Patents

Literature

42results about How to "Improved delayed fracture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel for Warm Working, Warm Working Method Using the Steel, and Steel Material and Steel Component Obtainable Therefrom

InactiveUS20090277539A1Improve toughnessImproved delayed fracture resistanceFurnace typesHeat treatment process controlRoom temperatureHardness

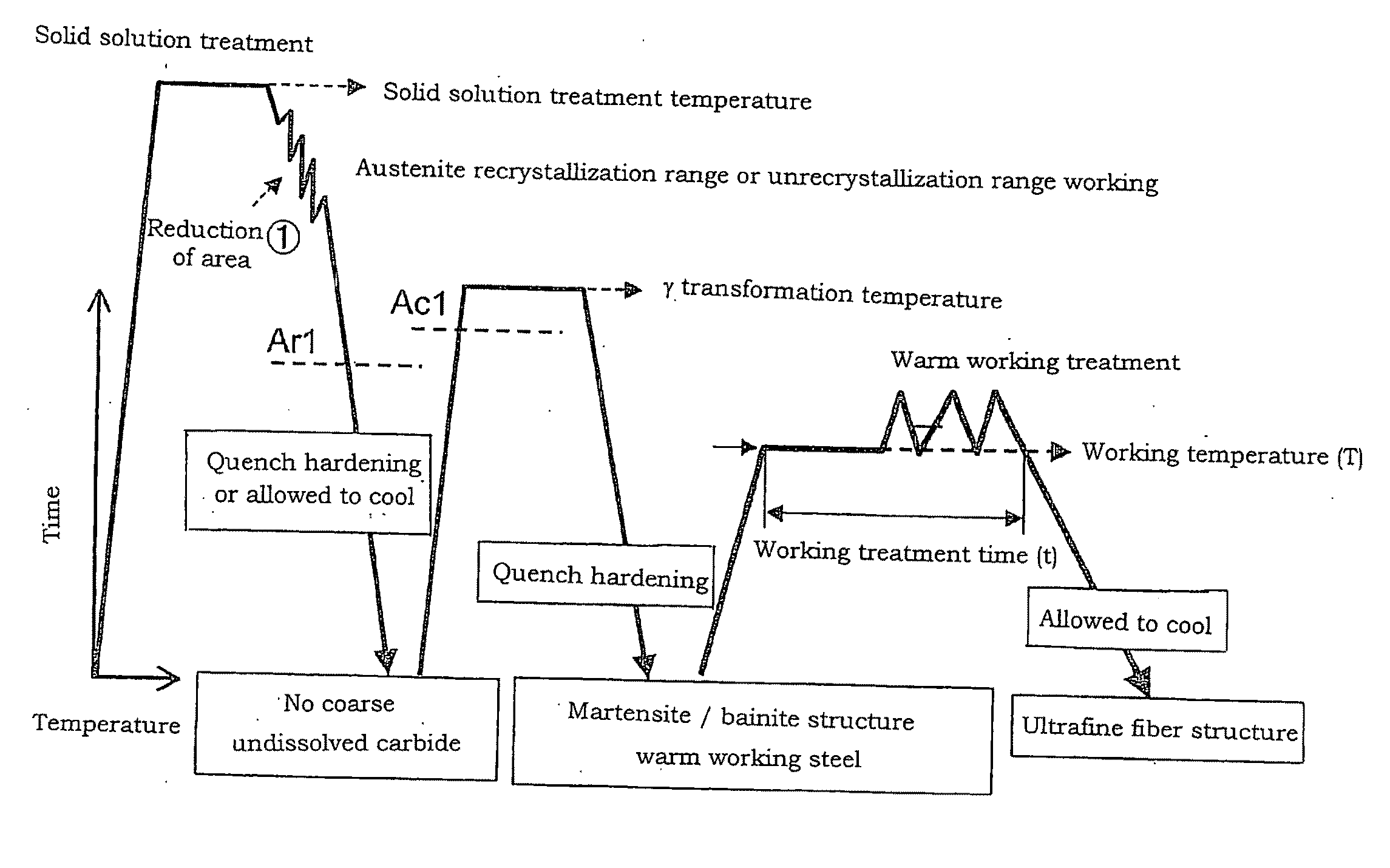

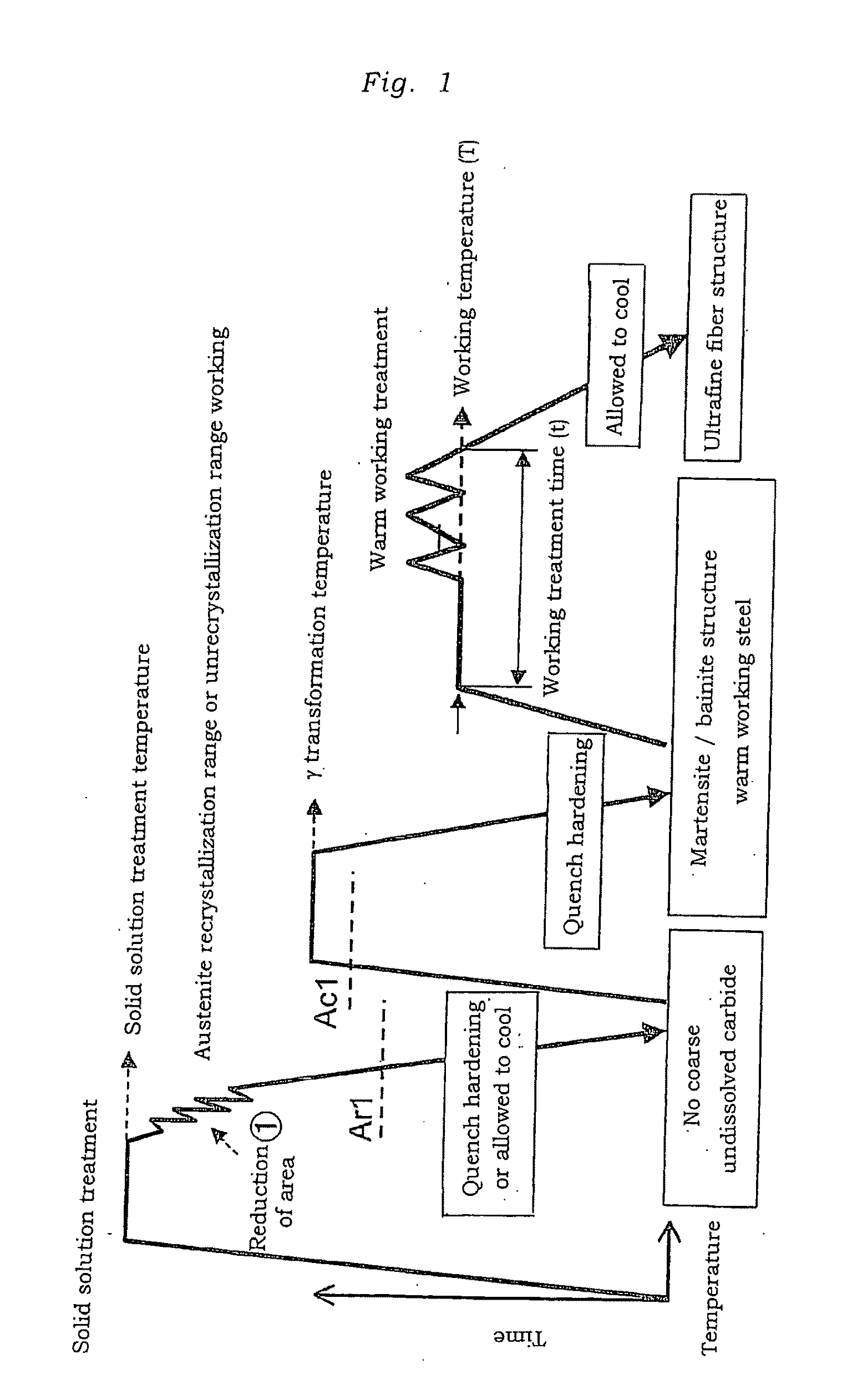

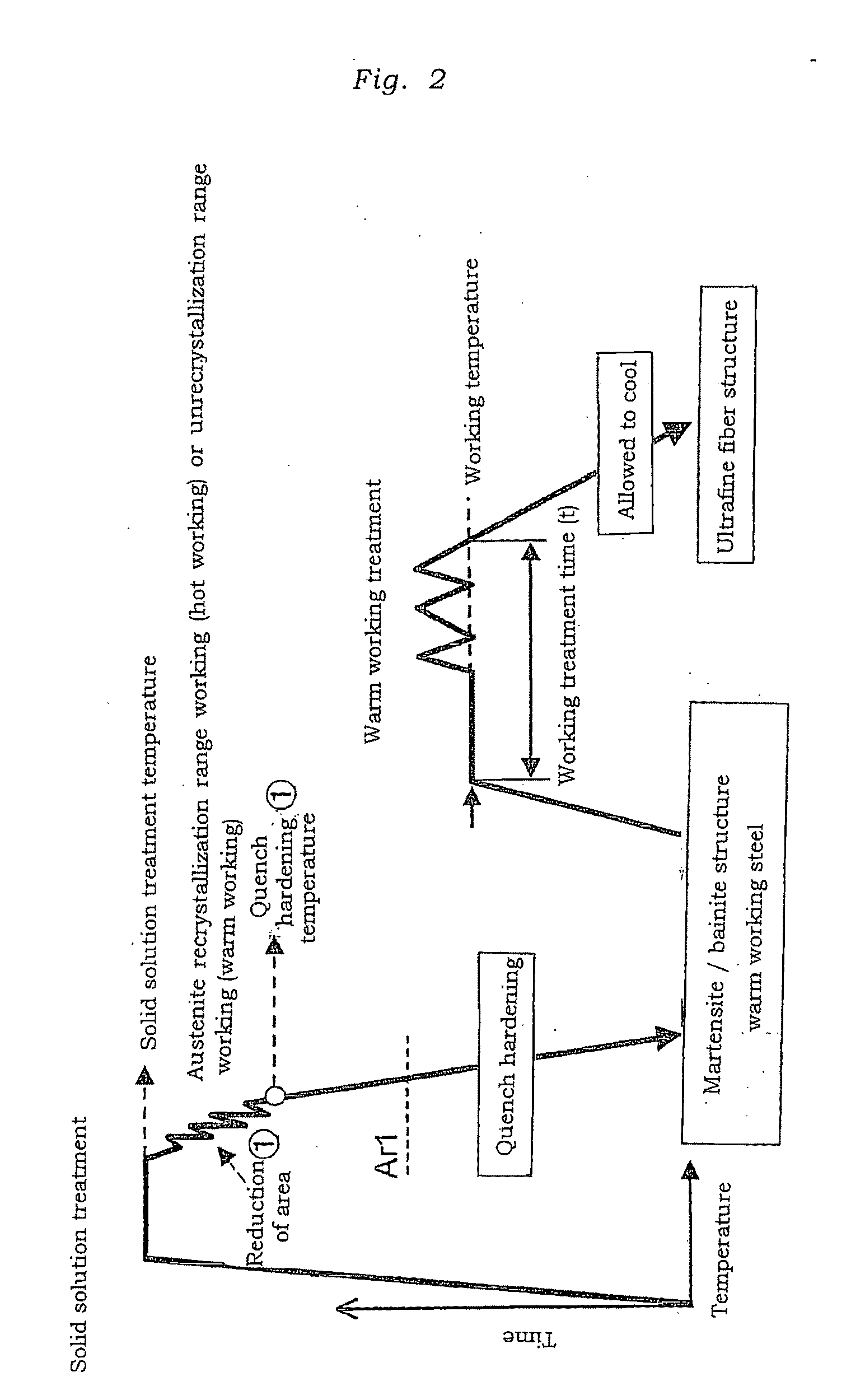

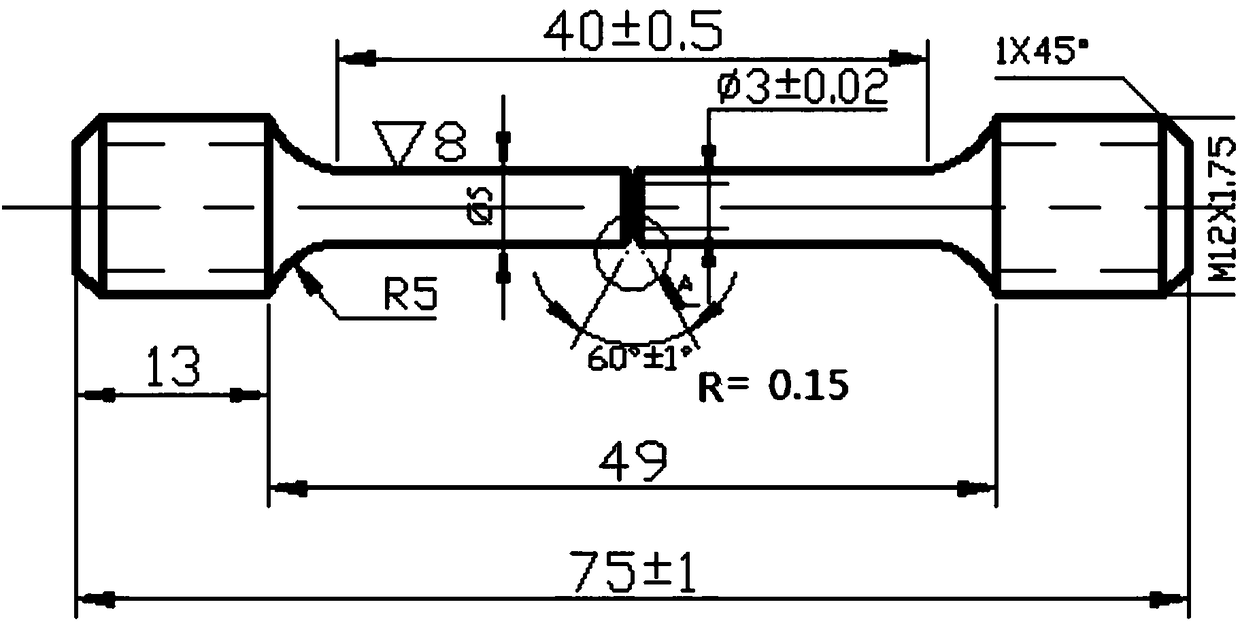

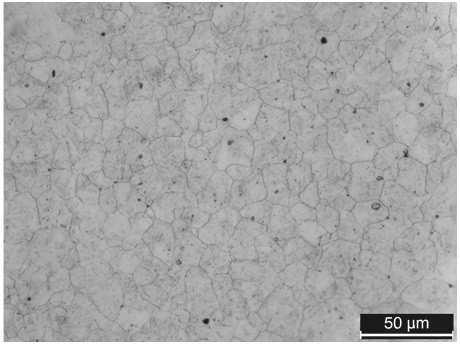

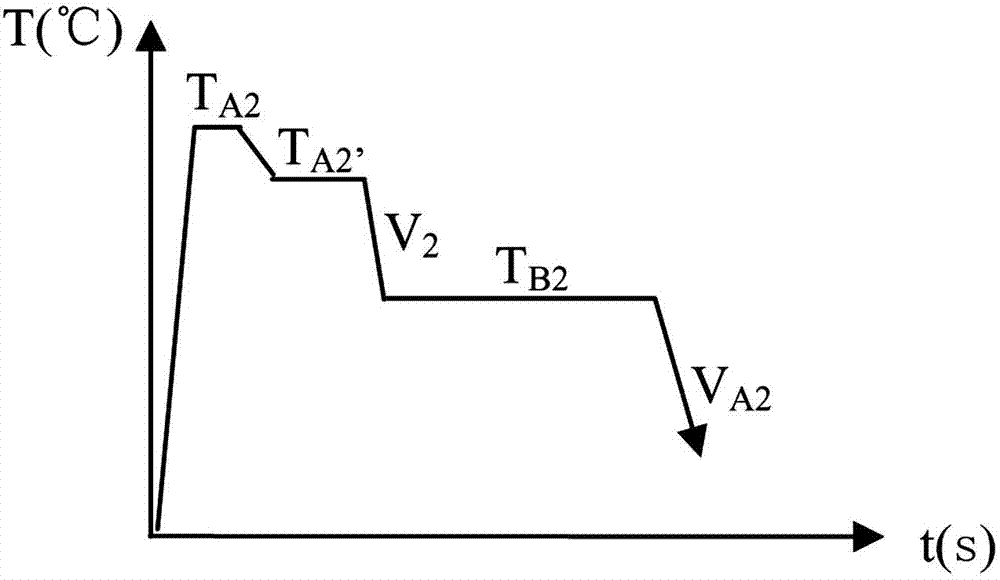

There are provided a steel for warm working, to be subjected to warm working as various structures, components of cars, and the like, a warm working method thereof, and a steel material and a steel component obtainable from the warm working method.[Solving Means] A steel is to have a particle dispersion type fiber structure formed in the matrix by warm working. The steel is characterized in that the total amount of the dispersed second-phase particles at room temperature is 7×10−3 or more in terms of volume fraction, and the Vickers hardness (HV) is equal to or larger than the hardness H of the following equation (2):H=(5.2−1.2×10−4λ)×102 (2)when the steel is subjected to any of annealing, tempering, and aging treatments in the as-unworked state under conditions such that a parameter λ expressed by the following equation (1):λ=T(log t+20)(T; temperature(K), t; time(hr)) (1)is 1.4×104 or more in a prescribed temperature range of 350° C. or more and Ac1 point or less. This steel is taken as the steel for warm working.

