Steel sheet, hot-dip galvanized steel sheet, alloyed hot-dip galvanized steel sheet, and production methods therefor

A technology for hot-dip galvanized steel sheets and steel sheets, which is applied to steel sheets, hot-dip galvanized steel sheets and alloyed hot-dip galvanized steel sheets, and their manufacturing fields, and can solve the problem of difficulty in applying the TRIP effect, and difficulty in improving formability and delay resistance. Fracture characteristics and other problems, to achieve the effect of excellent delayed fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

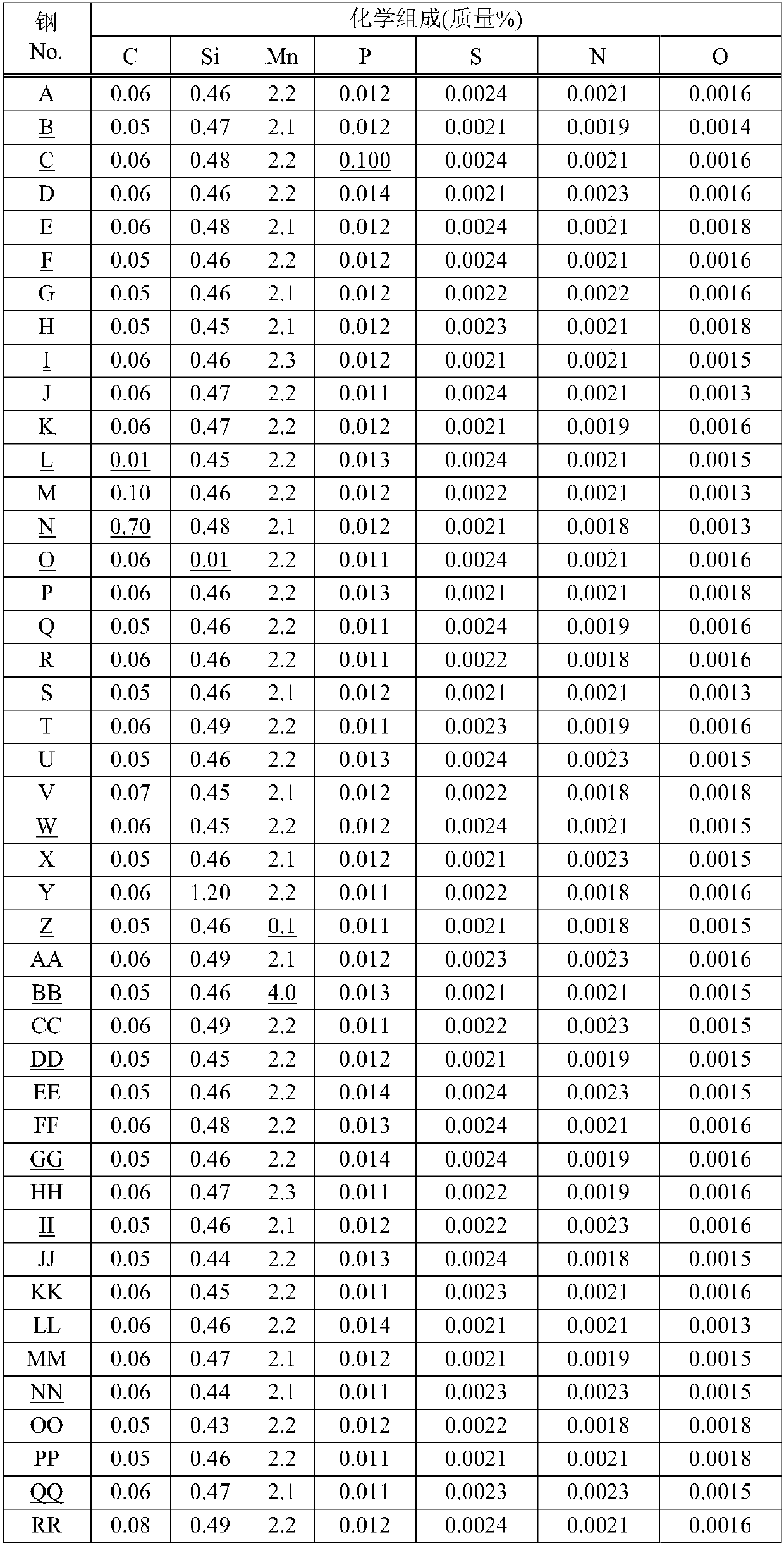

[0227] Next, examples of the present invention will be described, but the conditions in the examples are an example of conditions used to confirm the feasibility and effects of the present invention, and the present invention is not limited to this example of conditions. Various conditions can be adopted in the present invention, as long as the purpose of the present invention is achieved without departing from the spirit of the present invention.

