Patents

Literature

54results about How to "Excellent resistance to delayed fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

55Si2MnVNbN spring steel and production process thereof

InactiveCN101717893AHigh strengthHigh tensile strengthTemperature control deviceMetal rolling arrangementsWorking environmentSpring steel

The invention relates to spring steel and a production process thereof, in particular to 55Si2MnVNbN spring steel and a production process thereof. The 55Si2MnVNbN spring steel comprises the following components in percentage by weight: 0.52 to 0.60 percent of C, 1.60 to 1.90 percent of Si, 0.60 to 0.80 percent of Mn, 0.15 to 0.35 percent of Cr, 0.06 to 0.12 percent of V, 0.015 to 0.025 percent of Nb, 0.80 to 1.50 percent of N, less than or equal to 0.0035 of P, less than or equal to 0.0035 percent of S and the balance of Fe and inevitable impurities. The process comprises electric furnace electrosmelting, LF refining, VD furnace vacuum degassing, continuous casting and rolling. The spring steel can meet the requirements of springs on various severe working environments, high strength and long service life and has high tensile strength, high delayed fracture resistance, high corrosion resistance, high fatigue resistance and high elasticity attenuation resistance.

Owner:NANJING IRON & STEEL CO LTD

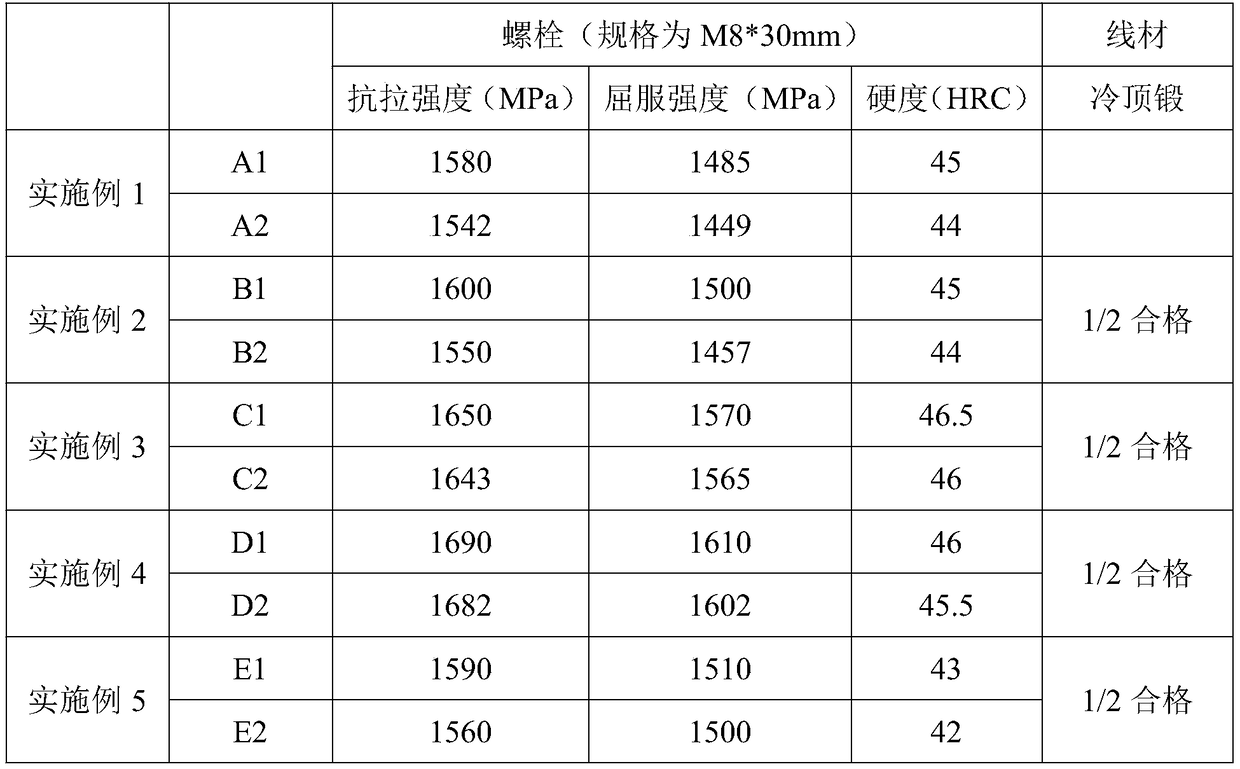

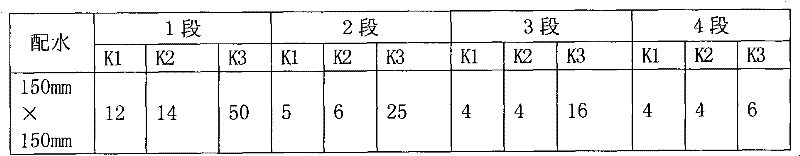

High-strength steel and high-strength bolt with excellent resistance to delayed fracture, and manufacturing method therefor

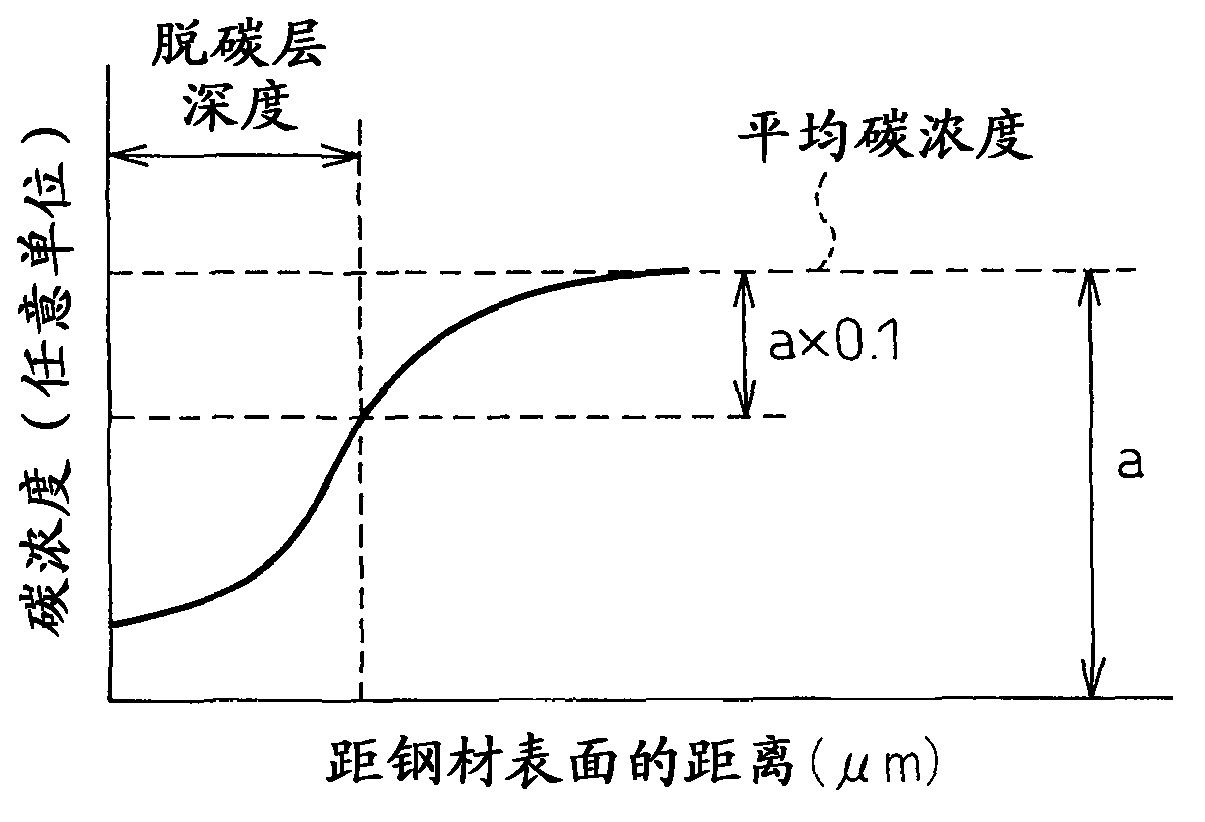

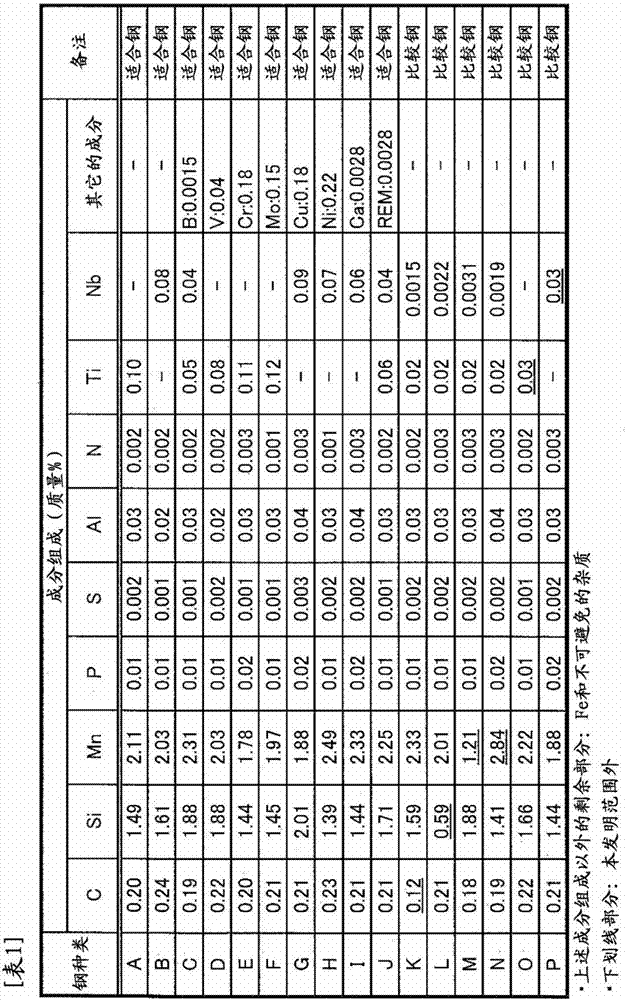

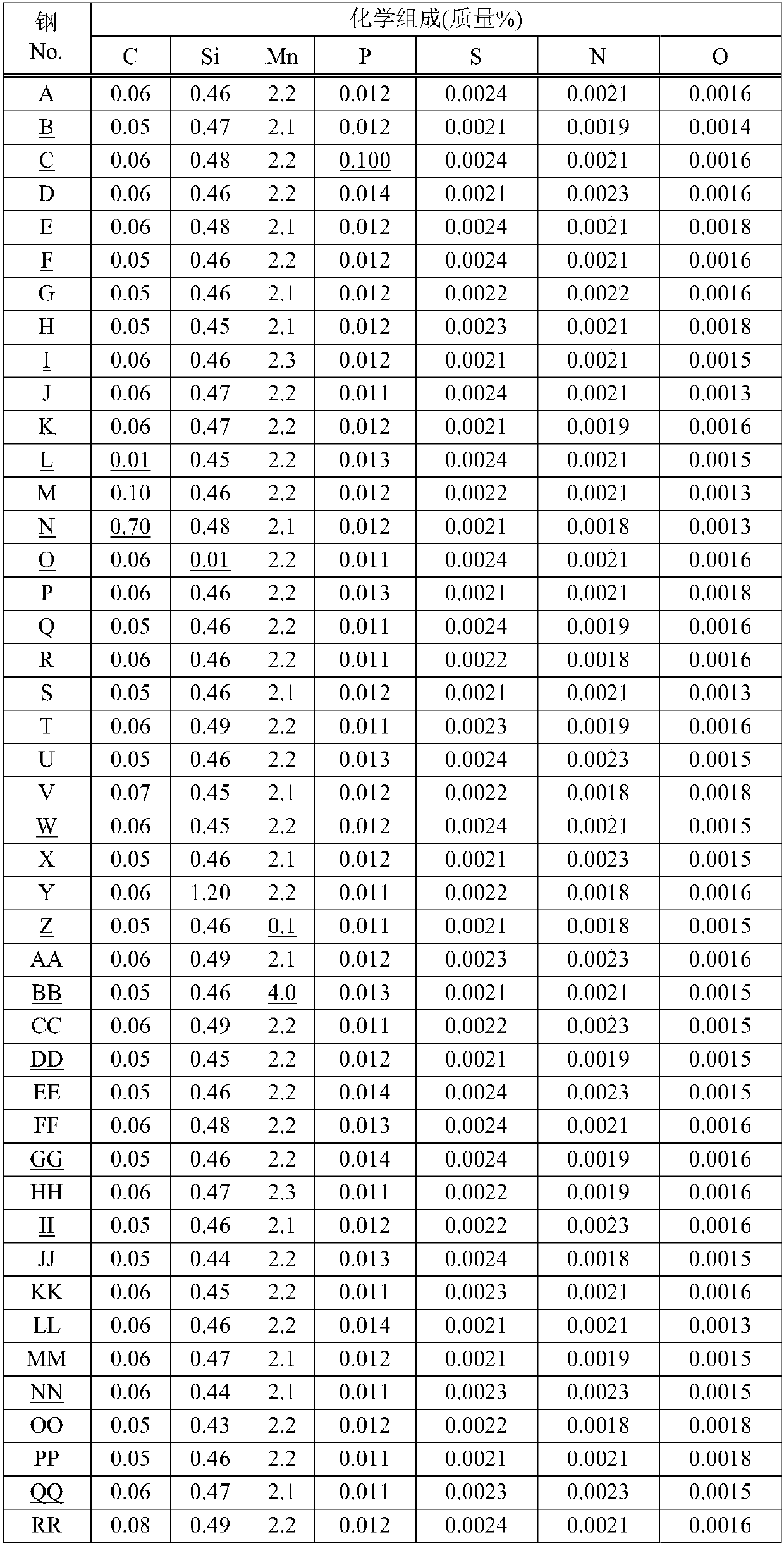

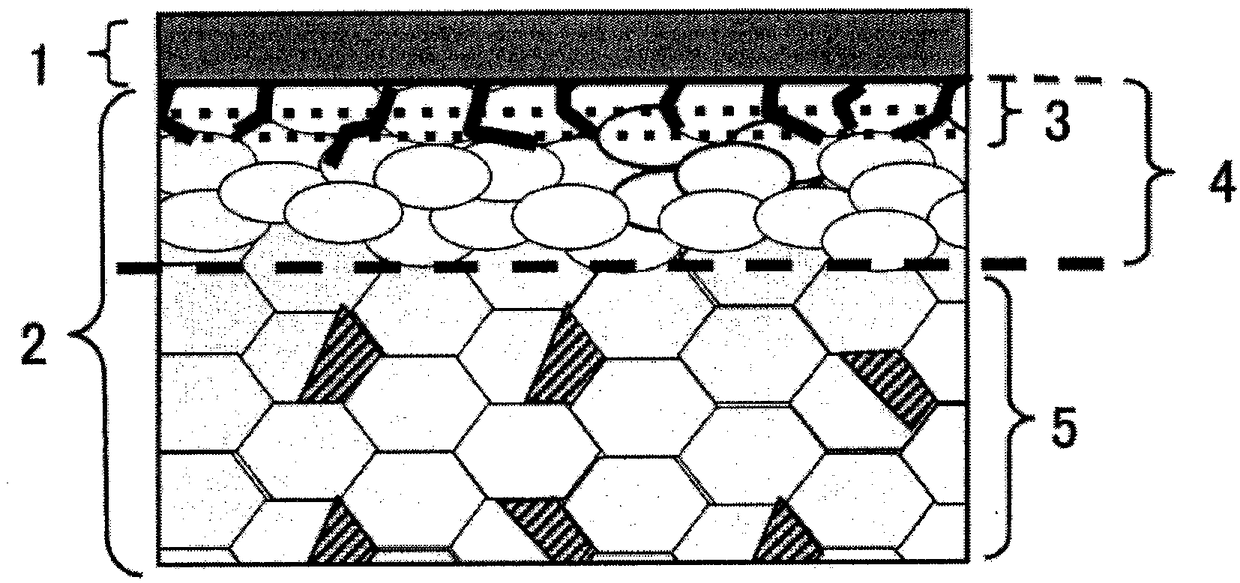

InactiveCN102791898AExcellent resistance to delayed fractureCheap manufacturingSolid state diffusion coatingFurnace typesNiobiumManganese

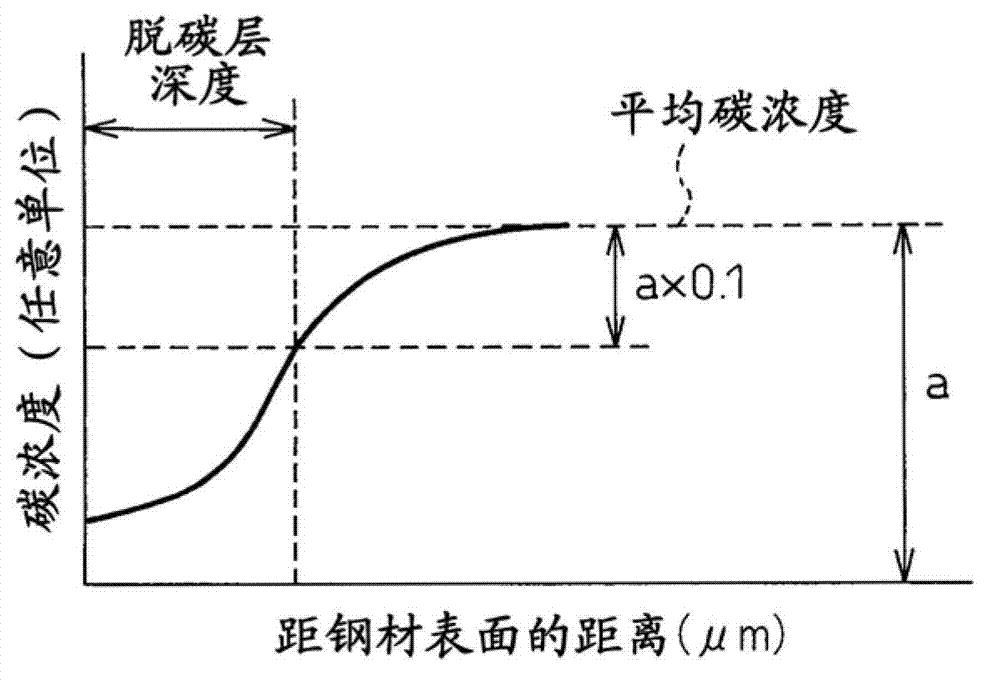

The disclosed steel contains, by mass, 0.10-0.55% carbon, 0.01-3% silicon, and 0.1-2% manganese. Said steel also contains one or more of the following: 0.05-1.5% chromium; 0.05-0.2% vanadium; 0.05-0.40% molybdenum; 0.001-0.05% niobium; 0.01-4% copper; 0.01-4% nickel; and 0.0001-0.005% boron. The remainder comprises iron and unavoidable impurities. The structure of the disclosed steel is primarily tempered martensite. Said steel, which is a high-strength steel that exhibits excellent resistance to delayed fracture, is characterized by the following being formed in a surface layer thereof: (a) a nitrided layer with a thickness of at least 200 [mu]m from the surface of the steel and a nitrogen concentration by mass that is at least 0.02% higher than that of the steel and no greater than 12.0%; and (b) a low-carbon region, at a depth between 100 [mu]m and 1000 [mu]m from the surface of the steel, with a carbon concentration by mass that is at most 0.9 times that of the steel and no less than 0.05%.