Owner:NAT INST FOR MATERIALS SCI

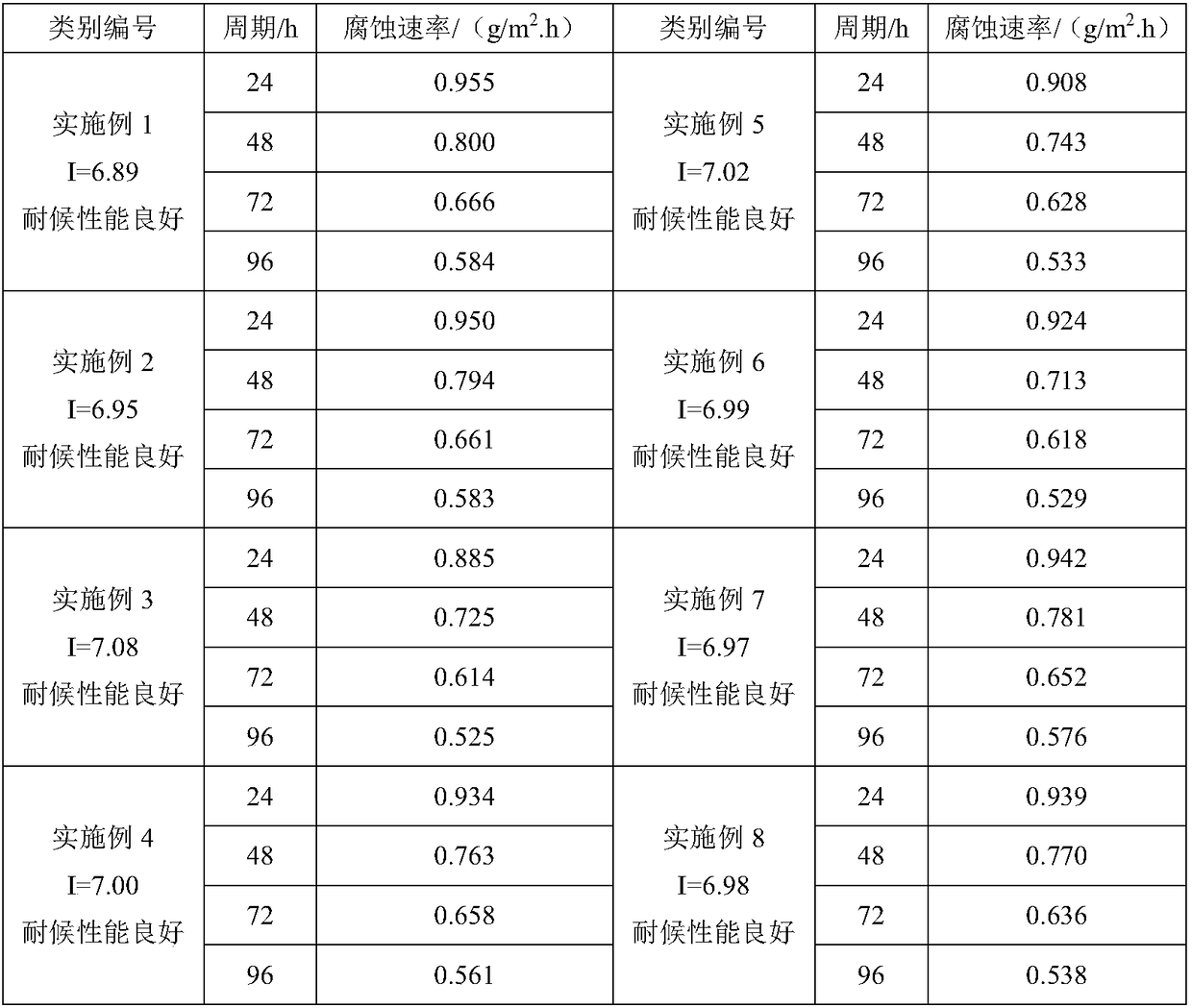

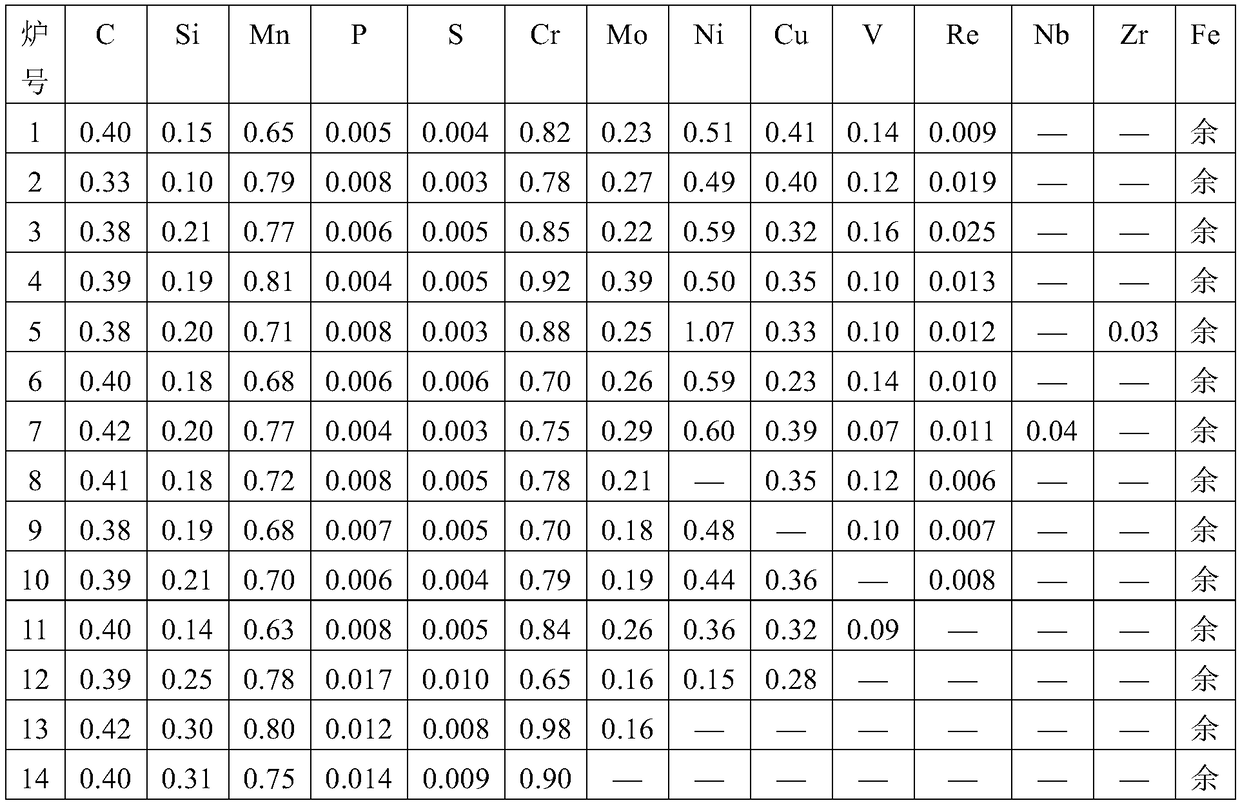

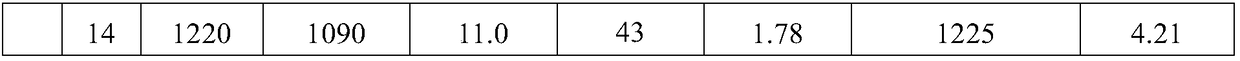

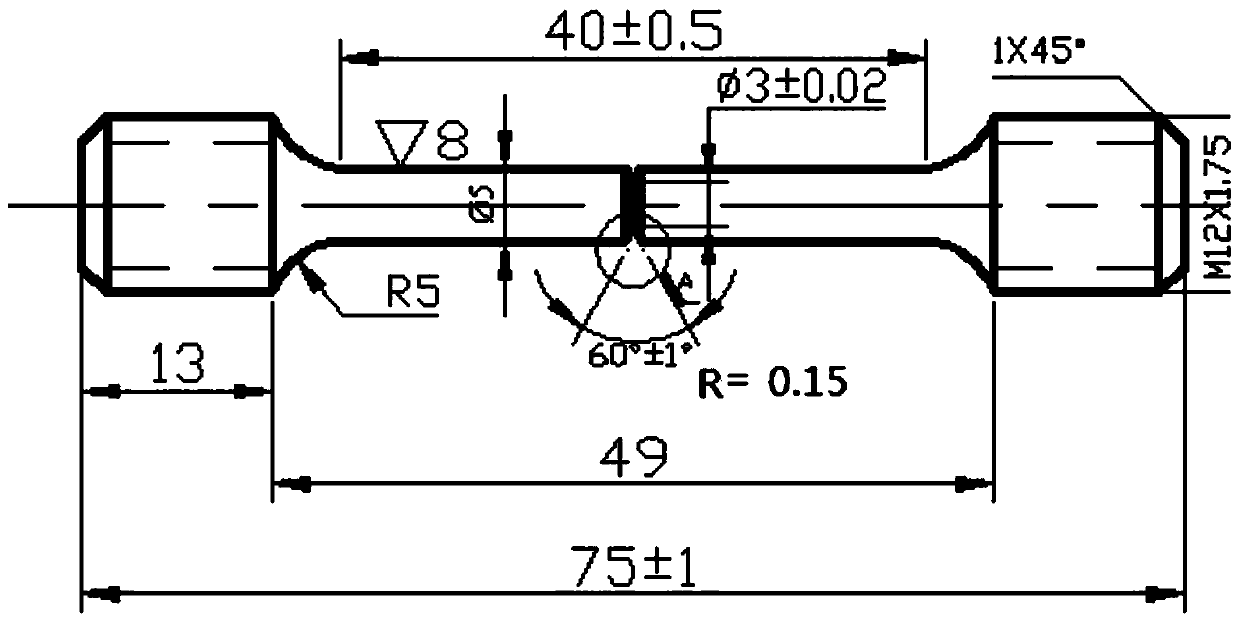

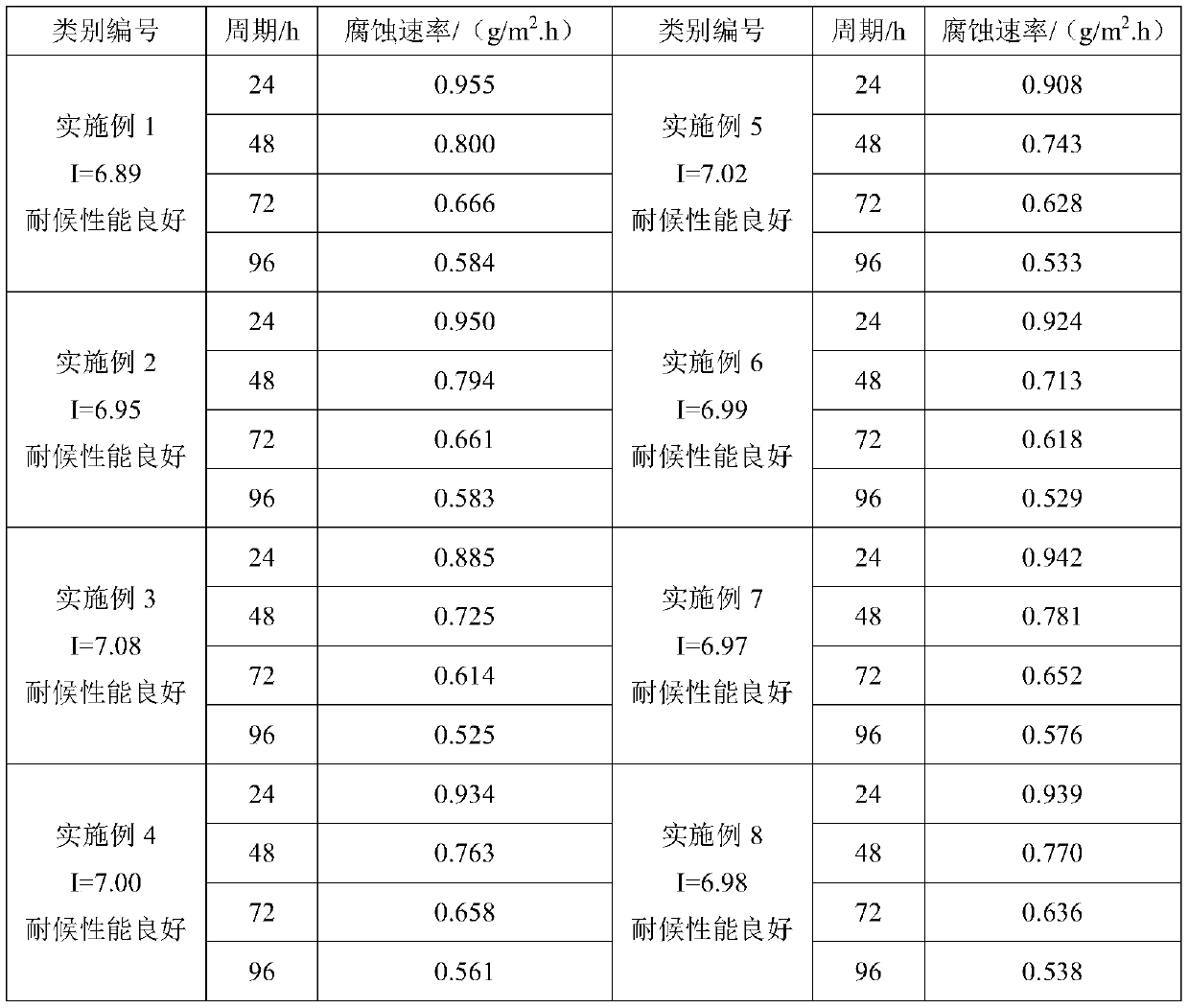

Delay-fracture-resisting 1040 MPa-grade weather-proof bolt

ActiveCN108070796AImproved delayed fracture resistanceReasonable regulationScrewsMetallurgyAtmospheric corrosion

Provided is a delay-fracture-resisting 1040 MPa-grade weather-proof bolt. The Delay-fracture-resisting 1040 MPa-grade weather-proof bolt is prepared from the chemical ingredients including, by mass percent, 0.21% to 0.32% of C, 0.10% to 0.50% of Si, 0.60% to 1.00% of Mn, 0.008% to 0.020% of P, not larger than 0.005% of S, 0.82% to 1.20% of Cr, 0.25% to 0.50% of Ni, 0.25 to 0.50% of Cu, 0.05% to 0.20% of Mo, 0.015% to 0.060% of Nb, 0.015% to 0.090% of V, 0.008% to 0.035% of Ti, 0.0008% to 0.0035% of B, 0.015% to 0.040% of Al, 0.003% to 0.007% of Ca, 0.015% to 0.045% of Zr, 0.010% to 0.045% of Re and the balance Fe and inevitable impurities. According to a method for preparing the bolt, the conventional high-purity smelting-continuous casting-rolling technology is mainly adopted, and metal raw materials are prepared into a steel material for the delay-fracture-resisting weather-proof bolt; and raw material acid pickling, steel pulling, blanking, end face chamfering, head cropping, head forming, head chamfering, shot blasting, semi-finished product surface treatment, hole shrinking, thread rolling, thermal treatment and finished product surface treatment are carried out according to aconventional method. The bolt is resistant to delay fractures and atmospheric corrosion and relatively low in cost.

Owner:YANSHAN UNIV +1

High-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture

PendingCN108754303AAccelerated corrosionImproved delayed fracture resistanceAtmospheric corrosionDelayed fracture

The invention discloses a high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture. The high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture comprises, by mass, 0.30-0.45% of C, below 0.25% of Si, 0.40-1.40% of Mn, below 0.012% of P, below 0.008% of S, 0.40-1.20% of Cr, 0.15-0.50% of Mo, 0.30-1.20% of Ni, 0.20-0.60% of Cu, 0.05-0.20% of V, 0.005-0.030% of Re, and the balance of Fe and inevitable impurity elements. Compared with steels in the prior art, the high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture has the advantages of high strength, excellent resistance to atmospheric corrosion and delayed fracture, and low cost, and can be used to 12.9 level high-strength bolts for bridges and other steel structures.

