Bolt, and steel material for bolts

A bolt and steel technology, applied in the direction of screws, threaded fasteners, furnaces, etc., can solve problems such as increased hydrogen intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

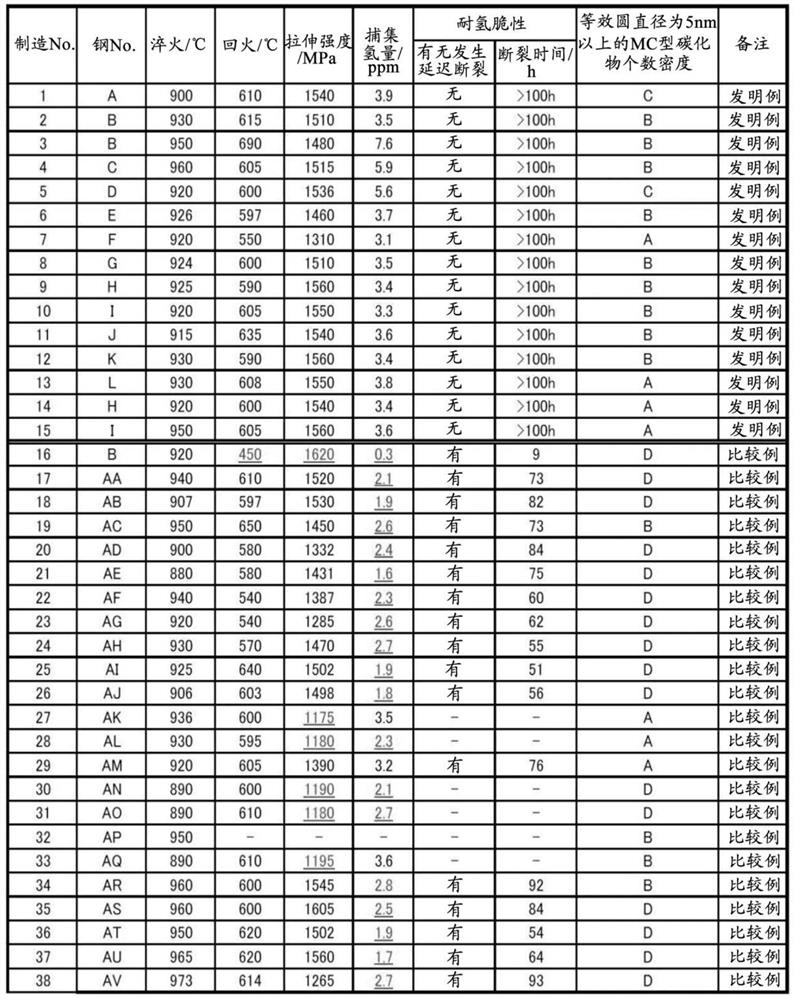

[0214] Next, examples of the present invention will be described, but each condition shown below is merely an example for confirming the practicability and effect of the present invention, and the conditions of the present invention are not limited to this example. In the embodiments of the present invention, various conditions can be adopted in order to achieve the purpose as long as the gist is not deviated from.

[0215]

[0216] (prepare the steel rod)

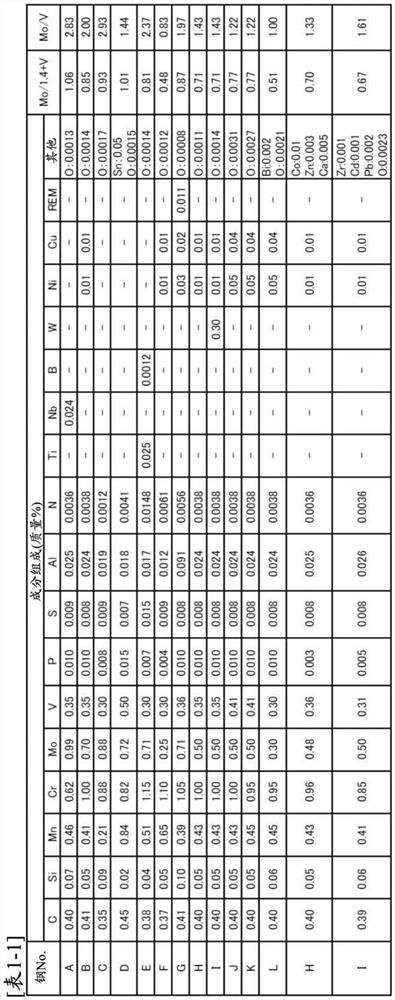

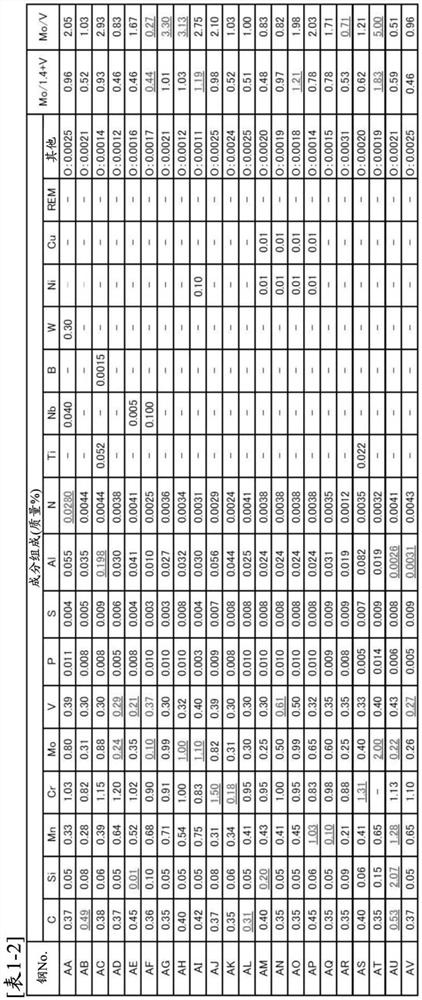

[0217] Steel rods having a diameter of 20 mm and a length of 1000 mm were prepared by melting, casting and hot forging steels having chemical compositions shown in Tables 1-1 and 1-2. In addition, in Table 1-1 and Table 1-2, underlined numerical values indicate that the numerical values are outside the range disclosed in the present invention. Meanwhile, in Table 1-1 and Table 1-2, the symbol "-" means that no corresponding element is included, and a space means that no other arbitrary elements are included.

[021...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com