Owner:NIPPON STEEL CORP

Industrial stable high-performance bolt steel and manufacturing method thereof

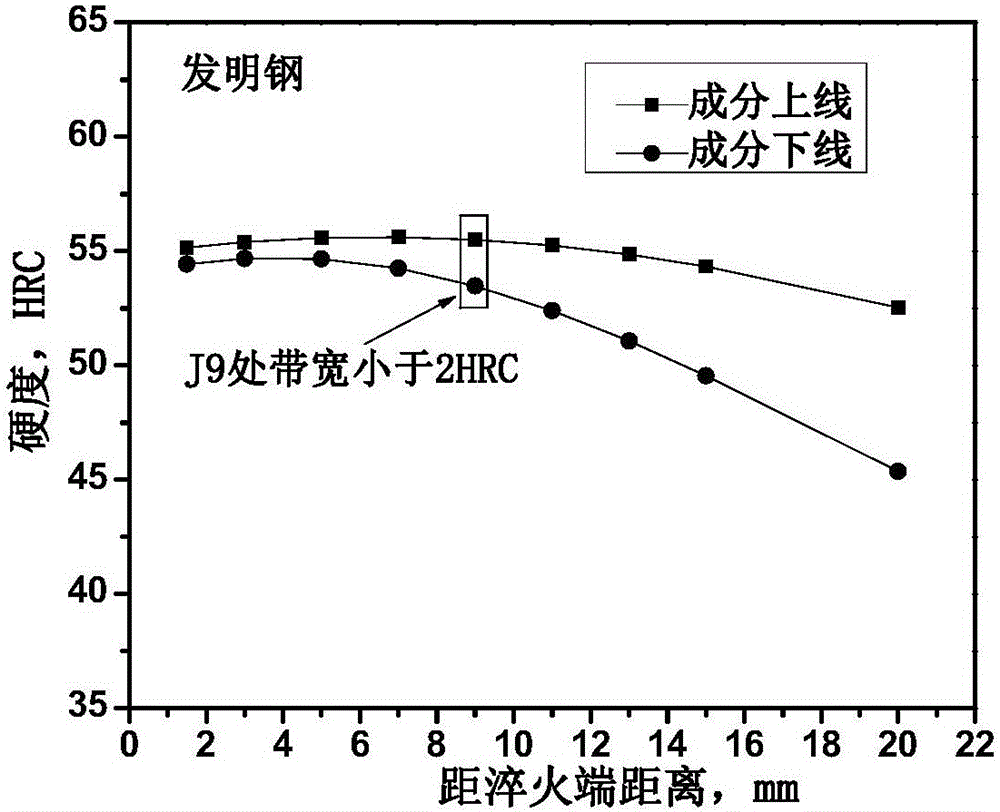

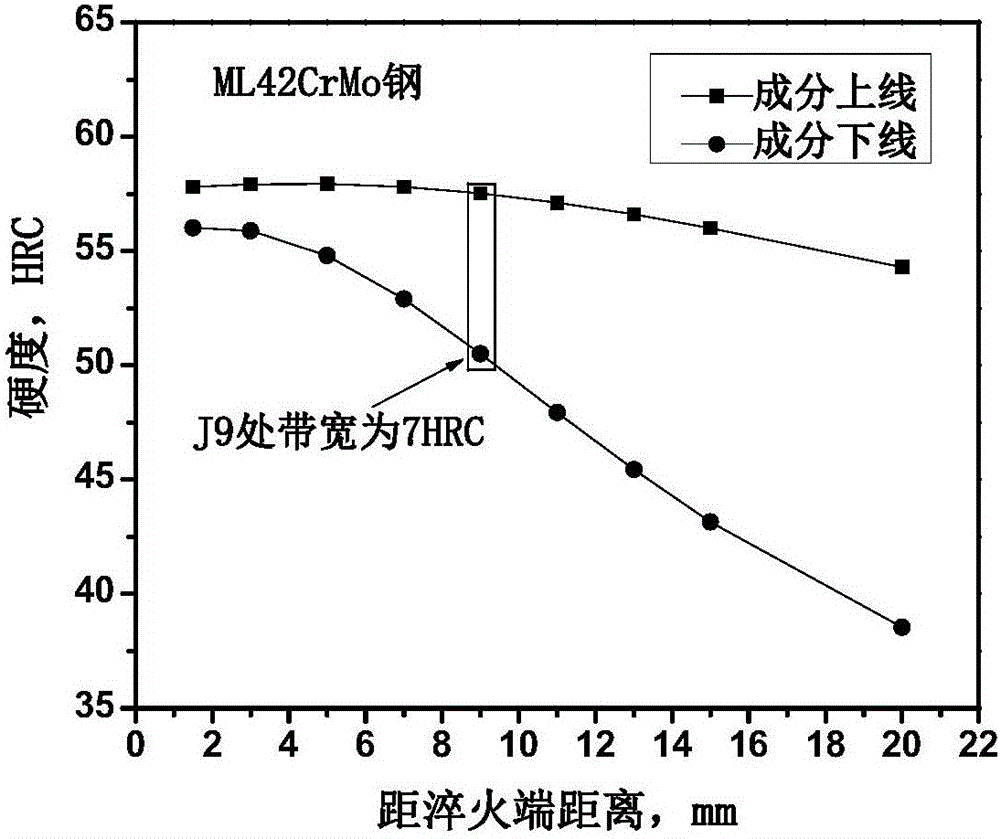

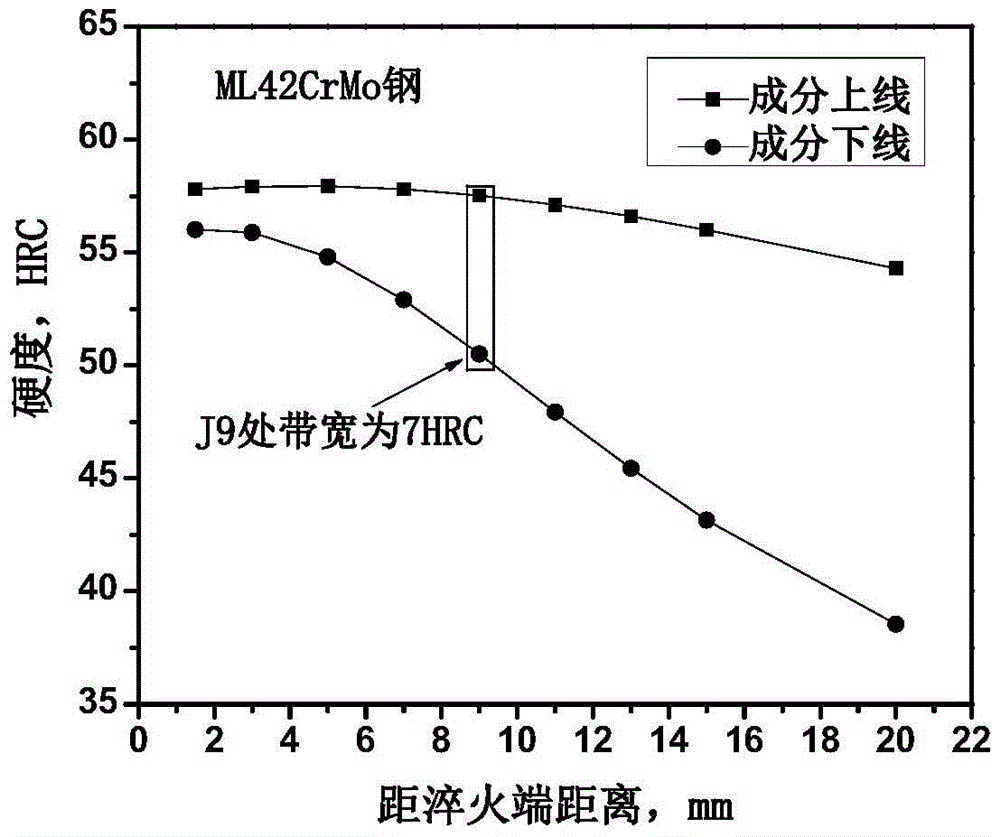

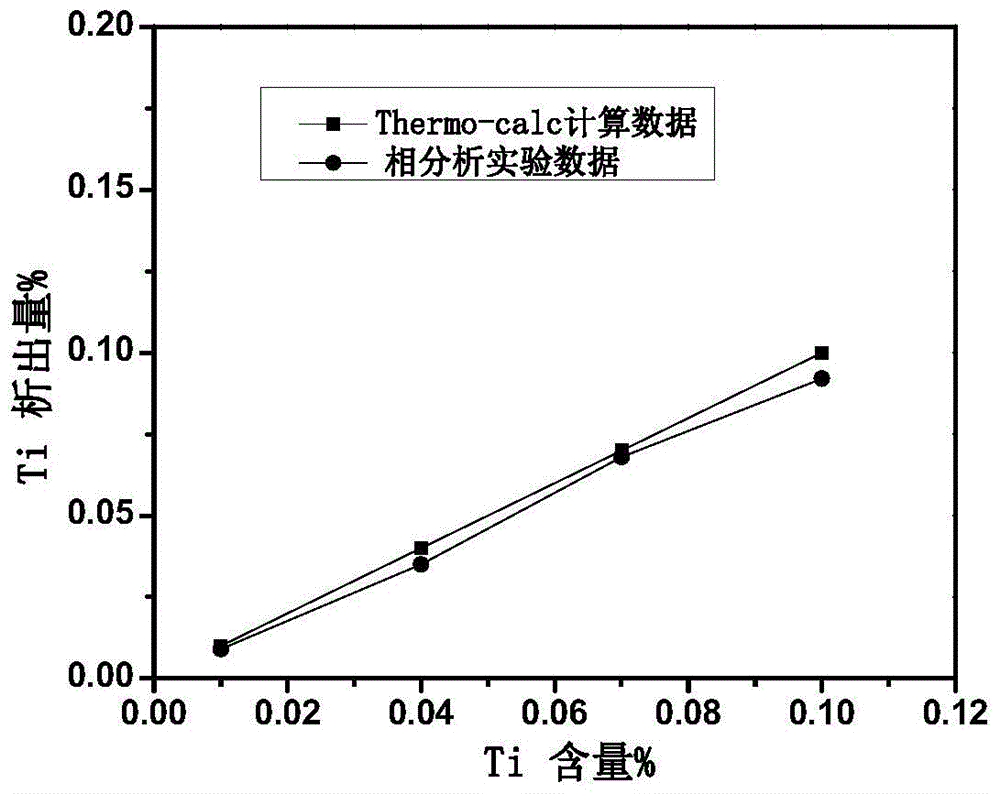

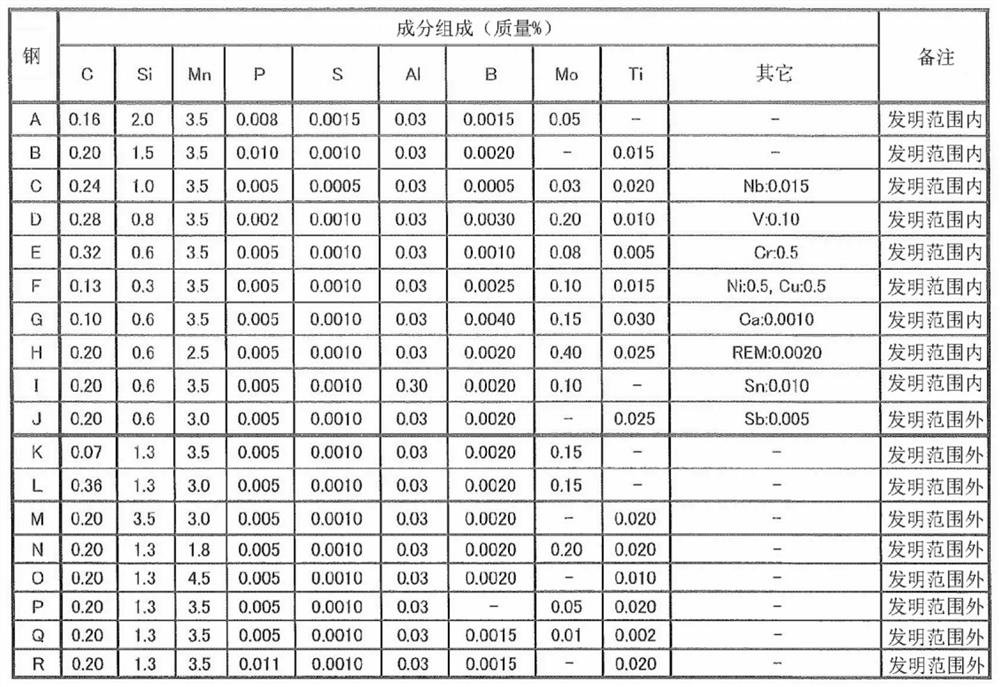

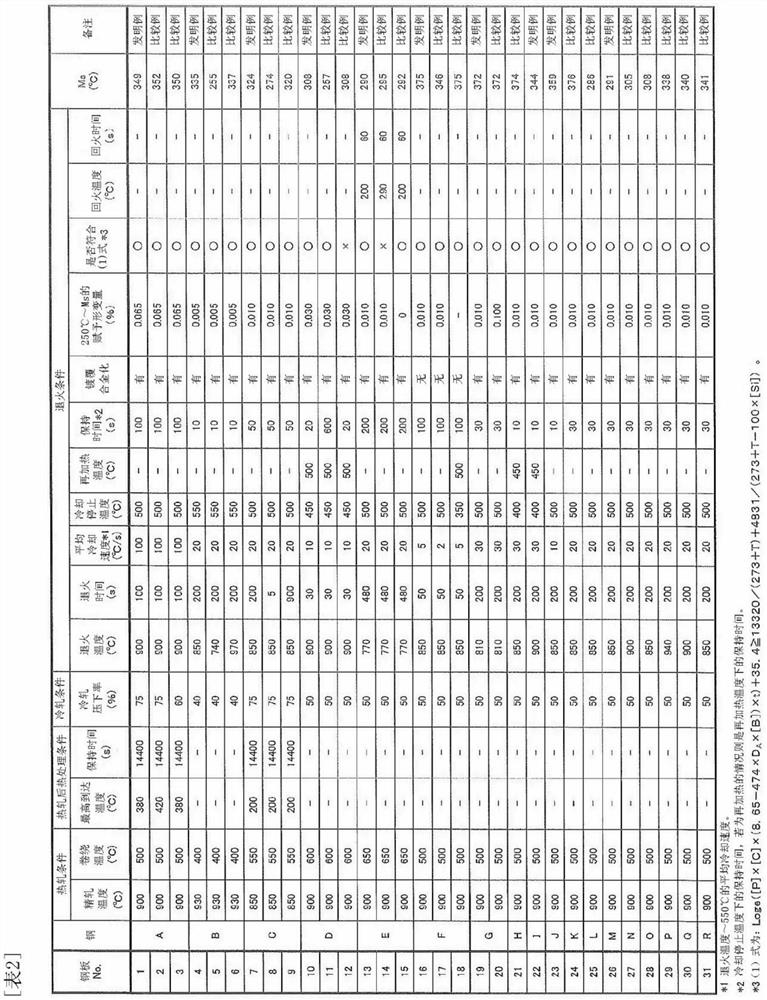

ActiveCN105002427AImprove high temperature tempering strengthReduce carbon contentChemical compositionAustenite grain

The invention discloses industrial stable high-performance bolt steel and a manufacturing method thereof and belongs to the technical field of high-strength bolt steel. The chemical components of the steel comprise, by mass, 0.28-0.37% of C, equal to or less than 0.10% of Si, 0.15-0.30% of Mn, equal to or less than 0.010% of P, equal to or less than 0.005% of S, 1.10-1.20% of Cr, 0.15-0.40% of Mo, 0.0005-0.003% of B, 0.03-0.08% of Ti, 0.015-0.030% of Al and equal to or less than 0.005% of N, and the balance is Fe, on the basis, 0.15-0.30% of V or 0.02-0.04% of Nb can be added. Through the adoption of a reasonable controlled rolling and controlled cooling technology, the original austenite grain size of the steel after phase change is further refined by 1-2 grades, 3-8 um superfine austenite grains and precipitated phase with the size of 1-20 nm are obtained, and therefore the high-temperature tempering strength of the steel is improved. The industrial stable high-performance bolt steel and the manufacturing method thereof have the advantages that compared with the prior art, the carbon content of the steel in the same strength grade is reduced, the hardness fluctuation after quenching+tempering is small, the strength after high-temperature tempering is high, the stability of batch quality is high, the cost is low, and the delayed fracture resistance is excellent.

Owner:CENT IRON & STEEL RES INST

High-strength steel and high-strength bolt with excellent resistance to delayed fracture, and manufacturing method therefor

InactiveCN102812145AExcellent resistance to delayed fractureCheap manufacturingSolid state diffusion coatingFurnace typesNiobiumManganese

The disclosed steel contains, by mass: 0.10-0.55% carbon; 0.01-3% silicon; 0.1-2% manganese; and up to 1.5% vanadium and / or up to 3.0% molybdenum, with the vanadium content (V) and the molybdenum content (Mo) satisfying the relation V+ 1 / 2 Mo > 0.4%. Said steel also contains one or more of the following: 0.05-1.5% chromium; 0.001-0.05% niobium; 0.01-4% copper; 0.01-4% nickel; and 0.0001-0.005% boron. The remainder comprises iron and unavoidable impurities. The structure of the disclosed steel is primarily tempered martensite. Said steel, which is a high-strength steel that exhibits excellent resistance to delayed fracture, is characterized by the following being formed in a surface layer thereof: (a) a nitrided layer with a thickness of at least 200 [mu]m from the surface of the steel and a nitrogen concentration by mass that is at least 0.02% higher than that of the steel and no greater than 12.0%; and (b) a low-carbon region, at a depth between 100 [mu]m and 1000 [mu]m from the surface of the steel, with a carbon concentration by mass that is at most 0.9 times that of the steel and no less than 0.05%.

Owner:NIPPON STEEL CORP

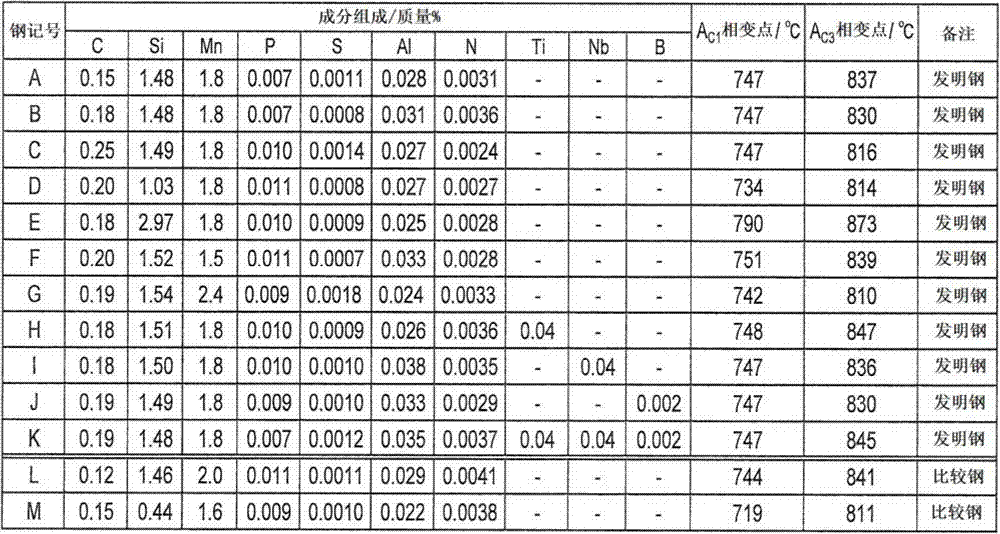

Ultrahigh-strength cold-rolled steel sheet with excellent ductility and delayed-fracture resistance, and process for producing same

InactiveCN102971442AHigh tensile strengthImprove ductilityFurnace typesMetal rolling arrangementsSheet steelAlloy

Provided is an ultrahigh-strength cold-rolled steel sheet that has a steel composition in which neither transition metal elements which considerably raise the alloy cost, such as V and Mo, nor Al, which may induce casting defects, is contained in excess and that, despite the composition, has excellent delayed-fracture resistance and a tensile strength of 1,320 MPa or higher. Also provided is a process for producing the steel sheet. The steel sheet having excellent ductility and delayed-fracture resistance is characterized by containing, in terms of mass%, 0.15-0.25% C, 1.0-3.0% Si, 1.5-2.5% Mn, up to 0.05% P, up to 0.02% S, 0.01-0.05% Al, and below 0.005% N, with the remainder comprising Fe and incidental impurities. The steel sheet is further characterized by having a metallographic structure which comprises 40-85 vol.% tempered martensite phase and 15-60 vol.% ferrite phase and by having a tensile strength of 1,320 MPa or higher.

Owner:JFE STEEL CORP

High-strength cold-rolled steel sheet and method for producing same

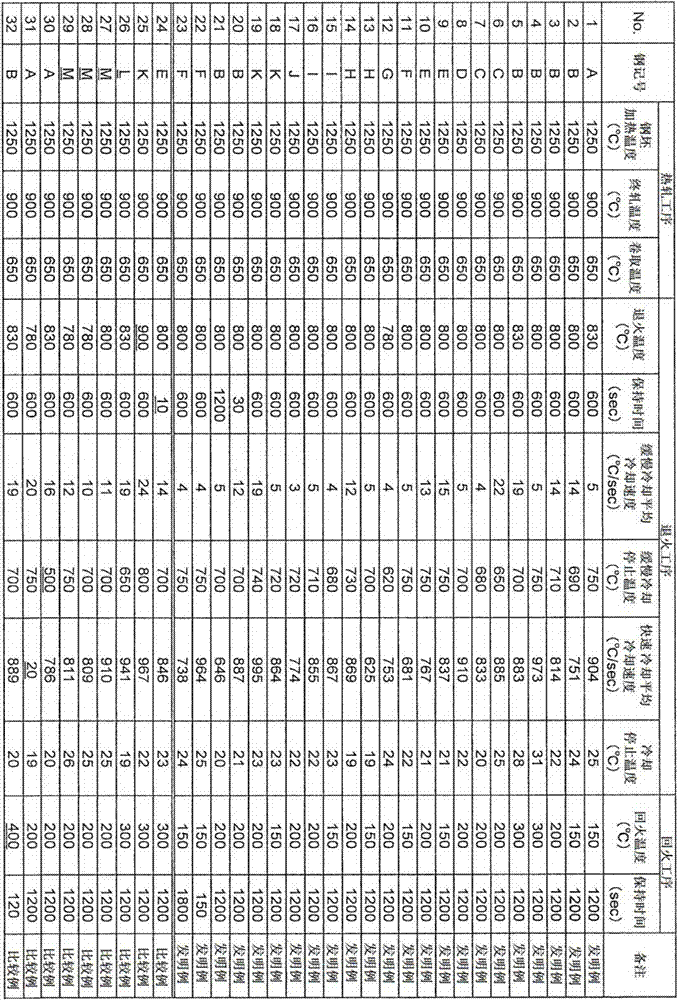

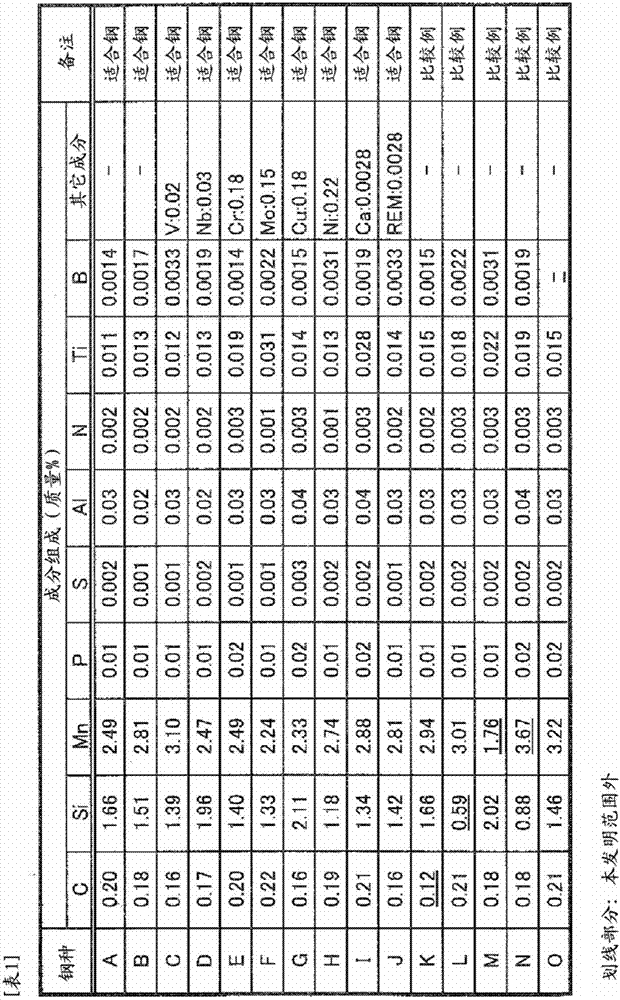

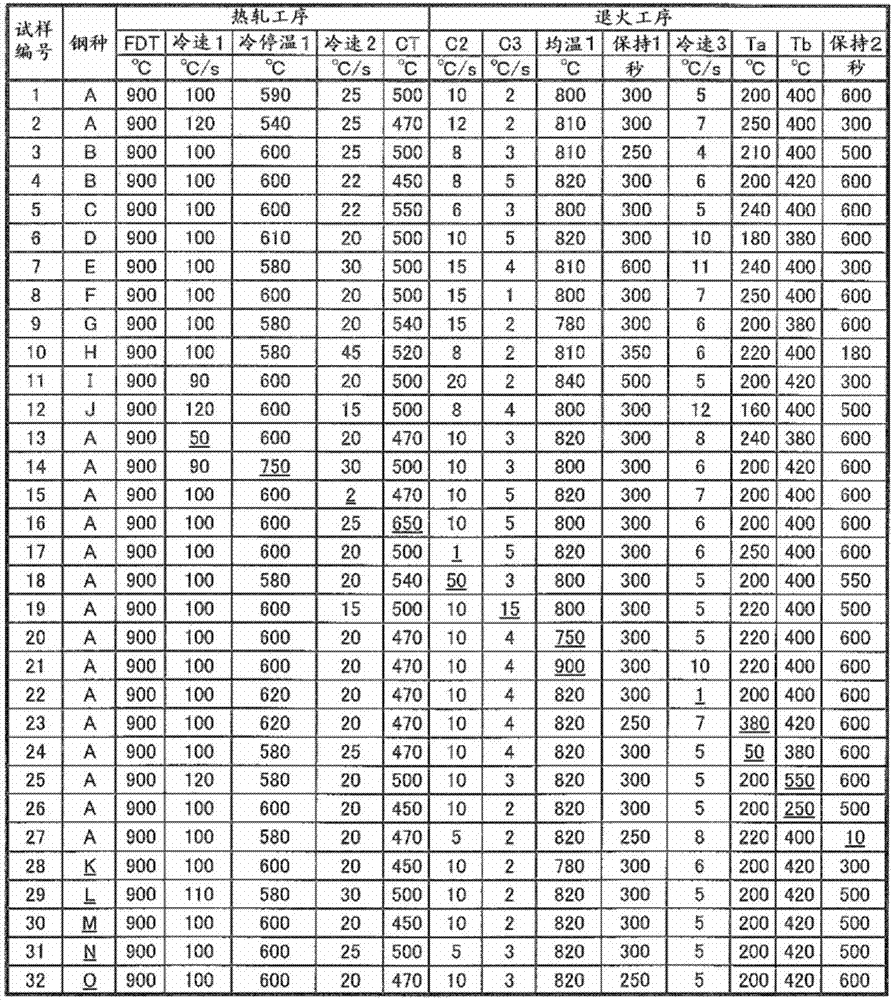

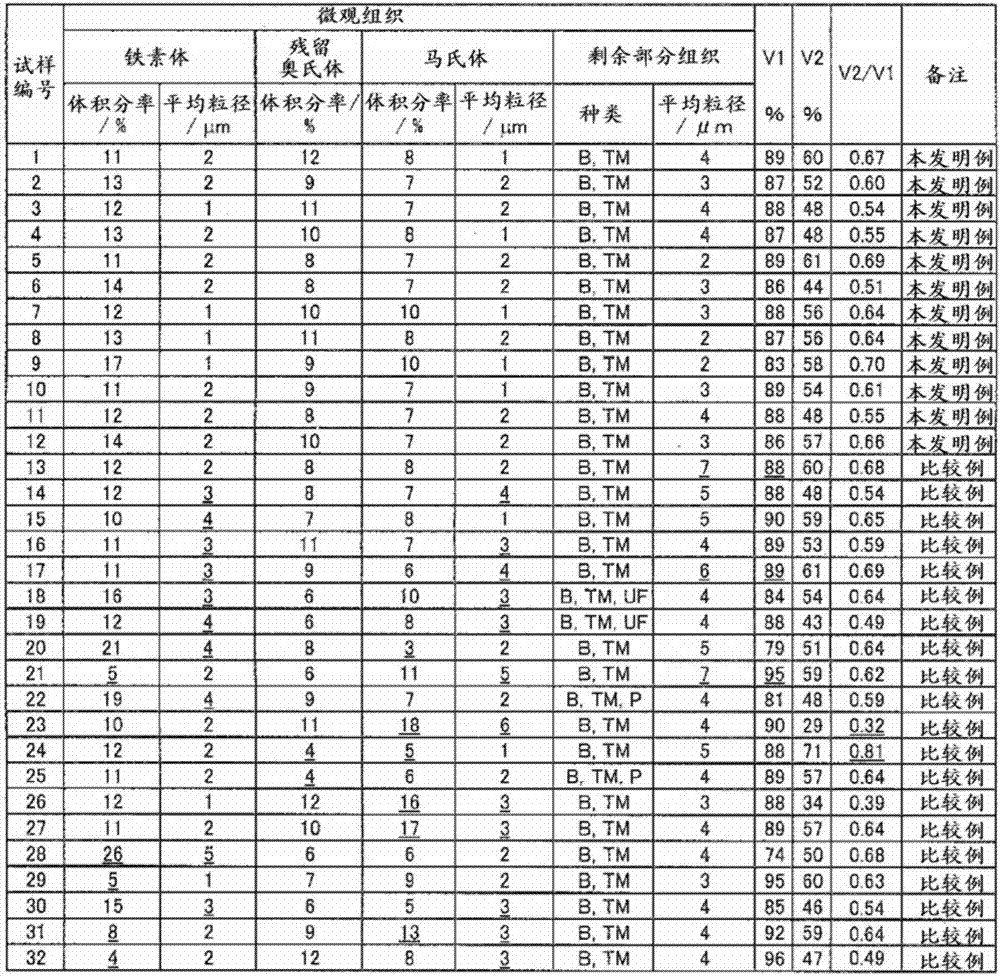

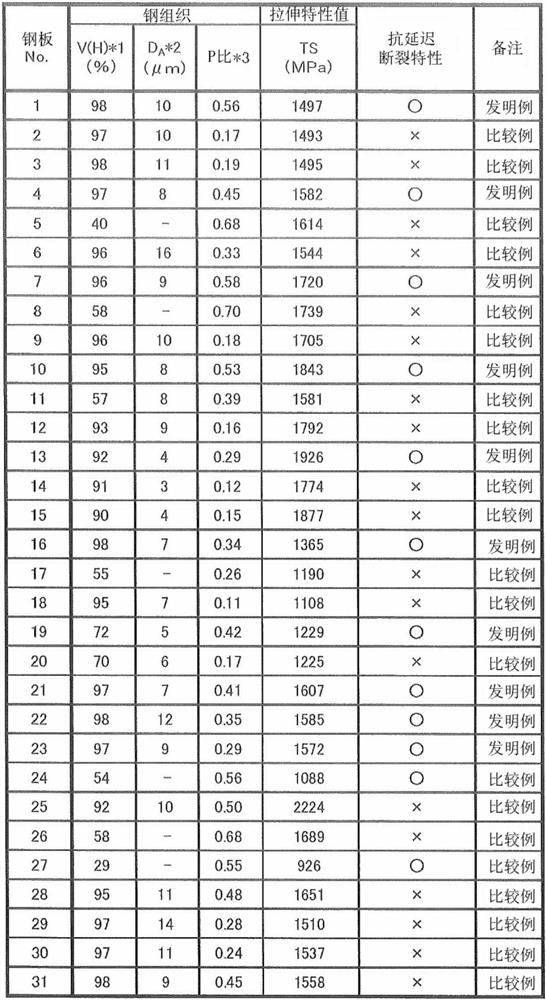

ActiveCN107002198AHigh tensile strengthHigh yield ratioFurnace typesHeat treatment furnacesSheet steelHigh intensity

Provided are: a high-strength cold-rolled steel sheet which solves problems of prior art and has a good balance among a plurality of characteristics (yield ratio, strength, elongation, bore expanding properties and delayed fracture resistance); and a method for producing this high-strength cold-rolled steel sheet. A high-strength cold-rolled steel sheet which is characterized by having a specific component composition and by having a microstructure that is a composite structure which contains 10-25% by volume of ferrite having an average crystal grain size of 2 [mu]m or less, 5-20% by volume of residual austenite, and 5-15% by volume of martensite having an average crystal grain size of 2 [mu]m or less, with the balance made up of tempered martensite and bainite having an average crystal grain size of 5 [mu]m or less, in said microstructure the volume fraction (V1) of hard phases other than ferrite and the volume fraction (V2) of the tempered martensite satisfying the condition of formula (1) which is 0.35<=V2 / V1<=0.75 Formula (1).