Owner:BEIJING JIAOTONG UNIV

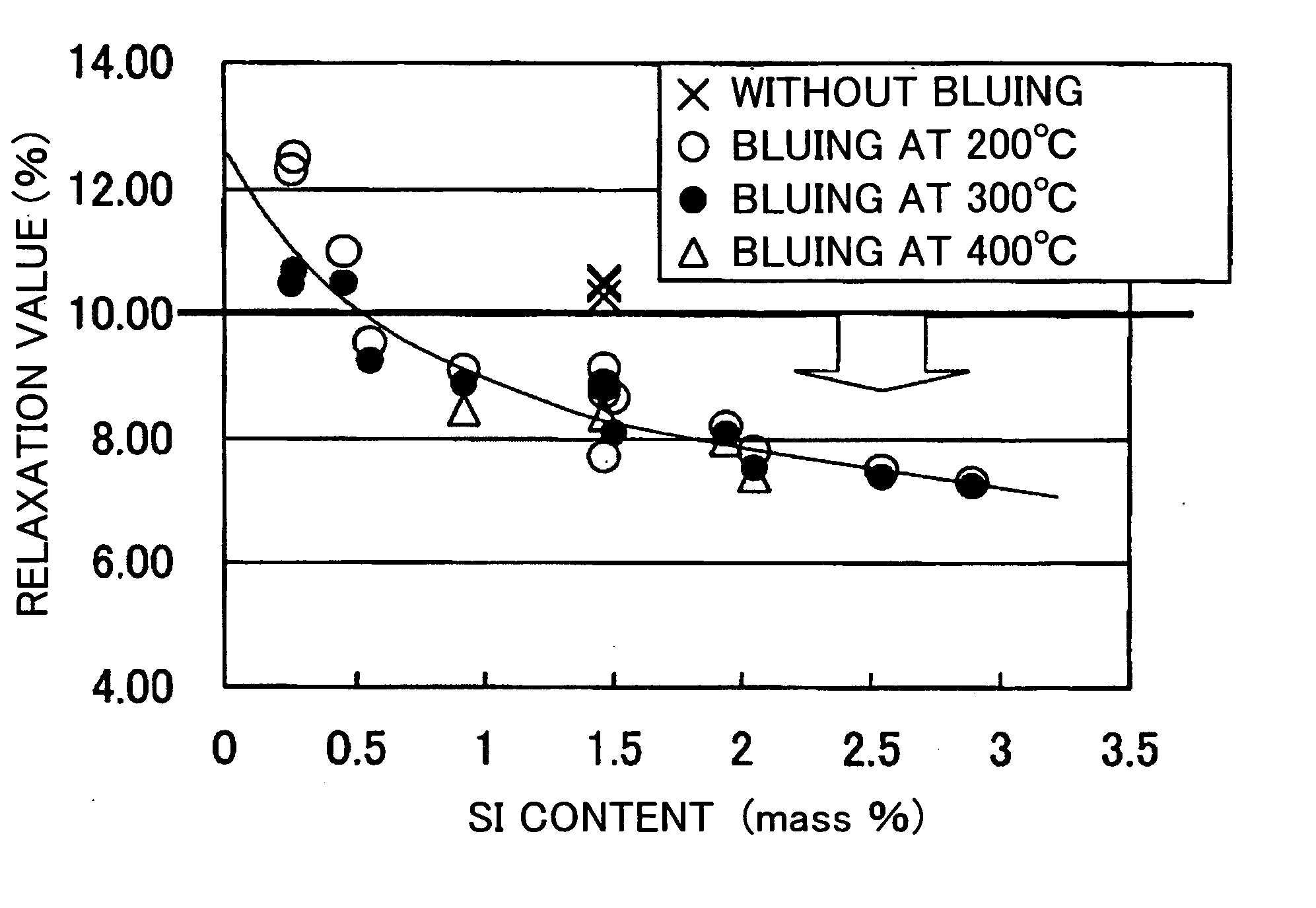

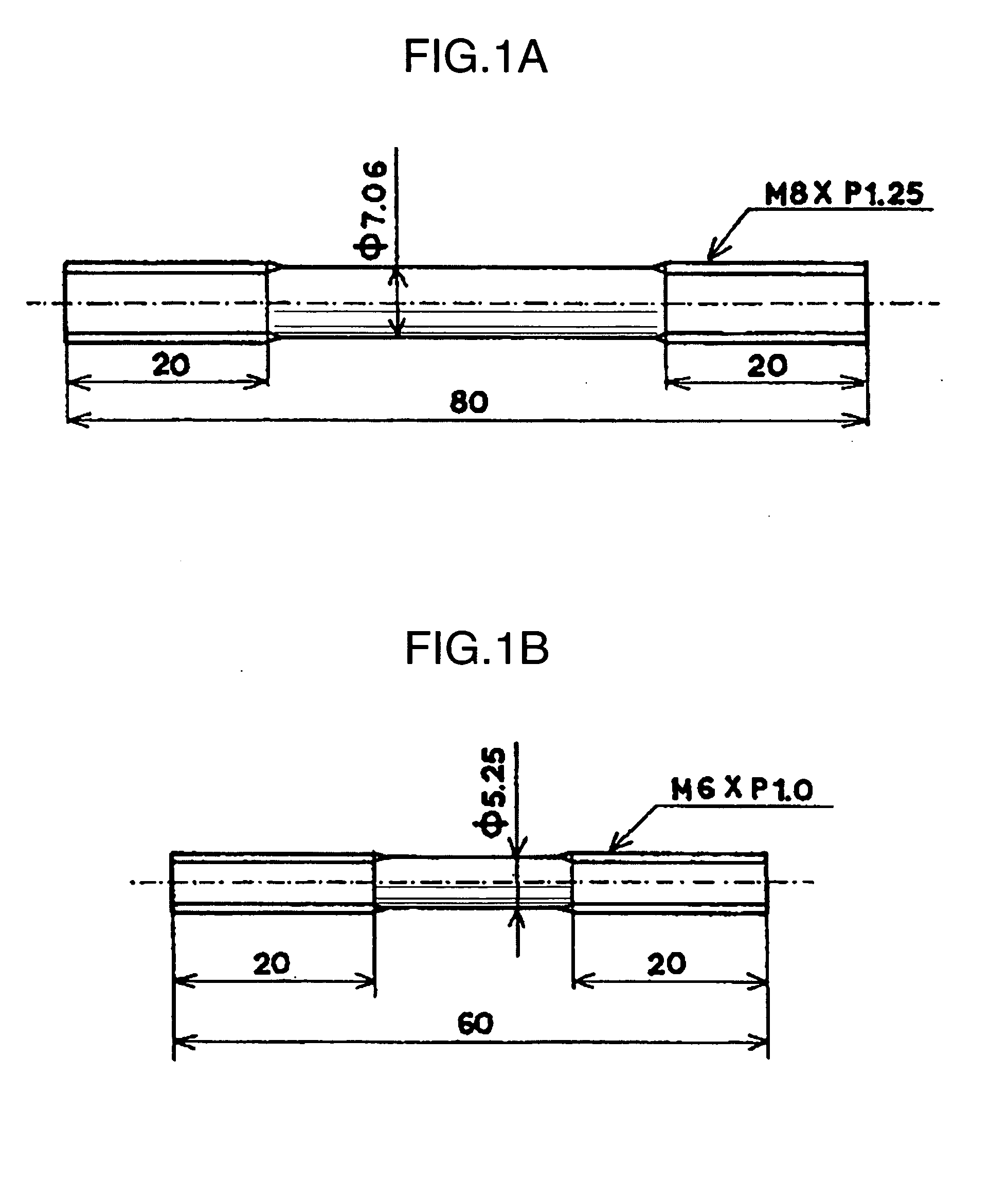

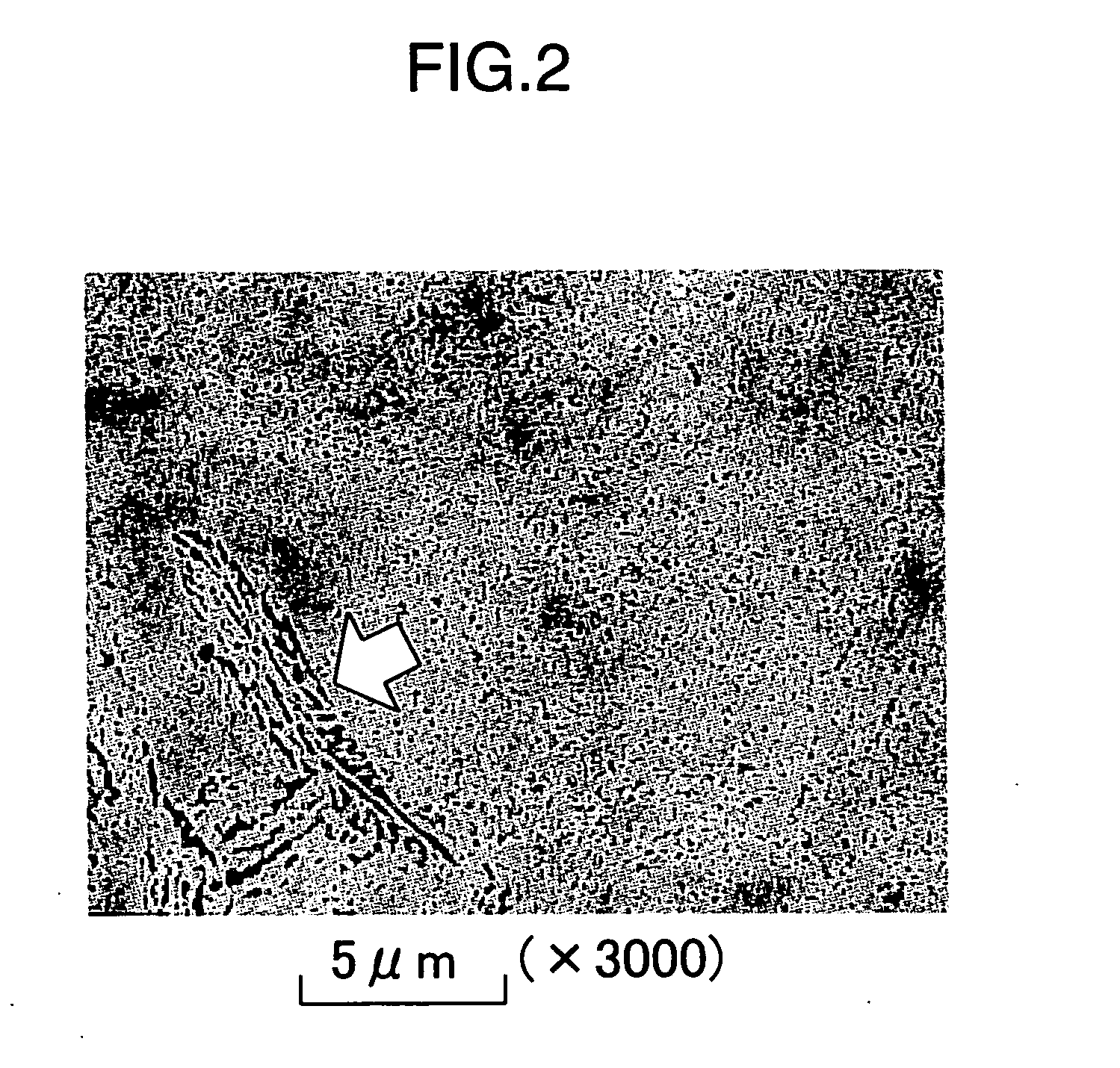

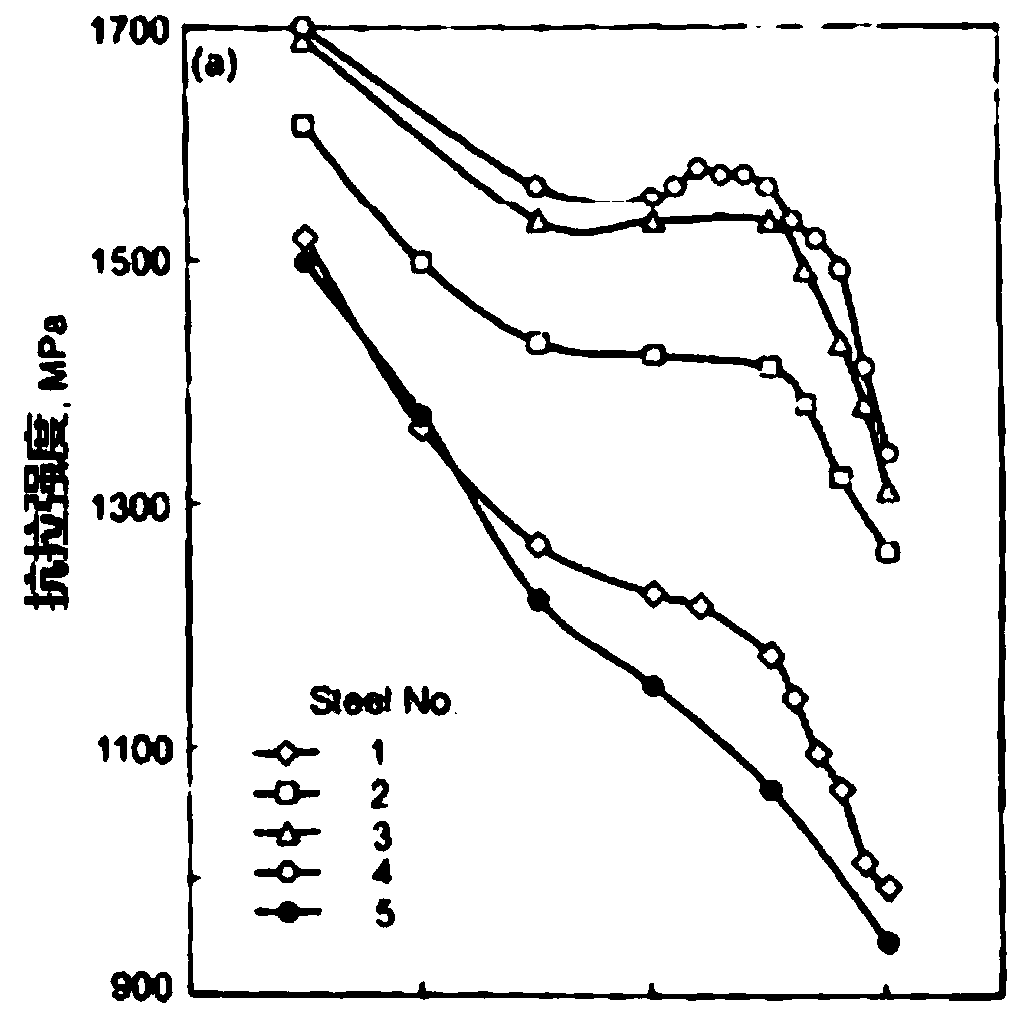

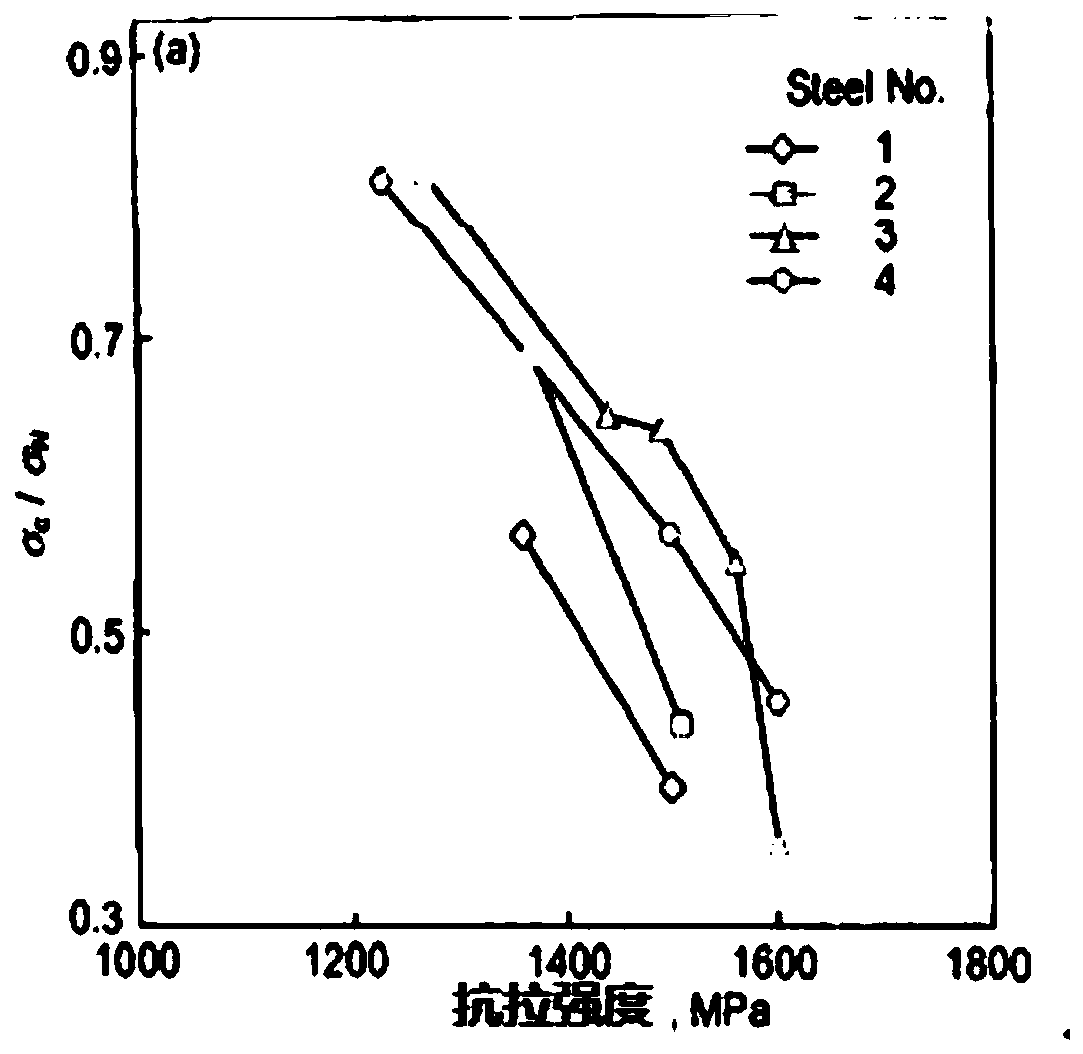

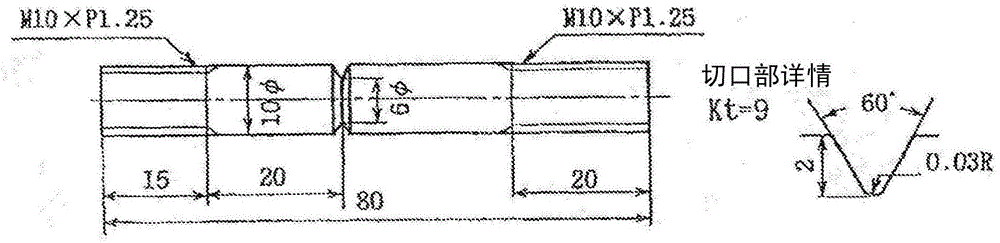

High-strength bolt superior in delayed fracture and resistance and relaxation resistance