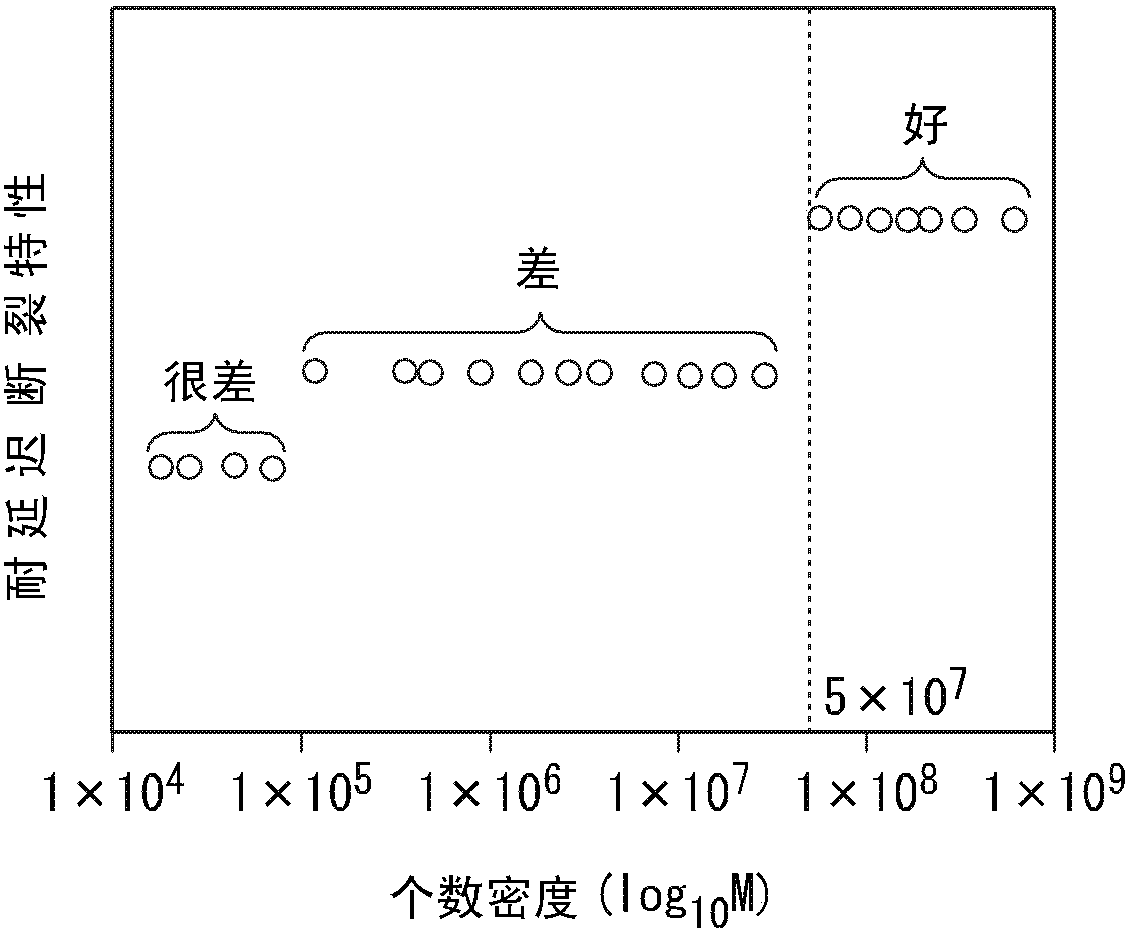

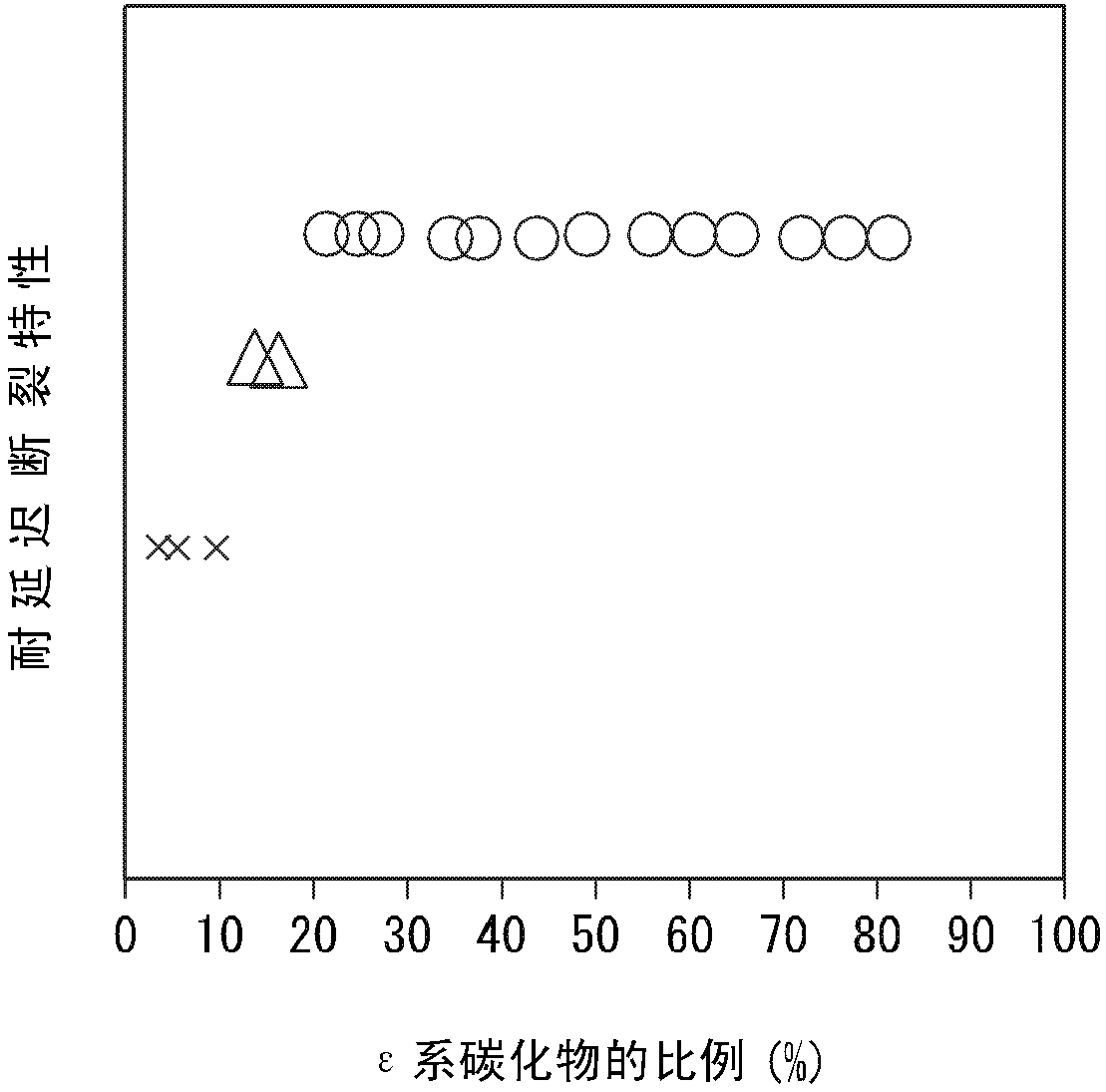

[0228] The manufacturing method of the embodiment of the steel sheet includes: (a) directly supplying a cast slab (a1) having the composition disclosed in the table to hot rolling, followed by coiling, or (a2) temporarily cooling and then heating it to supply Hot rolling, then coiling, (b) pickling, cold rolling, then annealing, then (c) two-stage cooling of the annealed steel sheet, then tempering, and then (d) The tempered steel plate is then cooled in two stages.

[0229] The manufacturing method of the embodiment of the hot-dip gal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com