Owner:JFE STEEL CORP

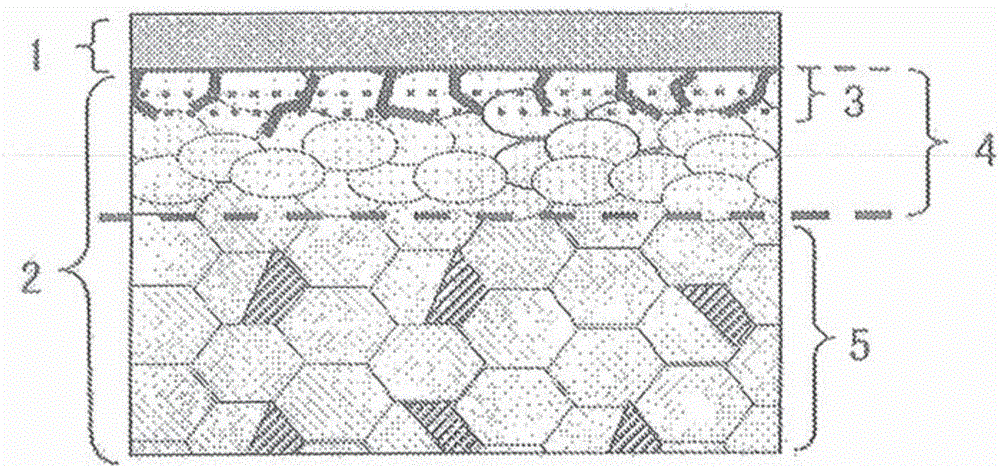

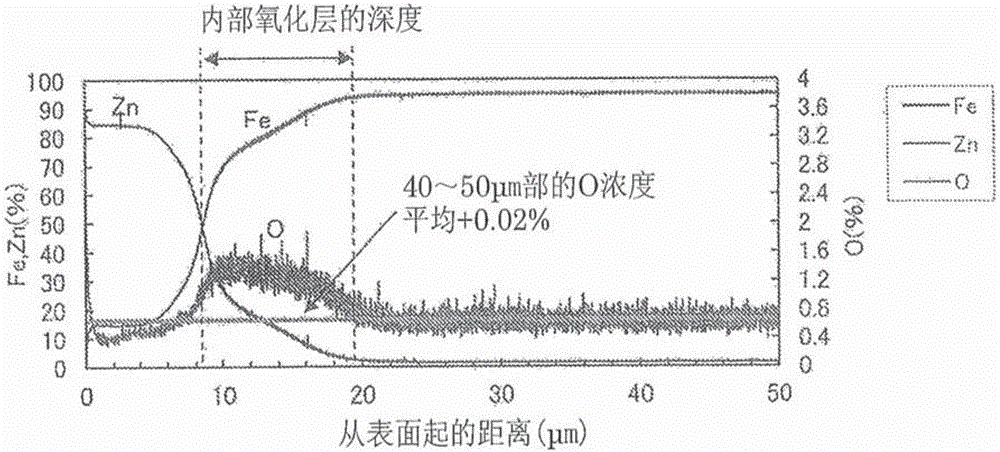

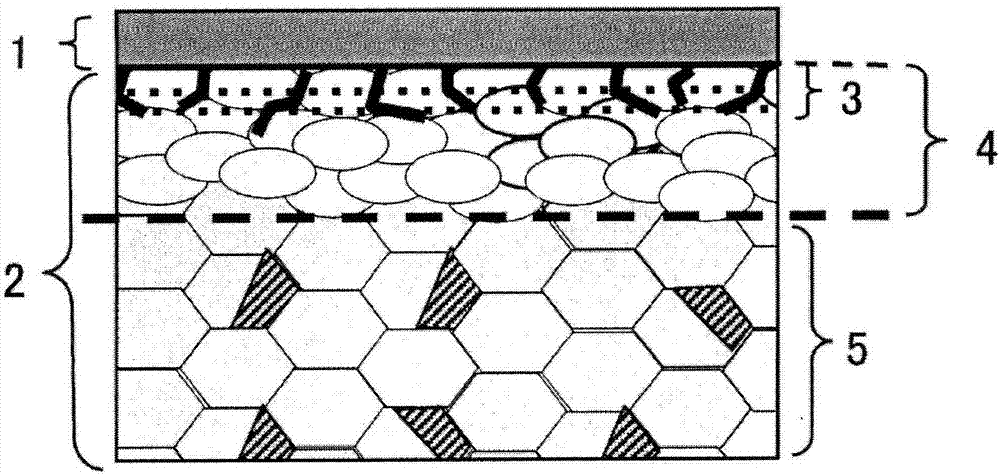

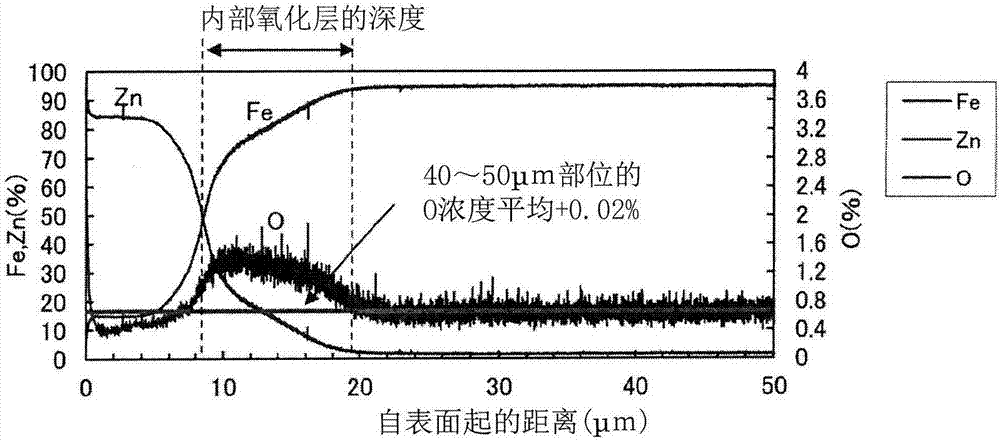

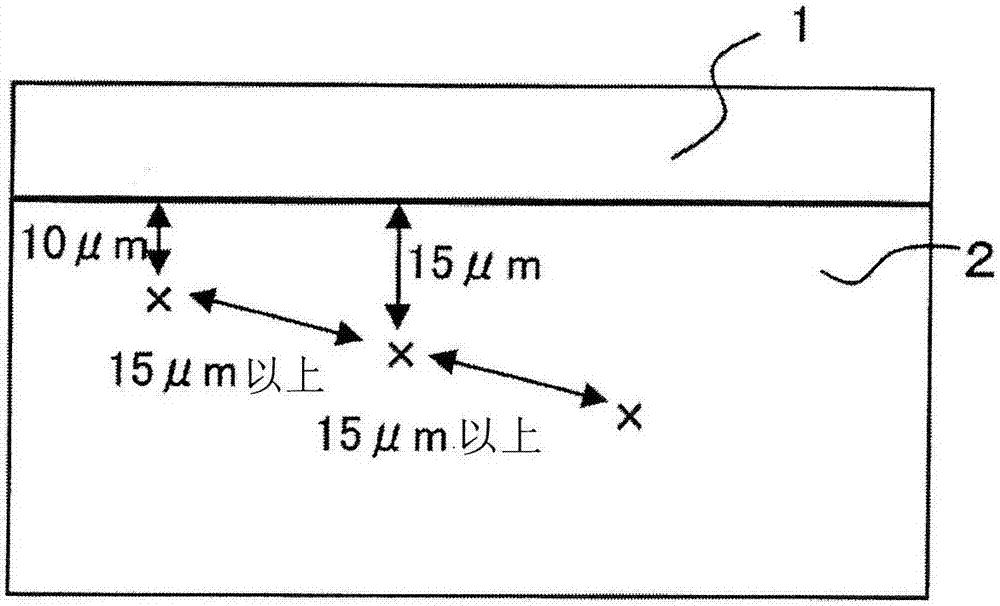

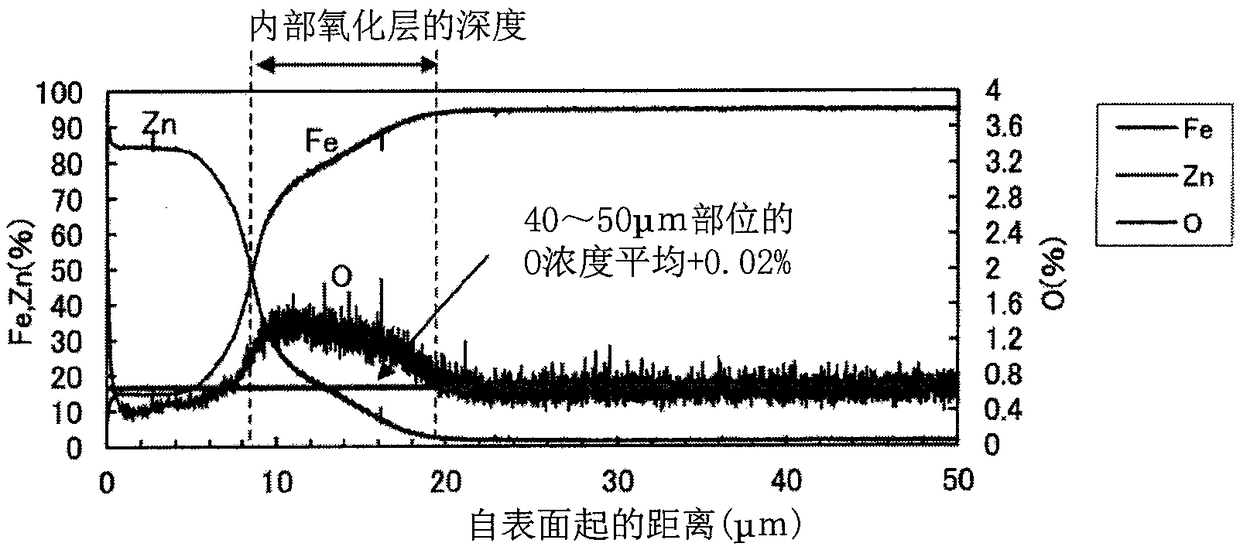

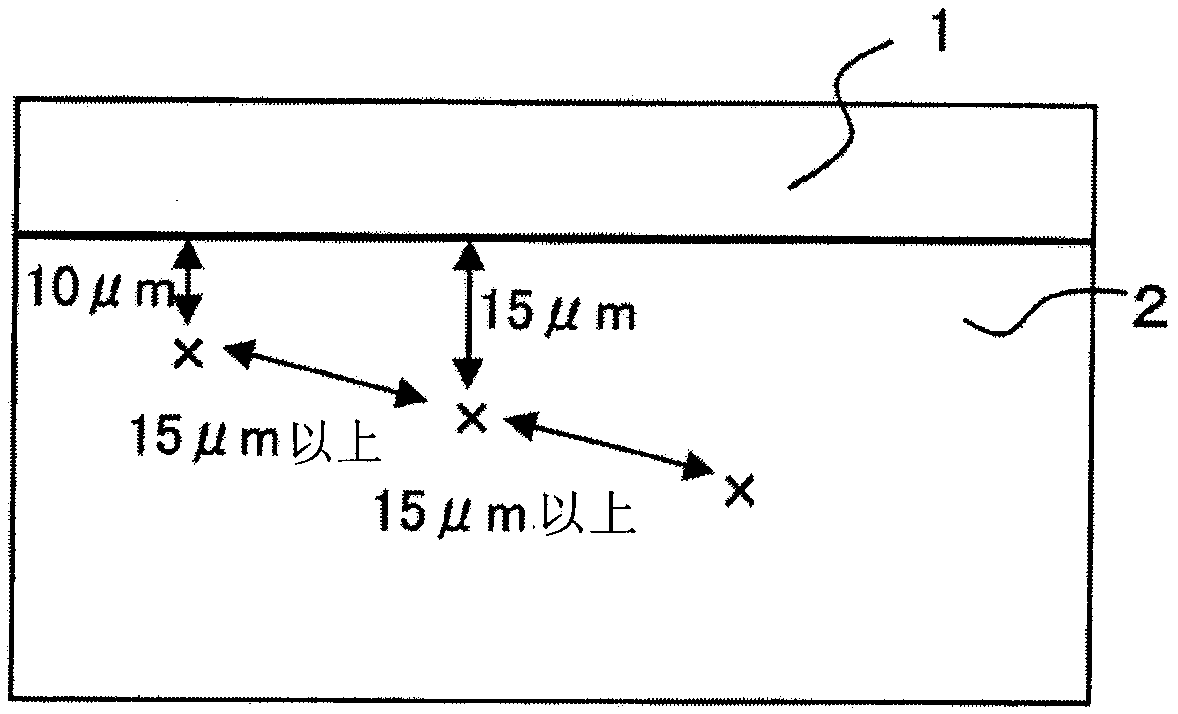

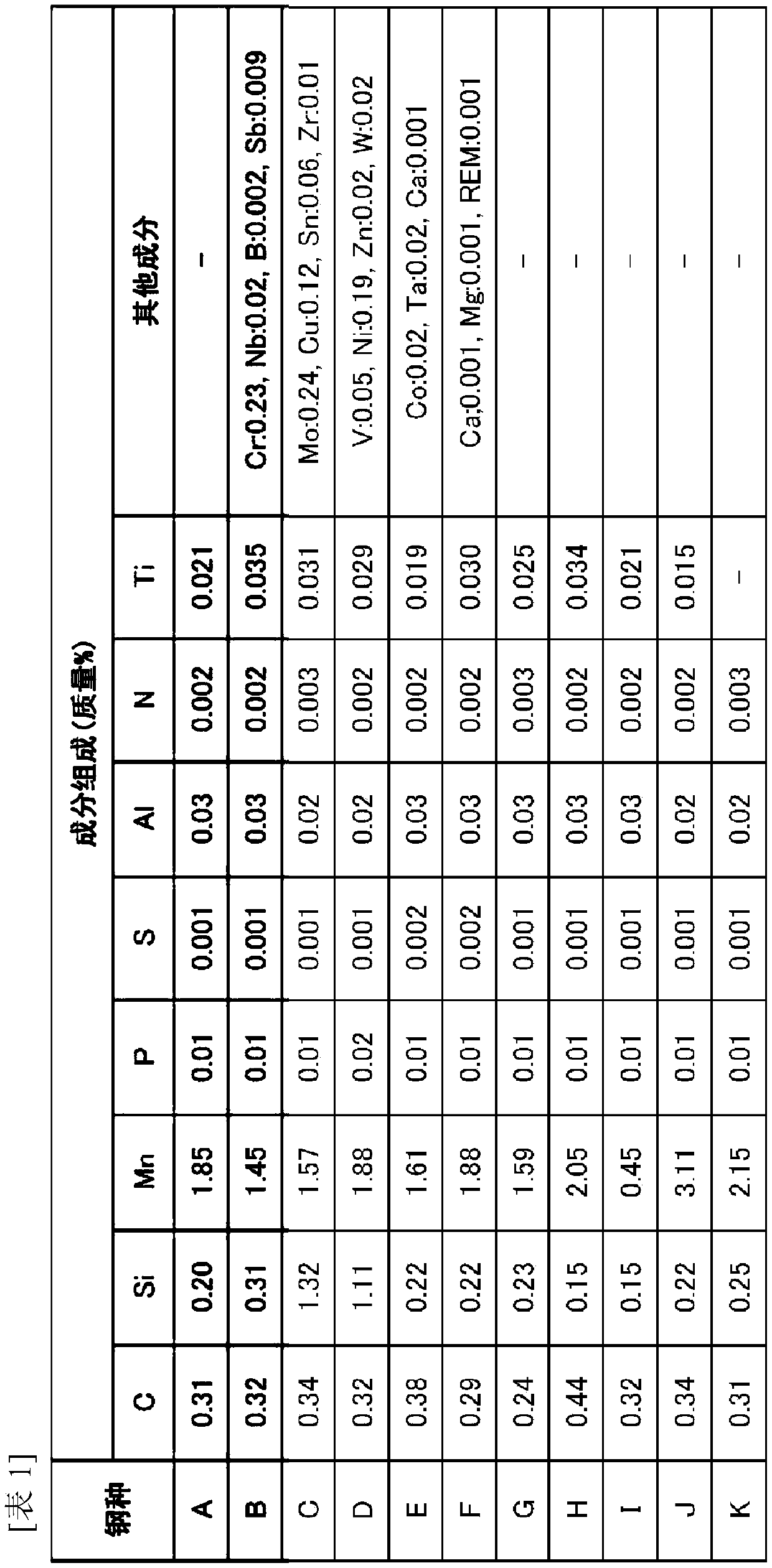

High-strength alloyed hot-dipped galvanized steel sheet having excellent workability and delayed fracture resistance, and method for producing same

InactiveCN106133164AEasy to processExcellent resistance to delayed fractureHot-dipping/immersion processesFurnace typesSoft layerInternal oxidation

Owner:KOBE STEEL LTD

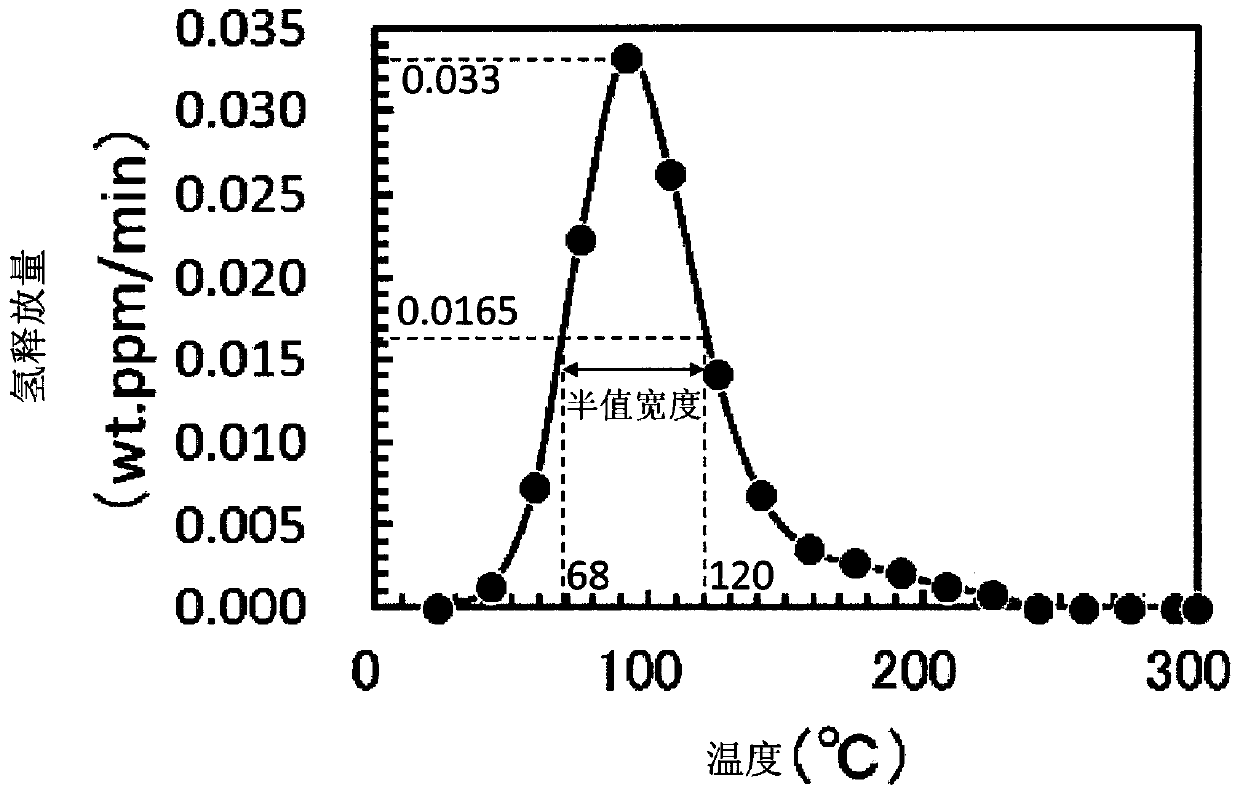

High strength galvanized steel sheet and production method therefor

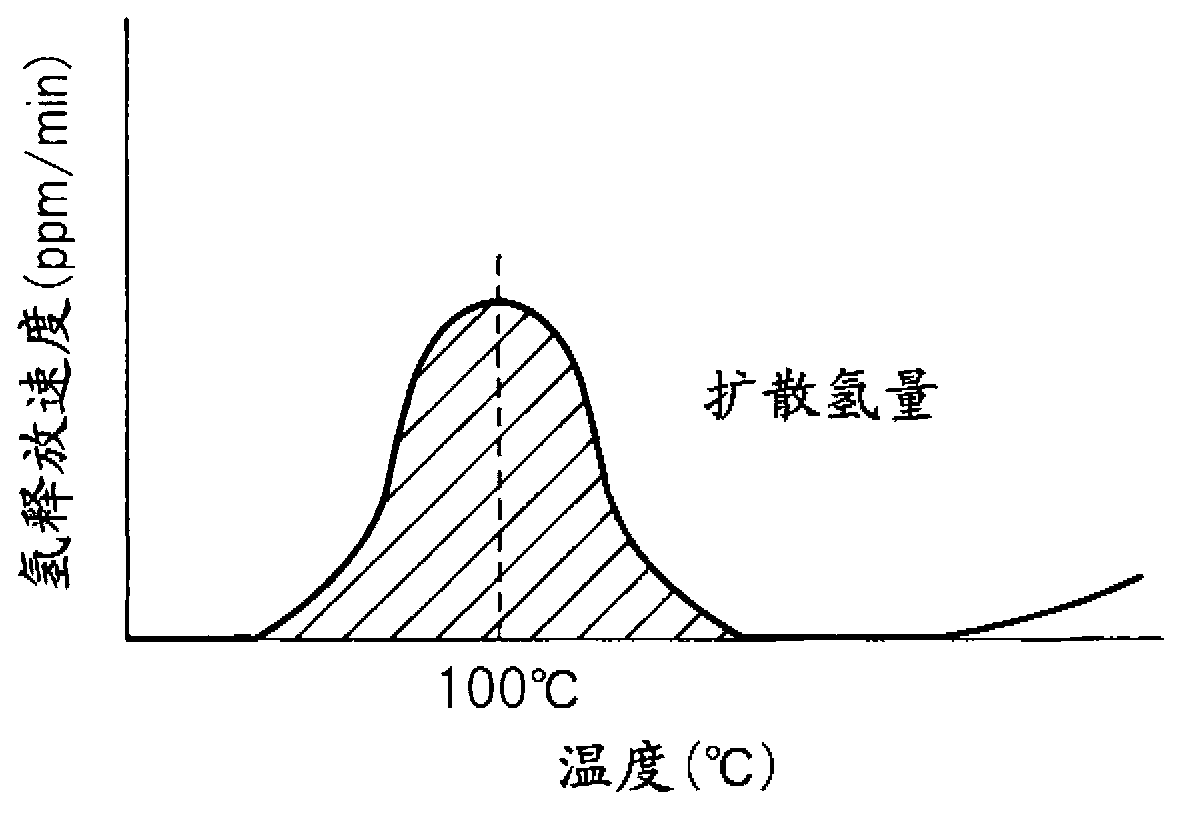

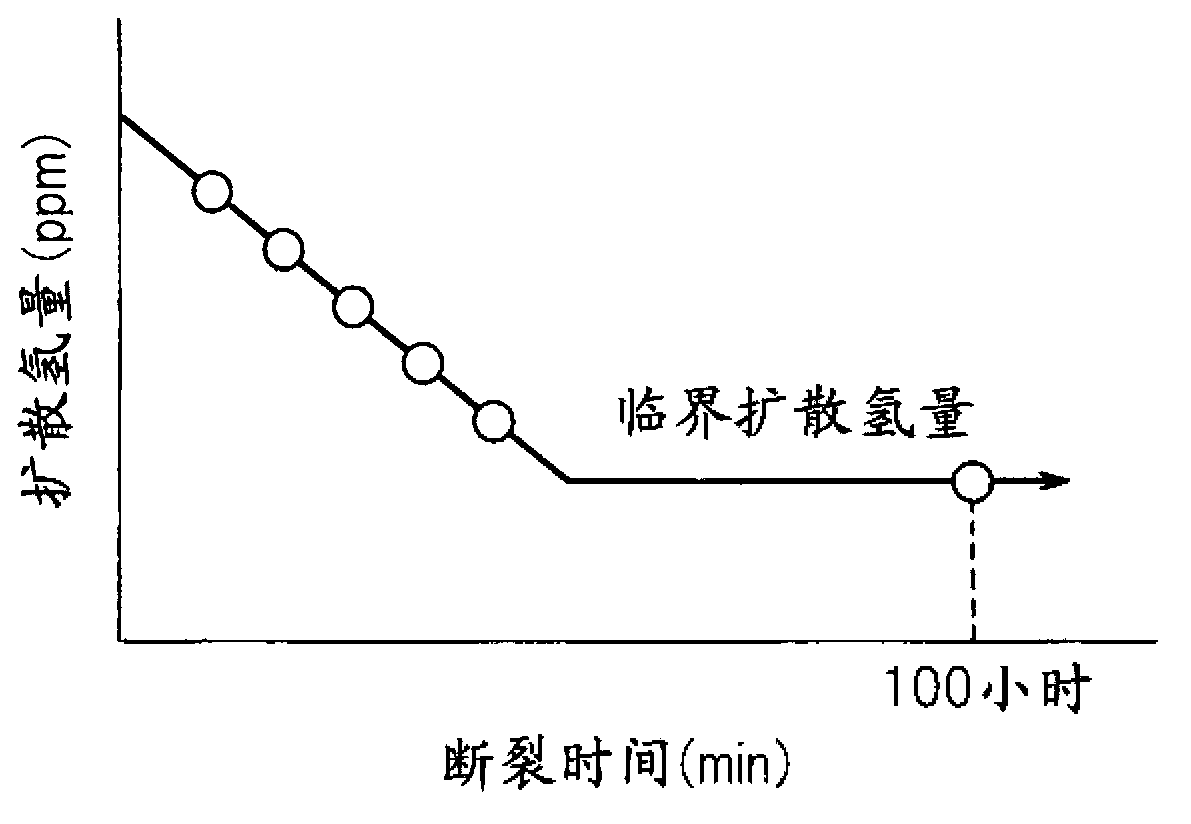

ActiveCN110268083AReduce the amount of diffusible hydrogenExcellent resistance to delayed fractureHot-dipping/immersion processesFurnace typesMartensiteDelayed fracture

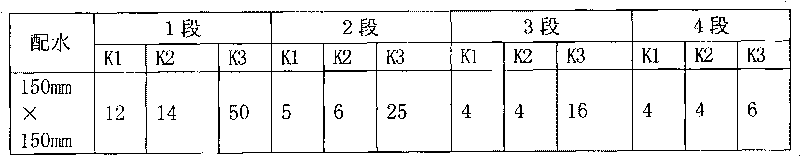

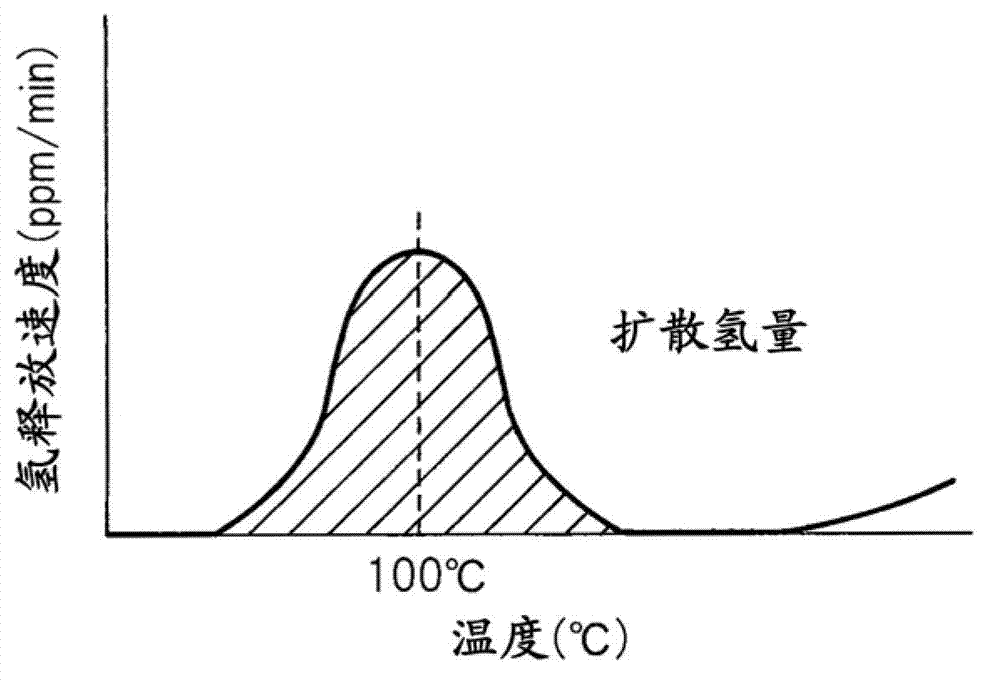

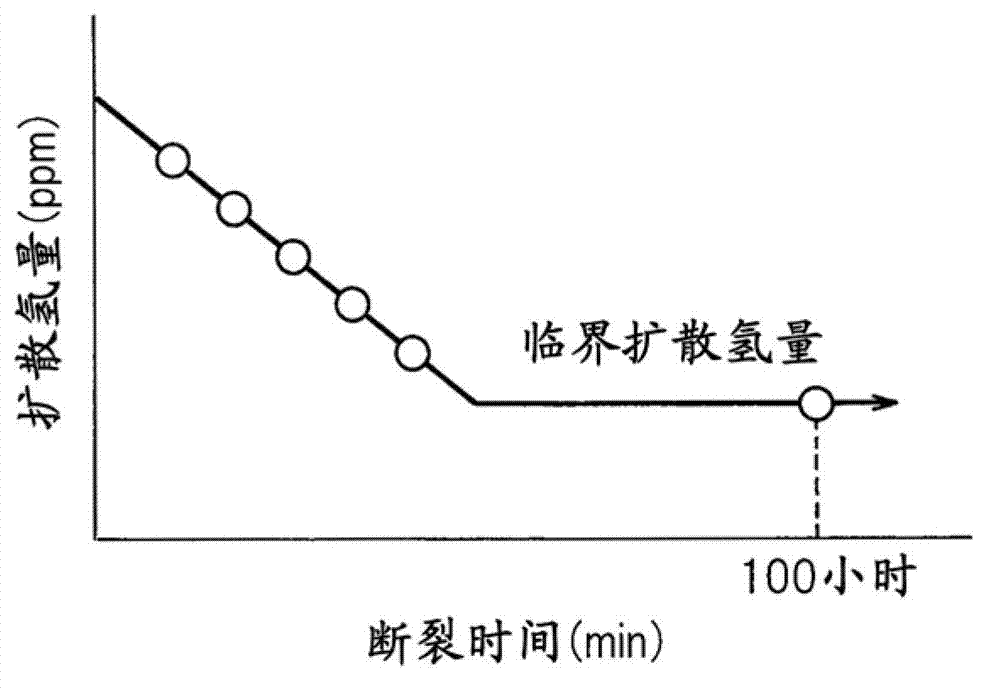

Provided are: a high strength galvanized steel sheet with excellent delayed fracture resistance characteristics resulting from reduction of the amount of diffusible hydrogen in the steel; and a production method therefor. The high strength galvanized steel sheet is provided with: a steel sheet having a specified component composition and a steel structure in which, in area ratio, the total amount of martensite and tempered martensite is at least 30%; and a galvanizing layer formed on the surface of the steel sheet. The amount of diffusible hydrogen obtained from an analysis method is 0.50 wt. ppm or less and the half width of the released hydrogen peak is 70DEG C or less.