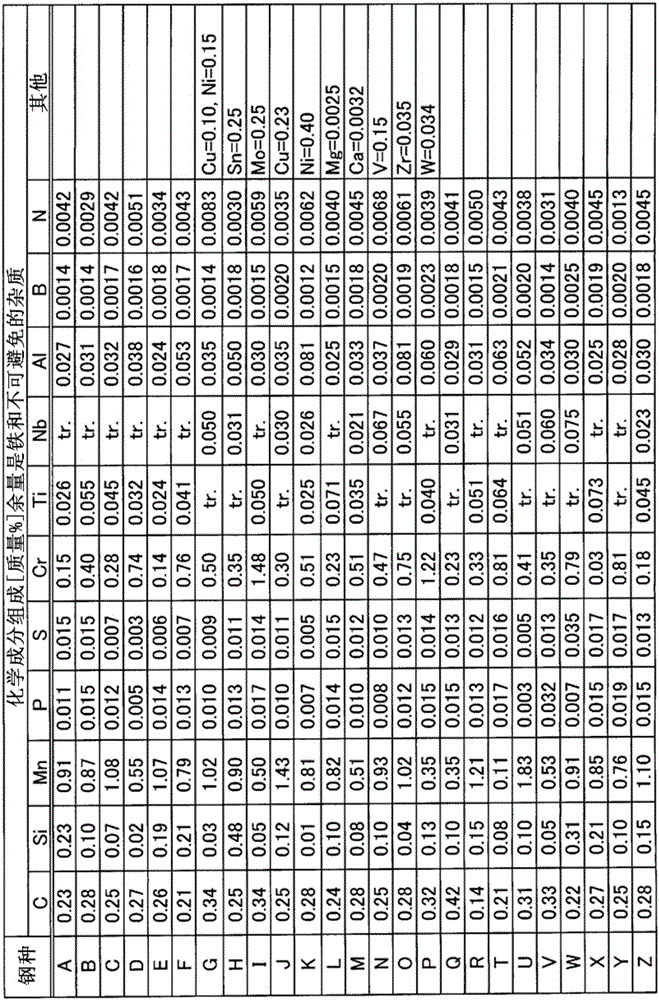

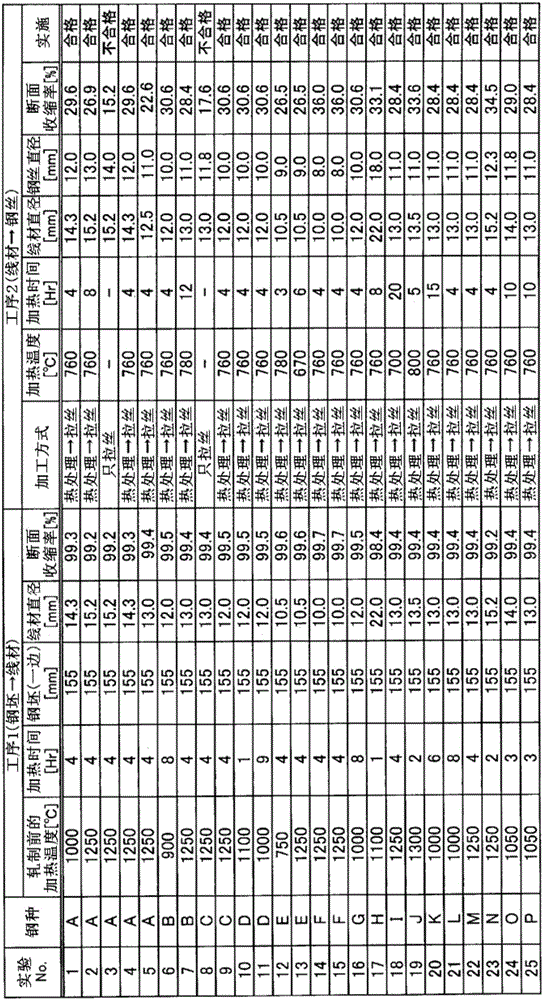

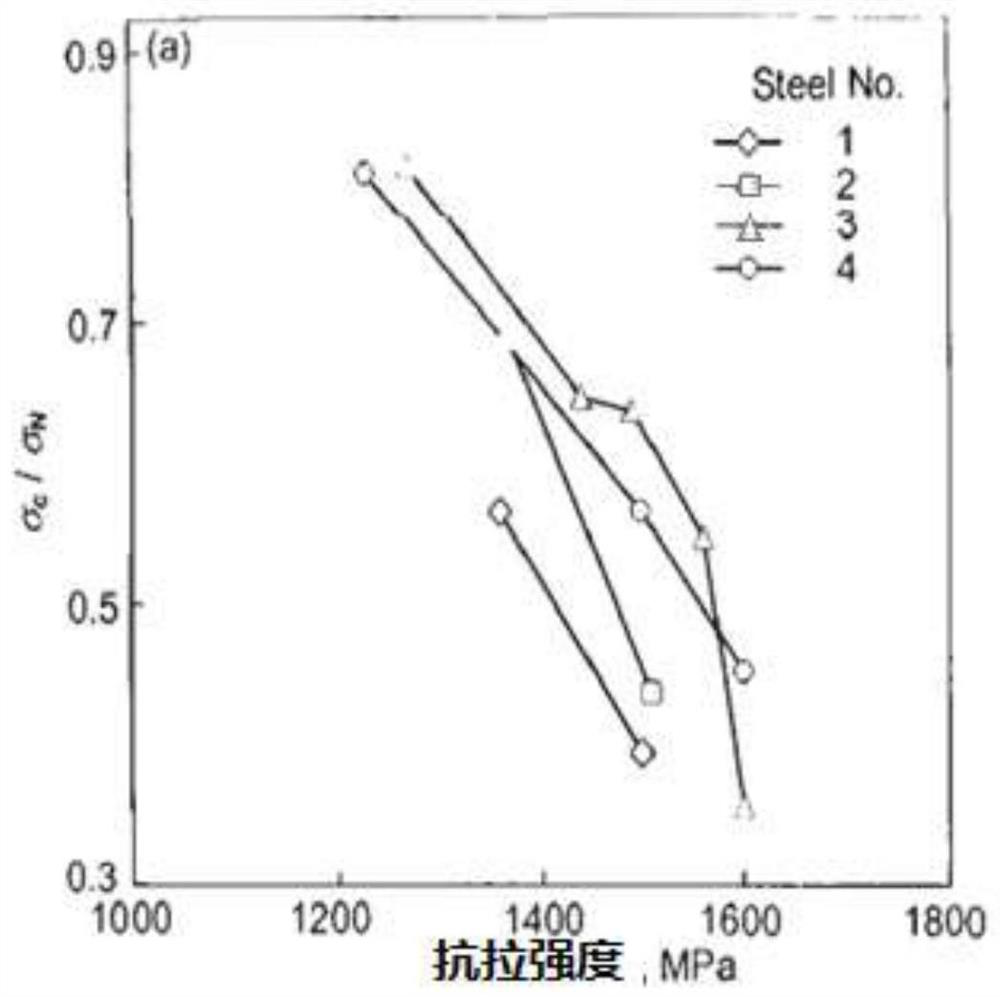

Disclosed is a high-strength bolt having a tensile strength of 1,200 N / mm2 or more and superior in delayed fracture resistance and relaxation resistance, prepared by wire-drawing a bolt steel containing the following elements: C: 0.5 to 1.0% (mass %, the same shall apply hereinafter), Si: 0.55 to 3%, Mn: 0.2 to 2%, P: 0.03% or less (but not 0%), S: 0.03% or less (but not 0%), and Al: 0.3% or less (but not 0%), and containing proeutectoid ferrite, proeutectoid cementite, bainite and martensite at a total areal rate of less than 20% and pearlite in balance; cold-heading the wire into a bolt shape; and then bluing the bolt in a temperature range of 100 to 500° C.

Owner:HONDA MOTOR CO LTD +2

Steel plate strip for 14.9-grade high-strength fastener and preparation method of steel plate strip

The invention discloses a steel plate strip for a 14.9-grade high-strength fastener and a preparation method of the steel plate strip. The steel plate strip is prepared from the chemical components inpercentage by mass: 0.44-0.48% of C, smaller than or equal to 0.20% of Si, 0.40-0.80% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, 1.0-1.5% of Cr, 0.6-0.8% of Mo, 0.03-0.06% of Nb, 0.2-0.5% of V, 0.03-0.06% of Ti, smaller than or equal to 0.20% of Ni, smaller than or equal to 0.20% of Cu, 0.010-0.050% of Alt, 0.0080-0.0160% of N, smaller than or equal to 0.00015% of H, smaller than or equal to 0.0015% of O, and the balance of Fe and impurities. According to the steel plate strip for the 14.9-grade high-strength fastener, the tensile strength of a finishedbolt can be improved, and the excellent delayed fracture resistance is achieved.

