Poly(vinyl alcohol) film, stretched film, polarizing film, and method for producing poly(vinyl alcohol) film

A polyvinyl alcohol film, polyvinyl alcohol technology, applied in the direction of polarizing elements, etc., can solve the problems of reduced stretch processability, etc., and achieve the effect of excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

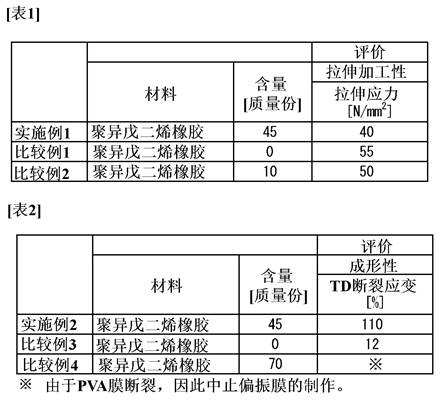

Examples

Embodiment

[0117] The present invention will be specifically described by the following examples, but the present invention is not limited by these examples. In addition, each evaluation method employed in the following examples and comparative examples is shown below.

[0118] [Measuring method of weight-average molecular weight of liquid rubber (polyisoprene rubber)]

[0119] The weight-average molecular weight of the liquid rubber is determined by GPC (gel permeation chromatography) in terms of molecular weight in terms of standard polystyrene.

[0120] The measurement apparatus and conditions are as follows.

[0121] Device: GPC device "GPC8020" manufactured by Tosoh Corporation

[0122] Separation column: "TSKgelG4000HXL" manufactured by Tosoh Corporation

[0123] Detector: "RI-8020" manufactured by Tosoh Corporation

[0124] Eluent: tetrahydrofuran

[0125] Eluent flow rate: 1.0ml / min

[0126] Sample concentration: 5mg / 10ml

[0127] Column temperature: 40°C.

[0128] [Stret...

Synthetic example 1

[0132] [Synthesis Example 1] Synthesis of Rubber Particles

[0133] (1) Synthesis of liquid rubber

[0134] A well-dried 5 L autoclave was replaced with nitrogen, 1200 g of hexane and 112 g of sec-butyllithium (10.5% by mass hexane solution) were charged, and the temperature was raised to 50°C. Thereafter, 1200 g of isoprene was gradually added while the polymerization temperature was controlled so as to be 50° C. under stirring conditions, and polymerization was carried out for 1 hour. Thereafter, methanol was added to terminate the polymerization reaction to obtain a polymer solution. Water was added and stirred to the obtained polymer solution, and the polymer solution was washed with water. The stirring was stopped, and after confirming that the polymer solution phase was separated from the water phase, the water was drained. Liquid polyisoprene (liquid rubber) was obtained by vacuum-drying the polymer solution after washing at 70° C. for 24 hours. When the weight aver...

Embodiment 1

[0138] (Production of PVA film)

[0139] 100 parts by mass of PVA (saponified product of a homopolymer of vinyl acetate, degree of polymerization 2,400, degree of saponification 99.5 mol %), 45 parts by mass of rubber particles, 10 parts by mass of glycerin as a plasticizer, 0.1 parts by mass Sodium polyoxyethylene lauryl ether sulfate as a surfactant and water were mixed to prepare a film-forming stock solution with a volatile component rate of 85% by mass. It should be noted that the rubber particles were obtained by mixing the aqueous dispersion obtained in Synthesis Example 1 with other components. The above-mentioned film-forming stock solution was cast on a metal drum with a surface temperature of 80° C., and dried until the volatile component rate (moisture content) became 5% by mass to obtain a long PVA film with a thickness of 30 μm, a length of 1.5 m, and a width of 30 cm (heat treatment front PVA film). The PVA film was heat-treated at a temperature of 110° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile stress | aaaaa | aaaaa |

| Tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com