Owner:JFE STEEL CORP

Low-carbon bainitic cold-work-strengthened non-quenched and tempered steel with excellent delayed fracture resistance

ActiveCN101935806AGood plasticity and cold workabilityExcellent resistance to delayed fractureAlloy steelMetallurgy

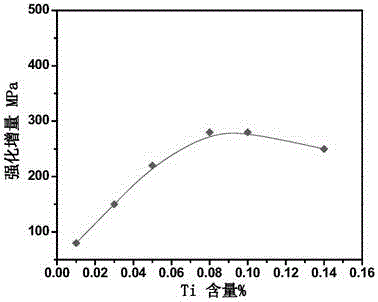

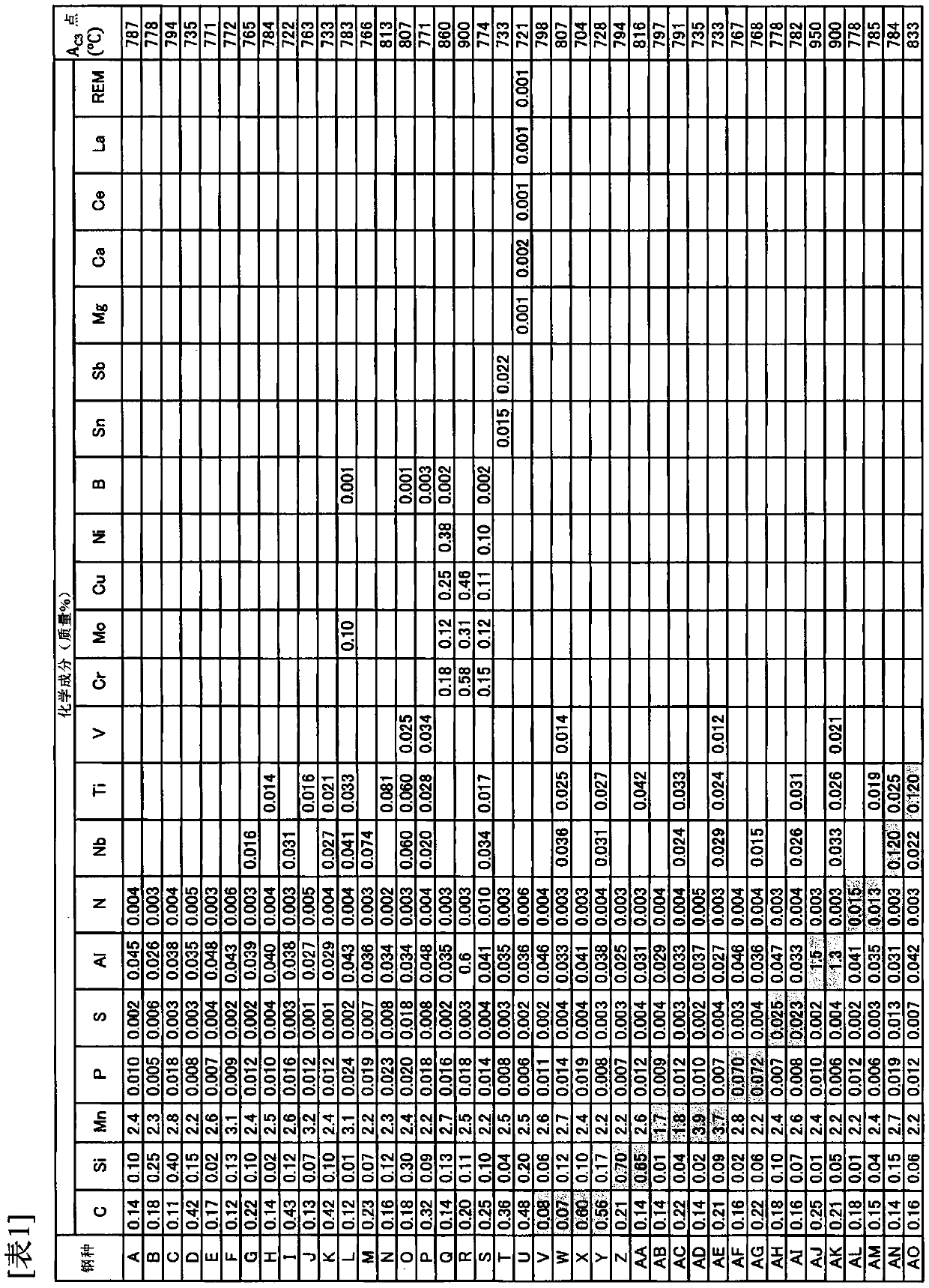

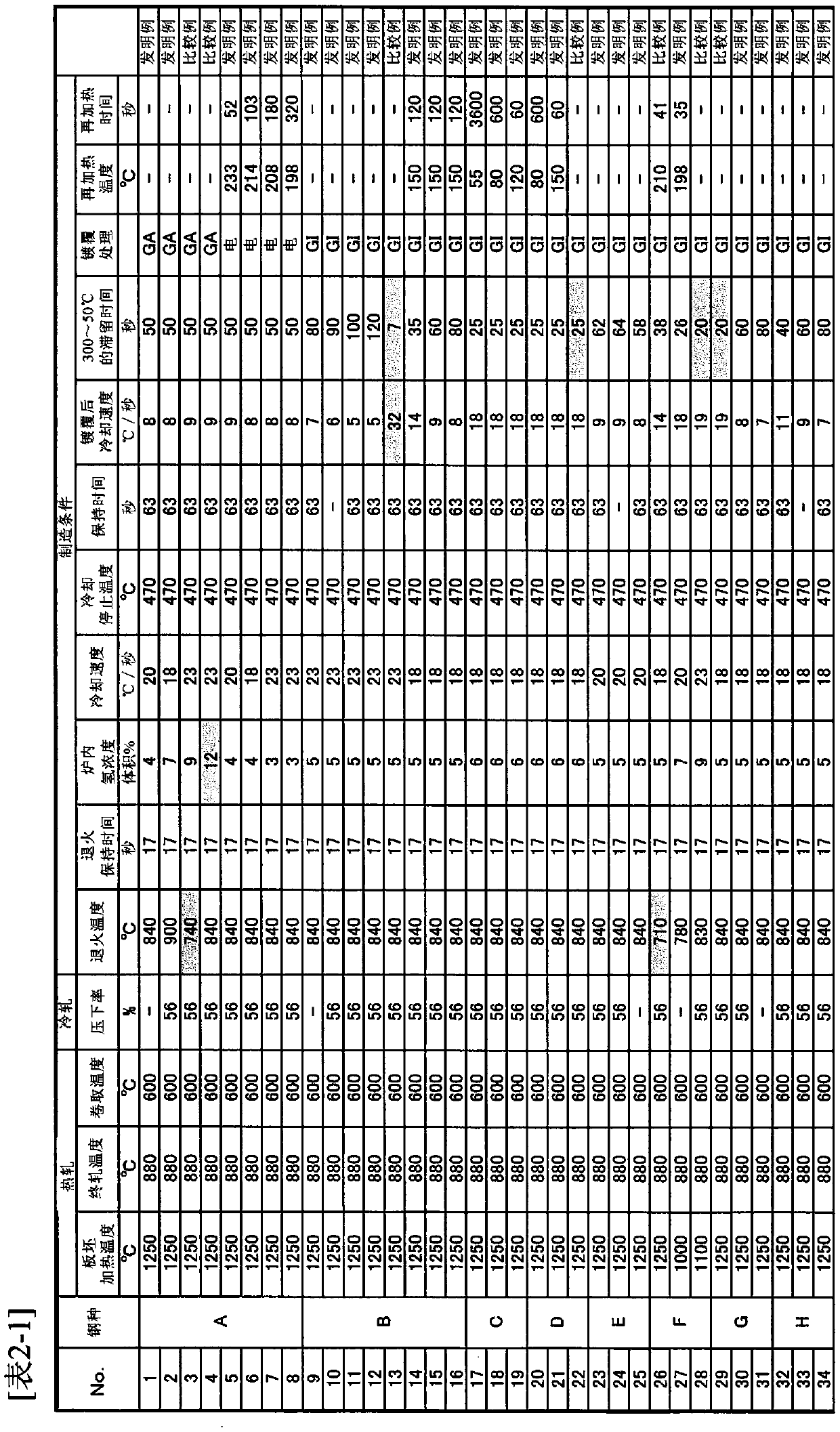

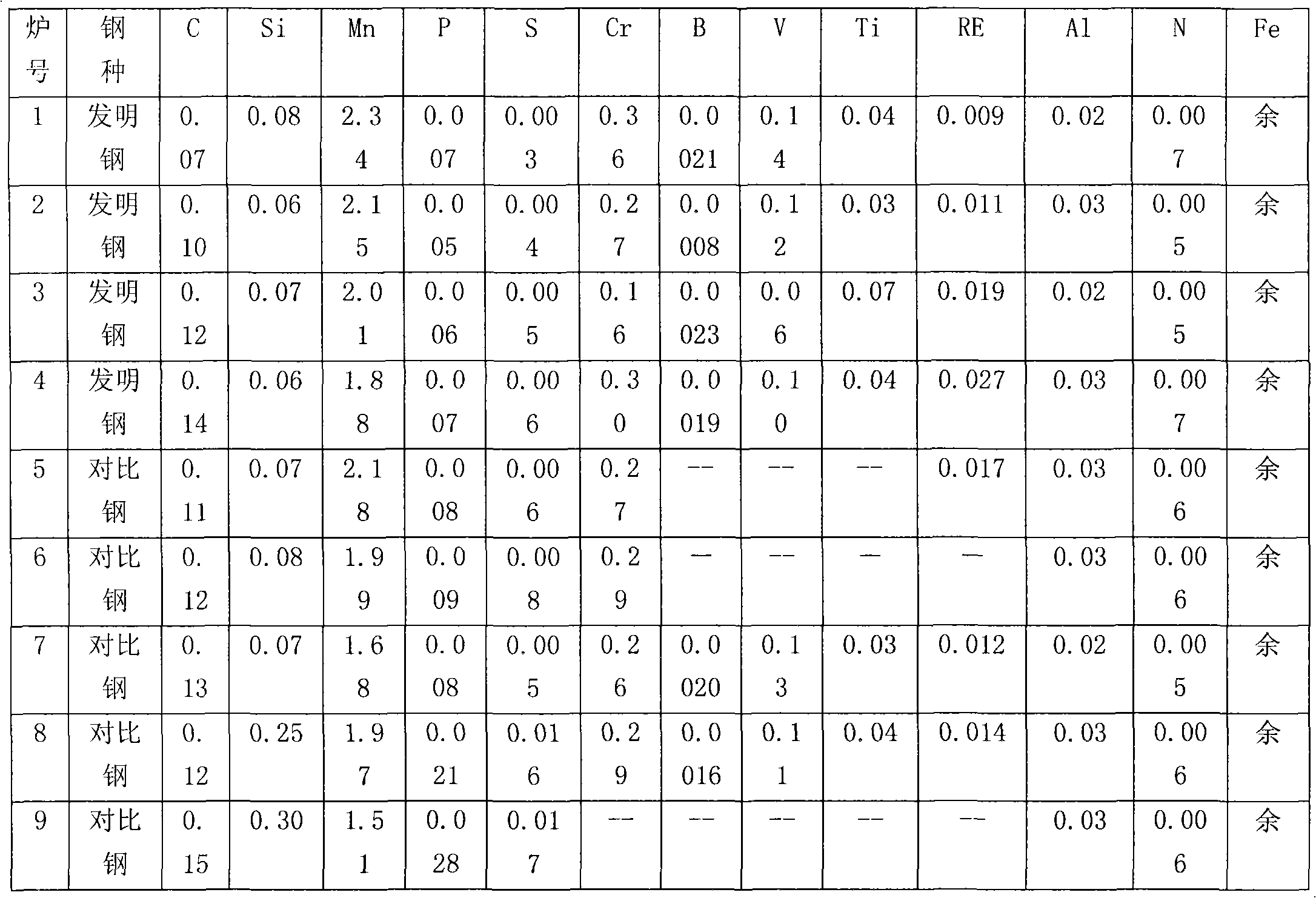

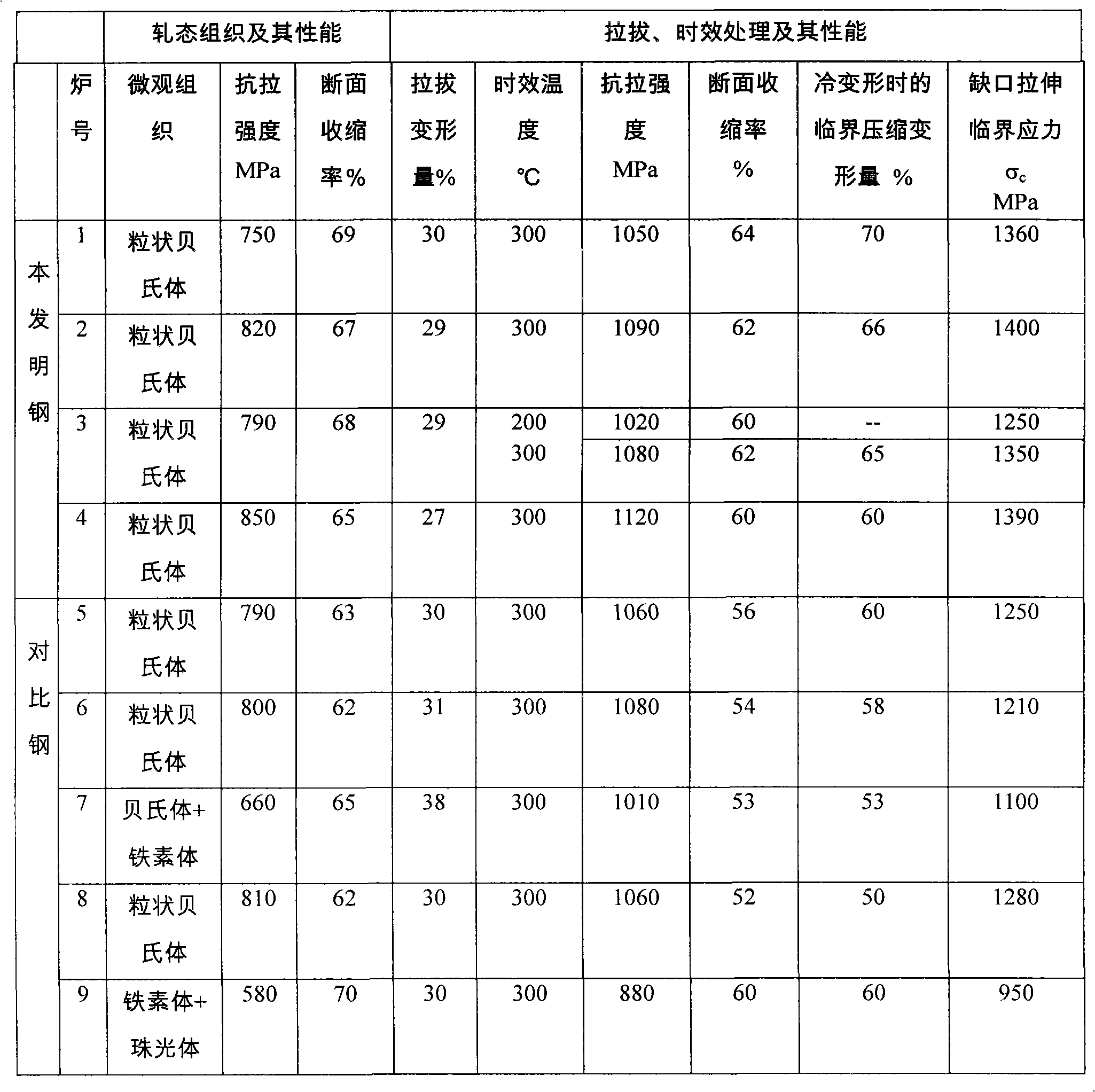

The invention relates to low-carbon bainitic cold-work-strengthened non-quenched and tempered steel with excellent delayed fracture resistance, which belongs to the technical field of alloy steel, and is applicable to manufacturing grade 10.9 high-strength bolts with tensile strength above 1000MPa. The steel comprises the following chemical components by weight percent: 0.06-0.15% of C, not more than 0.10% of Si, 1.80-2.40% of Mn, not more than 0.010% of P, not more than 0.008% of S, 0.10-0.40% of Cr, 0.0005-0.003% of B, 0.05-0.15% of V, 0.01-0.08% of Ti, 0.005-0.03% of RE, 0.01-0.05% of Al, 0.004-0.01% of N and the balance of Fe and other inevitable impurities; simultaneously, the elements of V and Ti further meet the following relational expression of a strengthening parameter theta: V(%) plus Ti(%) is not less than 0.10 and not more than 0.20; and a metallurgical structure is a granular bainite. The low-carbon bainitic cold-work-strengthened non-quenched and tempered steel has the advantages of not only having good plasticity and cold working performance, but also having excellent delayed fracture resistance and being used for manufacturing the grade 10.9 high-strength bolts with the delayed fracture resistance.

Owner:CENT IRON & STEEL RES INST

High-strength plated steel sheet and method for producing same

InactiveCN107109577AInhibition of hydrogen embrittlementHigh elongationHot-dipping/immersion processesFurnace typesExtensibilitySoft layer