Owner:NANJING IRON & STEEL CO LTD

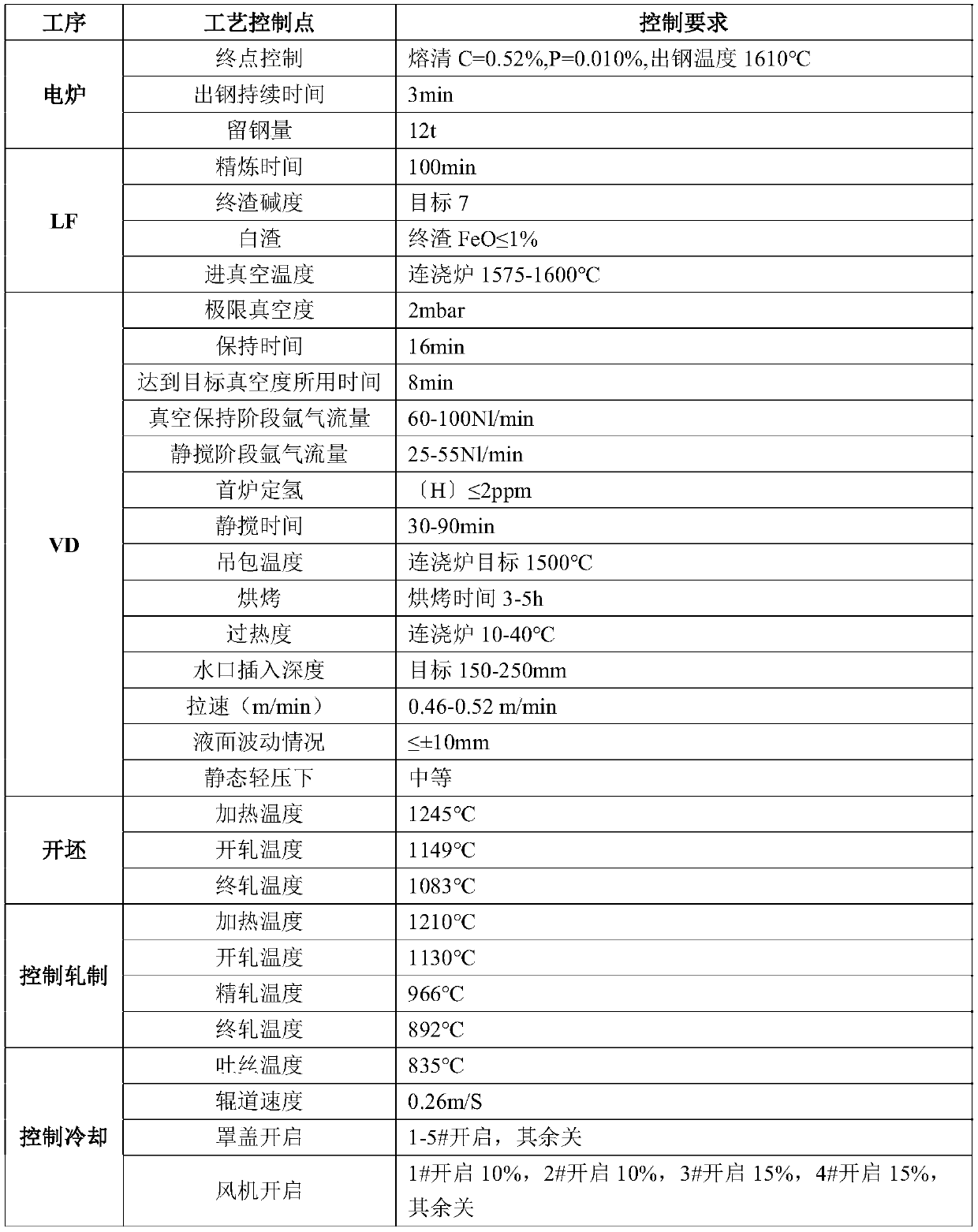

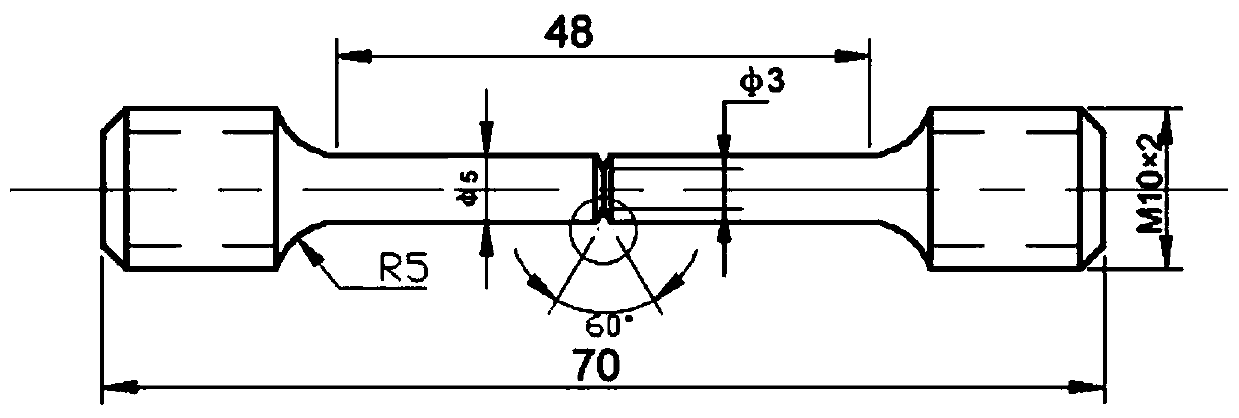

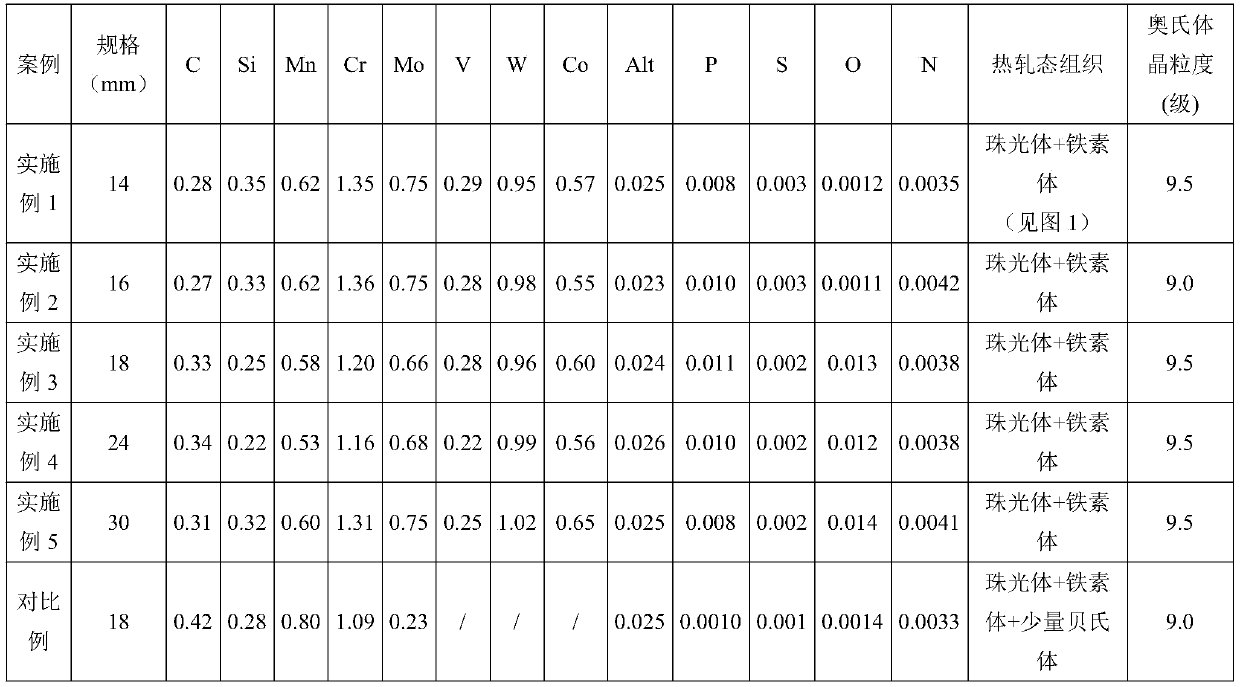

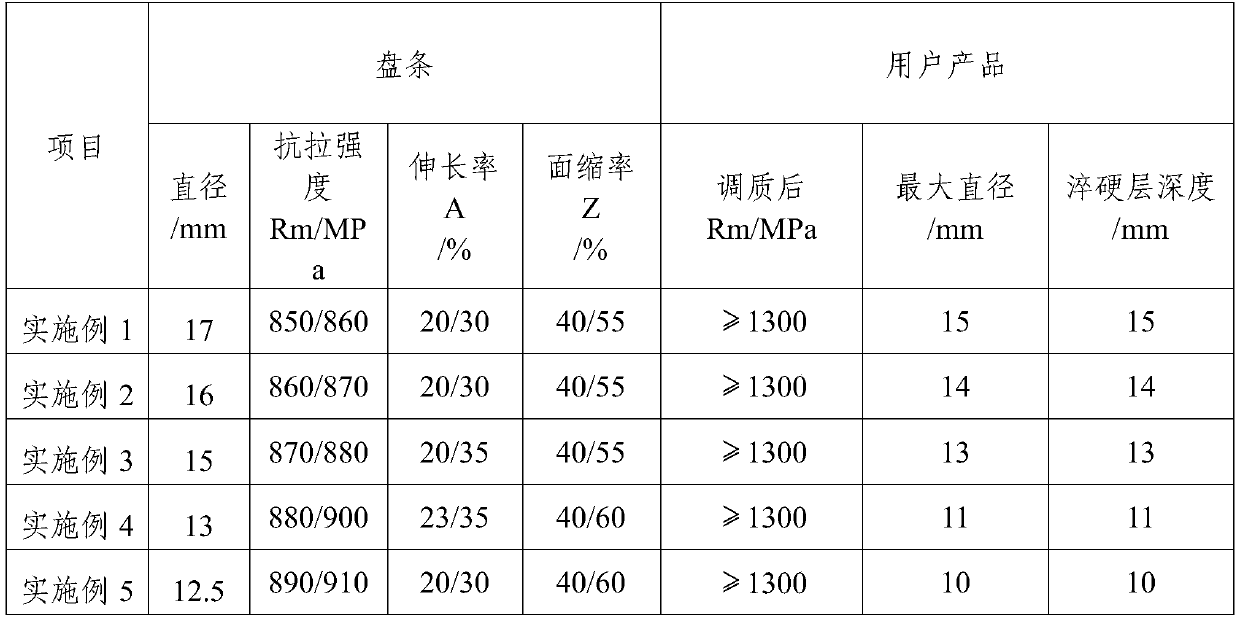

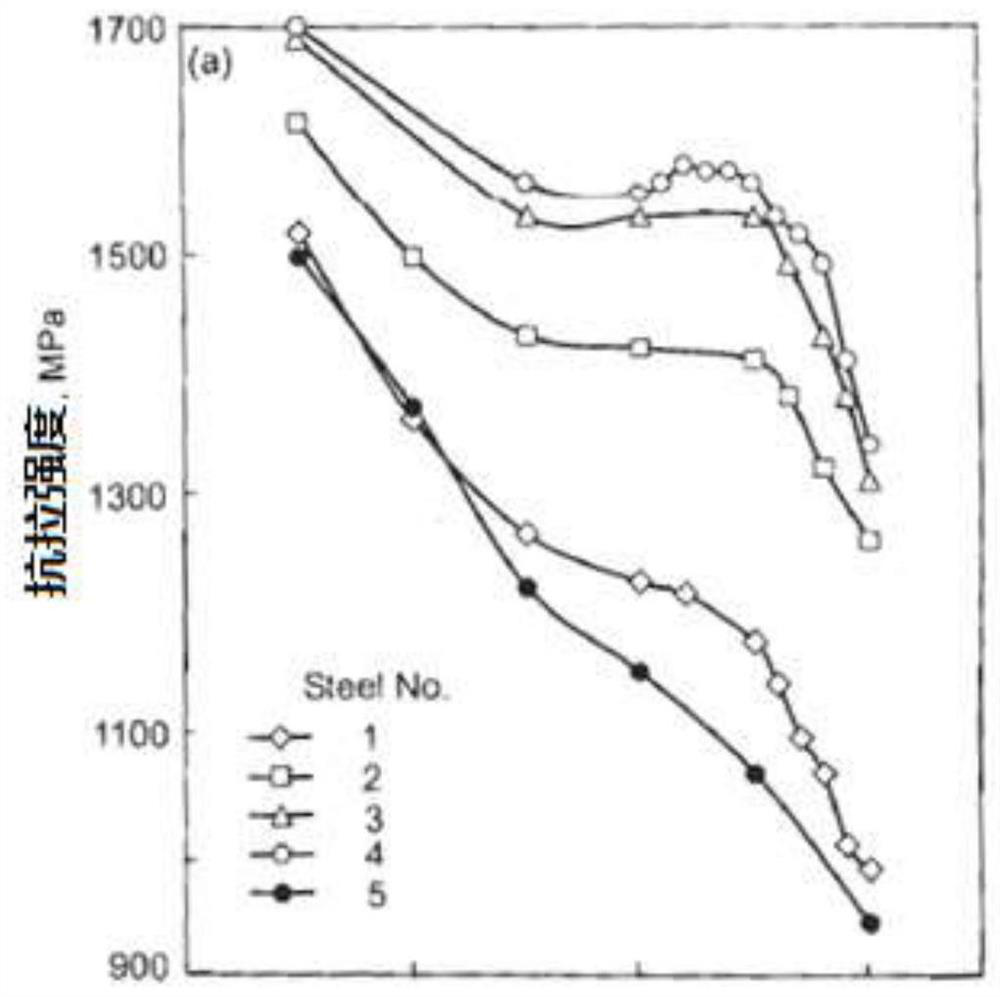

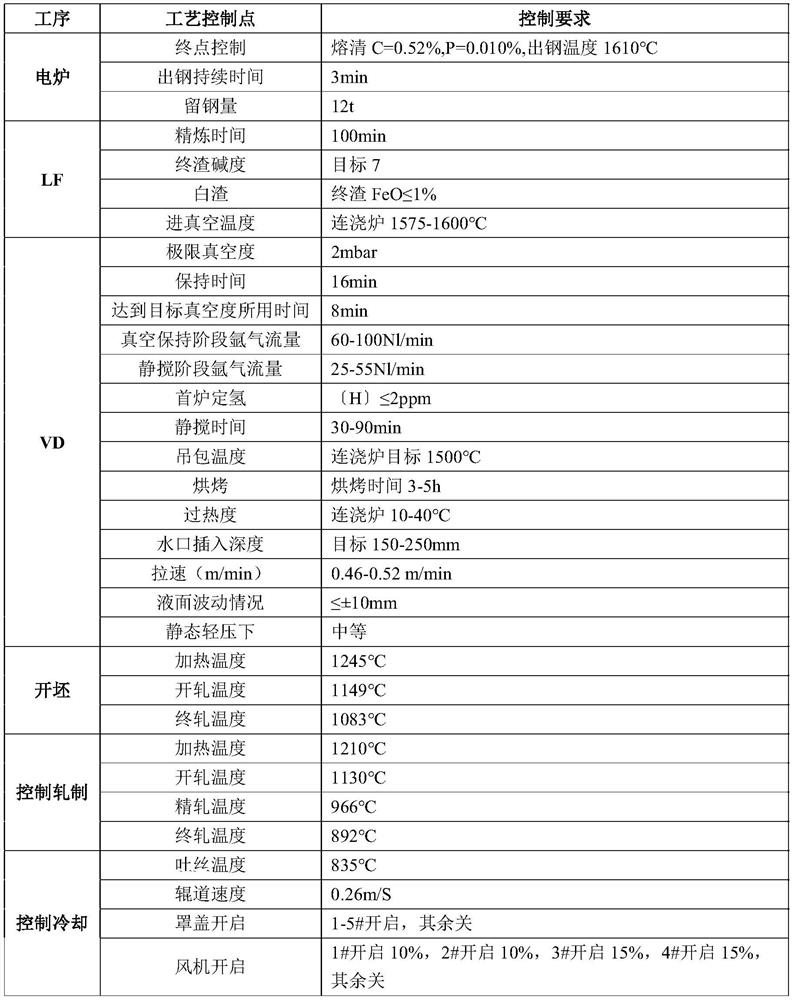

Extra large high strength steel for fastening part and production method

The invention belongs to the field of alloy steel smelting of iron and steel industries, and particularly provides an extra large high strength steel for a fastening part and a production method. The steel for the fastening part comprises, by mass, 0.43-0.47% of C, no more than 0.10% of Si, 0.60-0.90% of Mn, no more than 0.020% of P, no more than 0.010% of S, 0.02-0.06% of Als, 0.90-1.20% of Cr, 0.30-0.60% of Mo, 0.20-0.50% of V, 0.02-0.06% of Nb, 0.001-0.003% of B, and the balance Fe and unavoidable impurities. The production method of the steel comprises the following steps of molten iron desulfurization, converter smelting, deoxidation alloying, argon blowing, LF furnace treatment, continuous casting, casting blank heating, high line or bar rolling and stelmor control cooling. Steel inclusion produced through the method is low in grade, the extra large high strength steel is uniform in texture, good in cold heading property and hardenability and good in delayed fracture resistance, the tensile strength of wire rods reaches above 850 MPa, the depth of hardening layers of produced products reaches above 10 mm, the problem that the diameter of the large-scale fastening part needs to be increased to meet the tolerance requirements is solved to a certain extent, and the method is suitable for manufacturing the large-scale high strength fastening part.

Owner:武汉钢铁有限公司

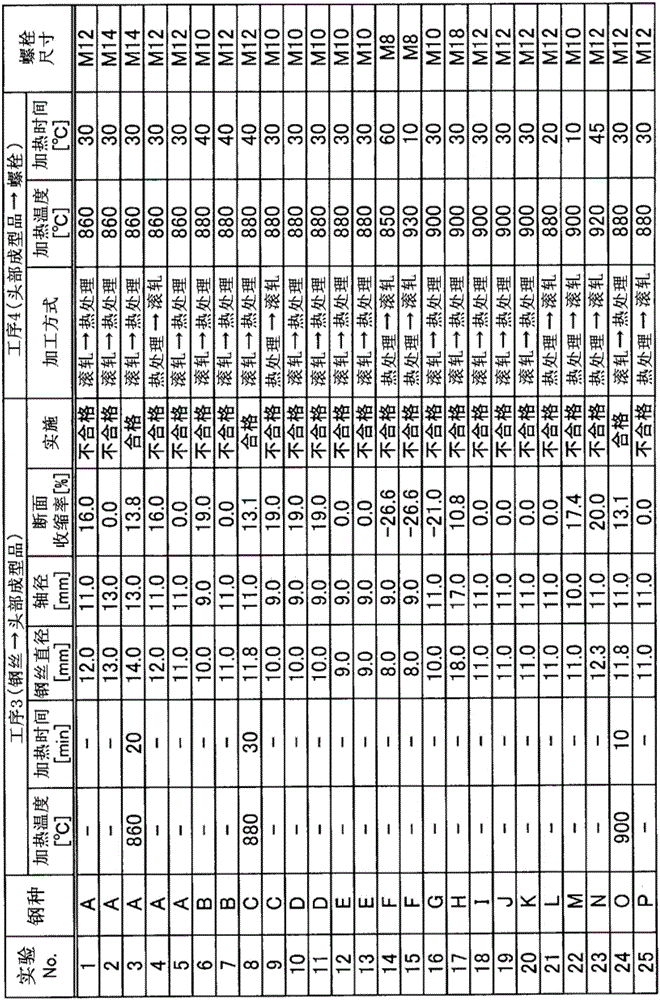

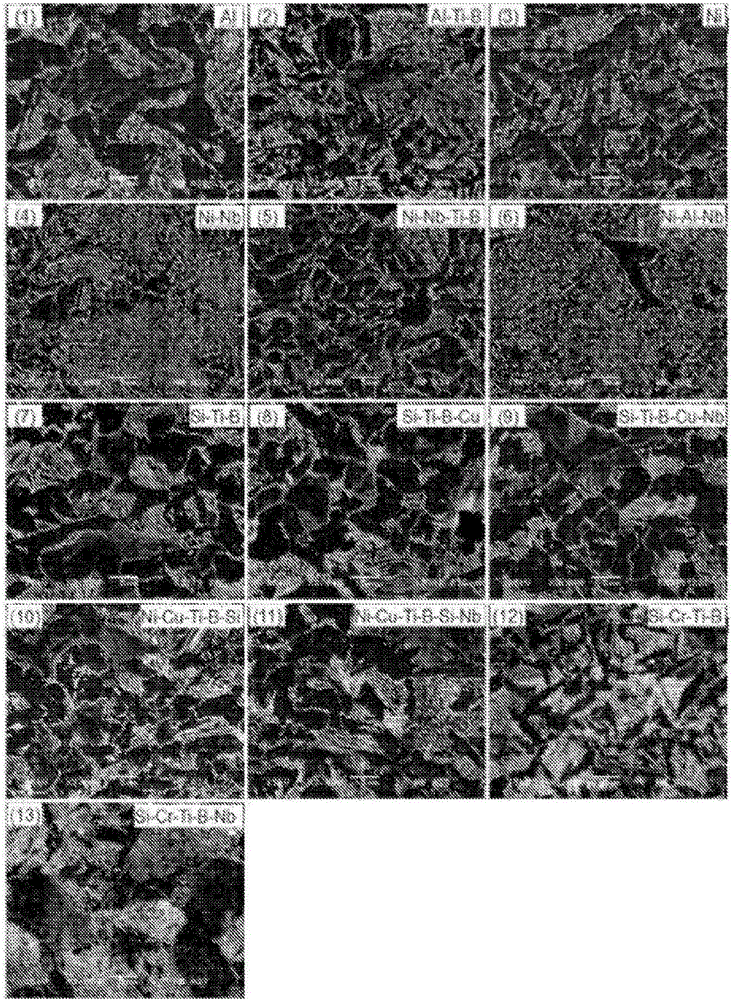

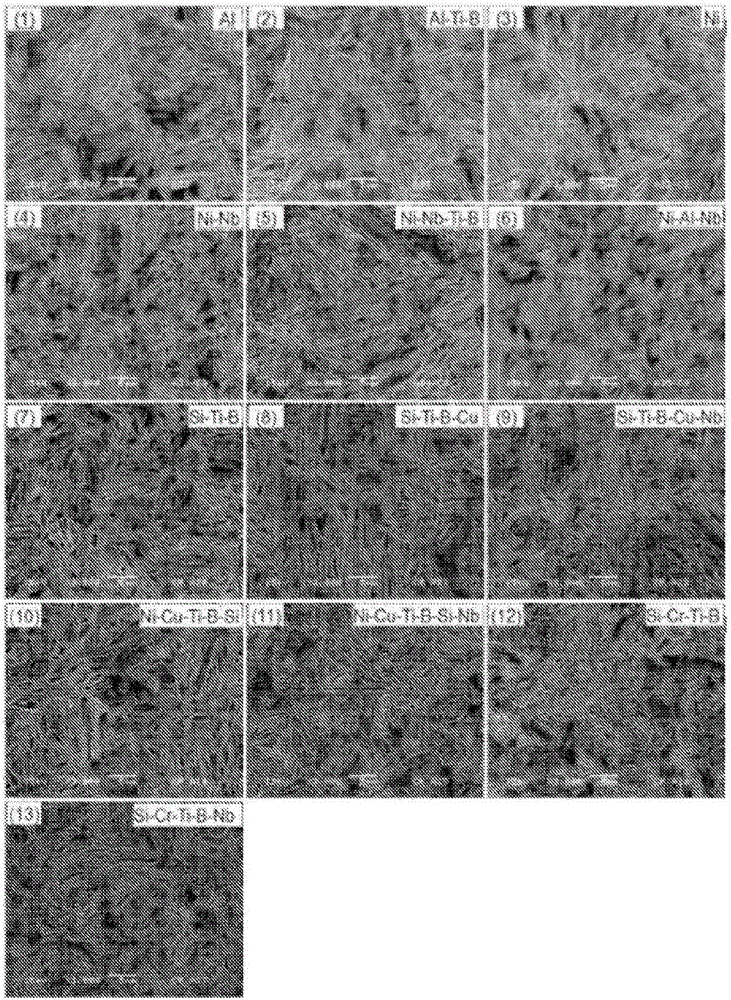

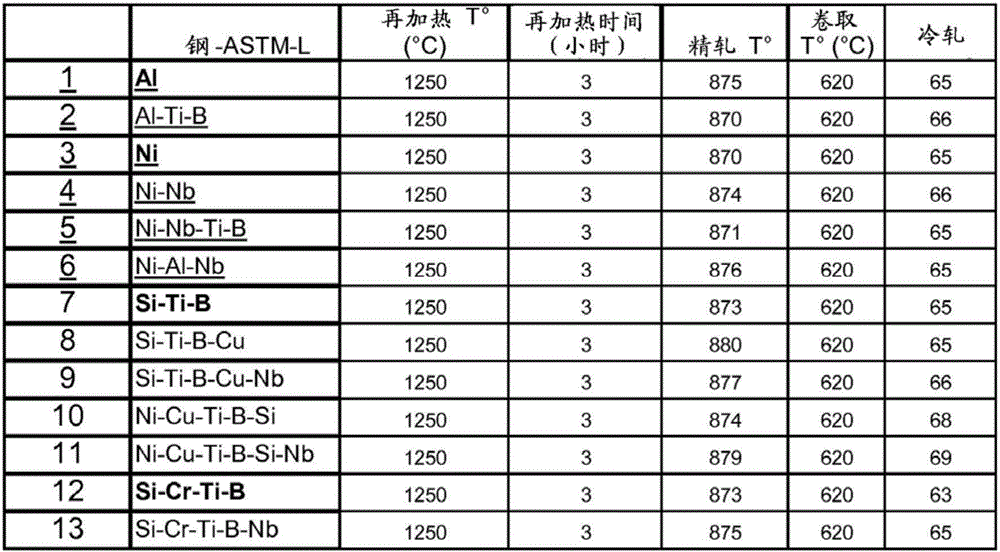

Steel wire for bolts, bolt, and methods for manufacturing same

InactiveCN105793456AImproved delayed fracture resistancePrevent coarsening of crystalsNutsBoltsAustenite grainChemical composition

Provided are: a high-strength bolt that has a tensile strength of 1,000-1,400 MPa and a delayed fracture resistance that is on par with standard steel alloys even when Mo and Cr are omitted or reduced with respect to SCM steel or SCr steel; a steel wire for a bolt that is for producing the aforementioned high-strength bolt; and a useful method for producing the bolt and the steel wire for a bolt. The steel wire for a bolt satisfies a predetermined chemical composition. With regard to the boron content of the surface of the steel wire for a bolt, when the diameter of the steel wire for a bolt is denoted by D0 and the boron content of a D0 / 4 portion of the steel wire for a bolt is 100%, the average proportion of the boron content of the surface of the steel wire for a bolt is 75% or less and the difference between the maximum value and the minimum value of this proportion is 25% or less. The prior austenite grain size number in an area from the surface of the steel wire for a bolt to a depth of 100 [mu]m is no.8 or higher.

Owner:KOBE STEEL LTD

Martensitic steel with delayed fracture resistance and manufacturing method

ActiveCN106164319AImprove toleranceGood formabilityFurnace typesHeat treatment furnacesAustenite grainImpurity

