Steel for high-strength bolt and application thereof

A technology of high-strength bolts and high-strength bolts, which is applied in the field of steel for bolts, can solve problems such as difficulty in balancing strength and cold heading performance, and affect safety in use, and achieve excellent comprehensive performance, excellent cold heading performance, and excellent delayed fracture resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

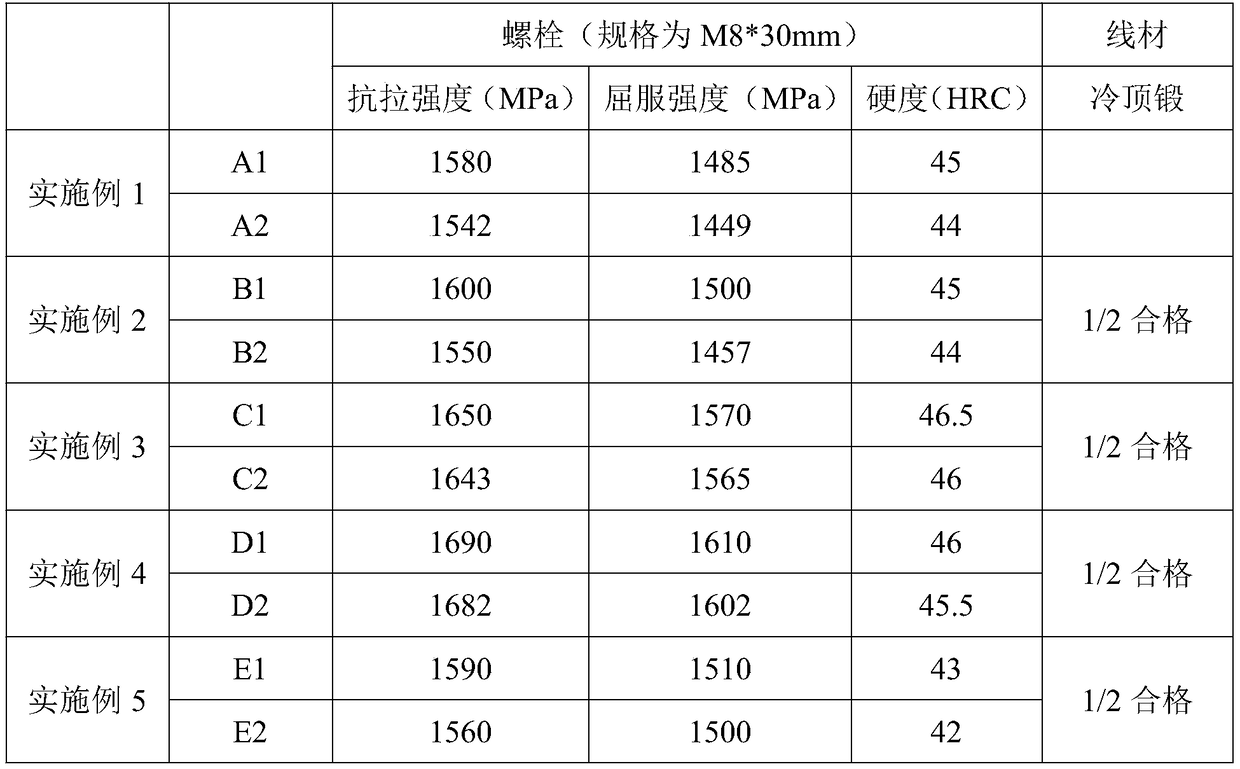

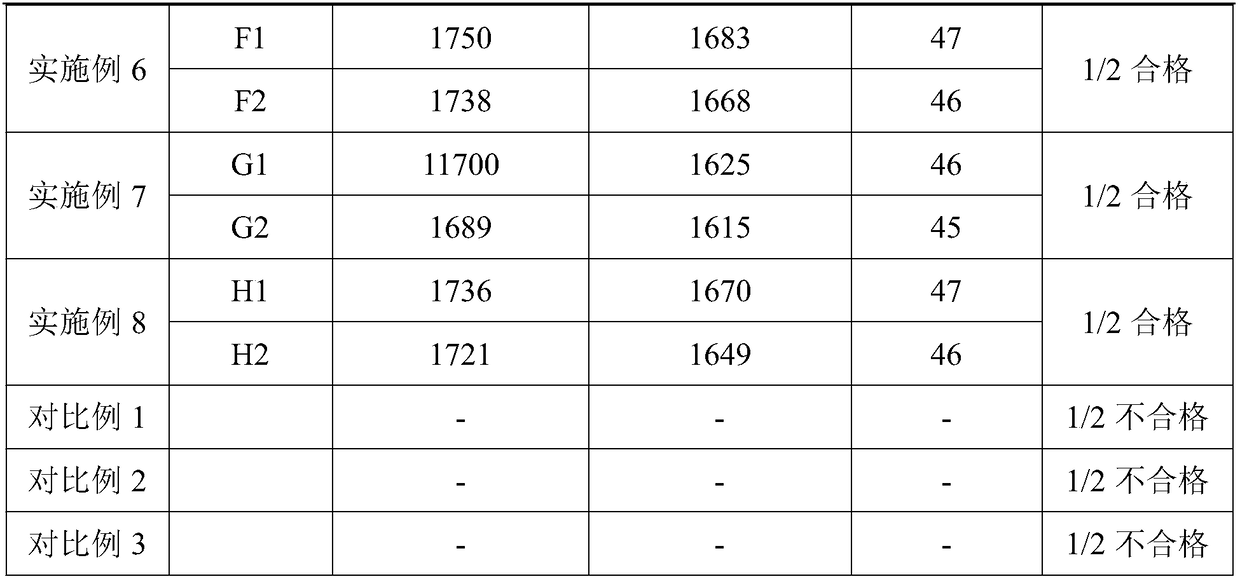

Embodiment 1

[0018] A steel for high-strength bolts, comprising the following components by mass percentage: 0.33% carbon, 1.7% silicon, 0.25% manganese, phosphorus ≤ 0.015%, sulfur ≤ 0.003%, titanium 0.05%, aluminum 0.05%, chromium 0.75% , nickel 0.6%, molybdenum 0.18%, niobium 0.07%, and the balance is iron and unavoidable impurities.

[0019] When utilizing the above-mentioned steel for high-strength bolts to prepare high-strength bolts (the specifications are M8*30mm (diameter*length)), first the steel for high-strength bolts is obtained by ironmaking, steelmaking, and hot rolling to obtain wire rods, and then through spheroidization, It can be obtained by descaling, wire drawing, cold heading, quenching, tempering and oiling. The specification of the finally prepared bolt is 8*30mm. Among them, the spheroidizing treatment is treated at 750°C for 5 hours, the descaling is treated in acid solution, the quenching treatment is treated at 890°C for 60 minutes, the quenching medium is supe...