Owner:KOBE STEEL LTD

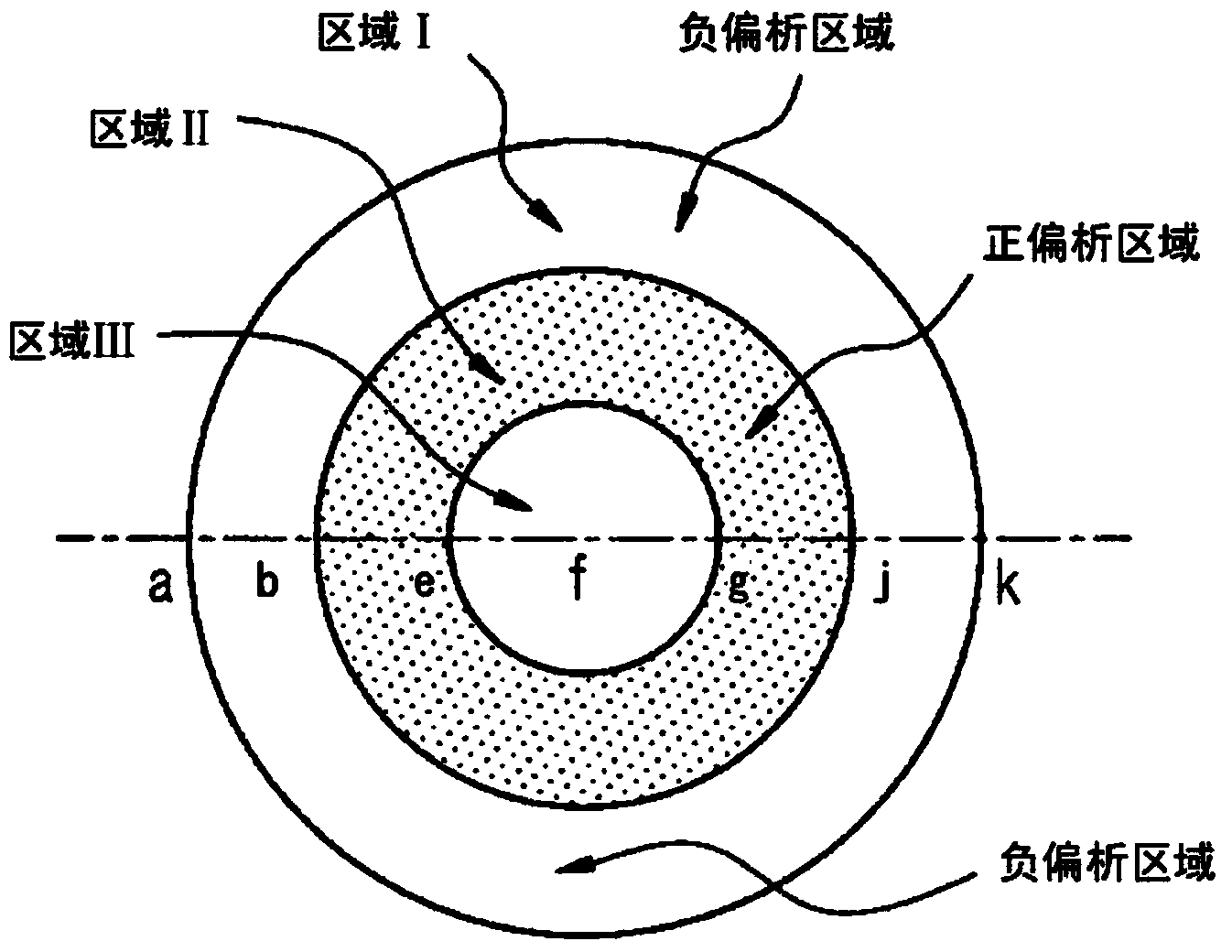

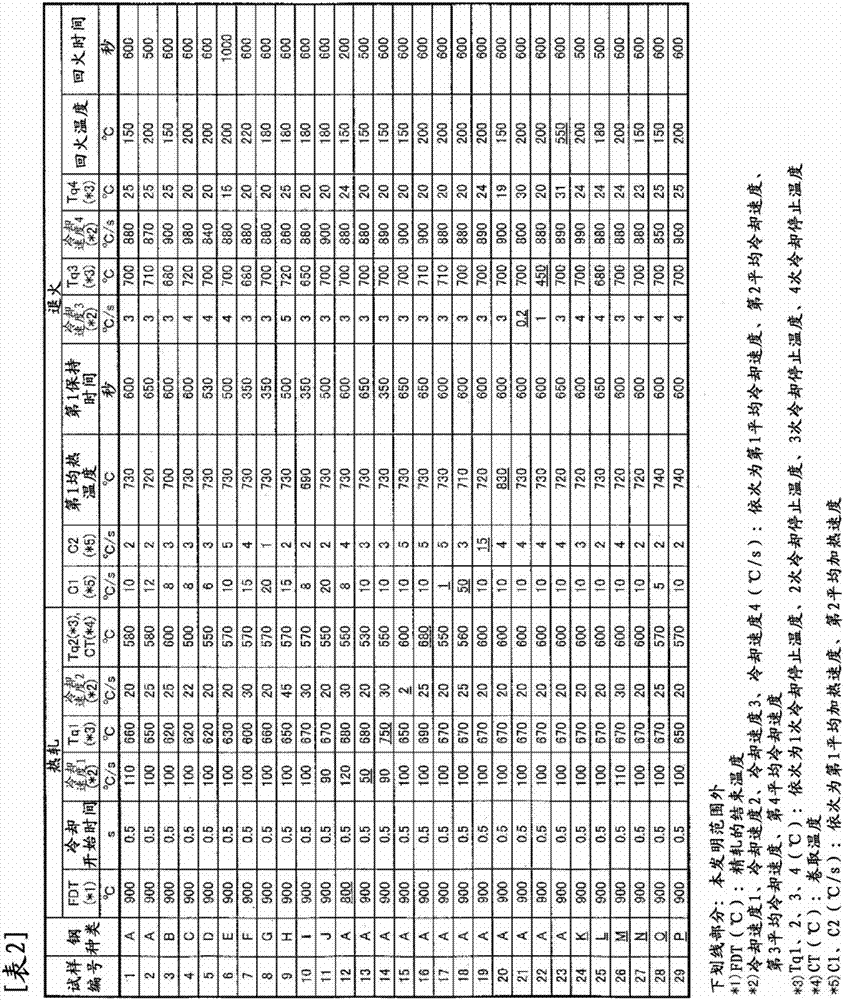

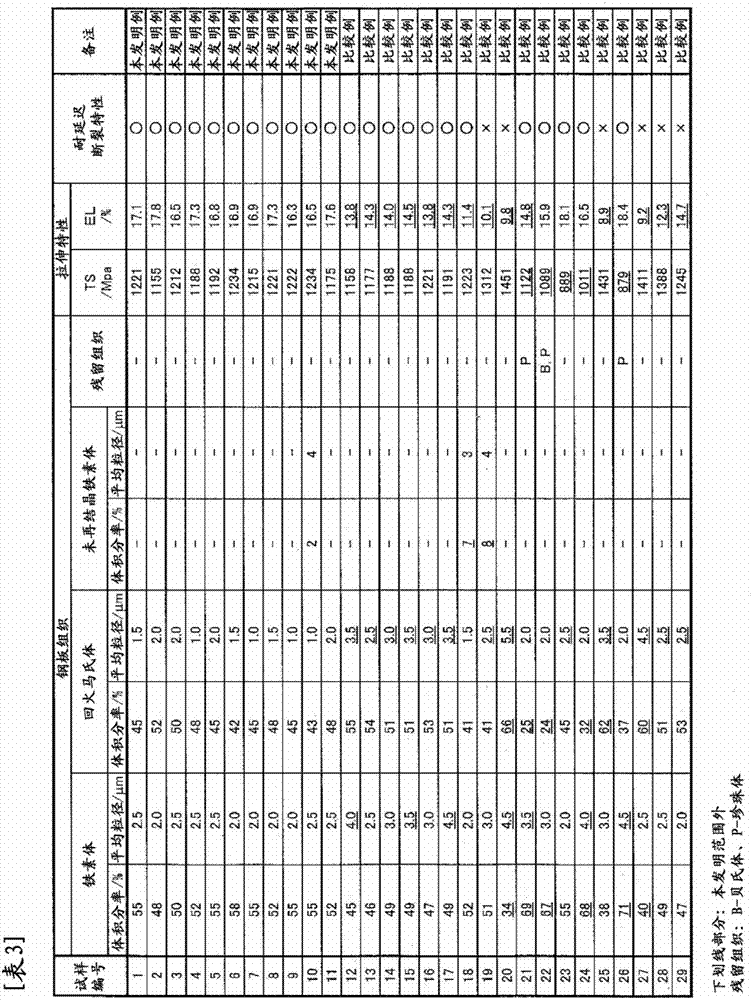

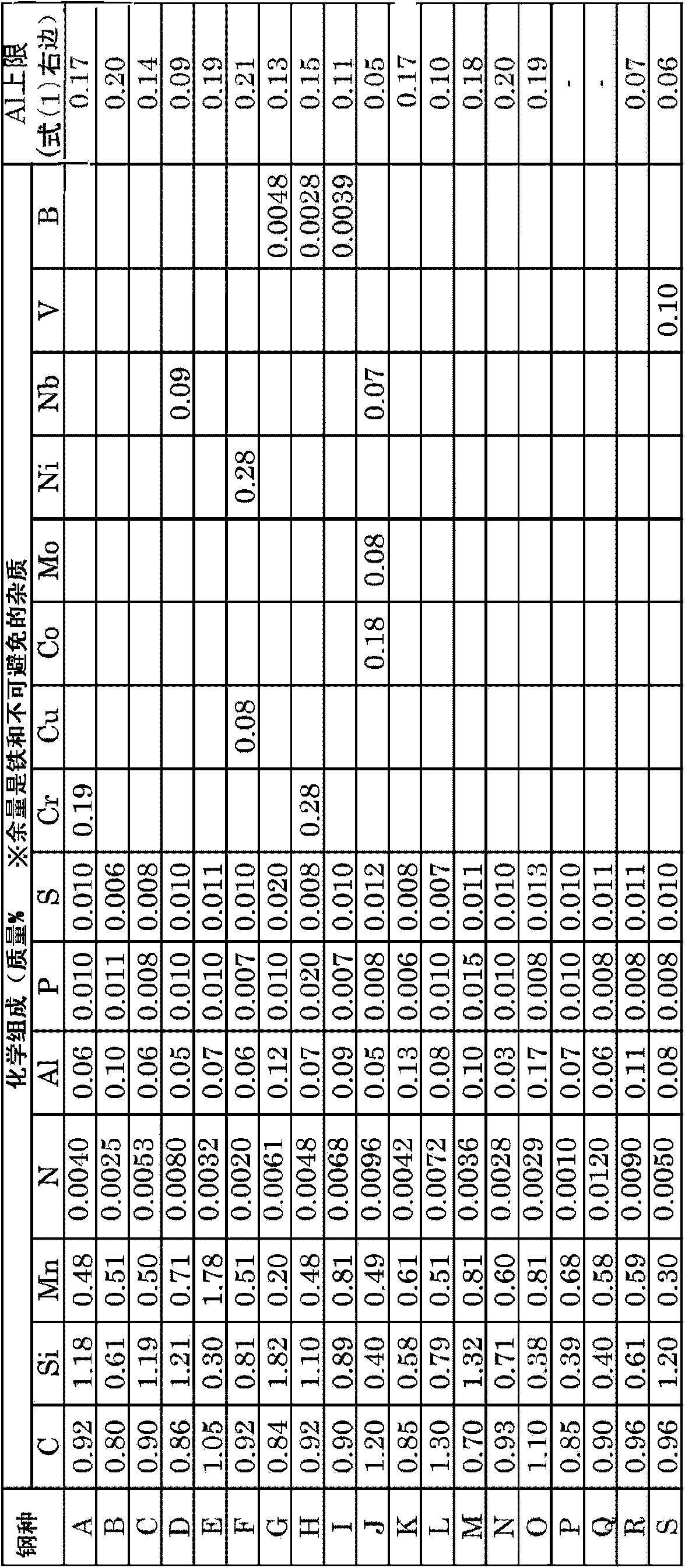

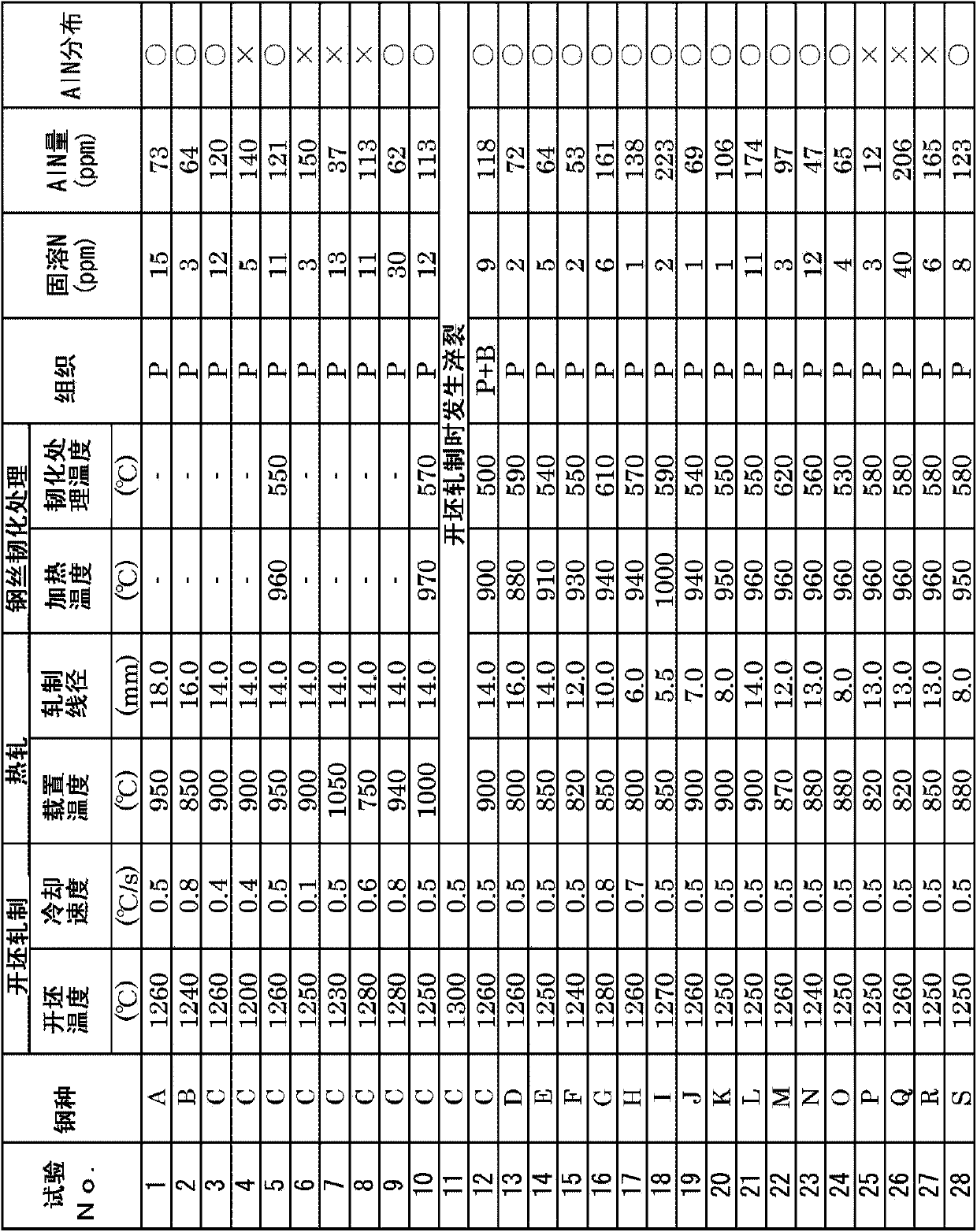

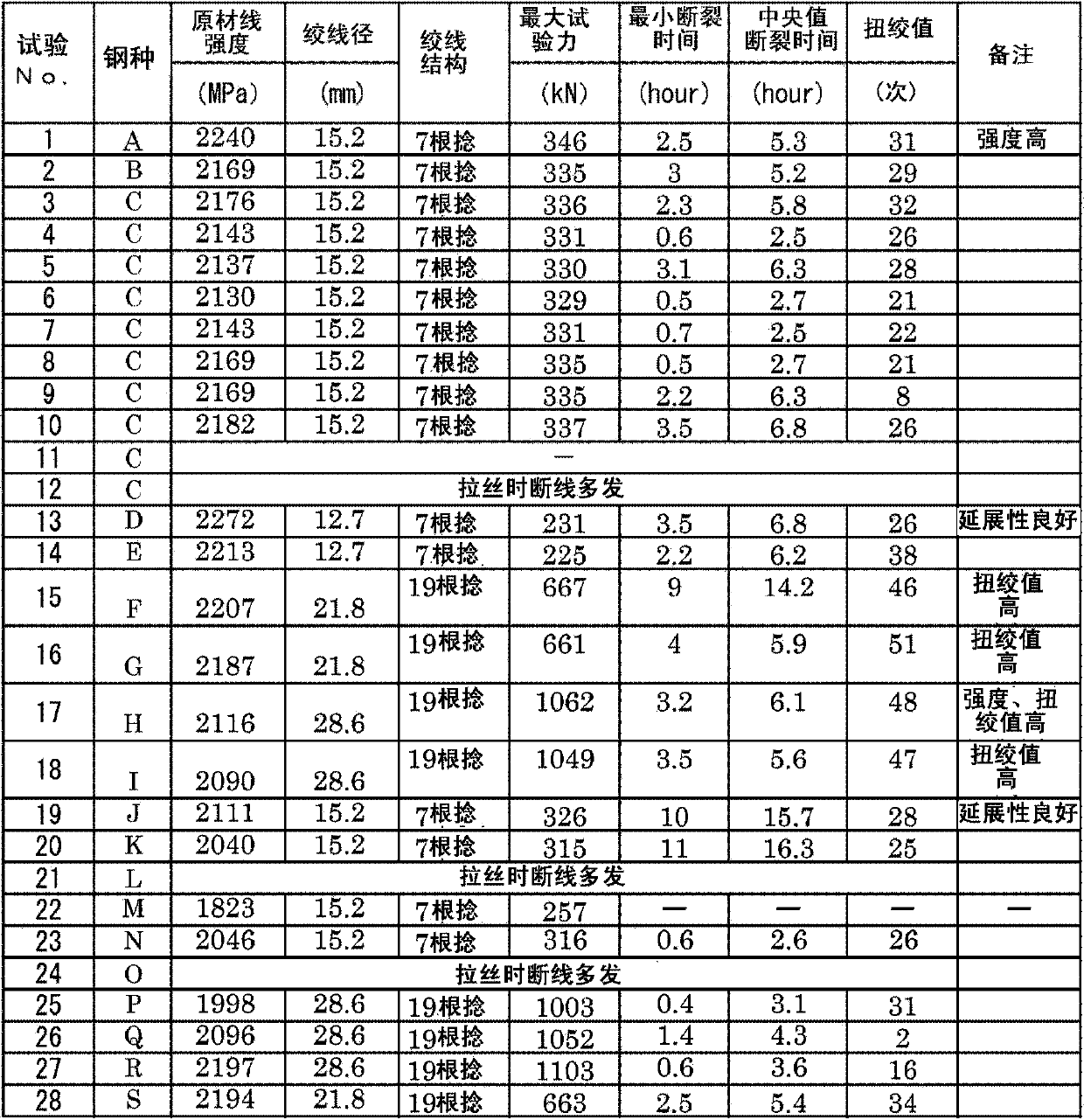

Wire rod, steel wire using same, and billet

ActiveCN103717326AImproved properties of delayed fractureExcellent drawing processabilityFurnace typesMetal rolling arrangementsWire rodEngineering

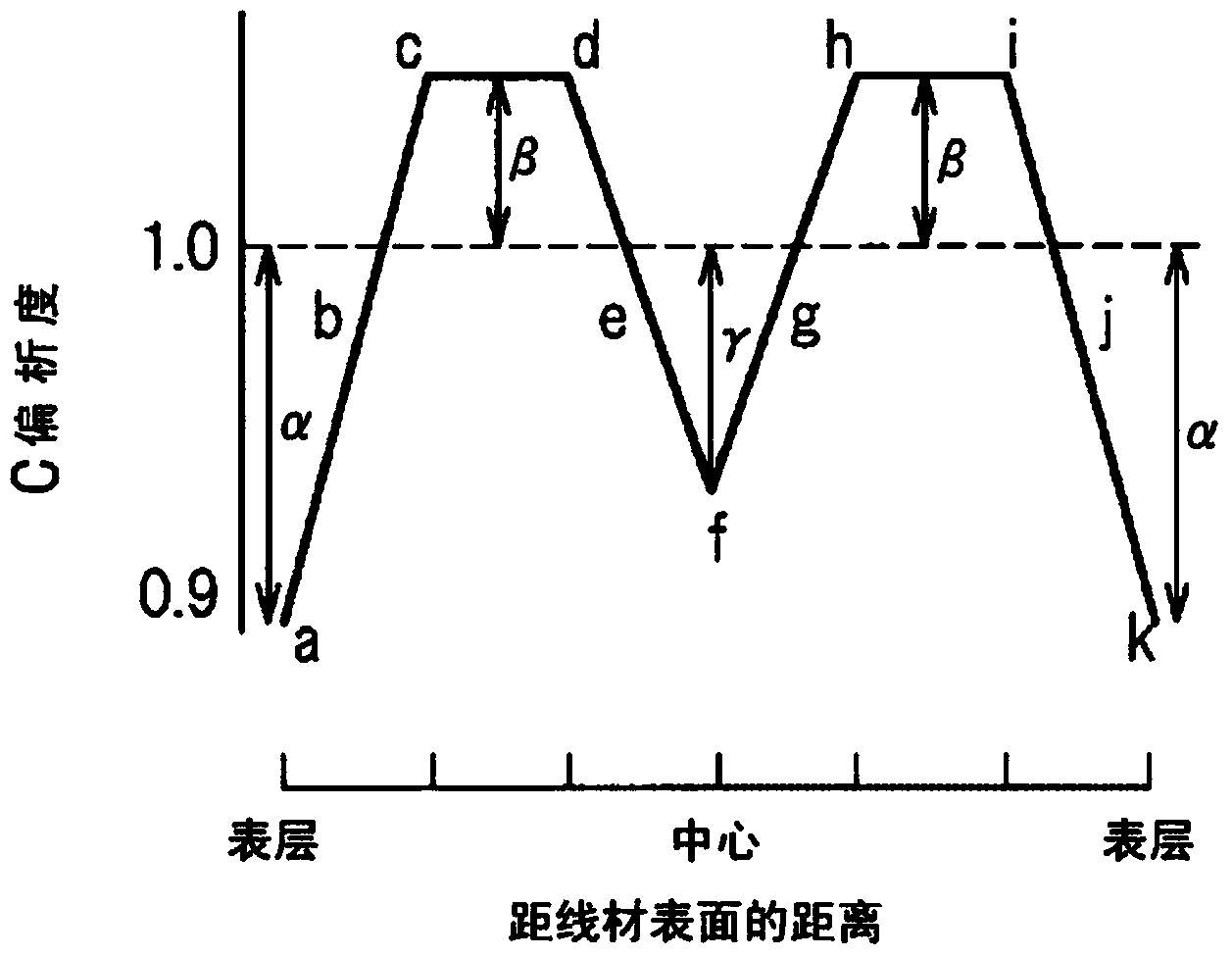

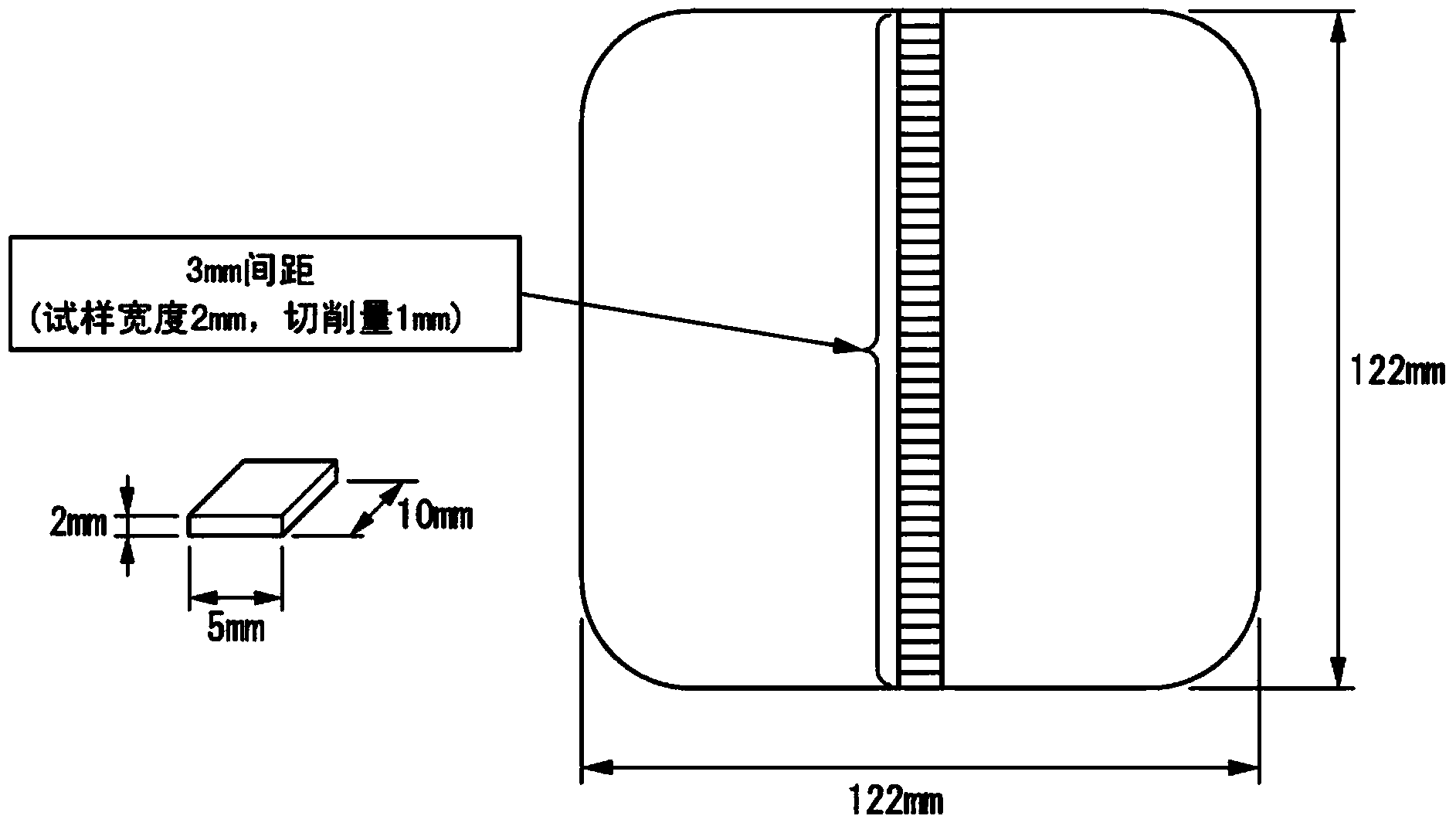

If an area that is formed concentrically inward from a surface of a wire rod and whose cross section ratio with respect to the cross sectional area of a cross section of the wire rod is between 13% and 56% is defined as area I, an area that widens concentrically about the central axis of the wire rod and whose cross section ratio with respect to the cross sectional area of the wire rod is between 3% and 11% is defined as area III, and an area between area I and area III is defined as area II, then area I is a first negative segregation portion where the degree of C segregation with respect to the average C concentration of the wire rod is between 0.75 and 0.95, area II is a positive segregation portion where the degree of C segregation is between 1.00 and 1.10, area III is a second negative segregation portion where the degree of C segregation is between 0.80 and 0.95; and the wire rod has a sandwich structure in which the first negative segregation portion, the positive segregation portion, and the second negative segregation portion are placed in order from the surface.

Owner:NIPPON STEEL CORP

High-strength cold-rolled steel plate and method for producing same

ActiveCN107250406AHigh elongationGood formabilityFurnace typesHeat treatment furnacesSheet steelHigh intensity

Provided are: a high-strength cold-rolled steel plate having a tensile strength (TS) of 1150 MPa or more and excellent elongation and delayed fracture resistance; and a method for producing same. The high-strength cold-rolled steel plate has a component composition comprising, in mass%, 0.16-0.30% of C, 1.20-2.20% of Si, 1.50-2.50% of Mn, 0.05% or less of P, 0.005% or less of S, 0.10% or less of Al, 0.007% or less of N, at least one of Ti and Nb (with the total of Ti + Nb being 0.04-0.15%), and a remainder of Fe and unavoidable impurities. The high-strength cold-rolled steel plate is configured so as to have a composite structure comprising 45-65% by volume fraction of ferrite having an average crystal grain size of 3 [mu]m or less, 35-55% by volume fraction of tempered martensite having an average crystal grain size of 2 [mu]m or less, and 5% or less (including 0%) of non-recrystallized ferrite having an average crystal grain size of 5 [mu]m or less.

Owner:JFE STEEL CORP

Wire rod and steel wire using same

ActiveCN104204255AExcellent resistance to delayed fractureImprove twist characteristicsFurnace typesHeat treatment furnacesWire ropeHigh intensity

The wire rod of the present invention includes predetermined amounts of C, Si, Mn, N, Al, P, and S, the remainder being iron and unavoidable impurities, the amount of Al and the amount of N satisfying the relationship indicated by equation (1): [Al] <= -2.1 × 10 × [N] + 0.255 (where [Al] and [N] in equation (1) are the content (mass%) of Al and N, respectively), at least 95 area% of the structure being a pearlite structure, the amount of AlN being at least 0.005%, and the ratio of AlN for which the AlN diameter dGM is 10-20 µm in the extreme-value distribution of the maximum values of dGM, expressed as the geometric mean (ab)1 / 2 of the length a and the thickness b, being at least 50% on a number basis. In this wire rod, reduction of delayed-fracture resistance characteristics that accompanies increasing of strength is suppressed, and the wire rod can be used in high-strength PC steel wire, wire rope, etc., having delayed-fracture resistance characteristics suitable for building codes.

Owner:KOBE STEEL LTD

Steel for high-strength bolt and application thereof

InactiveCN108950384AHigh strengthGood cold heading performanceFurnace typesHeat treatment furnacesNiobiumManganese

The invention discloses steel for a high-strength bolt. The steel comprises the following components of, by mass percent, 0.2-0.45% of carbon, 1.2-2.5% of silicon, 0.2-1.5% of manganese, less than orequal to 0.002% of phosphorus, less than or equal to 0.004% of sulfur, 0.02-0.10% of titanium, 0.02-0.2% of aluminum, 0.05-1.5% of chromium, 0.5-1.05% of nickel, 0.15-0.25% of molybdenum, 0.02-0.1% ofniobium and the balance iron and unavoidable impurities. The invention also correspondingly provides an application of the steel for the high-strength bolt. By adjusting the composition of the high-strength bolt and the amounts of the components, the components play synergistic effect mutually, and the finally obtained high-strength bolt has high comprehensive performance such as high strength, outstanding cold heading performance, outstanding and delayed fracture resistance. Fasteners such a bolt and a screw which are made of the steel for the high-strength bolt also have excellent comprehensive performance.

Owner:湖南铂固科技股份有限公司

55Si2MnVNbN spring steel and production process thereof

InactiveCN101717893BHigh strengthHigh tensile strengthTemperature control deviceMetal rolling arrangementsWorking environmentSpring steel

The invention relates to spring steel and a production process thereof, in particular to 55Si2MnVNbN spring steel and a production process thereof. The 55Si2MnVNbN spring steel comprises the following components in percentage by weight: 0.52 to 0.60 percent of C, 1.60 to 1.90 percent of Si, 0.60 to 0.80 percent of Mn, 0.15 to 0.35 percent of Cr, 0.06 to 0.12 percent of V, 0.015 to 0.025 percent of Nb, 0.80 to 1.50 percent of N, less than or equal to 0.0035 of P, less than or equal to 0.0035 percent of S and the balance of Fe and inevitable impurities. The process comprises electric furnace electrosmelting, LF refining, VD furnace vacuum degassing, continuous casting and rolling. The spring steel can meet the requirements of springs on various severe working environments, high strength andlong service life and has high tensile strength, high delayed fracture resistance, high corrosion resistance, high fatigue resistance and high elasticity attenuation resistance.

Owner:NANJING IRON & STEEL CO LTD

Hot-press member and method for manufacturing same, and cold-rolled steel sheet for hot pressing and method for manufacturing same

ActiveCN110799661AExcellent Resistance Welding Crack ResistanceImprove featuresHot-dipping/immersion processesSolid state diffusion coatingElectrical resistance and conductanceCrack resistance

Provided is a hot-press member that can have very high tensile strength such as TS: 1780 MPa or larger after hot pressing, and excellent crack resistance during resistance welding and delayed fractureresistance after resistance welding, the hot press member being obtained by appropriately adjusting the component composition thereof and making the microstructure thereof such that the average crystal grain size of prior austenite is 7 microns or less, the volume ratio of martensite is 90% or more, the average number of Nb-based precipitate having a grain size of less than 0.08 microns in a 100-micron<2> 2-section parallel with the thickness direction of the member is 5 or more in a region within 100 microns from the surface of the member in the plate thickness direction, and a Ni-diffused region having a thickness of 0.5 microns or more is present in the surface layer of the member.

Owner:JFE STEEL CORP

High-strength pc steel wire

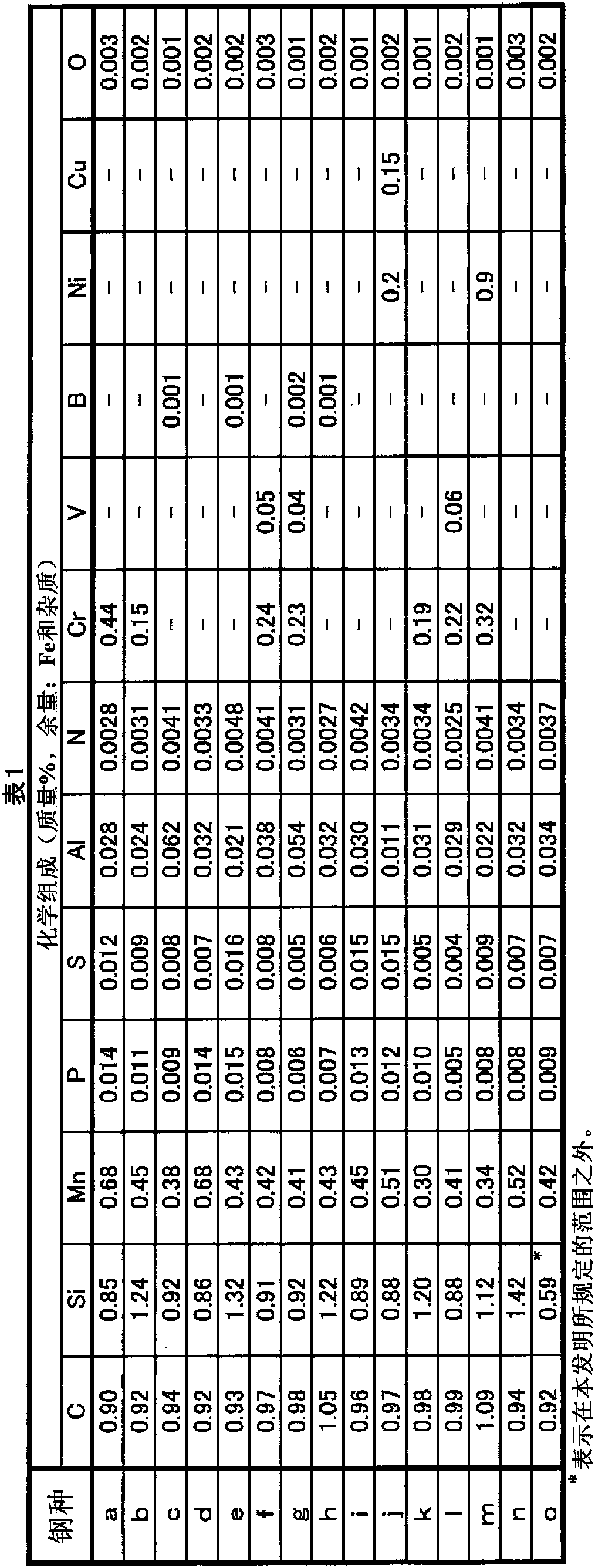

ActiveCN107849660ASimple manufacturing methodExcellent resistance to delayed fractureFurnace typesHeat treatment furnacesSurface layerChemical composition

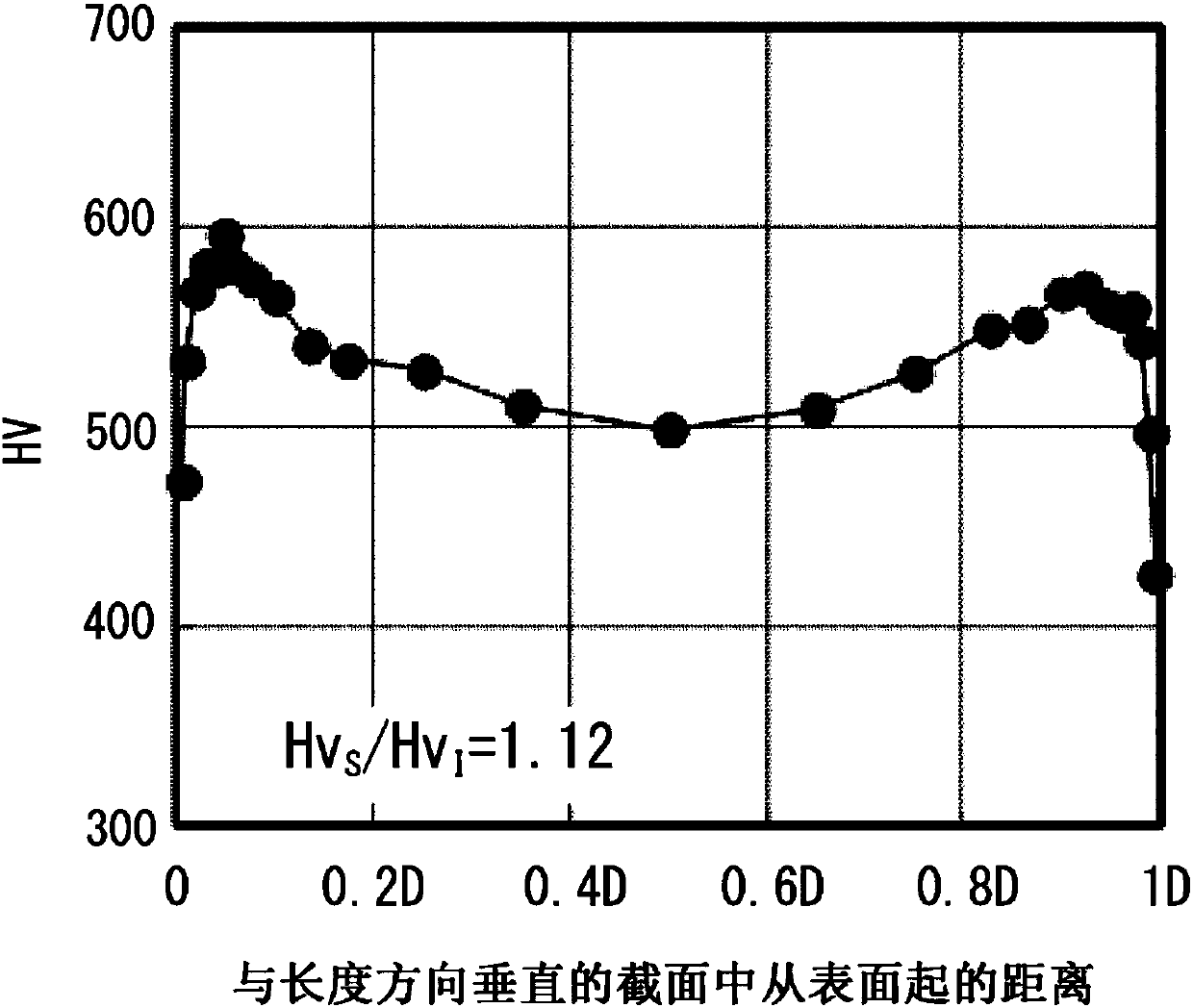

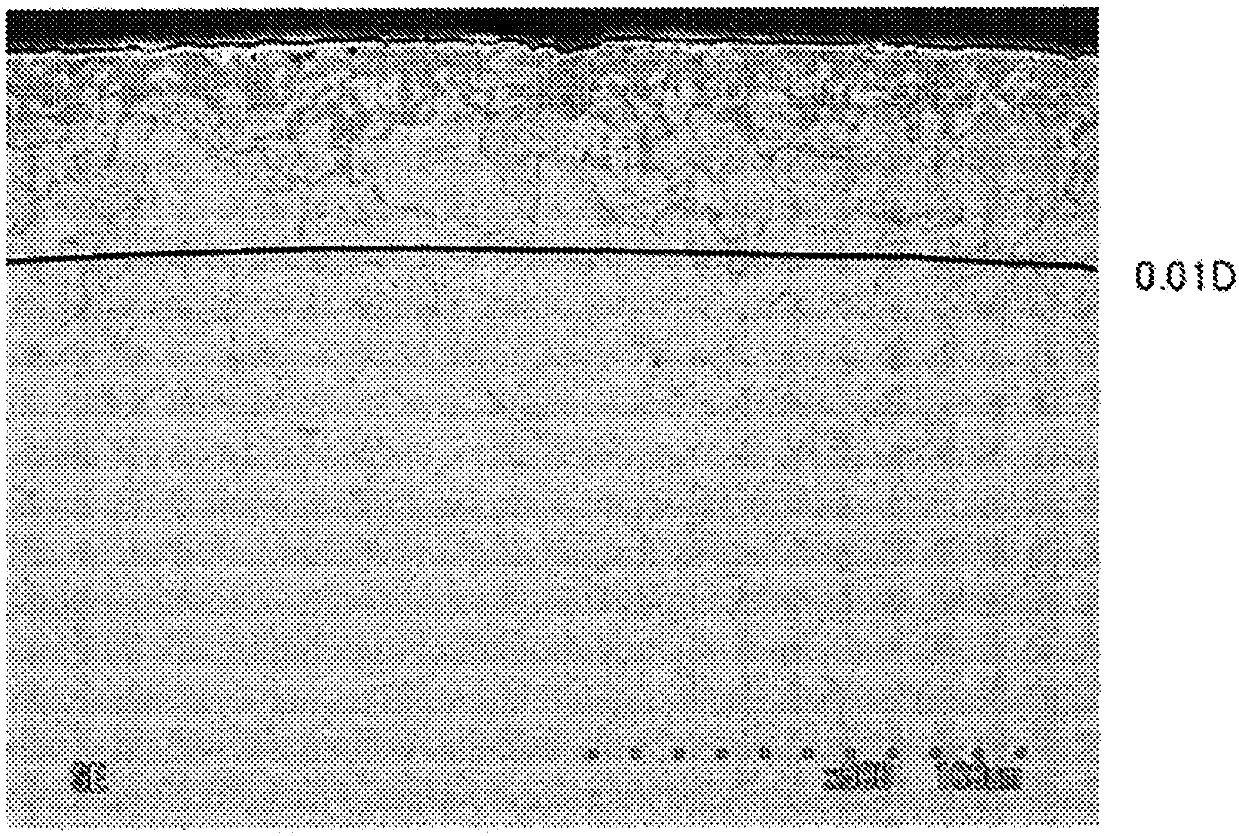

The chemical composition of this high-strength PC steel wire comprises, in mass%, C: 0.90-1.10%, Si: 0.80-1.50%, Mn: 0.30-0.70%, P: 0.030% or less, S: 0.030% or less, Al: 0.010-0.070%, N: 0.0010-0.010%, Cr: 0-0.50%, V: 0-0.10%, B: 0-0.005%, Ni: 0-1.0%, Cu: 0-0.50%, and the remainder is Fe and impurities. The ratio of the Vickers hardness (HvS) of the area 0.1D [D: diameter of steel wire] from thesurface of the steel wire (the surface layer) and the Vickers hardness (HvI) of the area interior to the surface layer satisfies [1.10 < HvS / HvI <= 1.15]. The metal composition of the region from thesurface of the steel wire up to 0.01D (the outermost layer) is, by area%, a pearlite structure: less than 80%, and the remainder is a ferrite structure and / or a bainite structure; the metal structurein the region interior to the aforementioned outermost layer region is, by area%, a pearlite structure: greater than or equal to 95%, and has a tensile strength of 2000-2400 MPa. This high-strength PCsteel wire has a simple manufacturing method and has excellent delayed fracture resistance.

