Alloy type temperature fuse and material for temperature fuse use

A technology of temperature fuses and fuses, applied in electrical components, heating/cooling contact switches, circuits, etc., can solve problems such as difficult heat-resistant cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

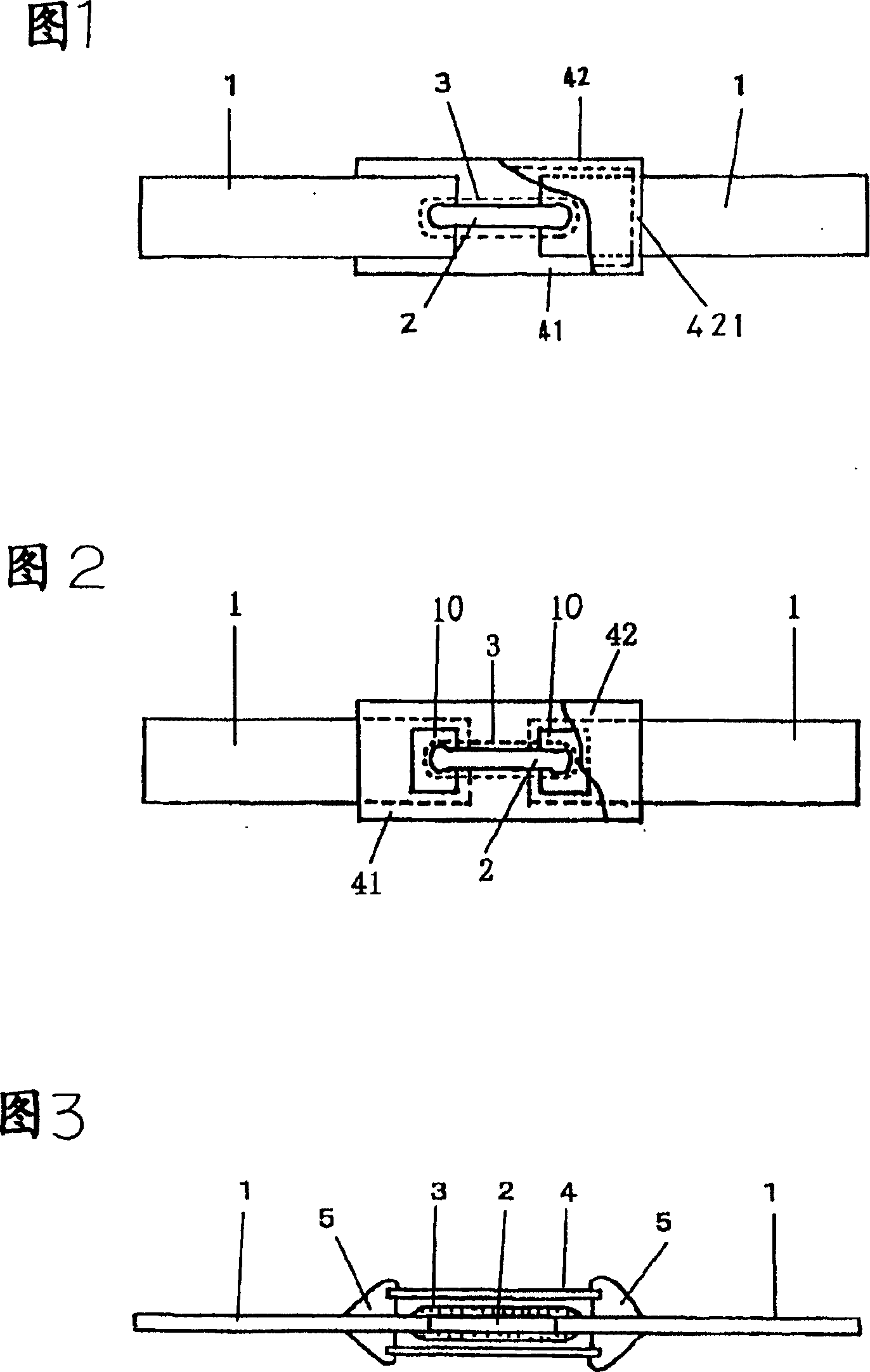

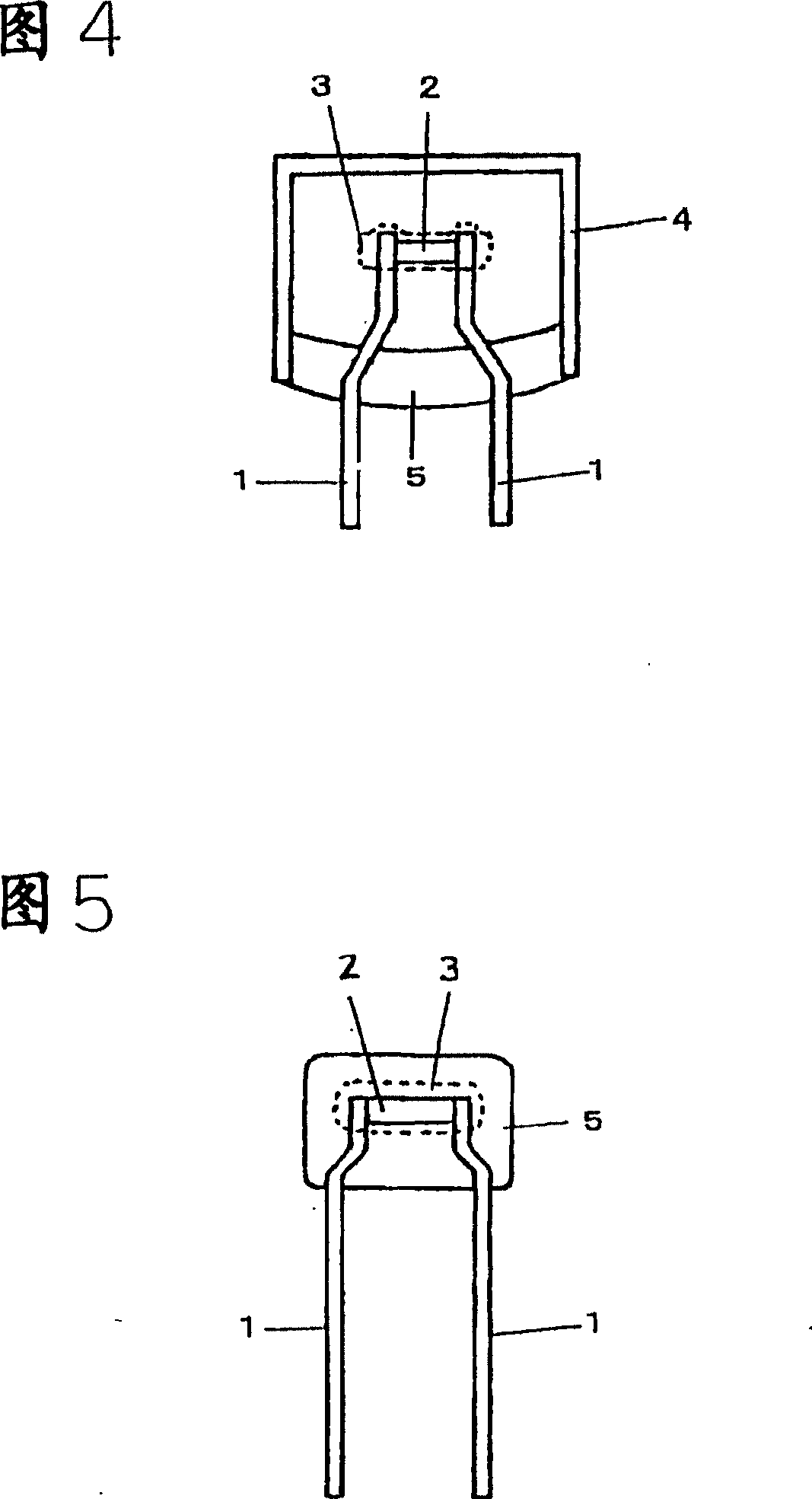

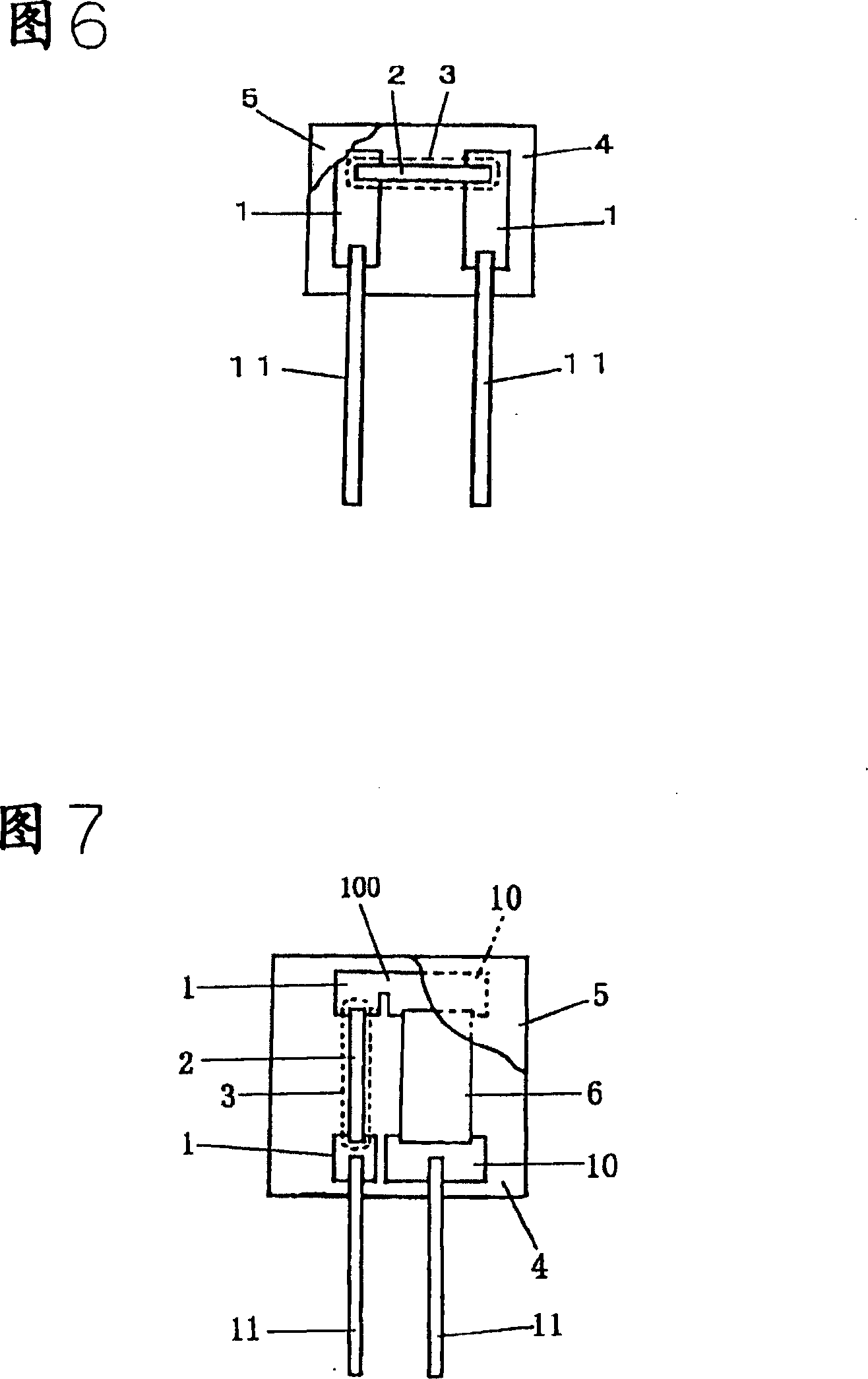

Method used

Image

Examples

Embodiment 1

[0101] The alloy composition of the fuse element is made to be In25%, Sn20%, and the balance is Bi. The drawing processability of the drawn fuse element is O.

[0102] The DSC measurement results of the fuse element are shown in Fig. 10. The liquidus temperature is about 84°C, the solidus temperature is about 80°C, and the maximum absorption peak temperature is about 81°C. The DSC measurement results, since the alloy composition is close to the above-mentioned 79°C Bi-In-Sn system ternary eutectic point Bi57.5%-In25.2%-Sn17.3%, it belongs to the graph of Fig. 14(B), but There is no solid phase transformation region on the temperature side lower than the solidus temperature.