Embodiment 2

[0021] A steel for high-strength bolts, comprising the following components by mass percentage: 0.35% carbon, 1.3% silicon, 0.3% manganese, phosphorus ≤ 0.015%, sulfur ≤ 0.003%, titanium 0.09%, aluminum 0.04%, chromium 0.05% , nickel 1.0%, molybdenum 0.15%, niobium 0.05%, and the balance is iron and unavoidable impurities.

[0022] In this embodiment, the method for preparing high-strength bolts (with a specification of M8*30mm) from steel for high-strength bolts is the same as that in Embodiment 1. The finally prepared bolts had a size of 8*30mm, and were tempered at 380°C to obtain sample B1, and tempered at 425°C to obtain sample B2.

Embodiment 3

[0024] A steel for high-strength bolts, including the following components in terms of mass percentage: 0.36% carbon, 1.3% silicon, 0.6% manganese, phosphorus ≤ 0.015%, sulfur ≤ 0.003%, titanium 0.09%, aluminum 0.04%, chromium 0.05% , nickel 0.8%, molybdenum 0.18%, niobium 0.05%, the balance is iron and unavoidable impurities.

[0025] In this embodiment, the method for preparing high-strength bolts (with a specification of M8*30mm) from steel for high-strength bolts is the same as that in Embodiment 1. The finally prepared bolts have a specification of 8*30mm, and tempered at 380°C to obtain sample C1, and tempered at 425°C to obtain sample C2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com