Owner:NIPPON STEEL CORP +1

High-strength plated steel sheet having excellent plating properties, workability, and delayed fracture resistance, and method for producing same

InactiveCN107109574AInhibition of hydrogen embrittlementUniform strengthHot-dipping/immersion processesFurnace typesSoft layerInternal oxidation

Owner:KOBE STEEL LTD

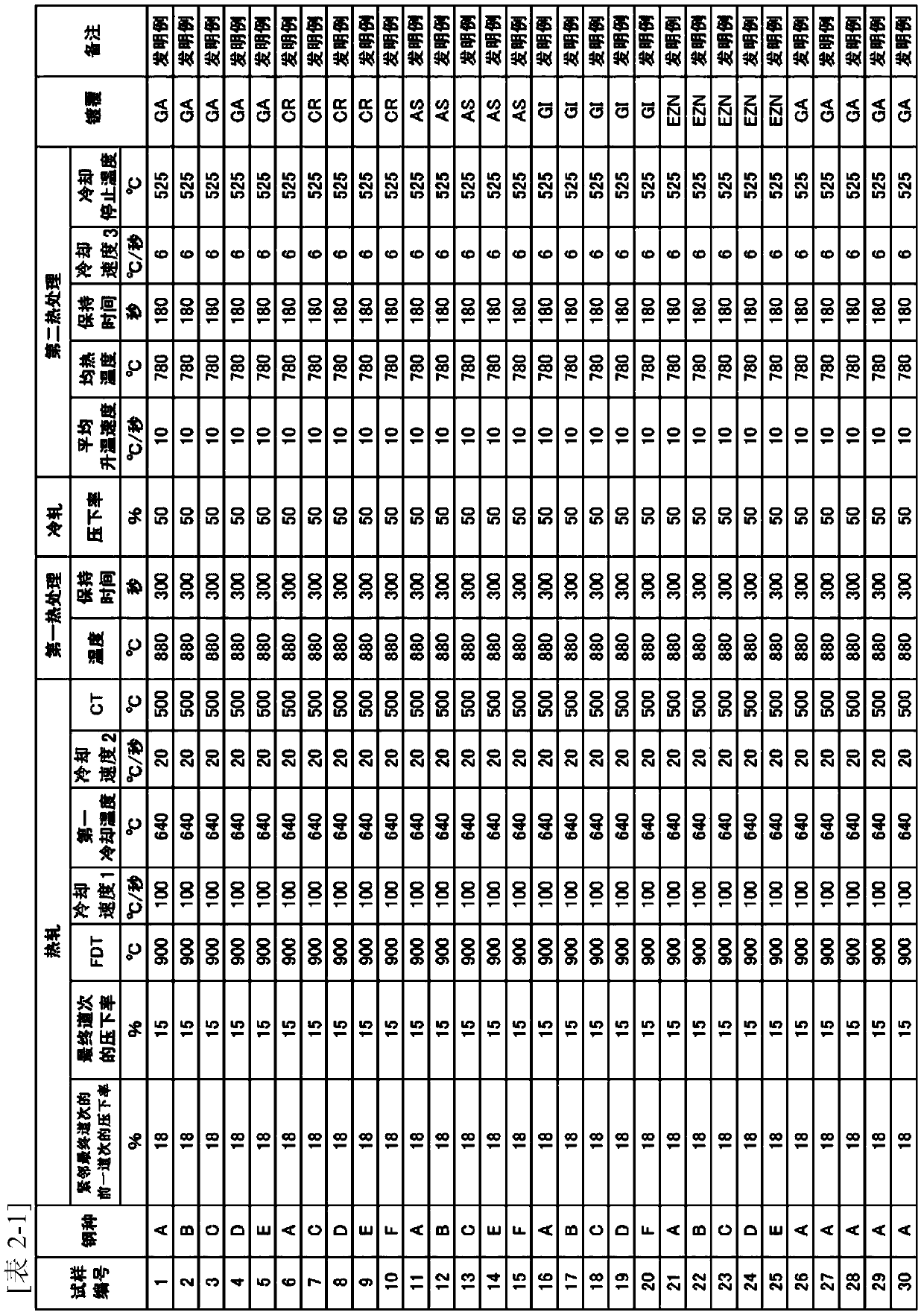

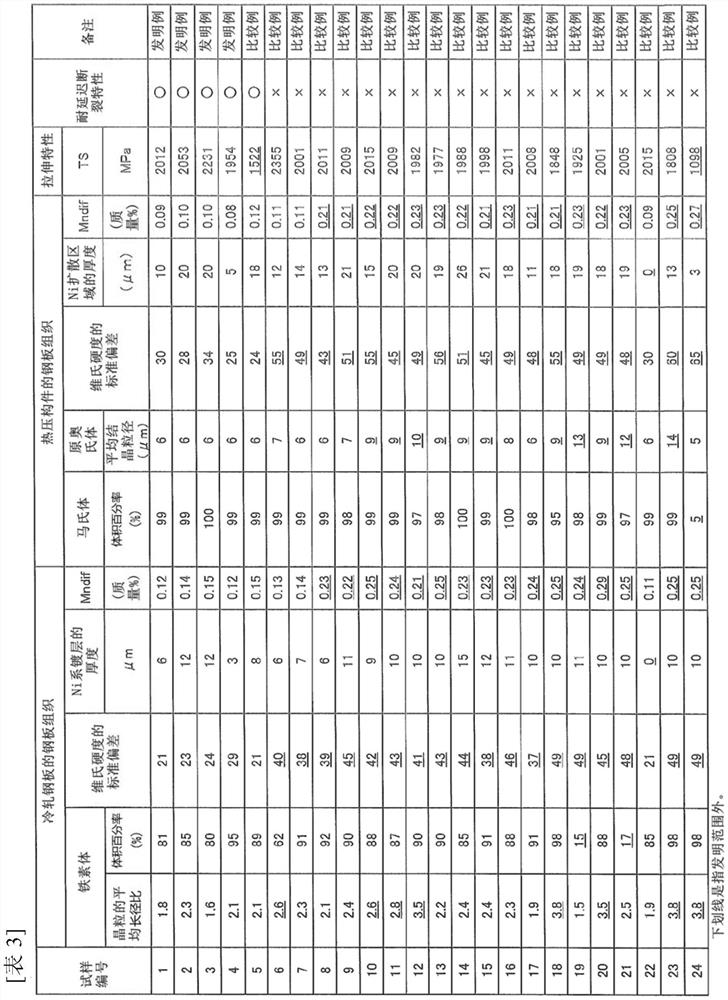

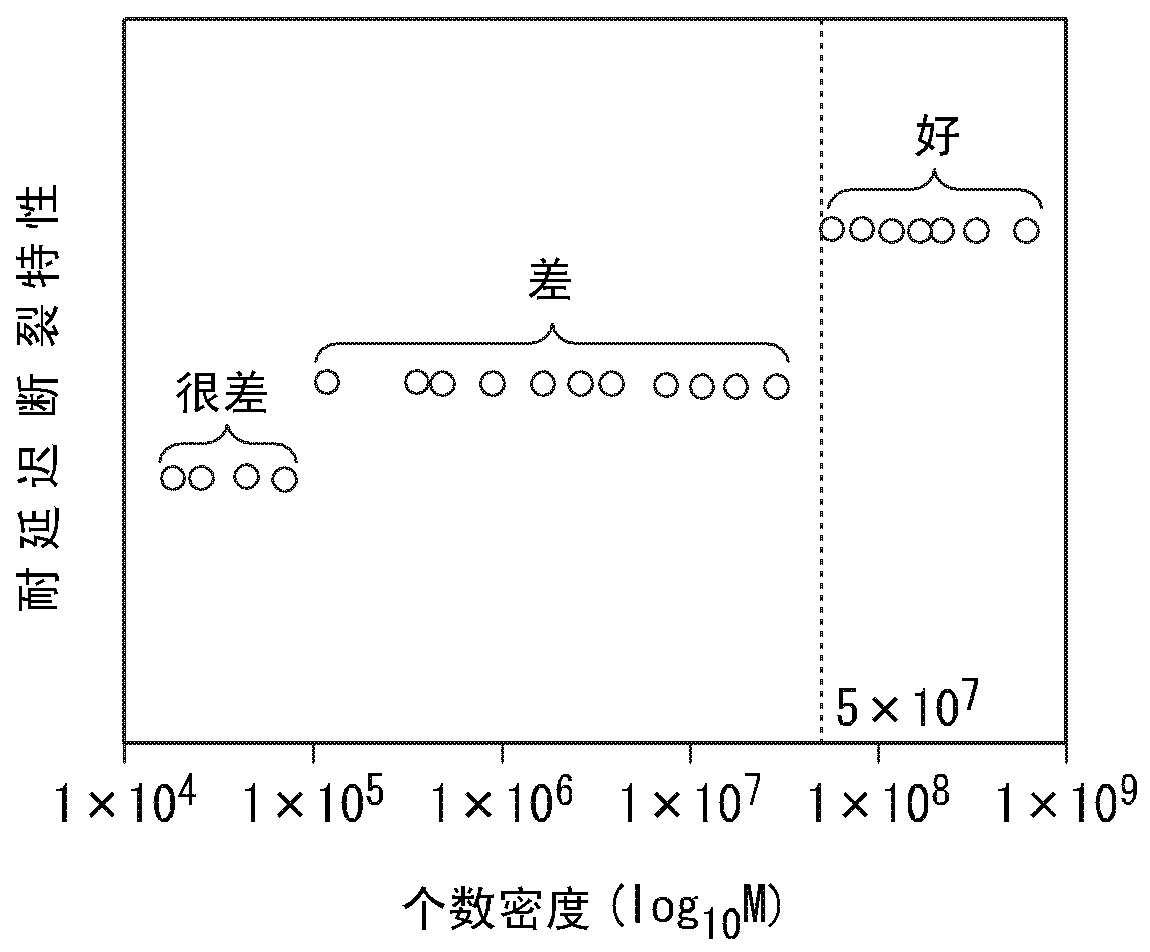

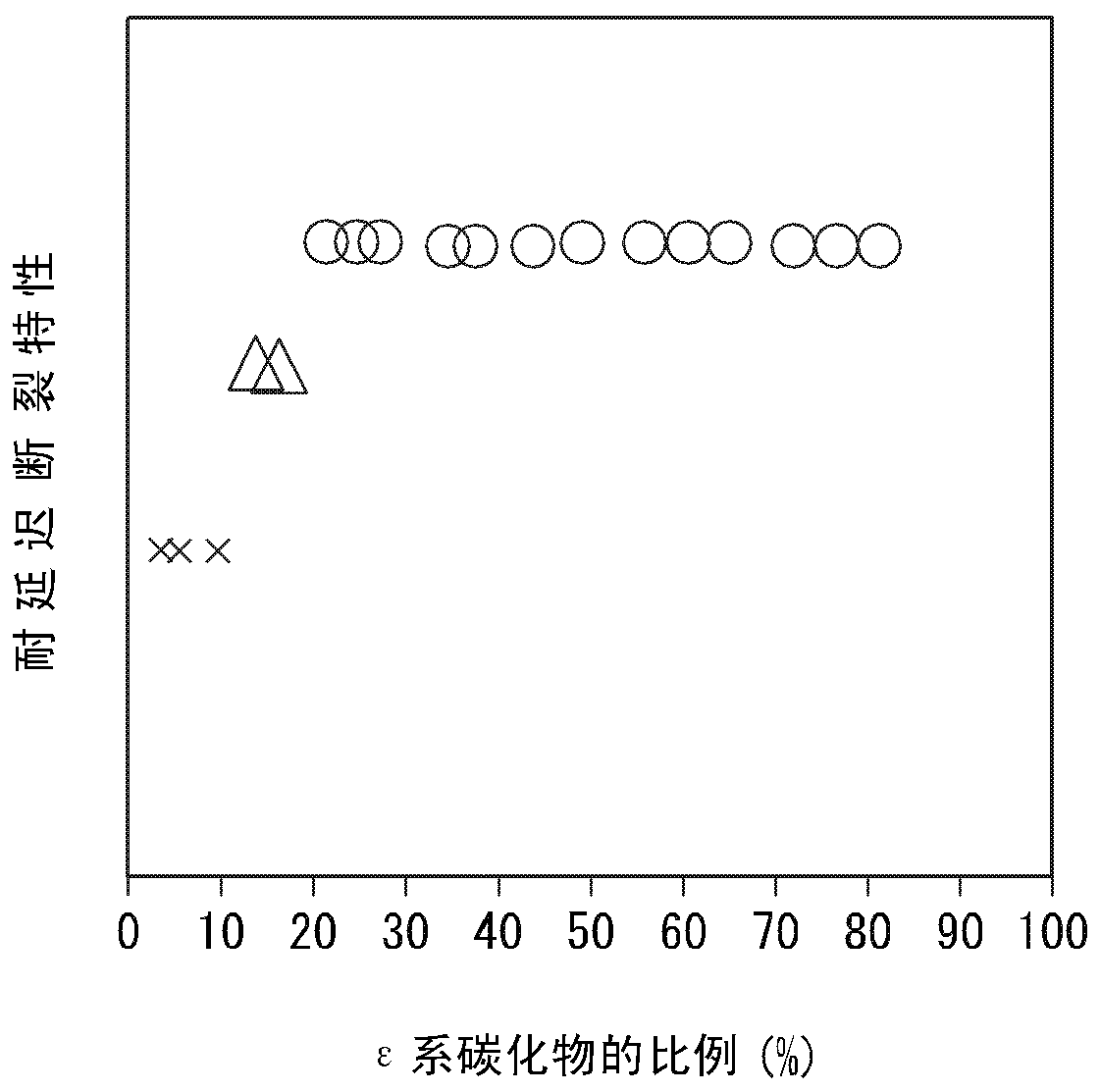

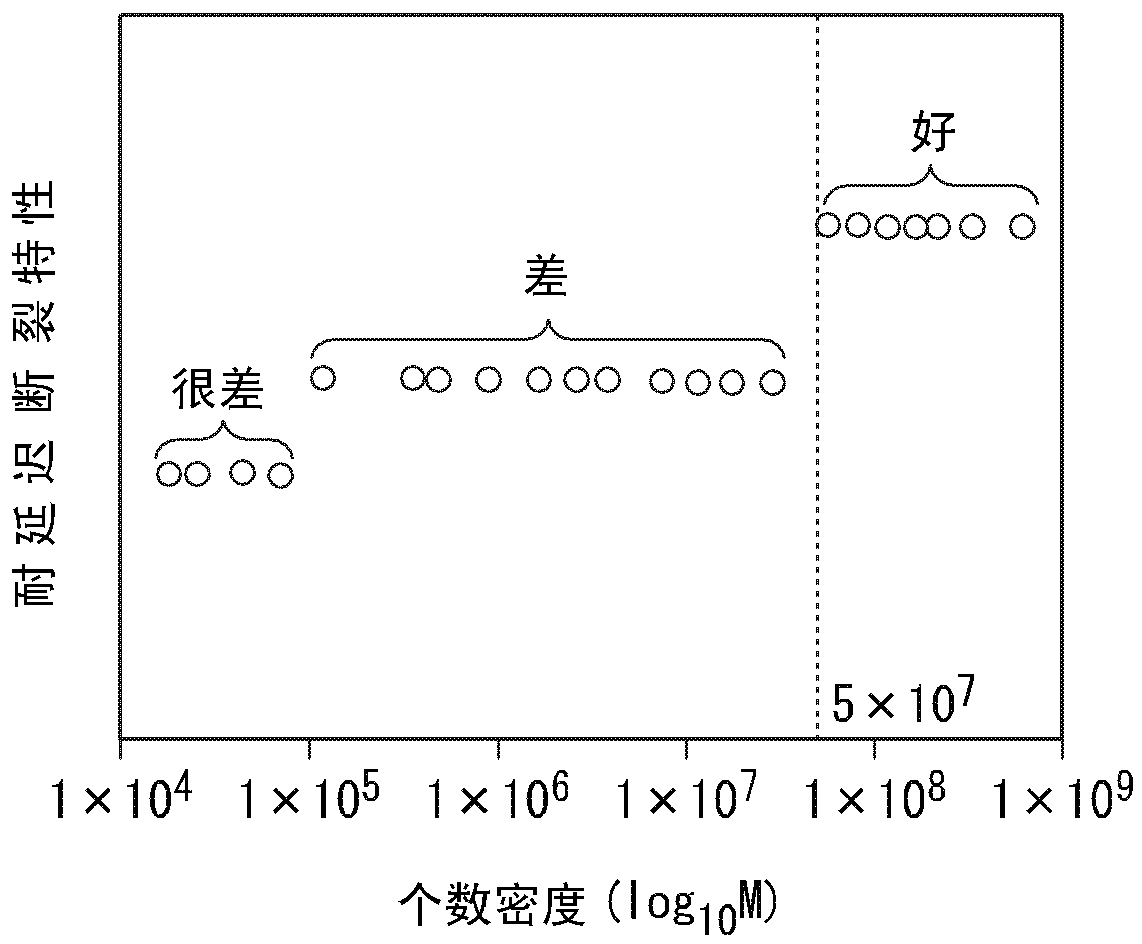

Steel sheet, hot-dip galvanized steel sheet, alloyed hot-dip galvanized steel sheet, and production methods therefor

ActiveCN107849666AHigh tensile strengthExcellent resistance to delayed fractureHot-dipping/immersion processesFurnace typesHot-dip galvanizationPearlite

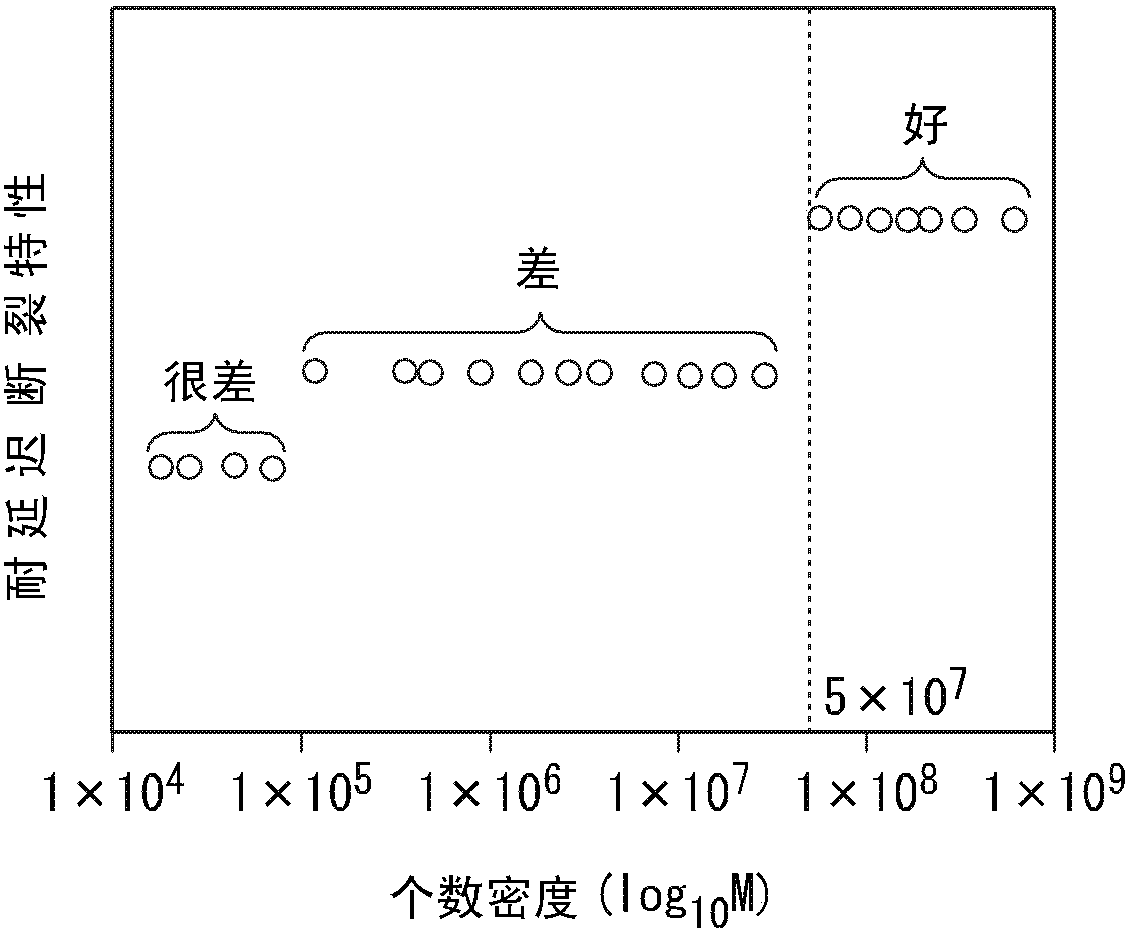

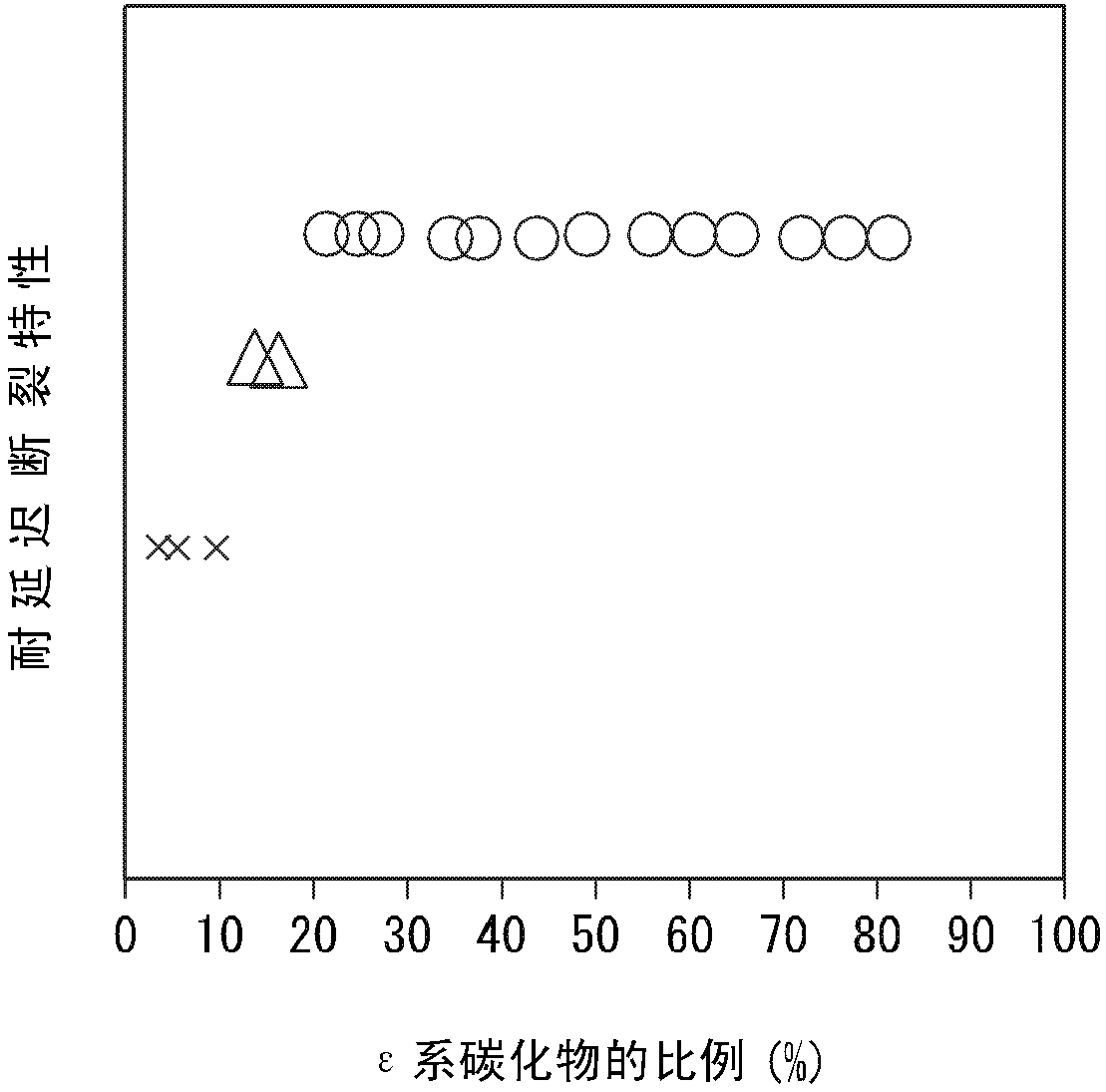

A steel sheet according to one embodiment of the present invention has a prescribed chemical composition. The structure of a portion comprising 1 / 4 of the sheet thickness includes, expressed as volumefractions, 30-70% of tempered martensite, and a total of at least 20% but not more than 70% of ferrite and / or bainite. The structure of the portion comprising 1 / 4 of the sheet thickness includes, expressed as volume fractions, less than 10% of retained austenite, not more than 10% of fresh martensite, and not more than 10% of pearlite. The total volume fraction of retained austenite, fresh martensite, and pearlite in said structure is not more than 15%. The number density of iron-based carbides having a longitudinal diameter of at least 5 nm in the tempered martensite in the portion comprising 1 / 4 of the sheet thickness is at least 5*107 per mm<2>. The ratio of the number of [Epsilon] carbides to the number of the iron-based carbides having a longitudinal diameter of at least 5 nm in theportion comprising 1 / 4 of the sheet thickness is at least 20%. The tensile strength is at least 780 MPa.

