55Si2MnVNbN spring steel and production process thereof

A spring steel and process technology, applied in the field of 55Si2MnVNbN spring steel and its production process, can solve the problems of easy decarburization, coarse grains, poor hardenability, etc., and achieve high tensile strength, high life, and excellent resistance to delayed fracture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

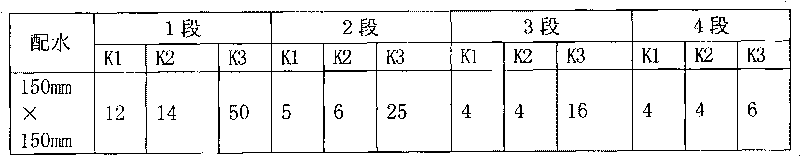

[0023] The present embodiment is 55Si2MnVNbN spring steel, and comparative example is 60Si2MnA spring steel, and composition is as shown in the table below:

[0024] Table 1

[0025]

C

mn

Si

P

S

Cr

Nb

Cu

V

N

Fe

Example

0.55

0.70

1.80

0.015

0.006

0.25

0.020

0.07

0.10

0.012

margin

[0026]

C

mn

Si

P

S

Cr

Nb

Cu

V

N

Fe

comparative example

0.60

0.85

1.80

0.020

0.008

0.003

0.002

0.07

0.01

0.005

margin

[0027] The specific process is as follows:

[0028] Electric furnace smelting:

[0029] It is required to tap steel without slag in red envelopes. The first three furnaces of the newly built furnace shell of the electric furnace shall not be used to produce the spring steel in this plan, and the use of new ladles shall be avoided a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com