Wire rod, steel wire using same, and billet

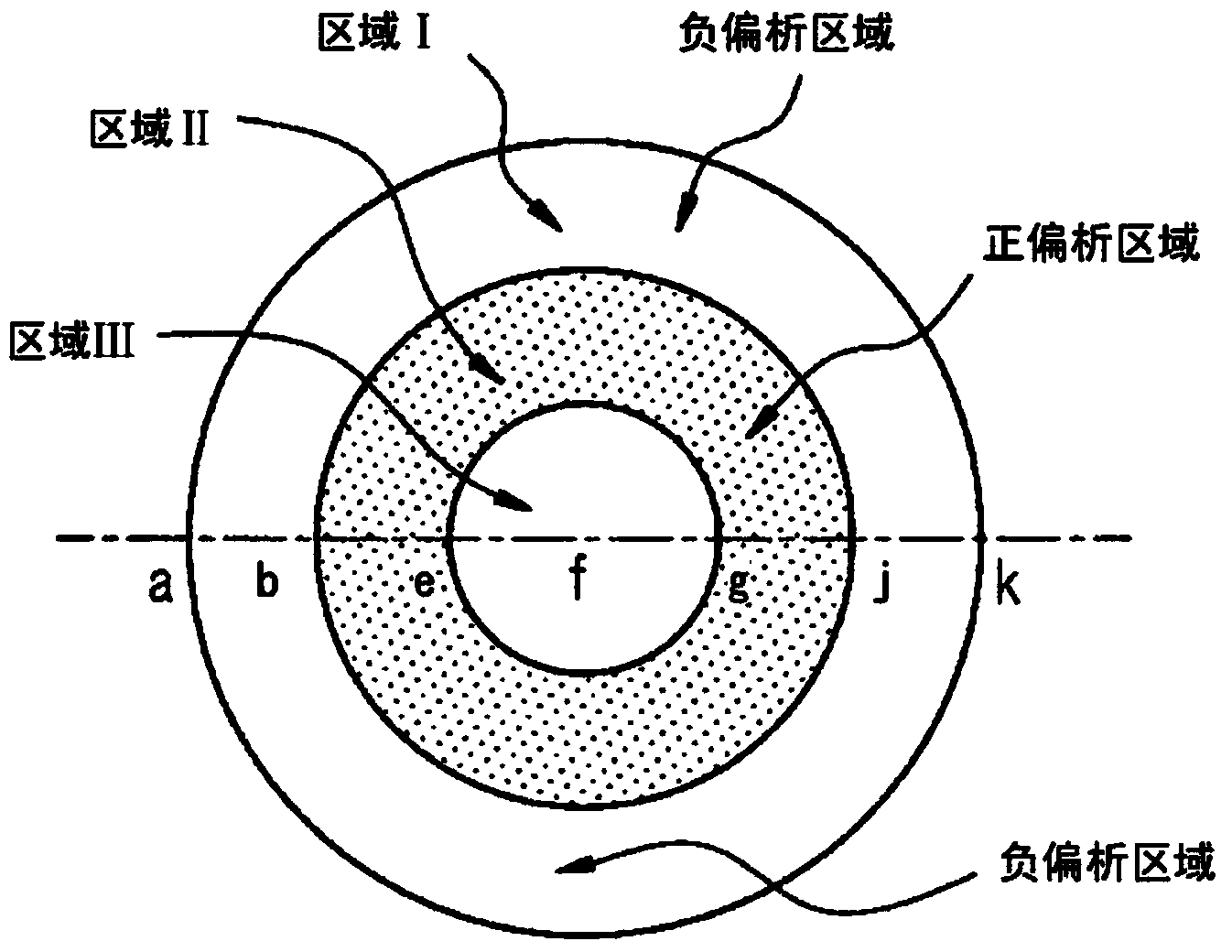

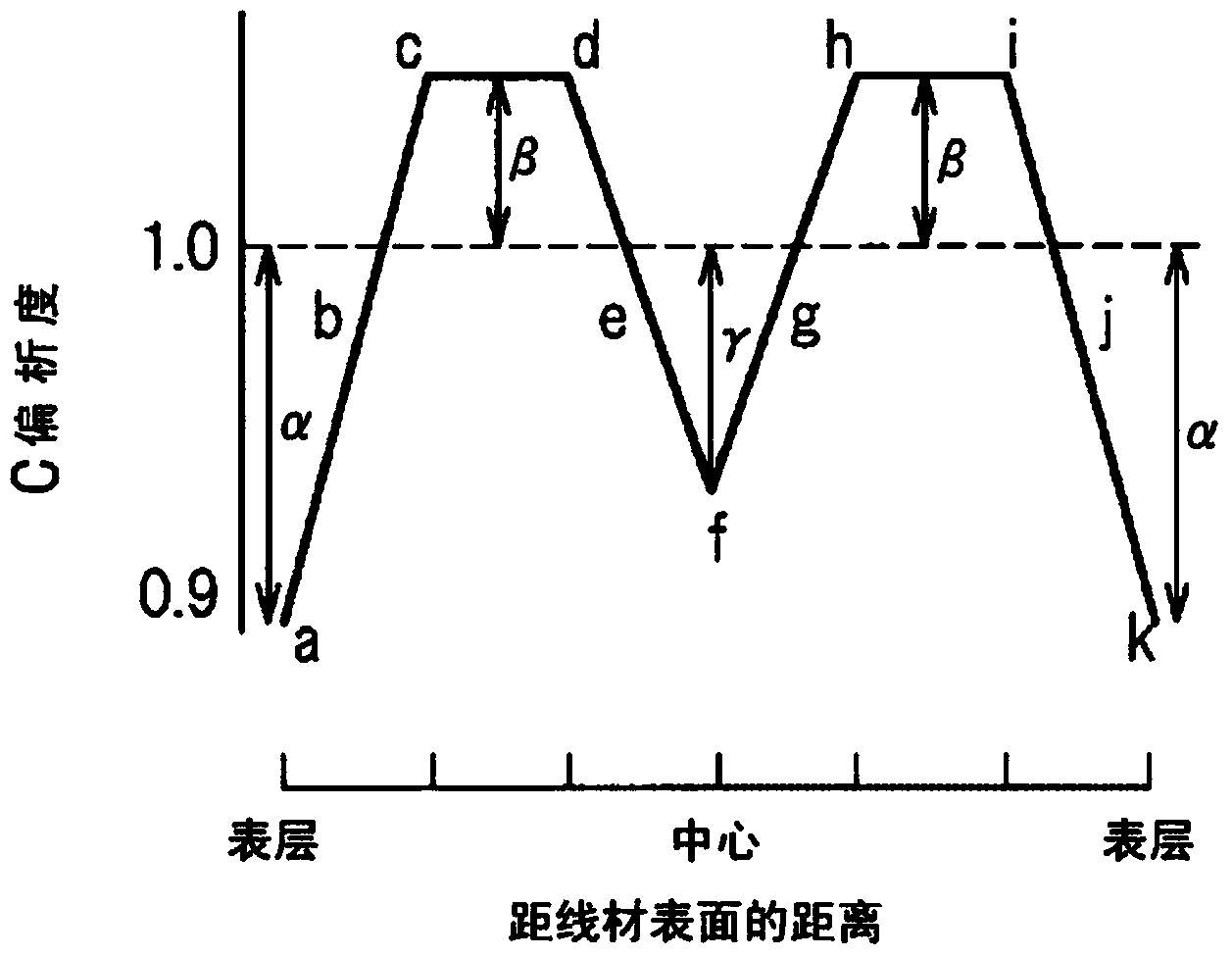

A wire and billet technology, applied in the field of high-strength PC stranded wire, can solve the problems of deterioration of the liquid phase hole end point and the center segregation point of the forging point, broken wires and insufficient strength, and can not improve the segregation effect of the center, so as to improve the ductility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiments of the present invention will be described below.