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Rail

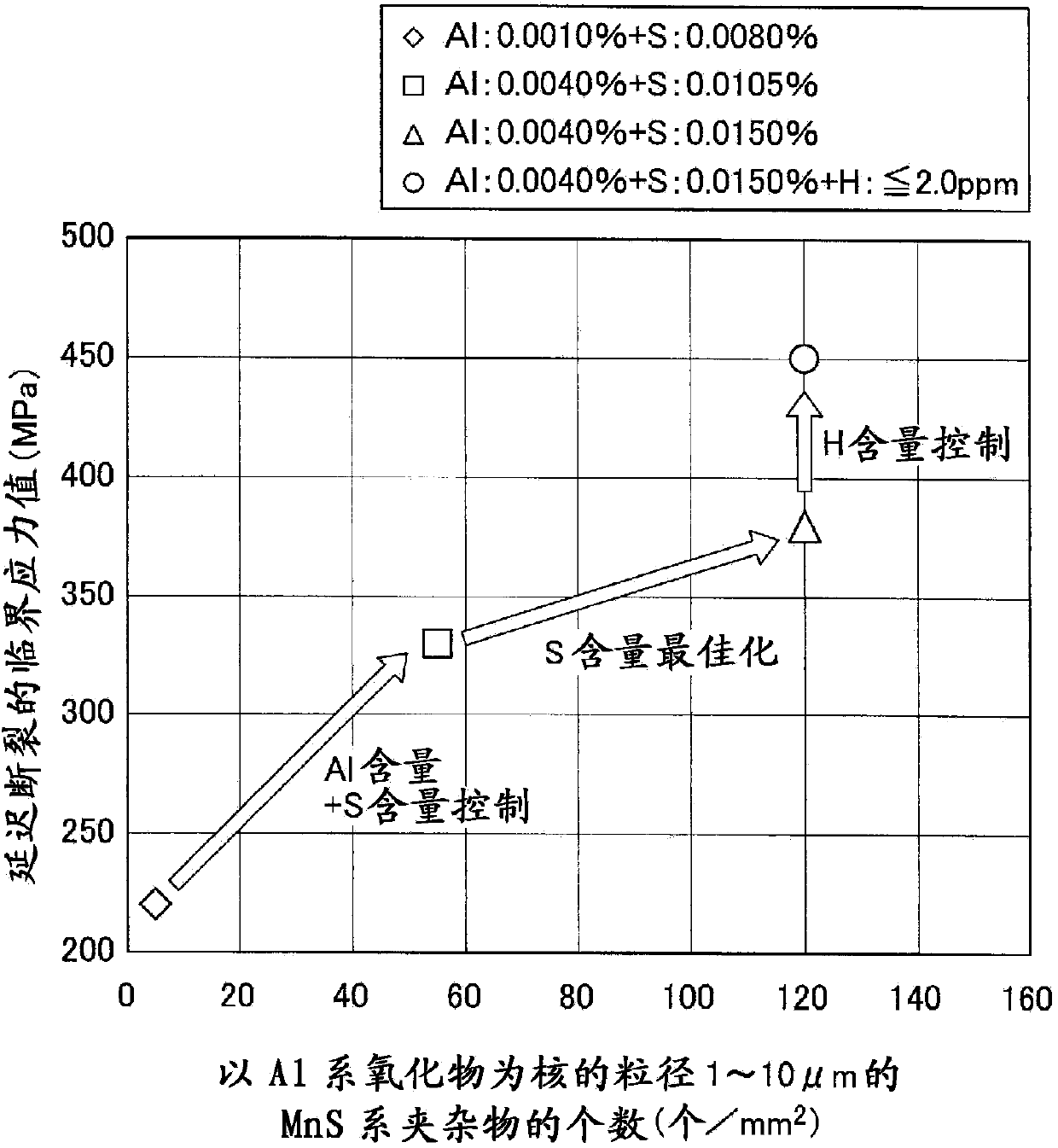

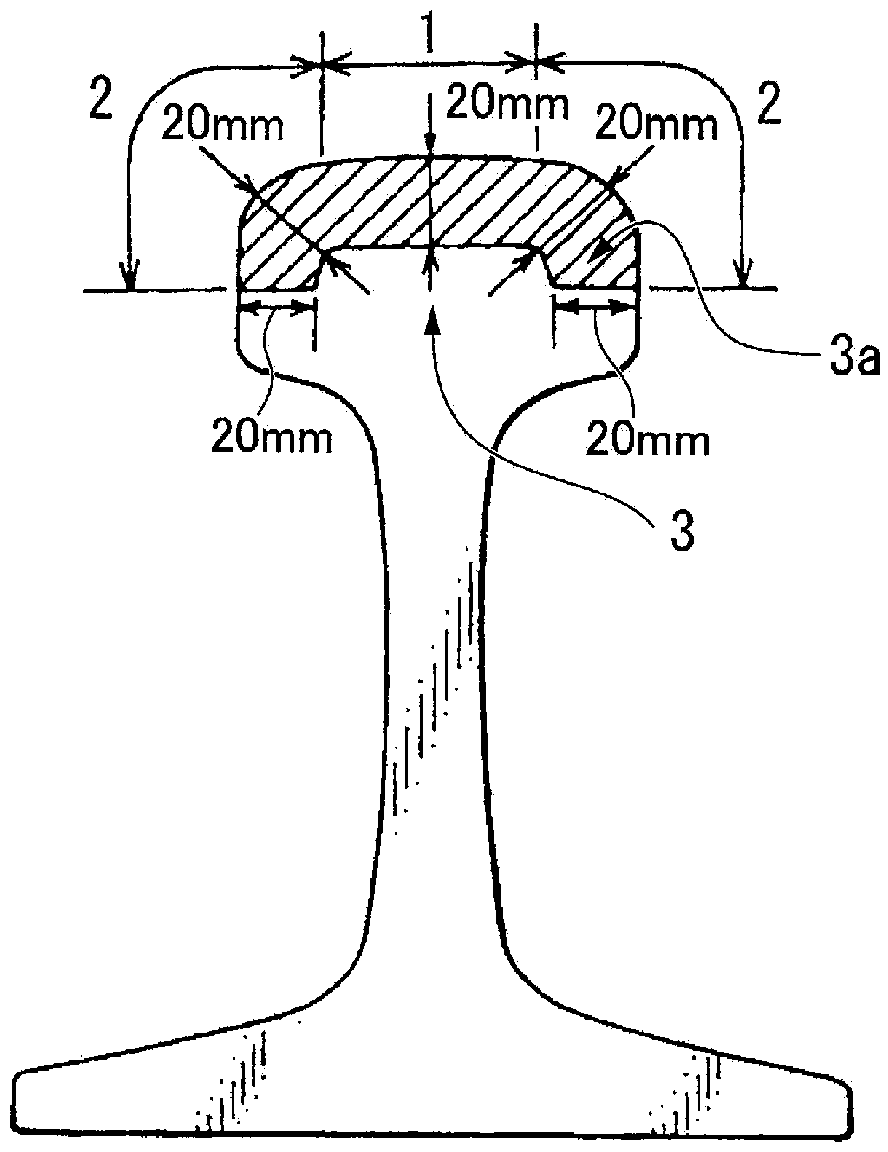

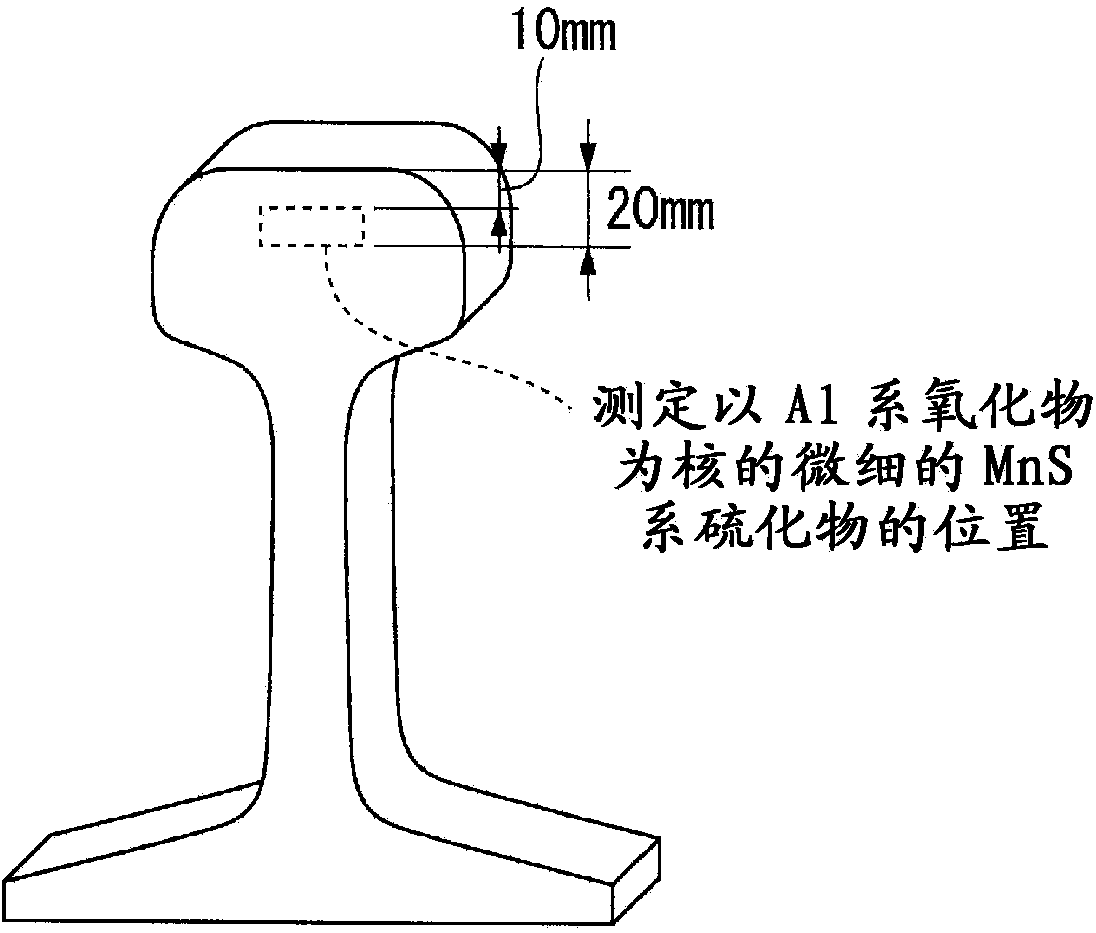

InactiveCN104185690AImproved delayed fracture resistanceExtended service lifeRailsFurnace typesSquare MillimeterPearlite

In this rail, at least 95% of the structure of a head corner part and a head surface part, which constitutes a range up to a depth of 20 mm using the surface of a head top part as a starting point, is a pearlite or bainite structure. The structure in a lateral cross section of the rail contains 20 to 200 MnS sulfides per square millimeter of detected area, the MnS-based sulfides having Al oxides as nuclei and measuring 1 to 10 µm in grain size.

Owner:NIPPON STEEL CORP

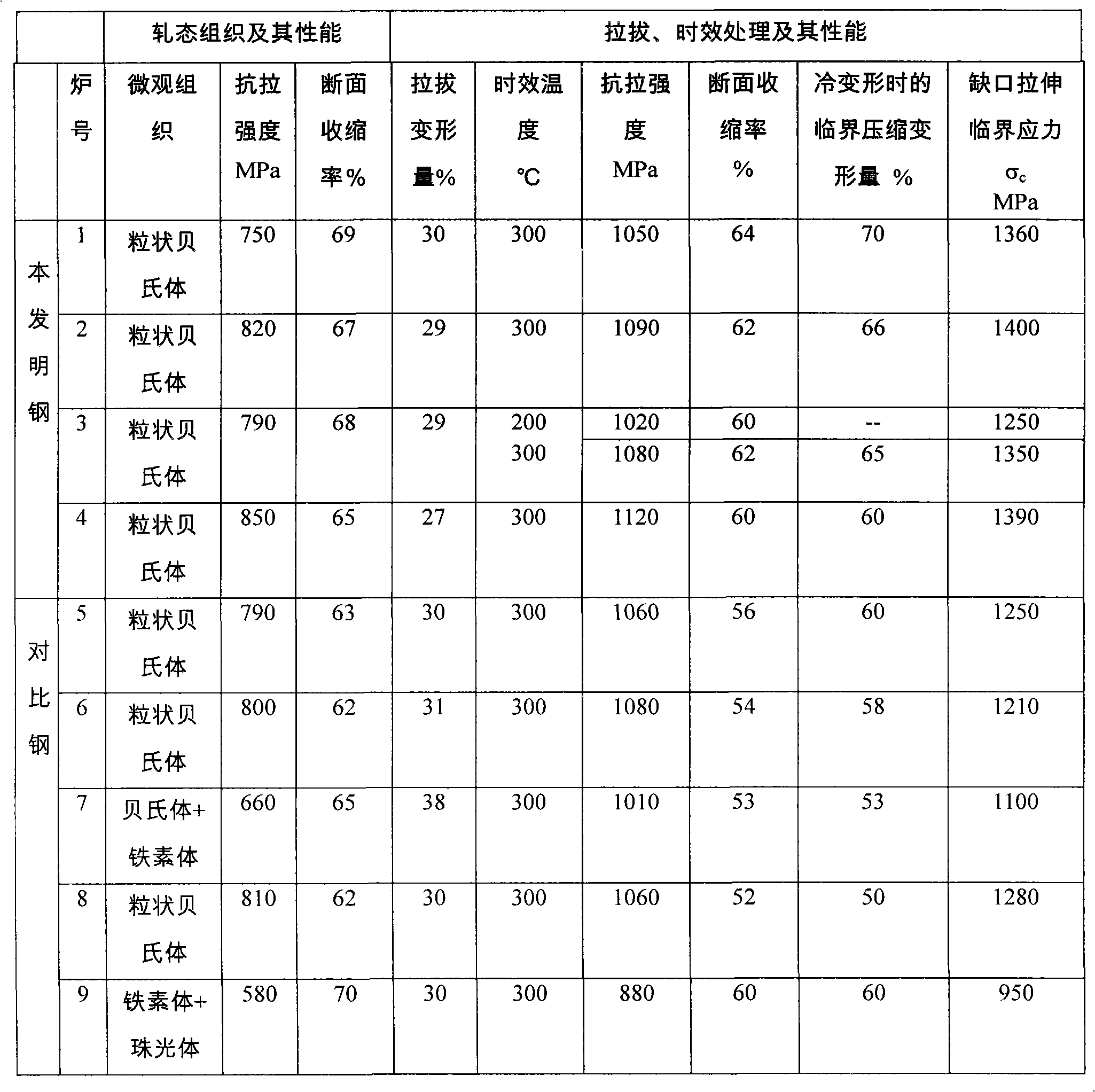

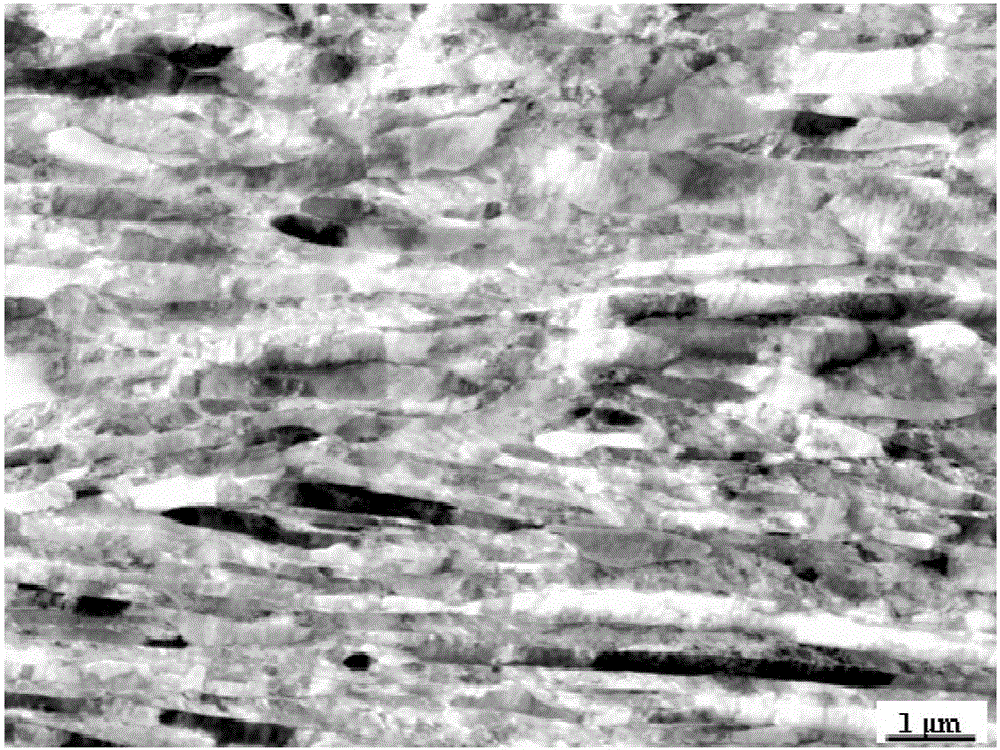

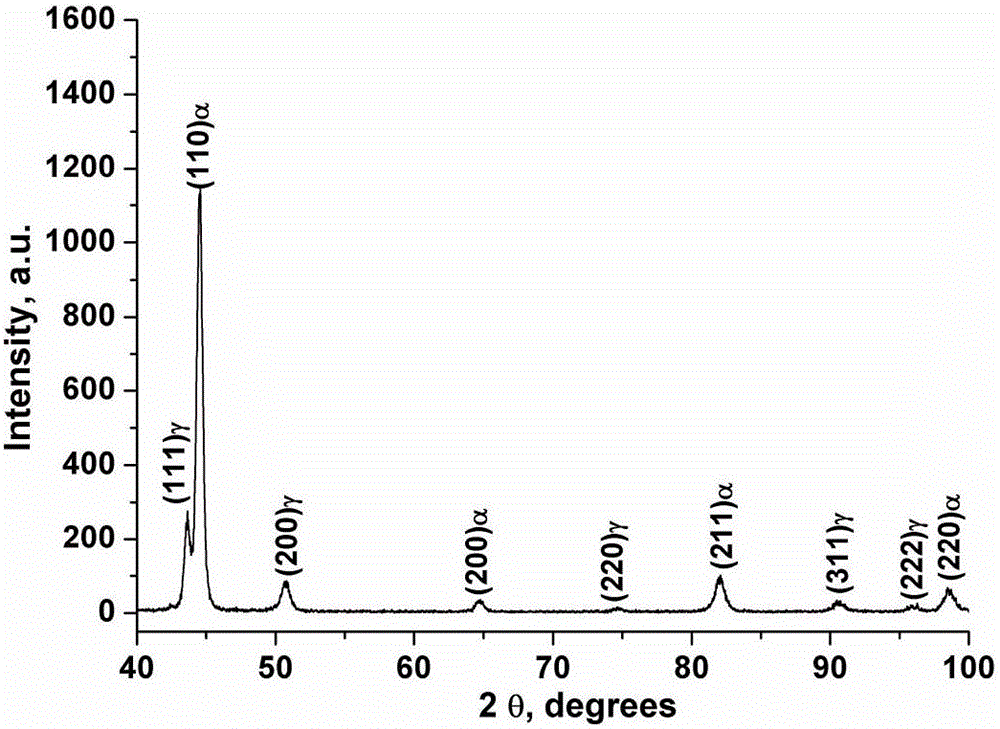

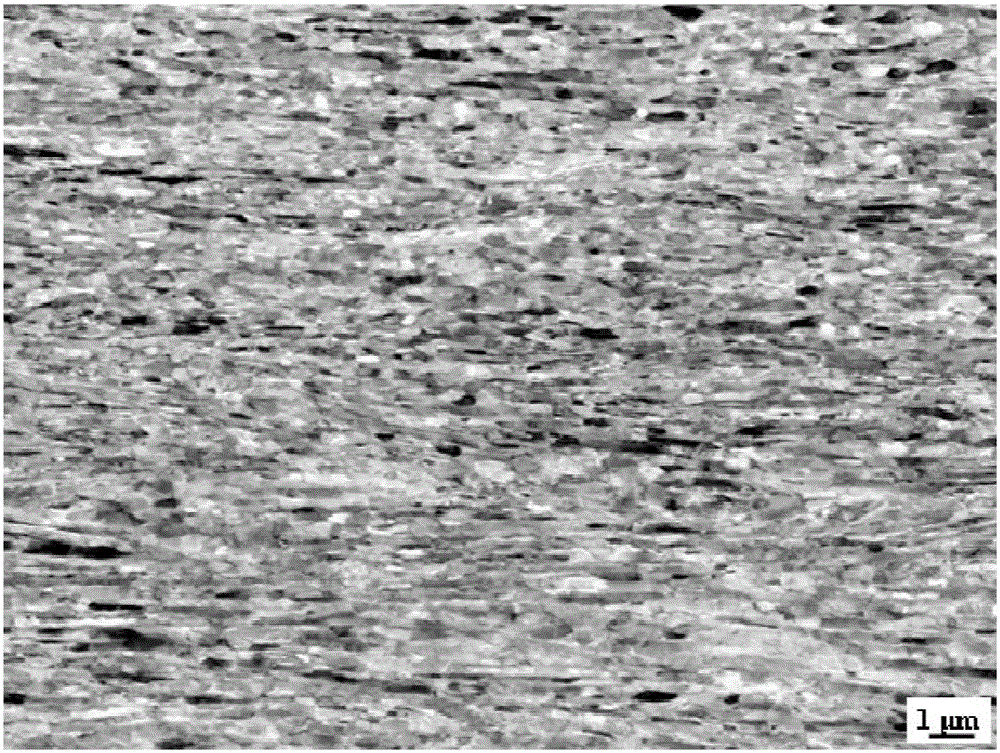

Low-carbon bainitic cold-work-strengthened non-quenched and tempered steel with excellent delayed fracture resistance

ActiveCN101935806AGood plasticity and cold workabilityExcellent resistance to delayed fractureAlloy steelMetallurgy

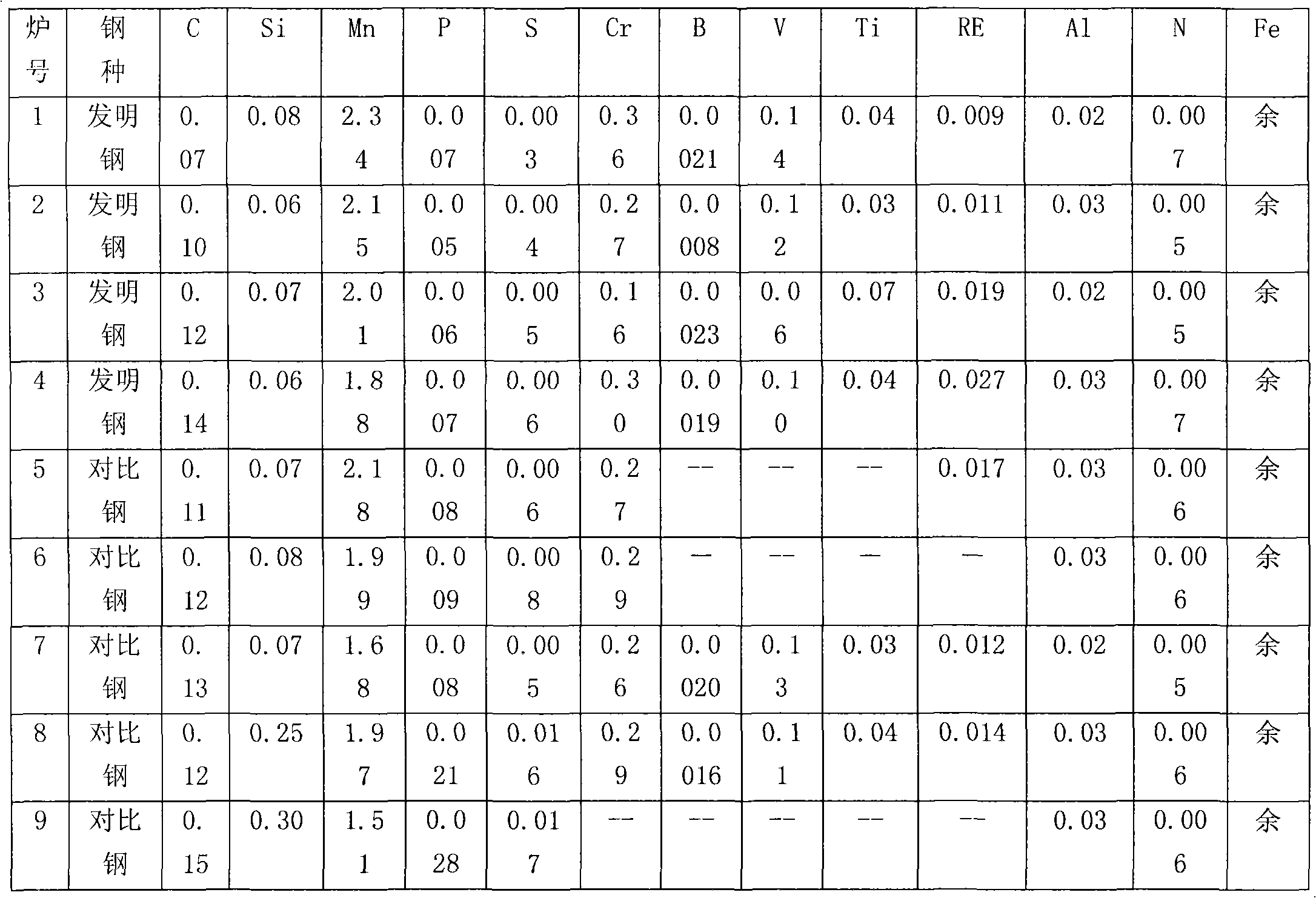

The invention relates to low-carbon bainitic cold-work-strengthened non-quenched and tempered steel with excellent delayed fracture resistance, which belongs to the technical field of alloy steel, and is applicable to manufacturing grade 10.9 high-strength bolts with tensile strength above 1000MPa. The steel comprises the following chemical components by weight percent: 0.06-0.15% of C, not more than 0.10% of Si, 1.80-2.40% of Mn, not more than 0.010% of P, not more than 0.008% of S, 0.10-0.40% of Cr, 0.0005-0.003% of B, 0.05-0.15% of V, 0.01-0.08% of Ti, 0.005-0.03% of RE, 0.01-0.05% of Al, 0.004-0.01% of N and the balance of Fe and other inevitable impurities; simultaneously, the elements of V and Ti further meet the following relational expression of a strengthening parameter theta: V(%) plus Ti(%) is not less than 0.10 and not more than 0.20; and a metallurgical structure is a granular bainite. The low-carbon bainitic cold-work-strengthened non-quenched and tempered steel has the advantages of not only having good plasticity and cold working performance, but also having excellent delayed fracture resistance and being used for manufacturing the grade 10.9 high-strength bolts with the delayed fracture resistance.