Owner:NIPPON STEEL CORP

High-strength plated steel sheet and method for producing same

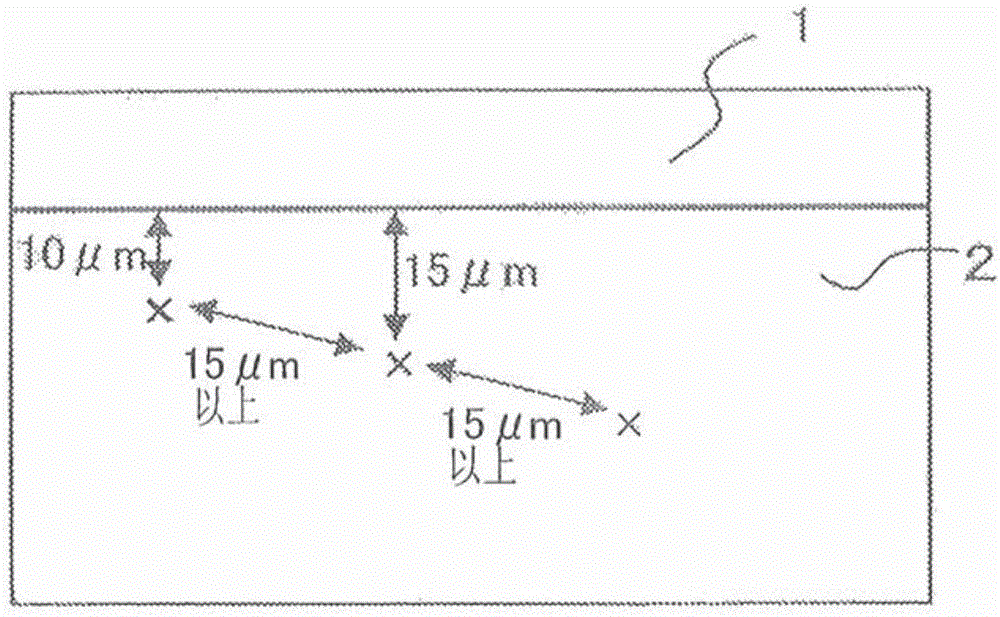

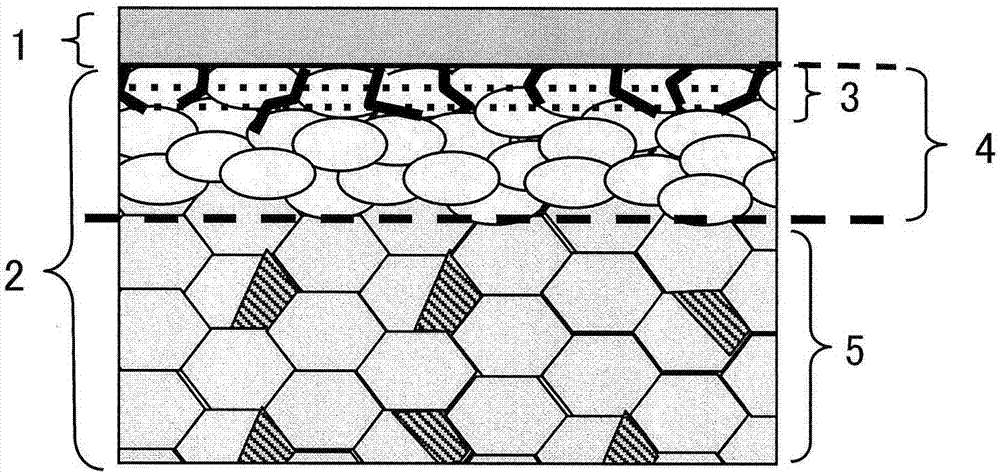

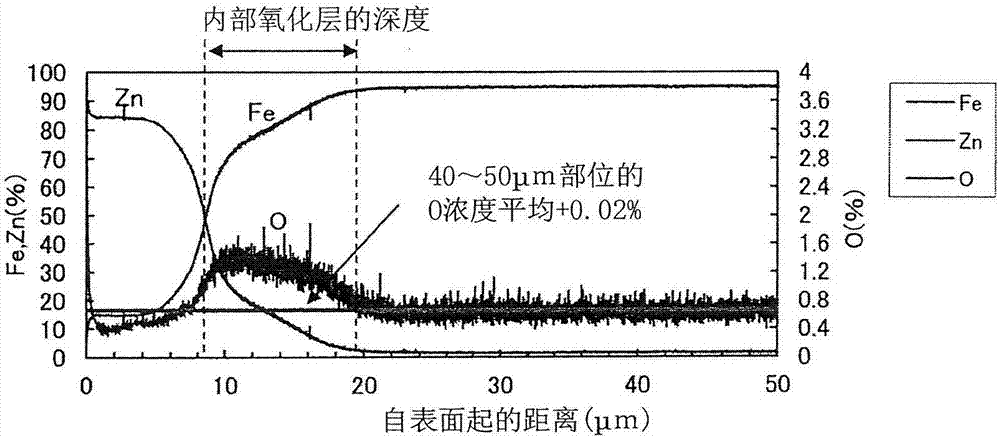

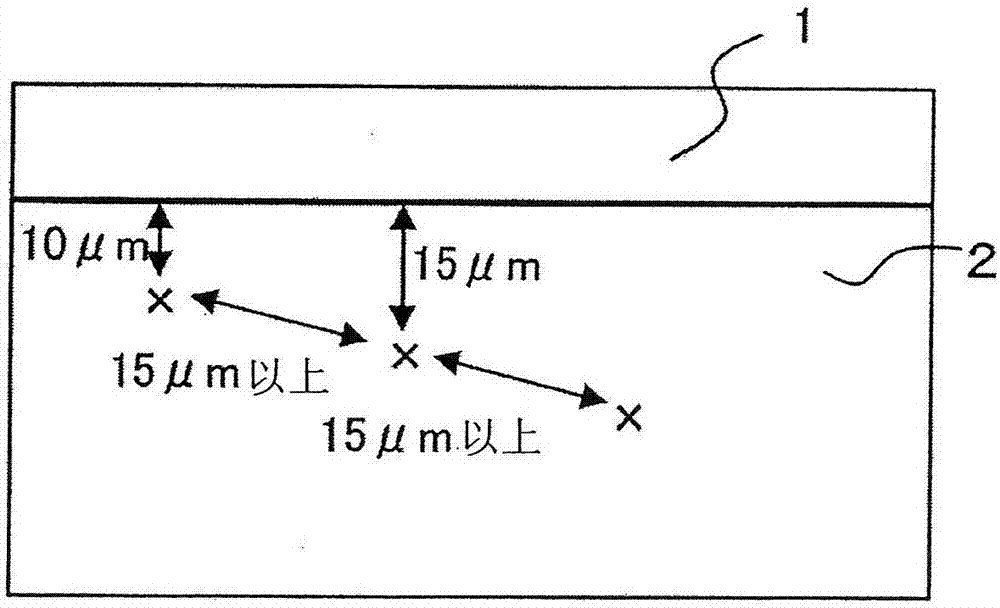

InactiveCN109266974AInhibition of hydrogen embrittlementHigh elongationHot-dipping/immersion processesFurnace typesInternal oxidationAustenite

Provided are a hot-dip galvanized steel sheet and an alloyed hot-dip galvanized steel sheet having a tensile strength of at least 980 MPa, having excellent plating properties, and having excellent workability in terms of extensibility, bendability and hole expandability, and delayed fracture resistance. Disclosed is a high-strength plated steel sheet that is a plated steel sheet having a hot-dip galvanized layer or an alloyed hot-dip galvanized layer on the surface of a base material steel sheet, and that comprises, in order from the interface between the base material steel sheet and the galvanized layer toward the base material steel sheet side: an inner oxide layer including at least one type of oxide selected from the group consisting of Si and Mn; a soft layer that is a layer including said inner oxide layer, and that has a Vickers hardness which is 90% or less of the Vickers hardness at a t / 4 position of the base material steel sheet, where t is the thickness of the base materialsteel sheet; and a hard layer constituted by a structure including, with respect to the entire metallographic structure, from 20 to 85% by area of a low-temperature transformation-forming phase, greater than 10% and less than or equal to 70% by area of polygonal ferrite, and greater than or equal to 5% by volume of retained austenite. The average depth D of the soft layer is 20 mu m or greater, the average depth d of the inner oxide layer is 4 mu m or greater and less than D, and the tensile strength is 980 MPa or greater.

Owner:KOBE STEEL LTD

Hot-pressed member and method for manufacturing same, and cold-rolled steel sheet for hot pressing and method for manufacturing same

ActiveCN110799660AHigh tensile strengthExcellent resistance to delayed fractureHot-dipping/immersion processesFurnace typesAustenite grainMaterials science

In the hot-pressed member according to the present invention, after the component composition thereof is properly adjusted, the microstructure thereof is configured so that there are an average of 5 or more Ti-based deposits having a grain size of 0.10 [mu]m or less per 100 [mu]m2 of a cross section parallel to the thickness direction of the member in a range from the member surface to a depth of100 [mu]m in a sheet thickness direction, the microstructure has a volume fraction of martensite of 95-100% in a depth range of 20-100 [mu]m in the sheet thickness direction from the member surface, and there are an average of 10 or more cementites having a grain size of less than 0.20 [mu]m among prior austenite grains, whereby the hot-pressed member not only has an extremely high tensile strength TS of 1780 MPa or greater after hot pressing, but excellent delayed fracture resistance after projection welding can also be obtained.

Owner:JFE STEEL CORP

High-strength steel plate and method for producing same

ActiveCN112639146AExcellent resistance to delayed fractureReduce concentrationHot-dipping/immersion processesFurnace typesPhysical chemistryDelayed fracture

Owner:JFE STEEL CORP

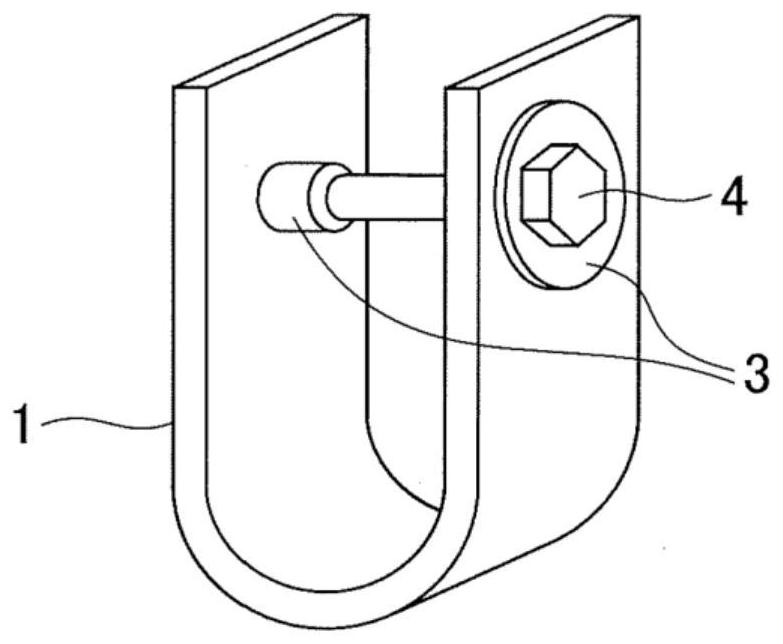

Bolt, and steel material for bolts

ActiveCN113383094AHigh strengthExcellent resistance to delayed fractureScrewsFurnace typesMechanical engineeringDelayed fracture

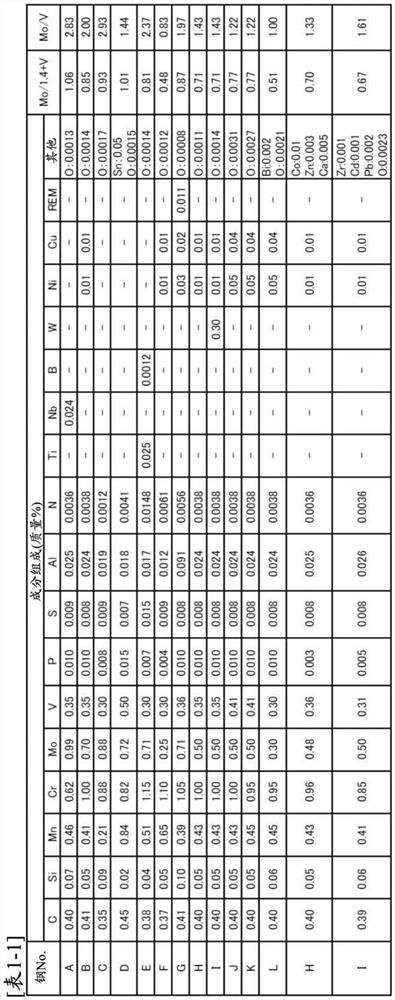

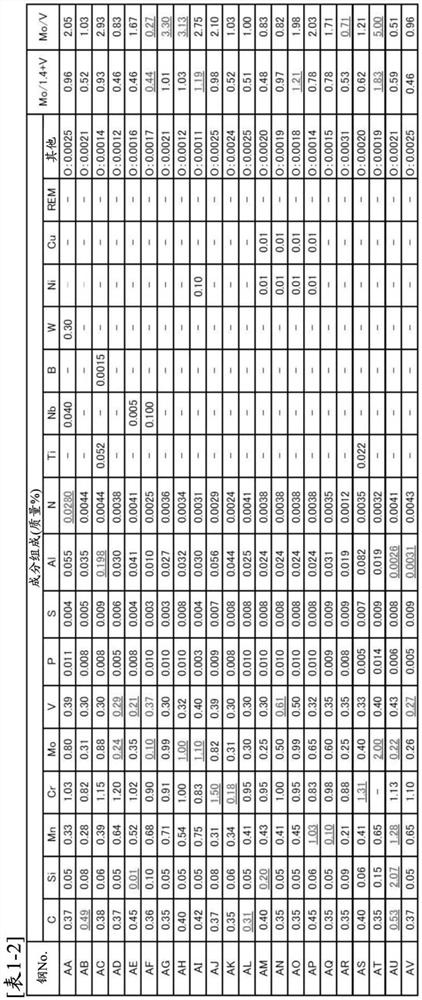

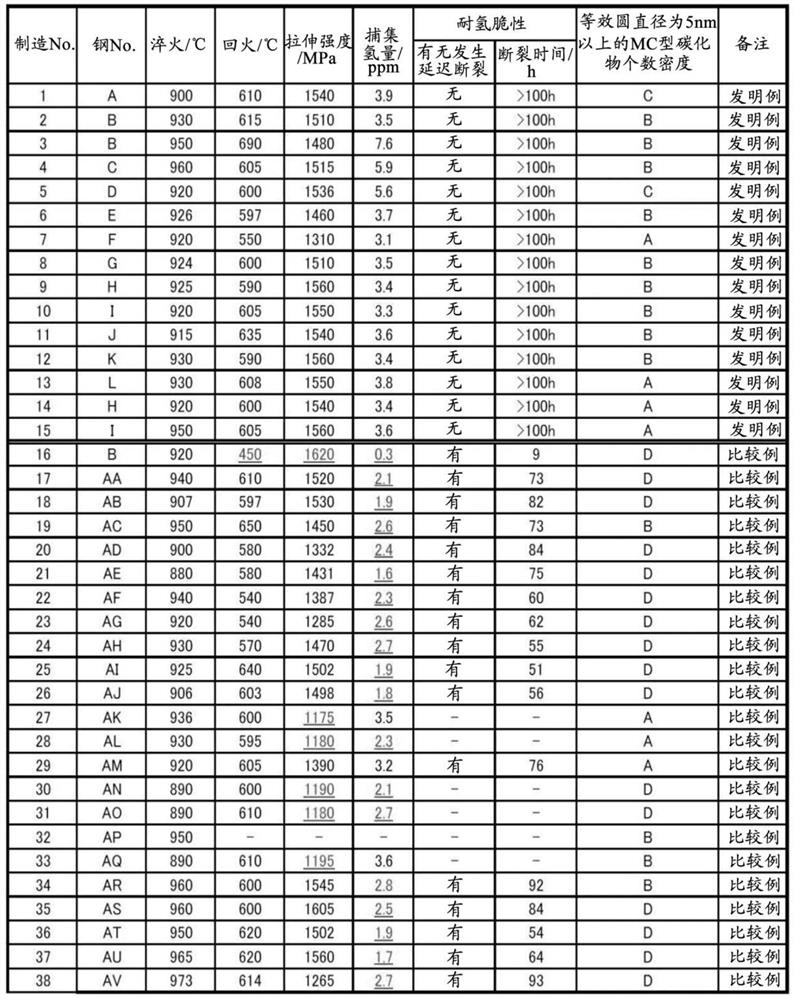

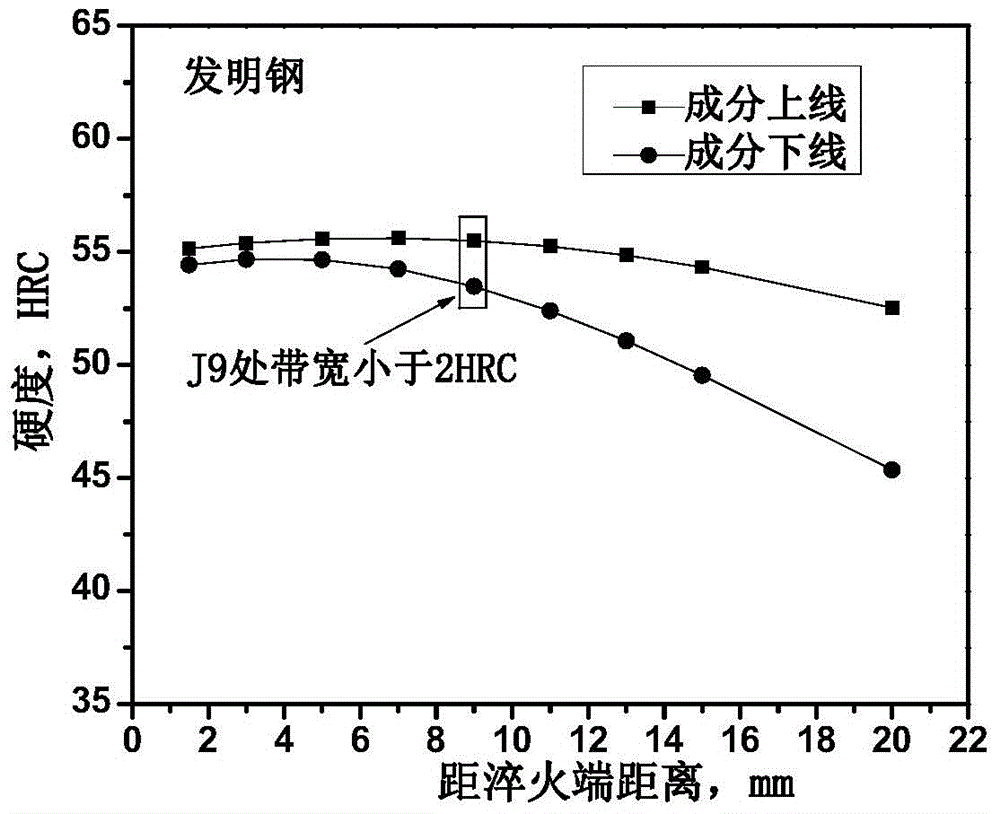

Provided are: a bolt exhibiting excellent delayed fracture resistant properties at a high strength level not less than 1200 MPa but less than 1600 MPa in terms of tensile strength where the possibility of delayed fracture occurring is extremely high; and a bolt steel material serving as a material for said bolt. The bolt has a compositional makeup satisfying formulae (1) and (2), and has a tensile strength not less than 1200 MPa but less than 1600 MPa. Herein, (1): 0.48<=Mo / 1.4+V<1.10. (2): 0.80<Mo / V<3.00, wherein the contents (mass%) of Mo and V contained in the bolt are respectively substituted into Mo and V.

Owner:NIPPON STEEL CORP

A kind of industrial stable high-performance bolt steel and its manufacturing method

ActiveCN105002427BImprove high temperature tempering strengthReduce carbon contentAustenite grainTempering

The invention discloses industrial stable high-performance bolt steel and a manufacturing method thereof and belongs to the technical field of high-strength bolt steel. The chemical components of the steel comprise, by mass, 0.28-0.37% of C, equal to or less than 0.10% of Si, 0.15-0.30% of Mn, equal to or less than 0.010% of P, equal to or less than 0.005% of S, 1.10-1.20% of Cr, 0.15-0.40% of Mo, 0.0005-0.003% of B, 0.03-0.08% of Ti, 0.015-0.030% of Al and equal to or less than 0.005% of N, and the balance is Fe, on the basis, 0.15-0.30% of V or 0.02-0.04% of Nb can be added. Through the adoption of a reasonable controlled rolling and controlled cooling technology, the original austenite grain size of the steel after phase change is further refined by 1-2 grades, 3-8 um superfine austenite grains and precipitated phase with the size of 1-20 nm are obtained, and therefore the high-temperature tempering strength of the steel is improved. The industrial stable high-performance bolt steel and the manufacturing method thereof have the advantages that compared with the prior art, the carbon content of the steel in the same strength grade is reduced, the hardness fluctuation after quenching+tempering is small, the strength after high-temperature tempering is high, the stability of batch quality is high, the cost is low, and the delayed fracture resistance is excellent.

Owner:CENT IRON & STEEL RES INST

High-strength hot-dip zinc-coated steel sheet and method for manufacturing same

ActiveCN113227430AExcellent resistance to delayed fractureHot-dipping/immersion processesFurnace typesAustenite grainCarbide

Provided are: a high-strength hot-dip zinc-coated steel sheet having high strength and excellent delayed fracture resistance properties; and a method for manufacturing the high-strength hot-dip zinc-coated steel sheet. A high-strength hot-dip zinc-coated steel sheet having a specified component composition and also having such a steel structure that the total content of martensite and bainite containing a carbide is 60 to 100% by area in a region extending to the depth of 300 to 400 [mu]m from the surface layer of the steel sheet as observed in the sheet thickness direction, the average grain diameter of prior austenite is 15 [mu]m or less, and the ratio of the height of a peak of an Auger electron spectrum of P at a position 5 nm or more away from a prior austenite grain boundary to that at the prior austenite grain boundary in the region extending to the depth of 300 to 400 [mu]m from the surface layer of the steel sheet as observed in the sheet thickness direction is 0.20 or more, wherein a hot-dip zinc coating layer is arranged on the surface of the steel sheet.

Owner:JFE STEEL CORP

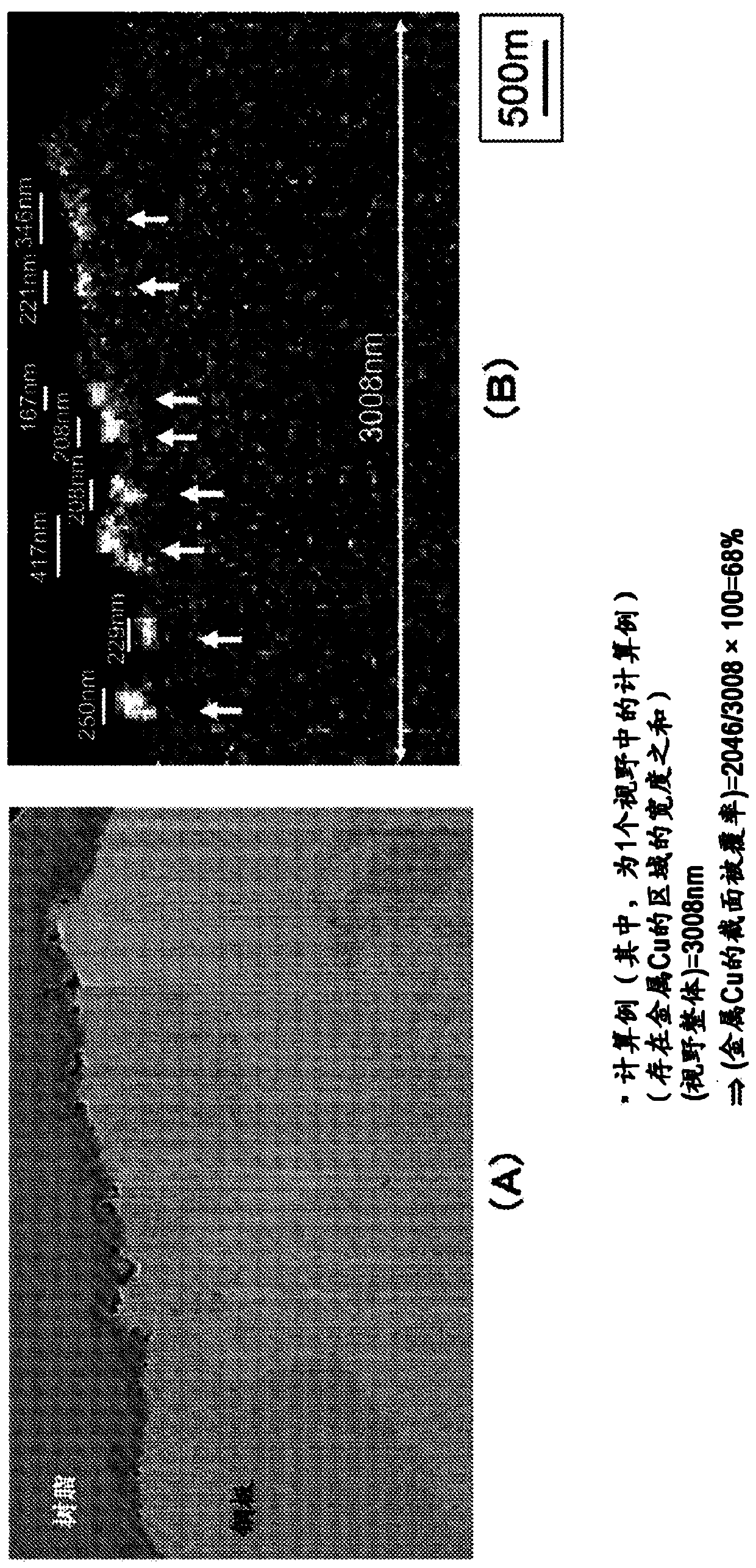

High-strength cold-rolled steel sheet and manufacturing method therefor

PendingCN110945160AExcellent resistance to delayed fractureStable manufacturingChemical conversionMetal

Provided is a high-strength cold-rolled steel sheet to which Cu is added to improve delayed fracture resistance characteristics, which has good chemical conversion treatability during low-temperaturechemical conversion treatment and for which excellent post-painting corrosion resistance and delayed fracture resistance characteristics can be attained. The high-strength cold-rolled steel sheet contains at least one of Si, Mn, and Al and 0.05-0.25 mass% of Cu, wherein: the steel structure is a recrystallized structure; no oxide layer containing at least one of Al, Si, and Mn is present on the surface of the steel sheet; and cross-sectional coverage by a deposited metal Cu on the steel sheet surface is 30% or less. A film of a pickling liquid on the surface of the steel sheet reacts with thesteel sheet between a period after pickling until washing with water causing Cu to be eluted from the steel plate and deposited on the surface of the steel plate. This deposited metal Cu lowers the chemical conversion treatability, and so, by keeping the cross-sectional coverage by this deposited metal Cu to a low level, chemical conversion treatability can be improved.

Owner:JFE STEEL CORP

High strength cold rolled steel plate

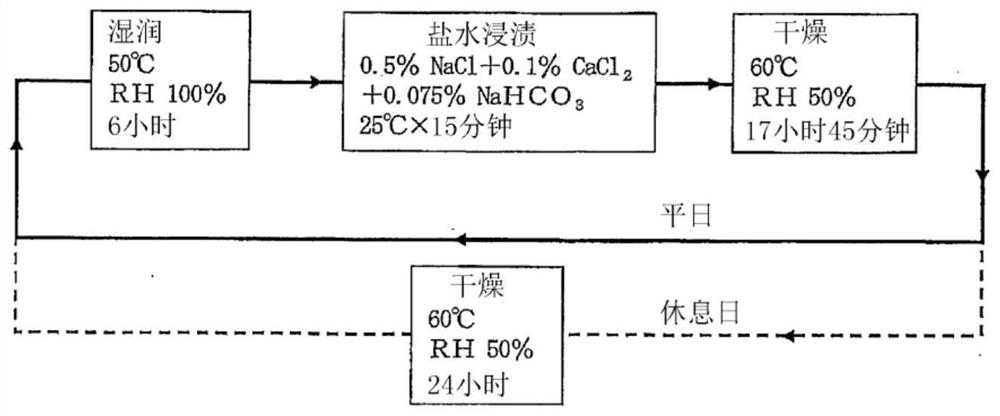

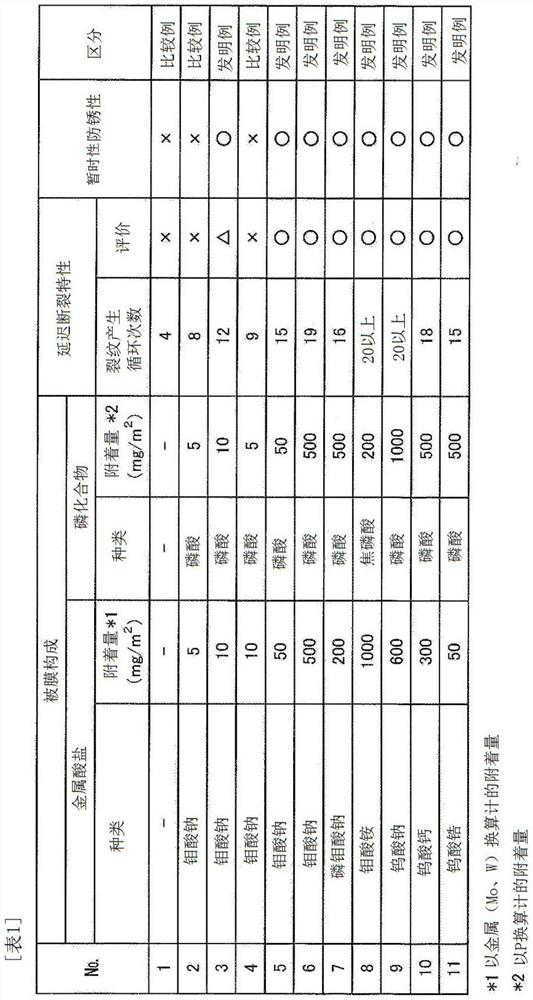

ActiveCN110139947BExcellent resistance to delayed fractureExcellent temporary rust resistanceMetallic material coating processesMolybdateTungstate

The present invention provides a steel plate suitable mainly for strength parts for automobiles and building materials, the steel plate has a tensile strength of 1180 MPa or more, is excellent in delayed fracture resistance, and is also excellent in temporary rust resistance. It has a film on the surface of a cold-rolled steel sheet with a tensile strength of 1180 MPa or more, and the film contains one or more metal salts and phosphorus compounds selected from molybdate and tungstate, and the metal salt is a metal (Mo, W) conversion calculated the total adhesion amount is 10 ~ 1000mg / m 2 , preferably 50-1000mg / m 2 , the attachment amount of phosphorus compound in P conversion is 10~1000mg / m 2 .