[0103] The temperature of the fuse element when the thermal fuse operates is 82±1°C. Therefore, it can be seen that the temperature of the fuse element at the time of operation of the thermal fuse is approximately the same as the maximum endothermic peak temperature of approximately 82°C.

[0104] The ...

Embodiment 2

[0106] The alloy composition of the fuse element is 30% In, 15% Sn, and the balance is Bi.

[0107] The drawing processability of the drawn fuse element is O.

[0108] As shown in 11, the DSC measurement results of the fuse element show that the liquidus temperature is about 86°C, the solidus temperature is about 81°C, and the maximum absorption peak temperature is about 82°C. This DSC measurement result, since the alloy composition is close to the above-mentioned 79°C Bi-In-Sn system ternary eutectic point Bi54.0%-In29.7%-Sn16.3%, it belongs to the graph of Fig. 14(B), but There is no solid phase transformation region on the temperature side lower than the solidus temperature.

[0109] The temperature of the fuse element when the thermal fuse operates is 82±1°C. Therefore, it can be seen that the temperature of the fuse element at the time of operation of the thermal fuse is approximately the same as the maximum endothermic peak temperature of approximately 82°C.

[0110] ...

Embodiment 3~7

[0112] With respect to Example 1, except that the alloy composition was changed to that shown in Table 1, the rest was the same as that of Example 1.

[0113] In any of the examples, good wire drawability was exhibited.

[0114] The solidus temperature and liquidus temperature of these embodiments are as shown in Table 1. The temperature of the fuse element when the thermal fuse operates, as shown in Table 1, fluctuates up and down within ±3°C and is in the solid-liquid coexistence area.

[0115] The melting pattern of the fuse element of these embodiments belongs to the pattern of Fig. 14 (A). Although the solid-liquid coexistence area is wide, the heat absorption peak is single and steep. As a result, the fluctuation of the operating temperature can be adjusted. Press down to within ±3°C.

[0116] The load aging test is qualified. This is presumably because the amount of In was as small as 15 to 30%, and the reaction between In and the co-solvent was suppressed as in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com