Owner:CENT IRON & STEEL RES INST

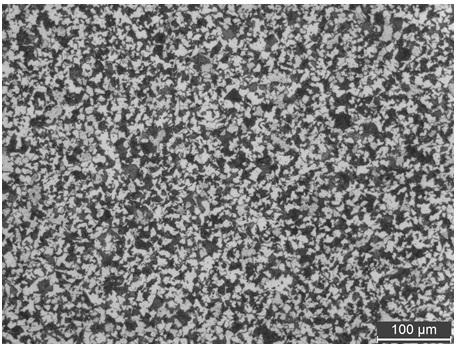

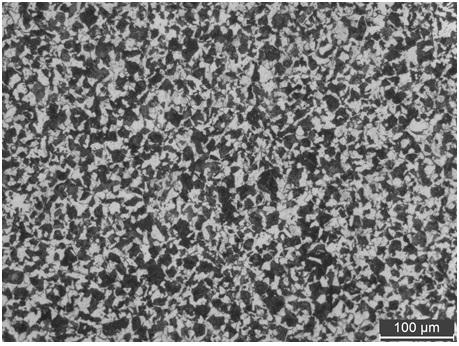

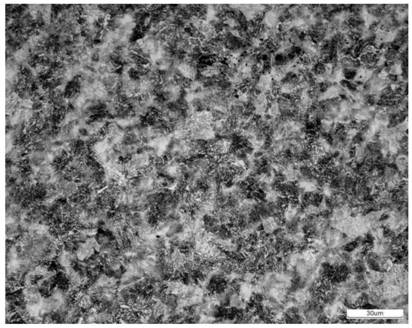

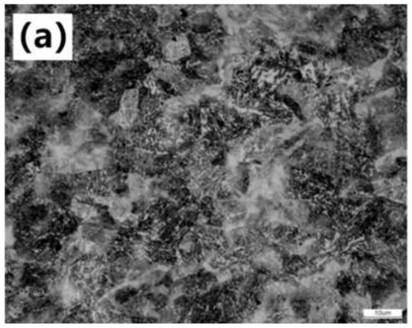

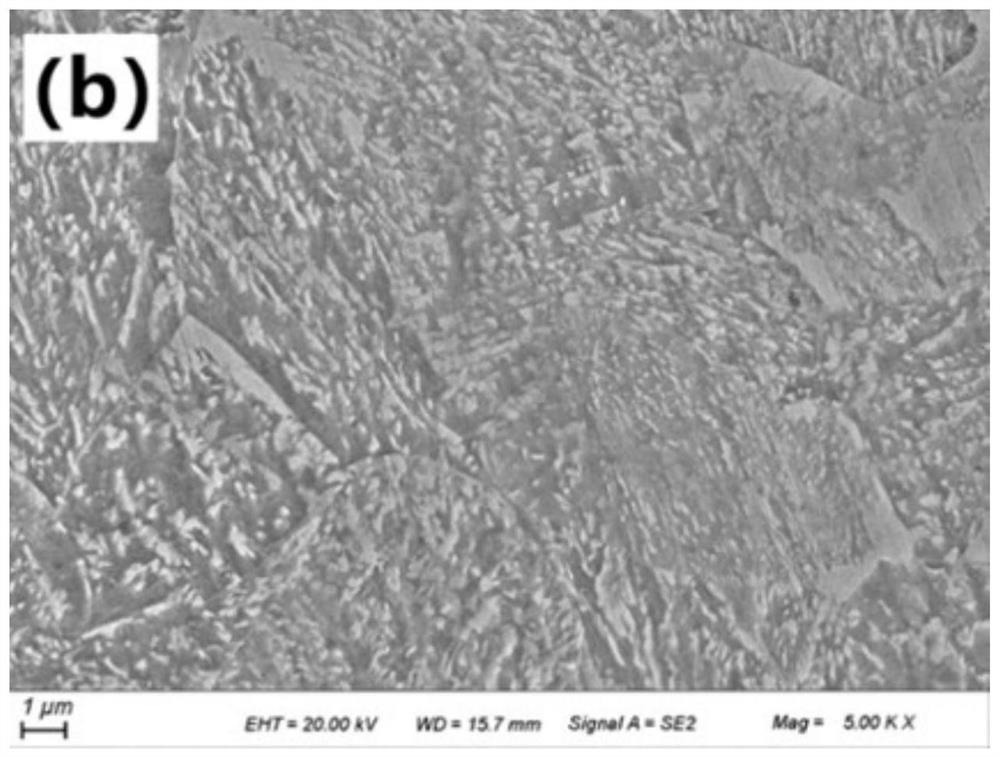

Nano/superfine medium-manganese TRIP (transformation induced plasticity) steel plate and warm-rolling preparation method thereof

The invention relates to a nano / superfine medium-manganese TRIP (transformation induced plasticity) steel plate and a warm-rolling preparation method thereof, belonging to the technical field of ultrahigh-strength steel. The nano / superfine medium-manganese TRIP steel plate comprises the following chemical components in percentage by weight: 0.17-0.25wt.% of C, 0.00-0.50wt.% of Si, 5.00-7.00wt.% of Mn, 1.00-1.50wt.% of Al, 0.014-0.03wt.% of N, 0.00-0.06wt.% of Nb, 0.00-0.25wt.% of Mo, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, forging, carrying out hot rolling, and carrying out warm rolling to obtain the nano / superfine medium-manganese TRIP steel plate; and carrying out heat treatment on the steel plate to obtain the nano / superfine medium-manganese TRIP heat-treated steel plate. By using the warm-rolling technique instead of the typical technique for producing manganese steel, the method provided by the invention has the advantages of simple technique, short production cycle and controllable plate shape. The prepared steel plate has a nano / superfine structure, has the advantages of high strength and favorable properties, and satisfies the target requirements of resource saving, energy consumption reduction, light weight and crash safety enhancement for automobile industry.

Owner:NORTHEASTERN UNIV

Ultrahigh-strength locking riveting rivet cold heading steel wire rod and preparing method thereof

The invention relates to the technical field of cold heading steel, and particularly discloses an ultrahigh-strength locking riveting rivet cold heading steel wire rod and a preparing method thereof.The cold heading steel wire rod comprises chemical components including, by weight percent, 0.33-0.38% of C, smaller than or equal to 0.30% of Si, 0.80-1.10% of Mn, smaller than or equal to 0.020% ofP, smaller than or equal to 0.020% of S, 0.10-0.30% of Cr, 0.010-0.050% of Nb, 0.020-0.050% of Ti, 0.020-0.050% of Al, 0.0010-0.0035% of B and the balance Fe and inevitable impurity elements. In the preparing process, RH vacuum refining is used for removing hydrogen in steel, a hot-rolled blank is placed in a slow cooling pit, the hydrogen content is further reduced, through heating and rolling procedure control, an obtained hot-rolled wire rod has easy spheroidizing annealing and good cold machining performance, and the toughness and delayed fracture resisting performance after heat treatmentare good.