Owner:JFE STEEL CORP

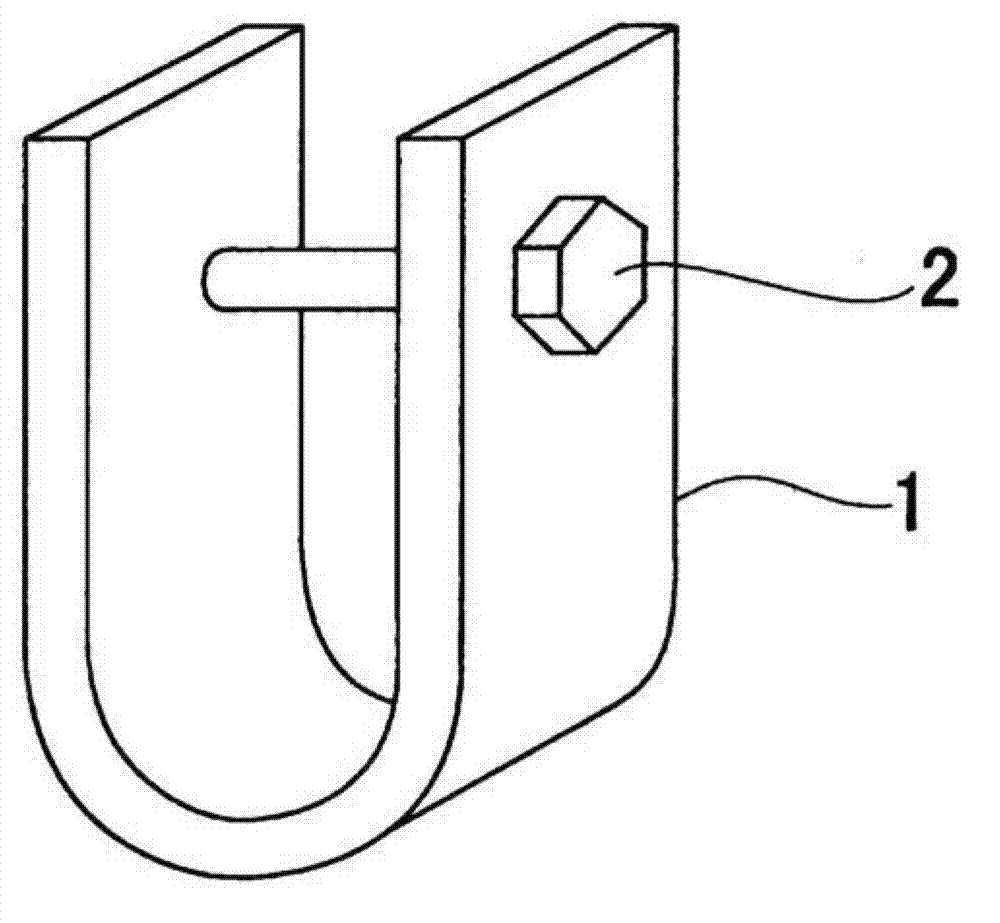

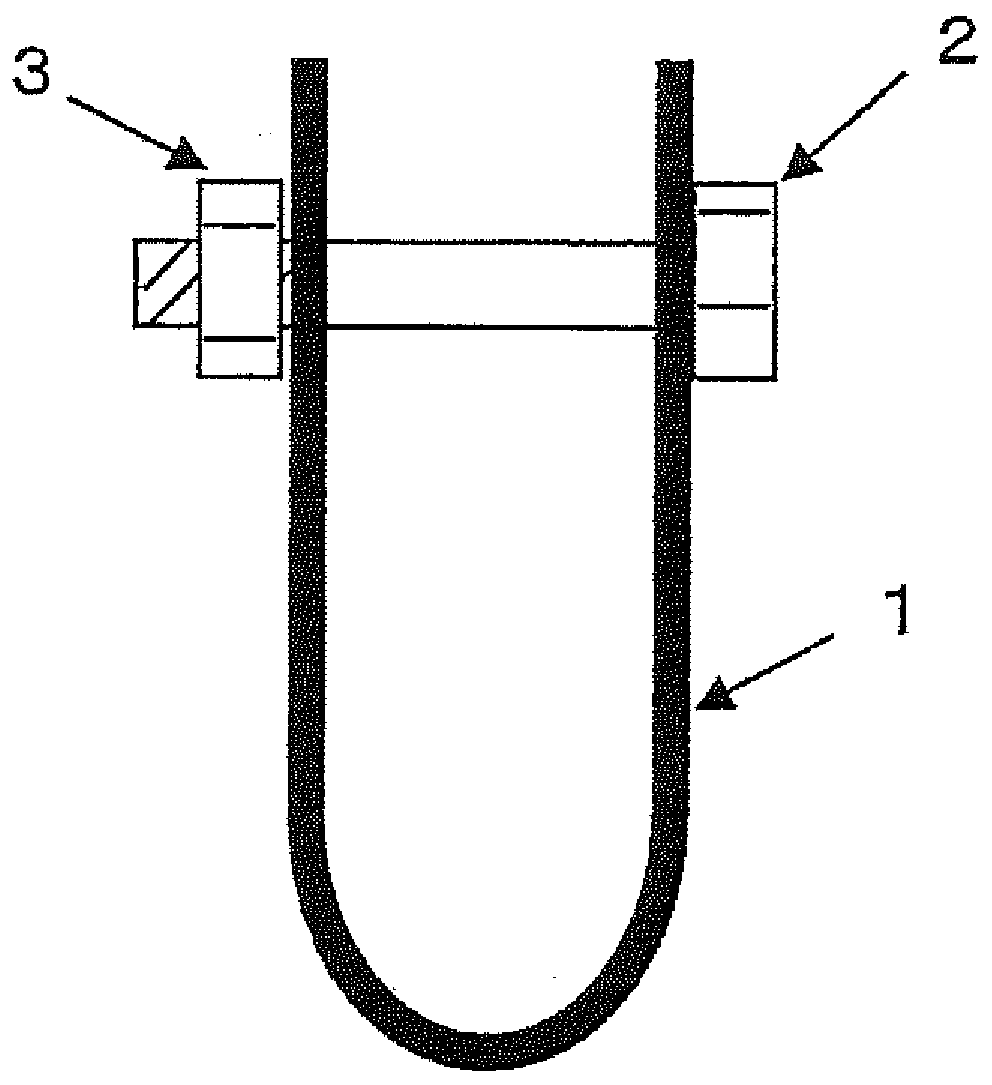

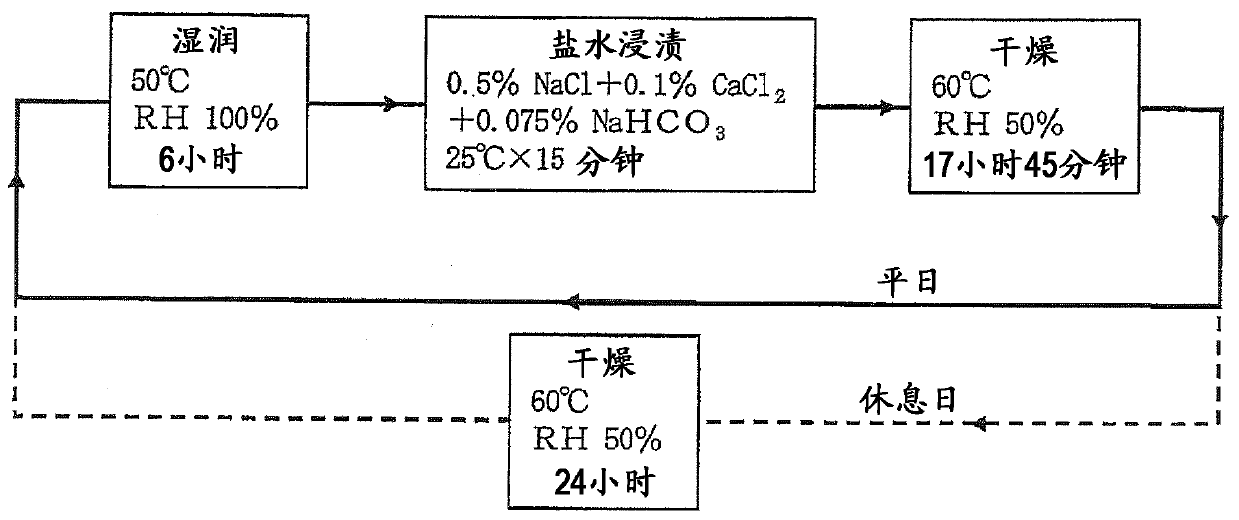

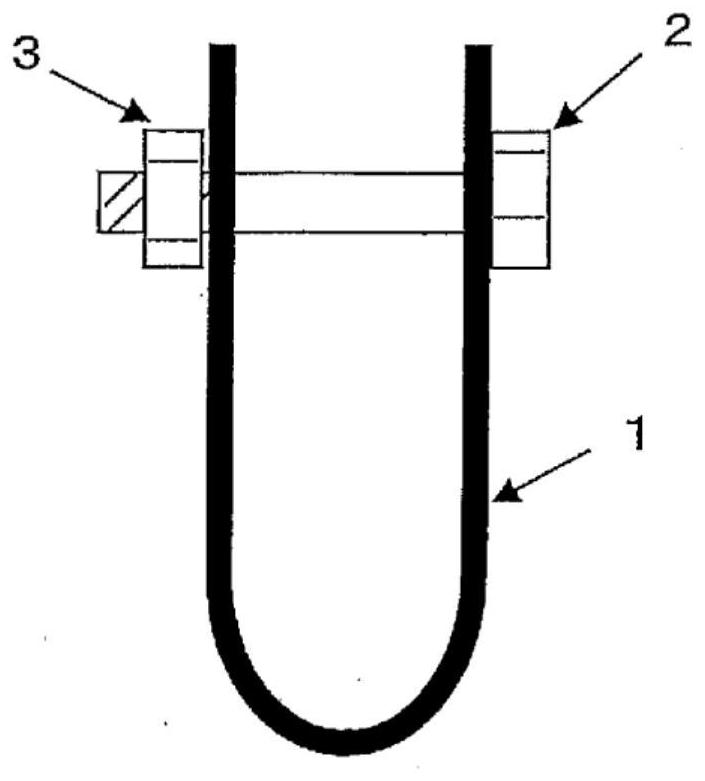

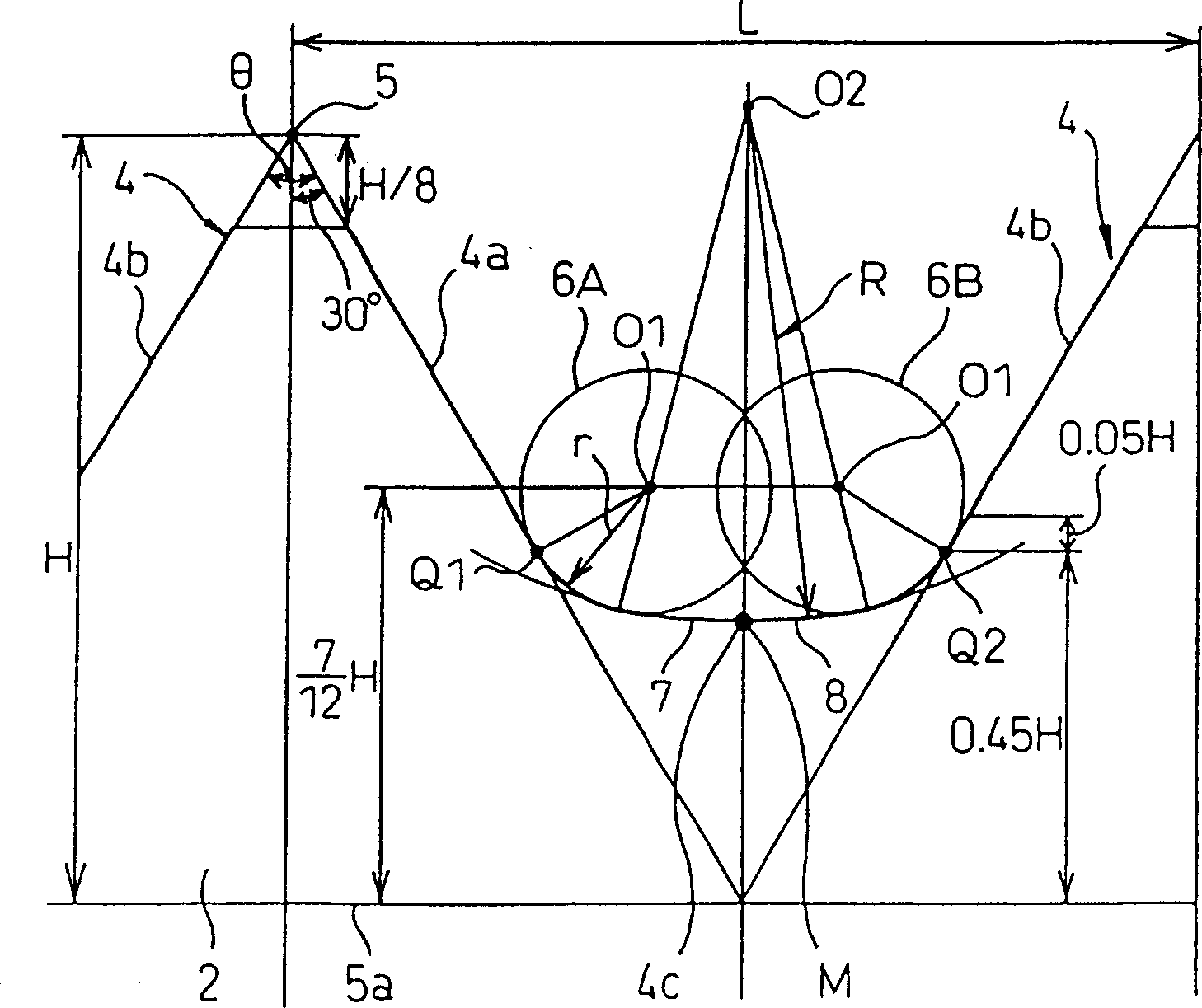

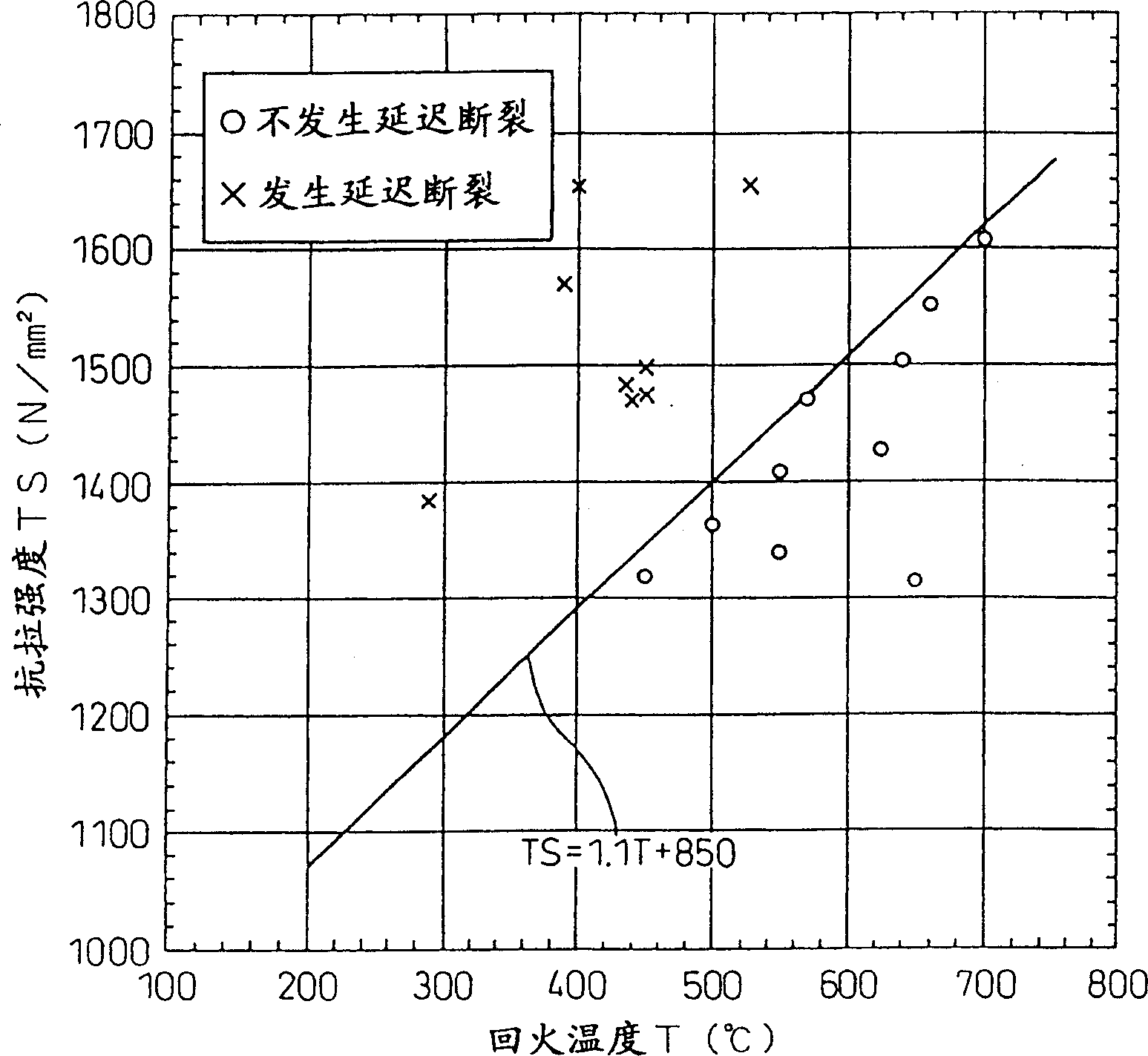

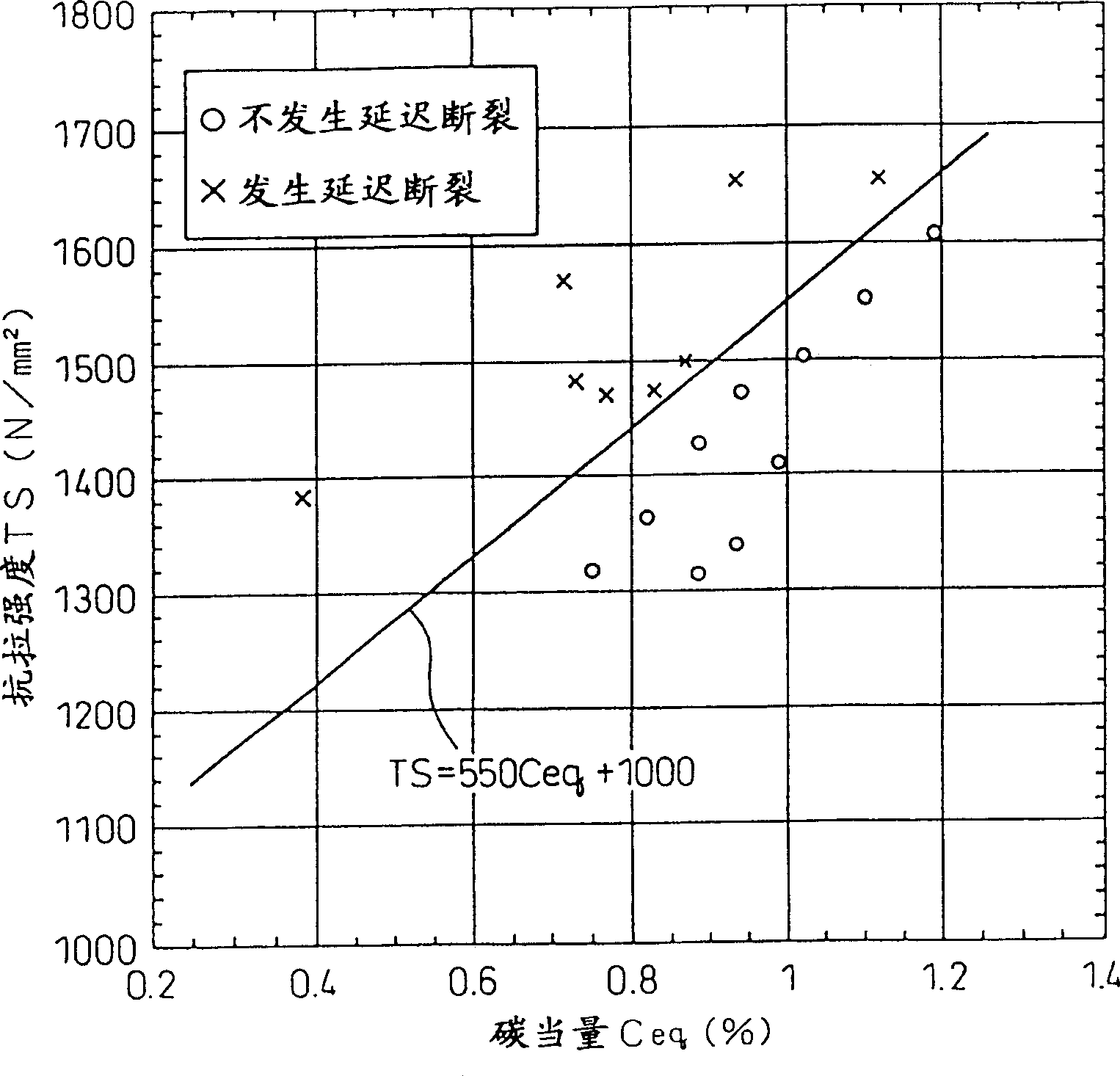

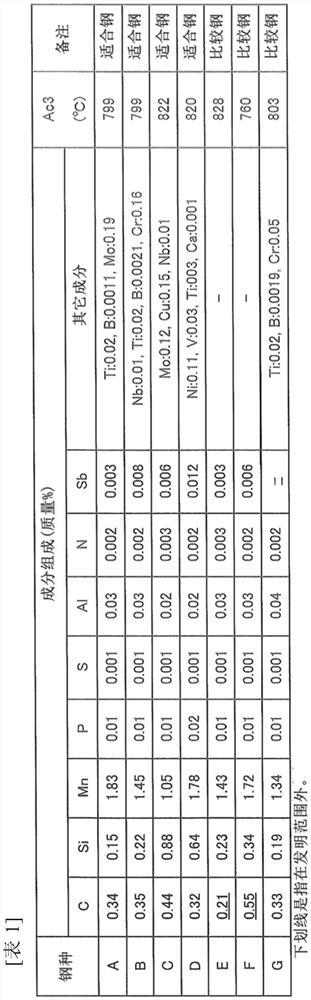

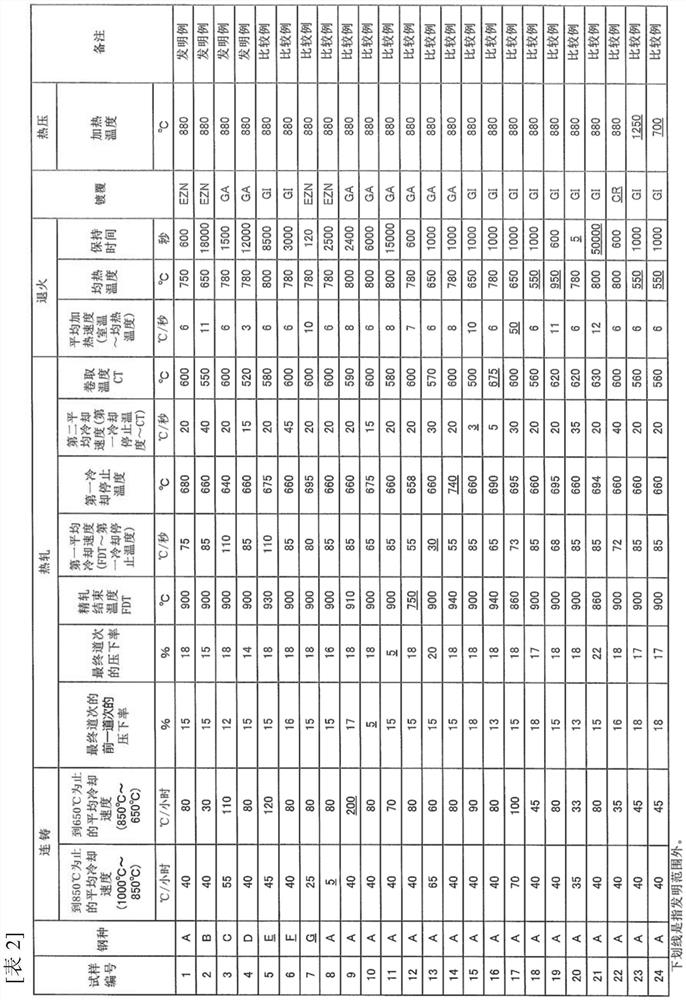

High-strength bolt excellent in delayed fracture resistance characteristics and its steel product

The present invention provides a high strength bolt superior in delayed fracture resistant property having a bolt tensile strength of 1200 N / mm<2> or more and a steel material for the same. <??>A high strength bolt comprised of a head portion and shaft portion formed by a steel material, wherein the relation between a bolt tensile strength TS (N / mm<2>) and tempering temperature T ( DEG C) satisfies the following expression (1), the relation between the bolt tensile strength TS (N / mm<2>) and the carbon equivalent Ceq (%) calculated from the chemical composition of the steel material used for the high strength bolt satisfies the following expression (2), and the tensile strength of the bolt is refined to a range of 1200 N / mm<2> to 1600 N / mm<2> by quenching and tempering: <DF NUM="(1)">TS≤.1T+850 < / DF> <DF NUM="(2)">TS≤550Ceq+1000 < / DF> where, <DF>Ceq=C+(Mn / 6)+(Si / 24)+(Ni / 40) +(Cr / 5)+(Mo / 4)+(V / 14) < / DF>

Owner:NIPPON STEEL CORP

Hot-pressed member, cold-rolled steel sheet for hot-pressed member, and methods respectively for producing these products

PendingCN113366135AExcellent resistance to delayed fractureHigh tensile strengthHot-dipping/immersion processesFurnace typesHardnessMartensite

The purpose of the present invention is to provide: a hot-pressed member having tensile strength of 1780 MPa or more and improved in delayed fracture resistance properties; a method for producing the hot-pressed member; a cold-rolled steel sheet for a hot-pressed member; and a method for producing the cold-rolled steel sheet. A hot-pressed member having a specified component composition, wherein the average crystal grain diameter of prior austenite is 8 [mu]m or less and the volume fraction of martensite in a region extending from the surface to the depth of 30 [mu]m or less is 95% or more in the micro structure of a steel sheet, there is an Ni-diffused region having a thickness of 0.5 [mu]m or more in a surface layer, the standard deviation of Vickers hardness is 35 or less, the Mndif (mass%) value in the thickness direction is 0.20 or less wherein Mndif (mass%) represents an Mn segregation degree, and the tensile strength is 1780 MPa or more.

Owner:JFE STEEL CORP

Steel sheets, hot-dip galvanized steel sheets, and alloyed hot-dip galvanized steel sheets, and methods for their manufacture

ActiveCN107849666BExcellent resistance to delayed fractureHot-dipping/immersion processesFurnace typesChemical compositionCarbide

A steel sheet according to one embodiment of the present invention has a predetermined chemical composition, and the microstructure of a 1 / 4 portion of the sheet thickness of the steel sheet contains, by volume percentage, tempered martensite: 30 to 70%, and ferrite and bainite. One or two types of: the total amount is 20% or more and 70% or less, and in the structure of the above-mentioned 1 / 4 part of the plate thickness, the retained austenite is less than 10% by volume percentage, and the fresh martensite is 10% or less, Pearlite is 10% or less, their total volume percentage is 15% or less, and the number density of iron-based carbides with a major diameter of 5 nm or more in the tempered martensite at the 1 / 4 part of the plate thickness is 5×10 7 Pieces / mm 2 In the above, the ratio of the number of ε-based carbides in the 1 / 4 part of the sheet thickness to the number of the iron-based carbides with a major diameter of 5 nm or more is 20% or more, and the tensile strength of the steel sheet is 780 MPa or more. .

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com