High-strength bolt excellent in delayed fracture resistance characteristics and its steel product

A high-strength bolt and high-strength technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of delayed fracture of bolts that cannot reach the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

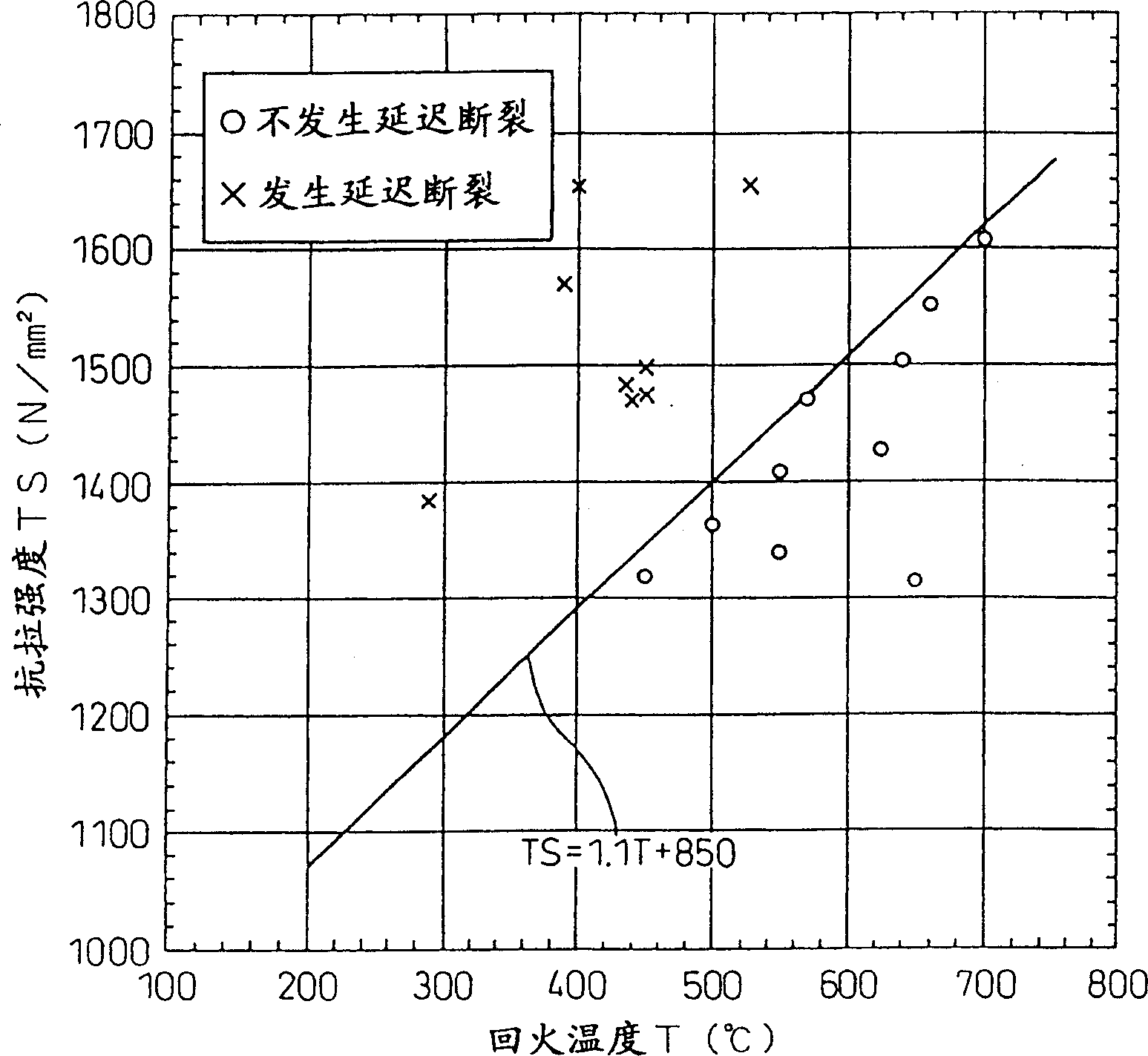

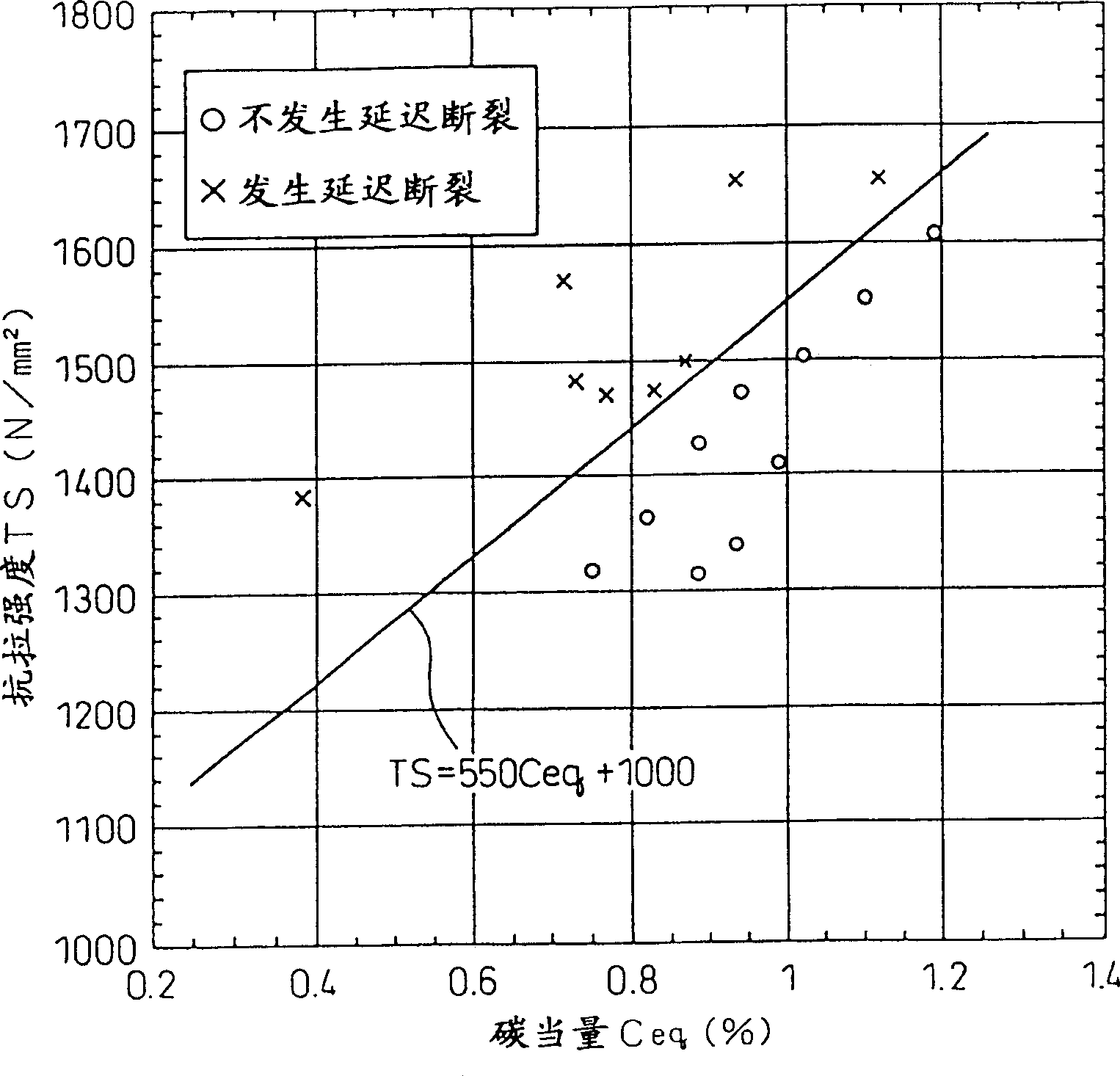

[0084] Use the steel for the test with the chemical composition shown in the following table 1, hot-roll it into a wire rod with a wire diameter of Ф21.5mm, use the various wire rods obtained, and make the threaded part M22 (JIS metric standard bolt of F10T) There are two types of bolts in the conventional shape and the shape of the present invention. Then, through quenching and tempering, the tensile strength of the bolt is 1200N / mm 2 ~1700N / mm 2 Adjust within the range. At this time, the tensile strength is adjusted by the composition and tempering temperature, and the tempering temperature is in the range of 290°C to 700°C. Table 2 shows the tempering temperature and tensile strength at this time.

[0085]

Steel for test

C eq

C

Si

mn

P

S

Cr

Mo

Al

V

Ni

Ti

Nb

1

2

3

4

5

6

7

8

9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| stress concentration factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com