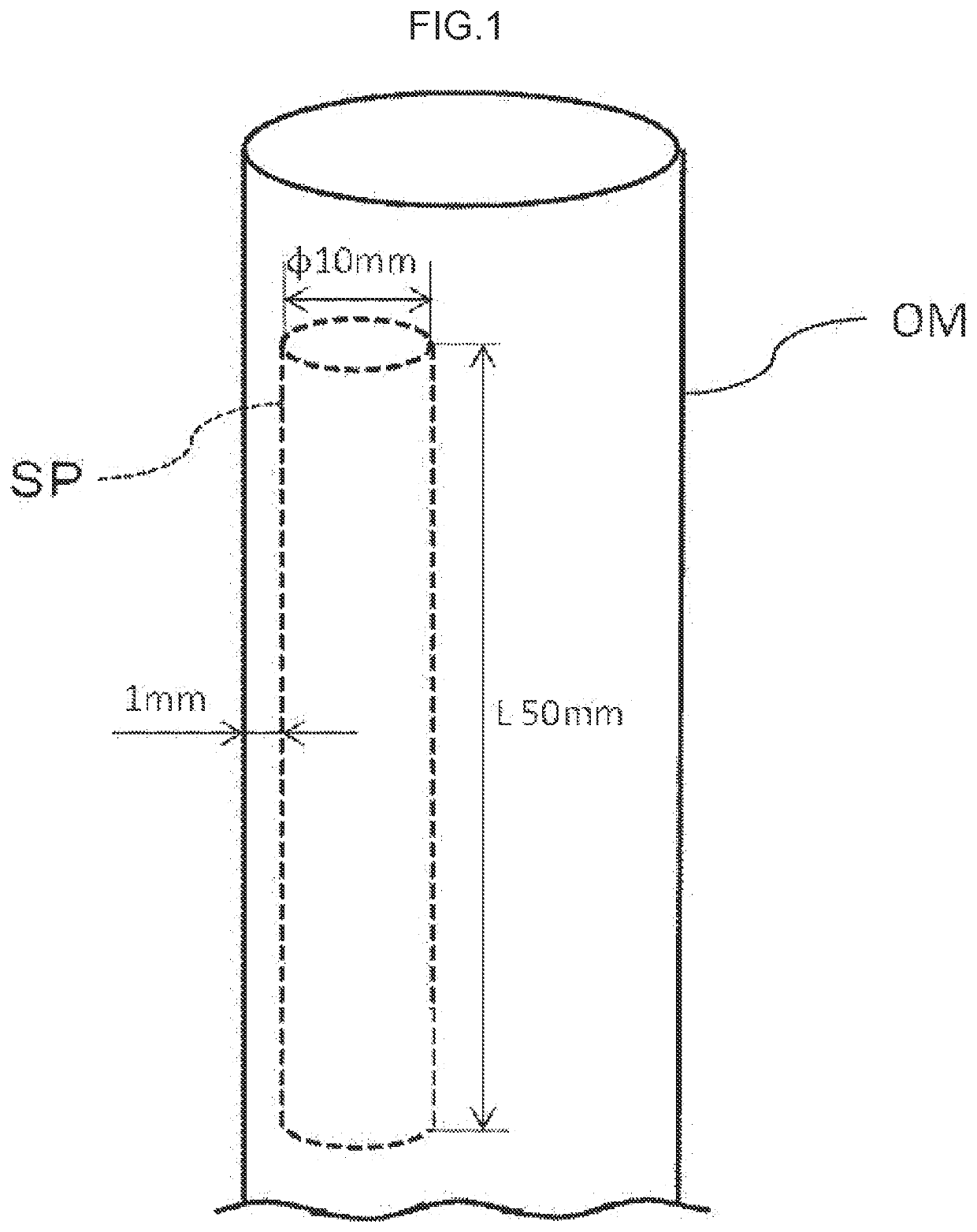

[0135]A test material having a chemical composition shown in Table 1 was heated to a temperature shown in Table 2, thereafter hot-rolled at a finish rolling temperature shown in Table 2, and cooled to 700° C. at an average cooling rate shown in Table 2 for rolling to a diameter ϕ of 20 mm, thereby producing a circularly notched test piece (notch depth of 2 mm, notch bottom radius of 0.25 mm, and notch angle of 60 degrees) made of a round rod steel having a size of 10 mm in diameter ϕ×50 mm in length L.

[0136]The test piece was heated in a carburizing heating atmosphere or in a condition simulating RX gas heating (1 atm, mixed atmosphere of 50% of hydrogen and Ar, heating temperature of 1,000° C., and heating duration of 30 minutes), cooled to 20° C. with water at a cooling rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com