Wire rod and steel wire using same

A wire rod and steel wire technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of different hydrogen diffusion behaviors, achieve excellent delayed fracture resistance, and improve the effect of twisting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

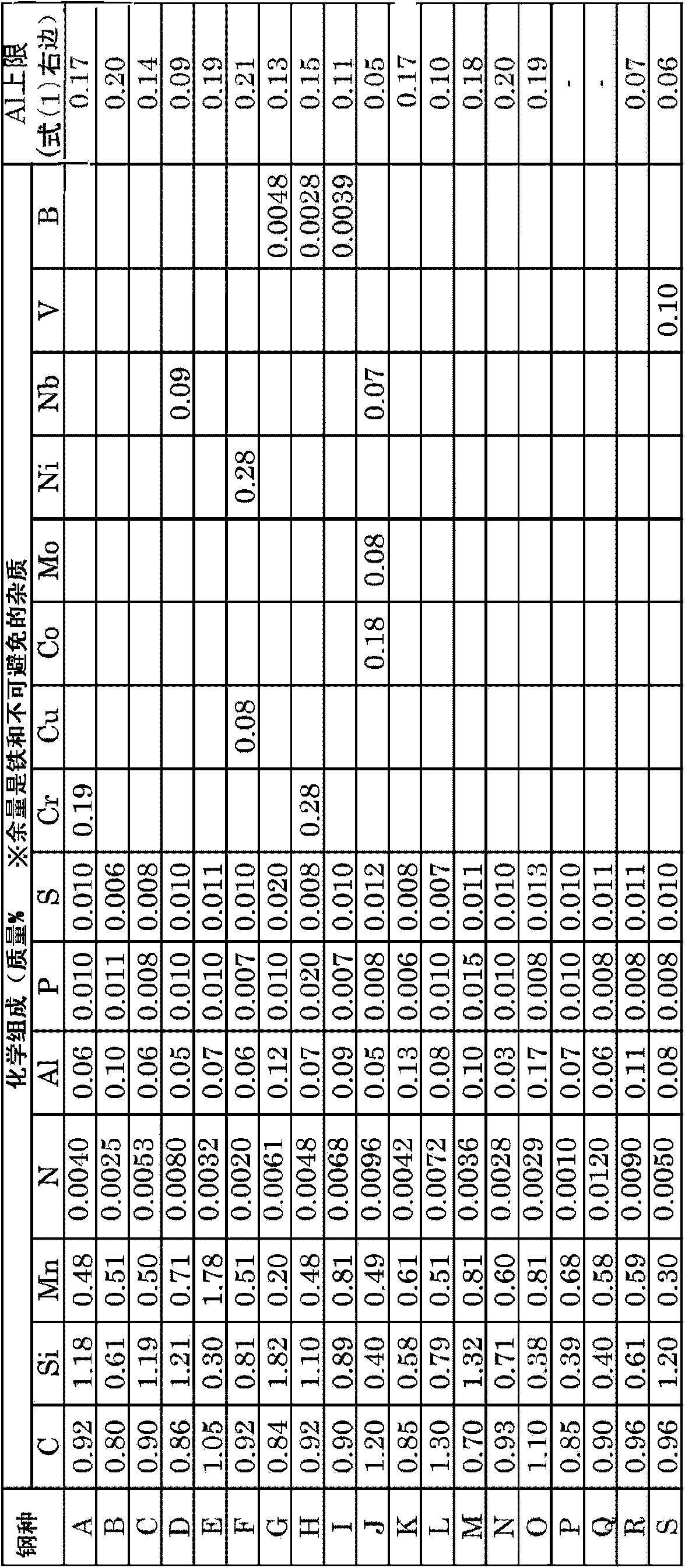

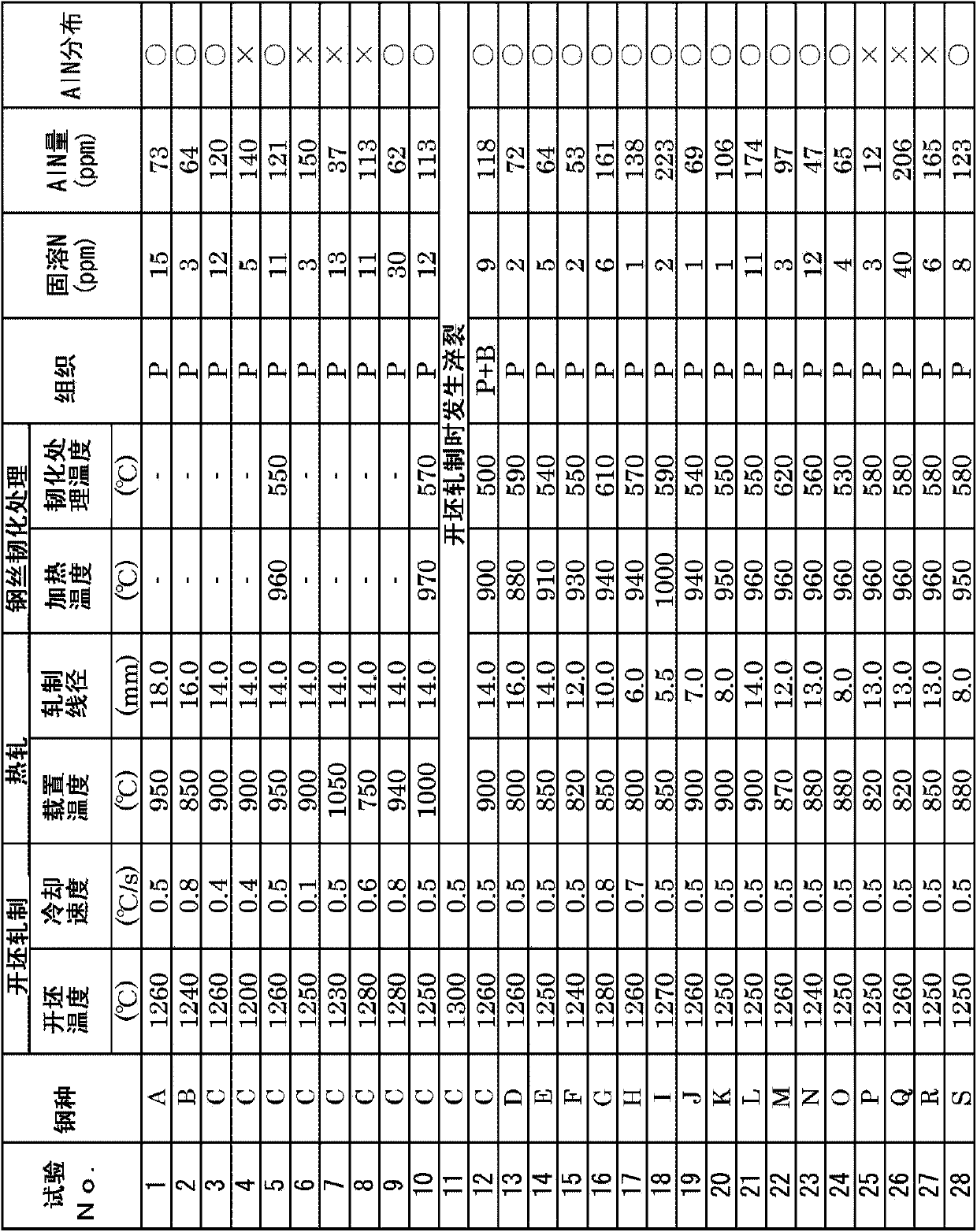

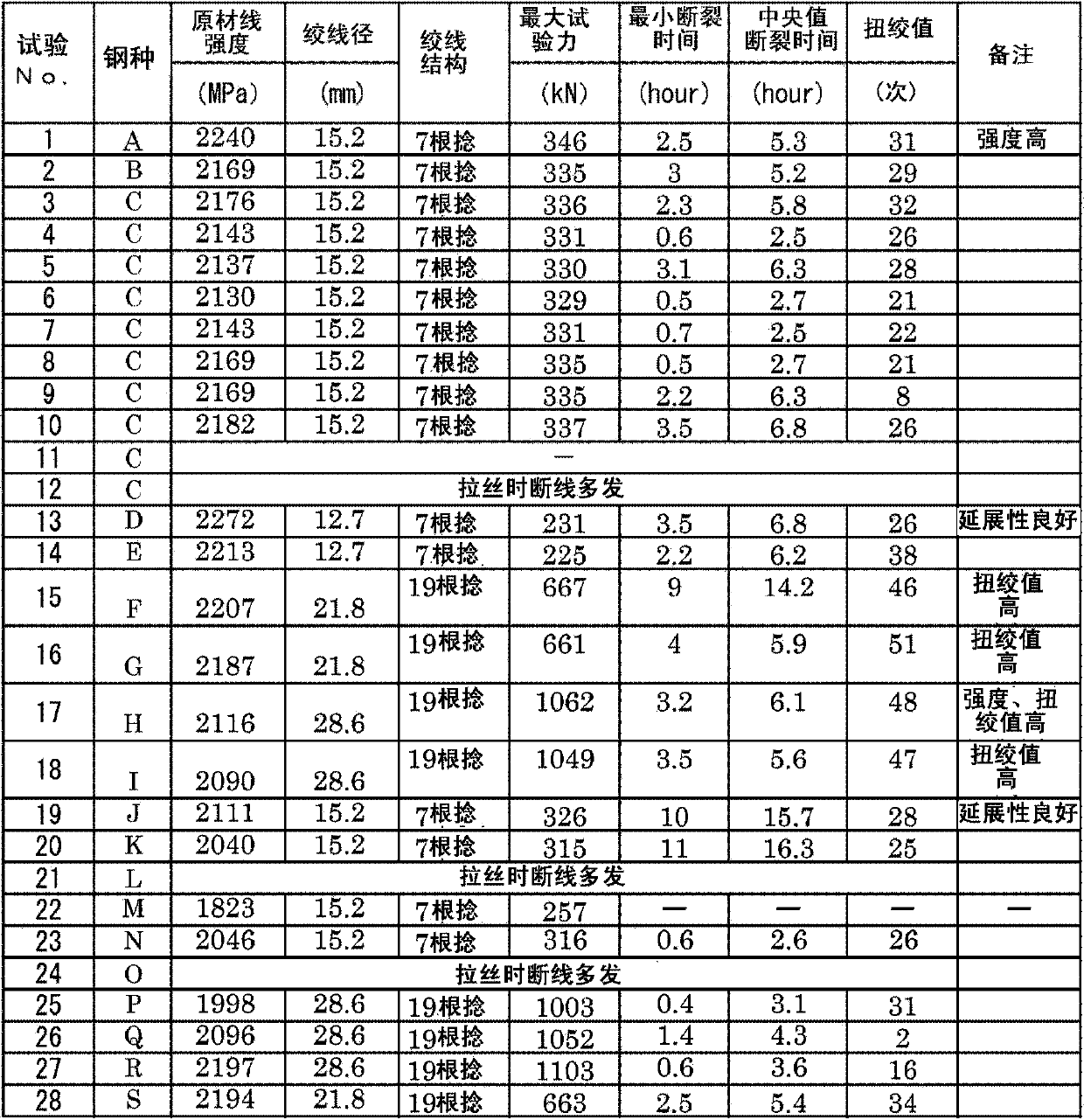

Embodiment Construction

[0023] The inventors of the present invention found that, in a wire rod whose main phase is pearlite, it is effective to secure a predetermined amount of AlN serving as hydrogen trapping sites, and to secure a predetermined amount or more of AlN having a size of 10 to 20 μm.

[0024] The larger the amount of AlN, the higher the hydrogen trapping effect, so it is made 0.005% or more. The amount of AlN is preferably 0.006% or more, more preferably 0.007% or more (especially 0.01% or more). The upper limit of the amount of AlN is not particularly limited, but is usually about 0.04%.

[0025] In addition, as an index for securing the number of AlNs having a size of 10 to 20 μm, the maximum extreme value distribution is used in the present invention. First, as the size of AlN, the square of the product of length a and thickness b of AlN (ab) is used 1 / 2 , denoting it as d GM (μm). In the present invention, the length a of AlN refers to the length of AlN in the longitudinal dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com