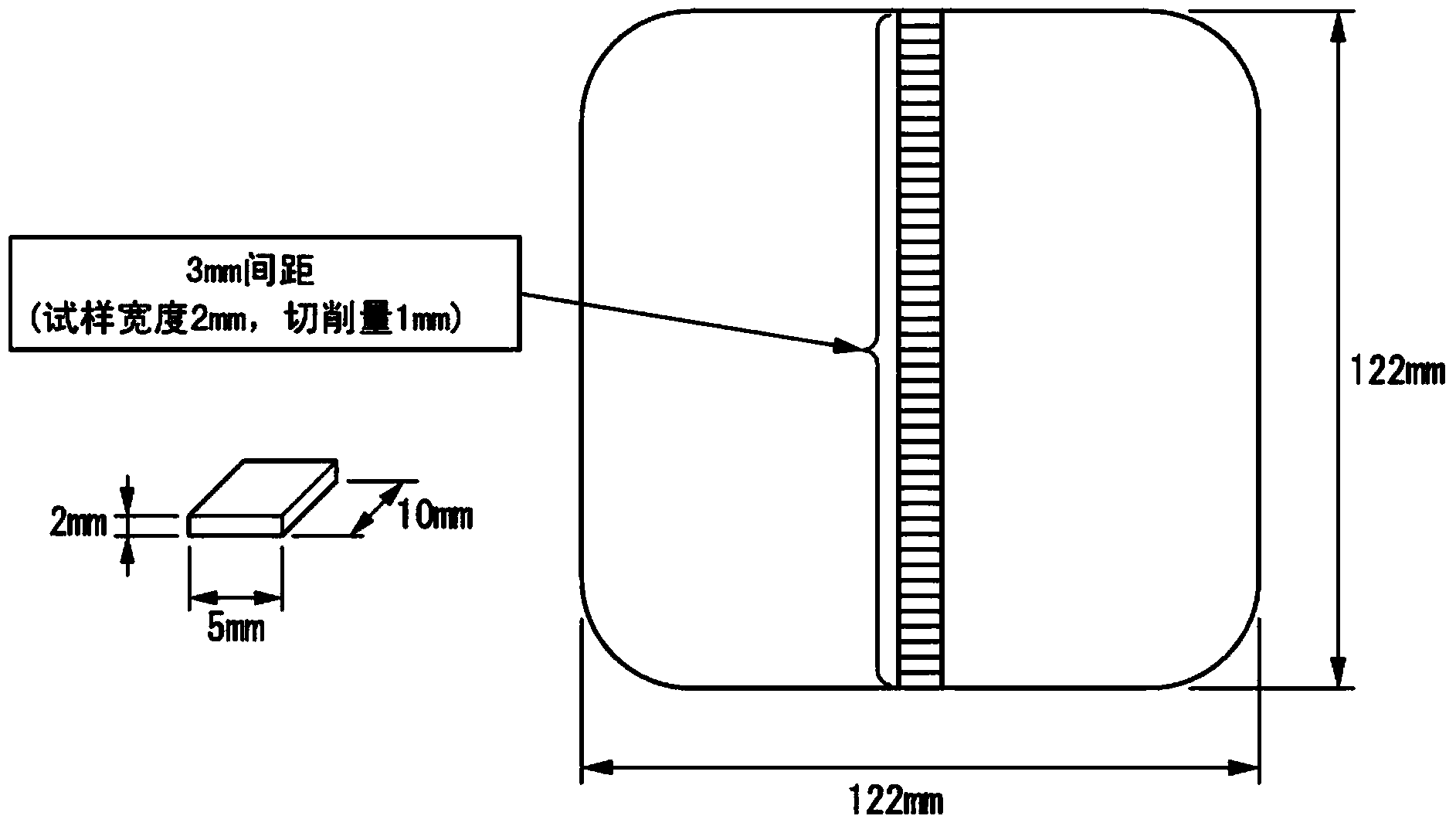

[0090] Steel types A to J having the chemical compositions shown in Table 1 were melted and continuously cast under the manufacturing conditions (steelmaking) shown in Table 2 to produce slabs (blooms) of 500 mm×300 mm. This cast slab was heated at 1250° C. for 45 minutes, and then slab-rolled to produce a 122 mm×122 mm billet (billet). The slab was heated under the manufacturing conditions (after steelmaking) shown in Table 2, rolled by a conventional method, and then coiled under the conditions shown in Table 2 to produce wire rods with a diameter of 12 mm and a diameter of 5.5 mm . The wire rods with a diameter of 12 mm and a diameter of 5.5 mm were further heat-treated under the conditions shown in Table 2.

[0091] In addition, in Table 1, "-" indicates that below the measurement limit, the remainder includes iron and impurities.

[0092] Table 1

[0093] (quality%)

[0094] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com