Owner:XINGTAI IRON & STEEL

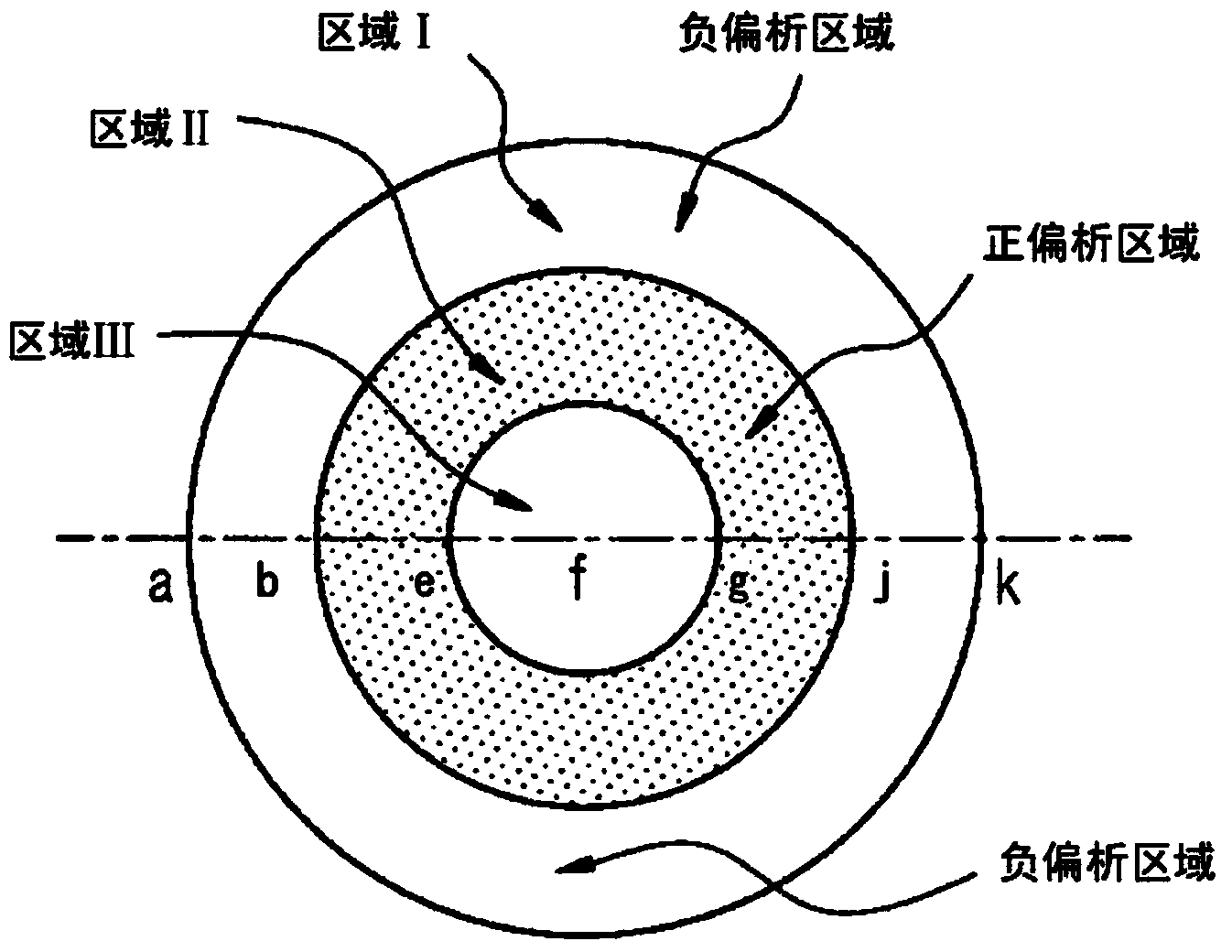

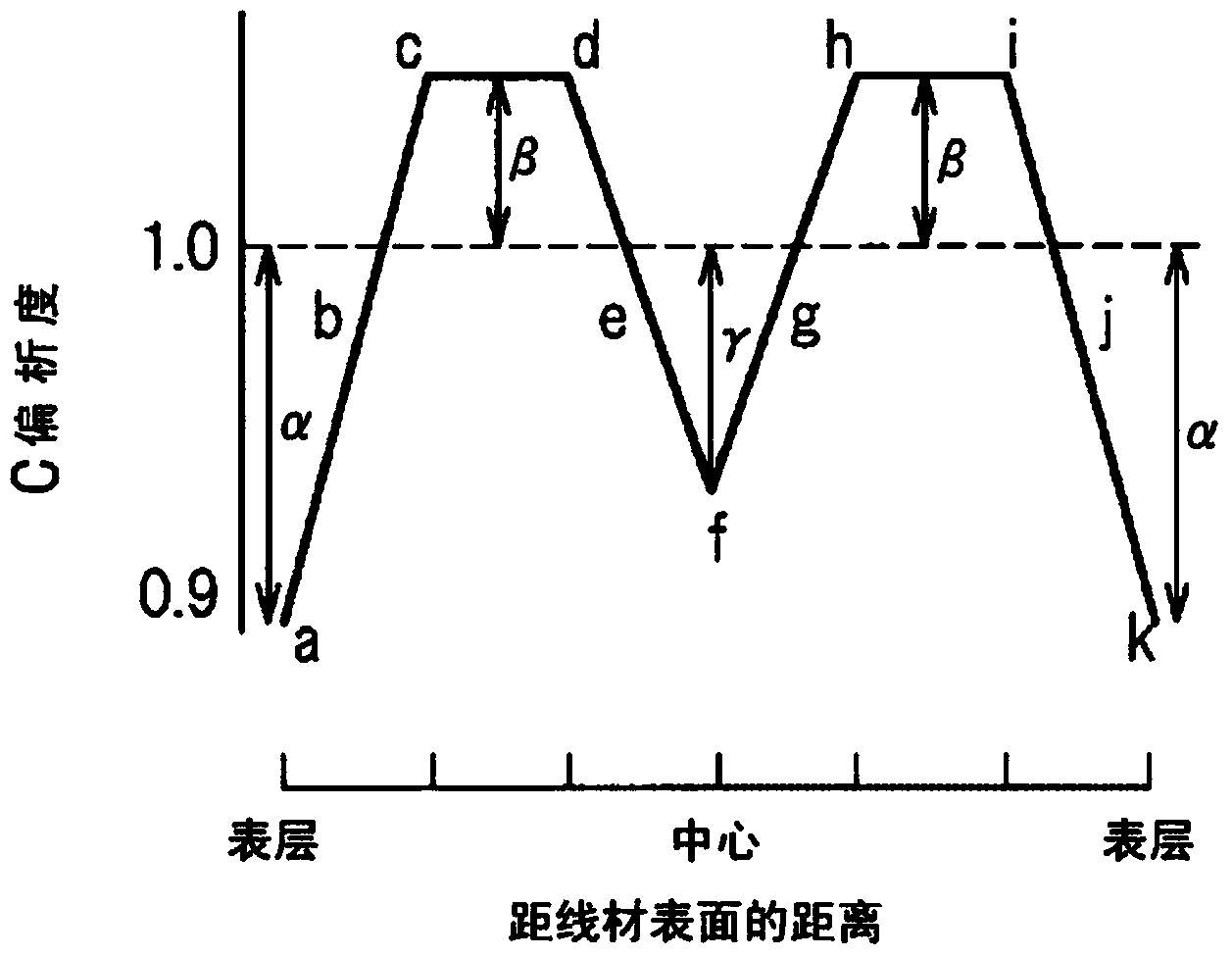

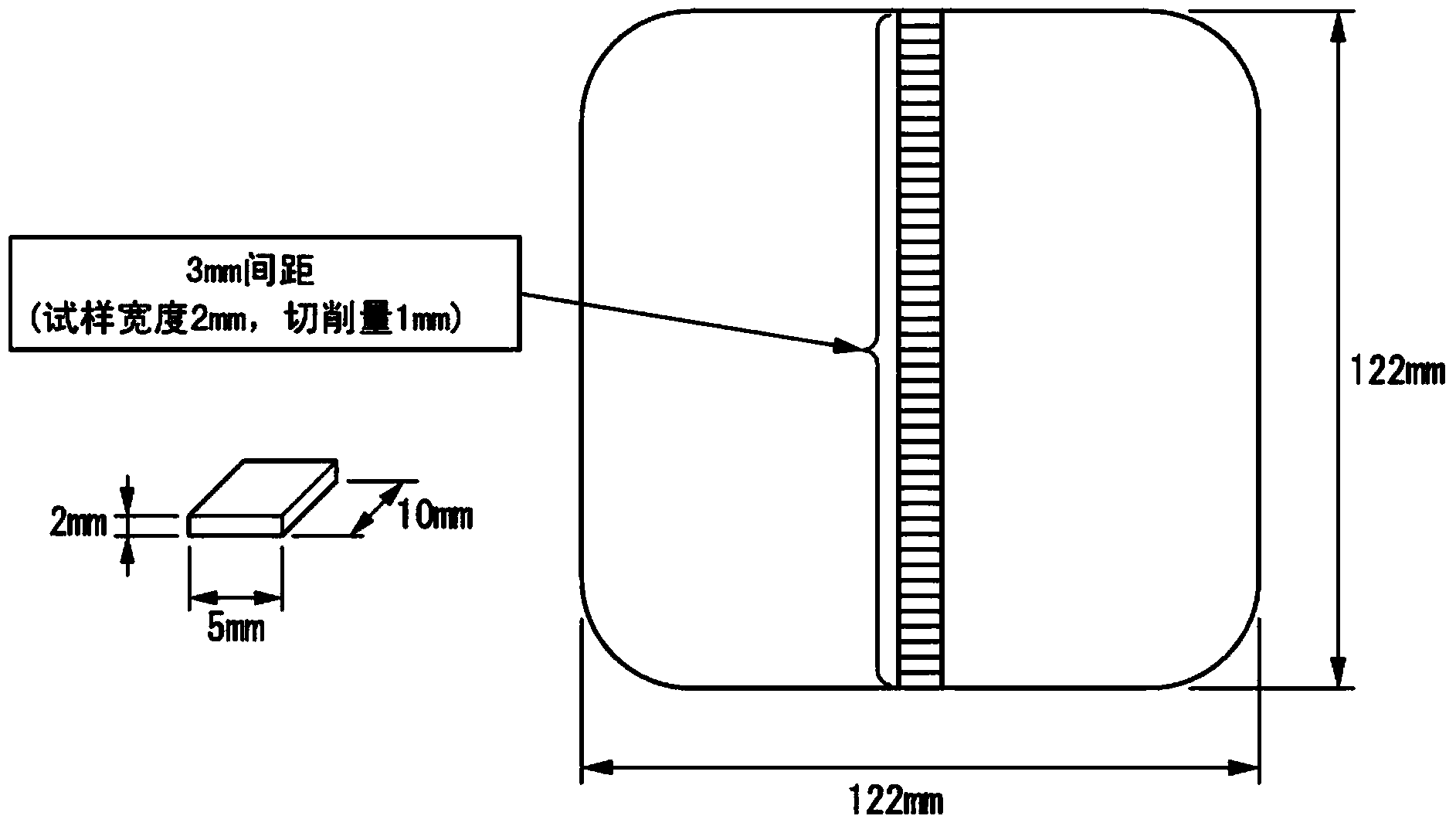

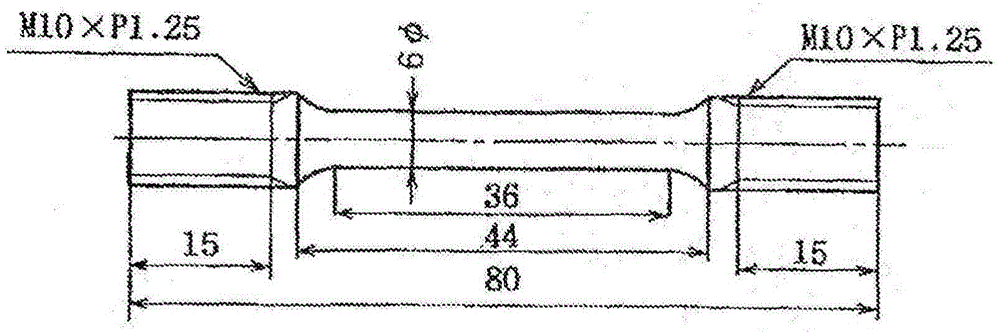

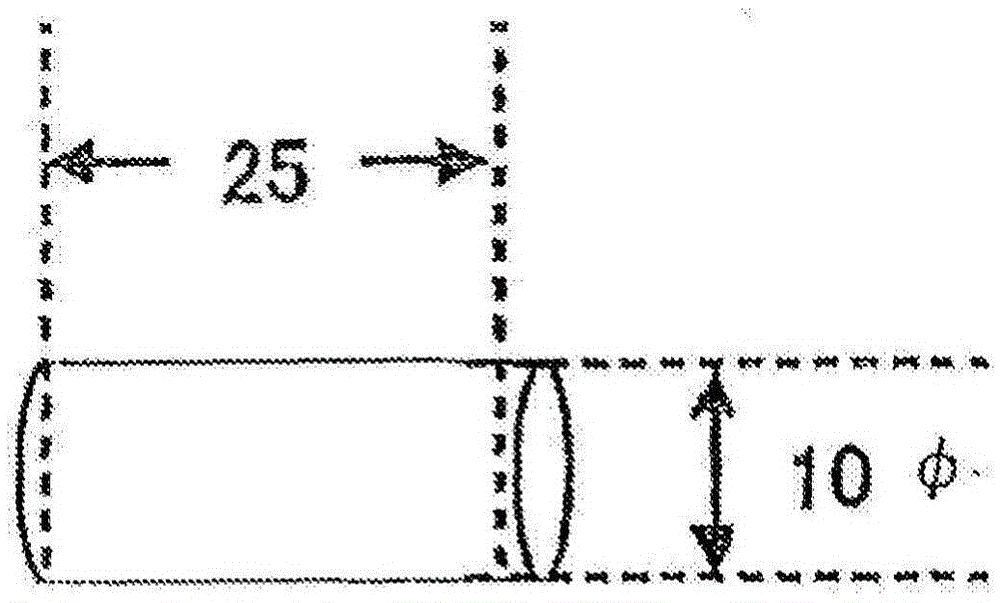

Wire rod, steel wire using same, and billet

ActiveCN103717326AImproved properties of delayed fractureExcellent drawing processabilityFurnace typesMetal rolling arrangementsWire rodEngineering

If an area that is formed concentrically inward from a surface of a wire rod and whose cross section ratio with respect to the cross sectional area of a cross section of the wire rod is between 13% and 56% is defined as area I, an area that widens concentrically about the central axis of the wire rod and whose cross section ratio with respect to the cross sectional area of the wire rod is between 3% and 11% is defined as area III, and an area between area I and area III is defined as area II, then area I is a first negative segregation portion where the degree of C segregation with respect to the average C concentration of the wire rod is between 0.75 and 0.95, area II is a positive segregation portion where the degree of C segregation is between 1.00 and 1.10, area III is a second negative segregation portion where the degree of C segregation is between 0.80 and 0.95; and the wire rod has a sandwich structure in which the first negative segregation portion, the positive segregation portion, and the second negative segregation portion are placed in order from the surface.

Owner:NIPPON STEEL CORP

Dynamic tdd ul/dl configuration indication for tdd eimta in carrier aggregation

ActiveCN105579603AGood formabilityImproved delayed fracture resistanceLoad modified fastenersFurnace typesTime-division multiplexingComputer science

Systems, methods, apparatuses, and computer program products for time division duplex (TDD) uplink / downlink (UL / DL) configuration indication for TDD interference management and traffic adaptation (eIMTA) are provided. One method includes providing, by a network node, a time division duplex (TDD) uplink / downlink (UL / DL) configuration indication pattern. The TDD UL / DL configuration indication pattern may be used to indicate multiple TDD UL / DL configurations in DCI format C associated with the certain configured carriers andthe concrete fixed downlink subframe index.

Owner:KOBE STEEL LTD

Nut production process

InactiveCN109531071AReduce contentIncrease contentFurnace typesHeat treatment furnacesChemical compositionHardness

The invention discloses a nut production process. The process comprises the following steps that S1, through a casting process, a workblank part is made, and the workblank part comprises, by weight ratio, 0.28 to 0.32 of C, 0.32 to 0.45 of Mn, 0.05 to 0.09 of Zn, 0.15 to 0.25 of Si, 0.01 to 0.03 of La, not larger than 0.015 of P, not larger than 0.015 of S, 0.50 to 1.20 of Ni, 0.15 to 0.25 of Sn,0.15 to 0.25 of Al, 0.2 to 0.5 of Mo and the balance iron; S2, the workblank part is put into a mold cavity, cold heading extrusion molding is carried out, and the nut workblank is made; S3, the nut workblank is turned and tapped; S4, heat treatment is carried out; S5, surface treatment is carried out, cleaning oil removal is carried out, blackening treatment is carried out, static electricity manner is adopted to spray an anti-corrosion agent to the nut, and the sprayed nut is cured to obtain a nut finished product. The nut produced through the nut production process has the hardness value and strength value needed by the high-strength nut, is not prone to being corroded and long in service life.

Owner:重庆旺达汽车零部件有限公司

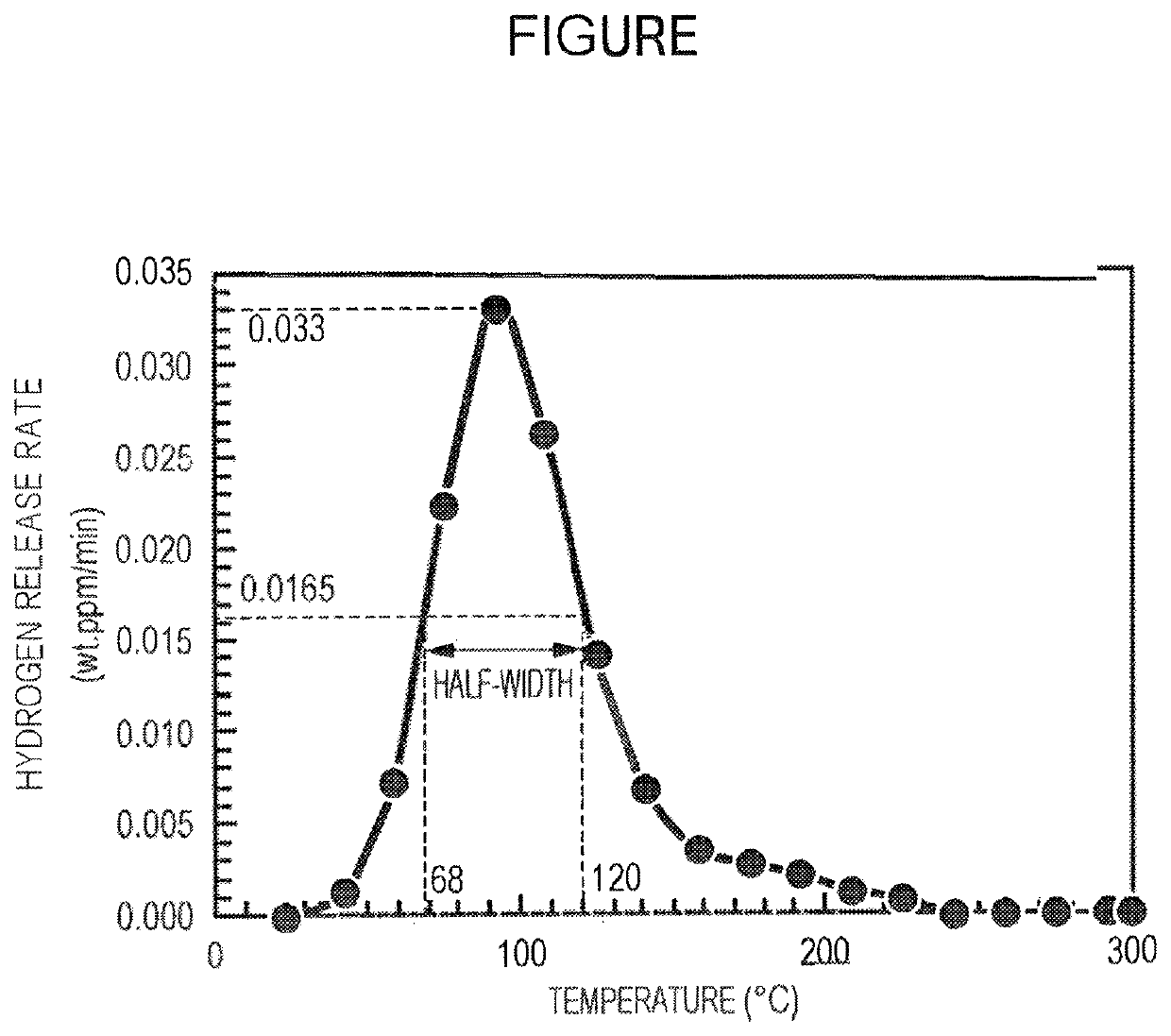

High-strength galvanized steel sheet and method for producing the same

ActiveUS20200032364A1Excellent delayed fracture resistanceHigh strengthHot-dipping/immersion processesFurnace typesHydrogen contentMartensite

Provided are a high-strength galvanized steel sheet having excellent delayed fracture resistance by reducing the diffusible hydrogen content in the steel and a method for producing the same.The high-strength galvanized steel sheet includes a steel sheet having a prescribed composition and a microstructure including martensite and tempered martensite, the total area fraction of the martensite and the tempered martensite being 30% or more, and a galvanizing layer formed on the surface of the steel sheet. The diffusible hydrogen content in the high-strength galvanized steel sheet is 0.50 wt. ppm or less. The half-width of the hydrogen release peak of the high-strength galvanized steel sheet is 70° C. or less. The diffusible hydrogen content and the half-width of the hydrogen release peak are determined by a prescribed analysis method.

Owner:JFE STEEL CORP

High-strength bolt and machining method thereof

InactiveCN110656286AGood plasticityImproved delayed fracture resistanceFurnace typesMetallic material coating processesUltimate tensile strengthMachining

The invention discloses a high-strength bolt. The bolt comprises the following components, by weight, of: 0.30% to 0.38% of C, 0.5% to 0.7% of Mn, 0.28% to 0.32% of SI, 0.018% to 0.024% of P, 0.018% to 0.024% of S, 0.3% to 0.5% of Ni, 0.05% to 0.10% of Sn, 0.1% to 0.2% of Cu, 0.2% to 0.3% of Mo, 0.9% to 1.2% of Cr, 0.03% to 0.05% of Mg, 0.02% to 0.05% of B and the balances Fe and inevitable impurities. The invention further discloses a machining method for the high-strength bolt. The bolt which adopts the components in percentage and the the machining method disclosed by the invention is excellent in strength value, can effectively resist corrosion and prolongs the service life of the bolt.

Owner:JIANGSU YONGHAO HIGH STRENGTH BOLT

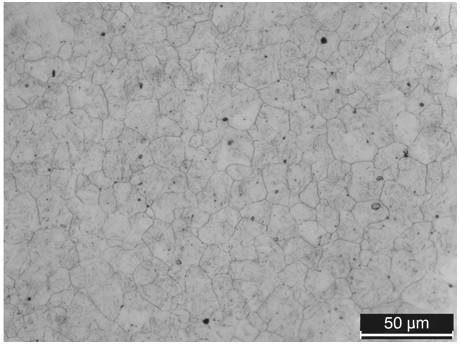

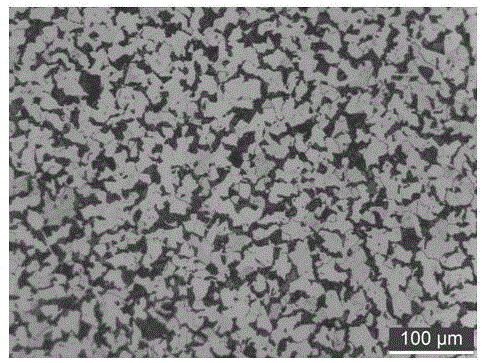

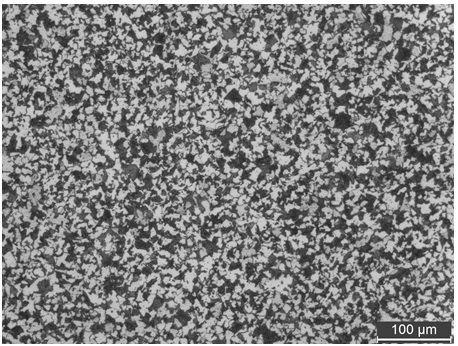

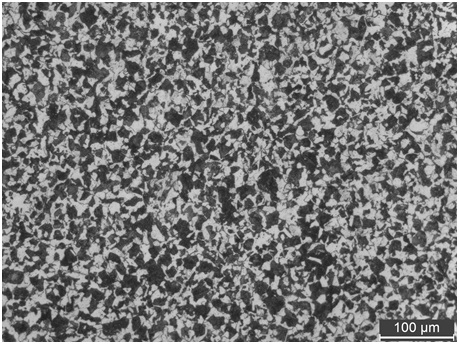

Cold forging steel for high-strength large-dimension bolt and production method thereof

InactiveCN105132815AMeet the requirements of high-strength fastenersEasy to processChemical compositionHardness

The invention discloses cold forging steel for a high-strength large-dimension bolt and a production method thereof. The production method comprises a heating process, a rolling process and a cooling process. Steel billet adopted by the production method consists of the following chemical components in percentage by weight: 0.17-0.23% of C, 0.70-1.00% of Mn, 0.30% of Si, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 0.65-1.20% of Cr, 0.0008-0.0050% of B, 0.01-0.06% of Ti and the balance of Fe and inevitable impurity elements; and in the heating process, the steel billet is heated to 1000-1100 DEG C and the temperature-preserving time is 80-130 minutes. According to the production method, by optimizing components and the processes, a produced coil has relatively low strength and hardness, meets process properties of carrying out cold processing in a non-annealed mode, has good hardenability, meets large-dimension bolt hardenability requirements, and further has certain delayed fracture resistance; and a microstructure consists of uniform ferrites and pearlite, has tensile strength of 500-560 MPa, and area reduction greater than or equal to 60%, so that 1 / 3 cold upsetting is qualified, and the production cost is low. The cold forging steel has good cold processing performance and hardenability.

Owner:XINGTAI IRON & STEEL

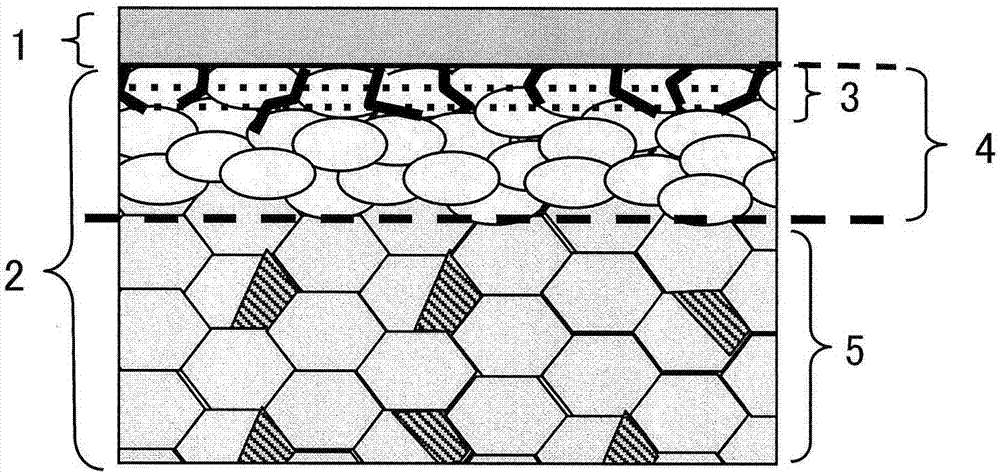

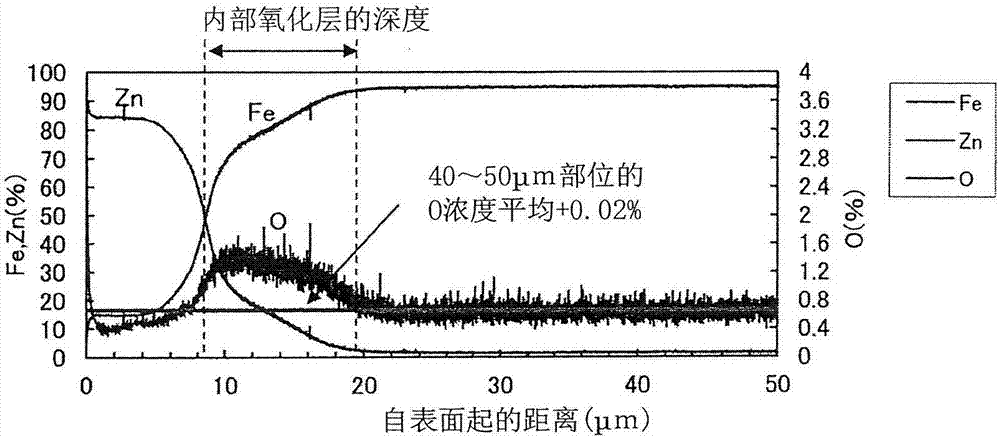

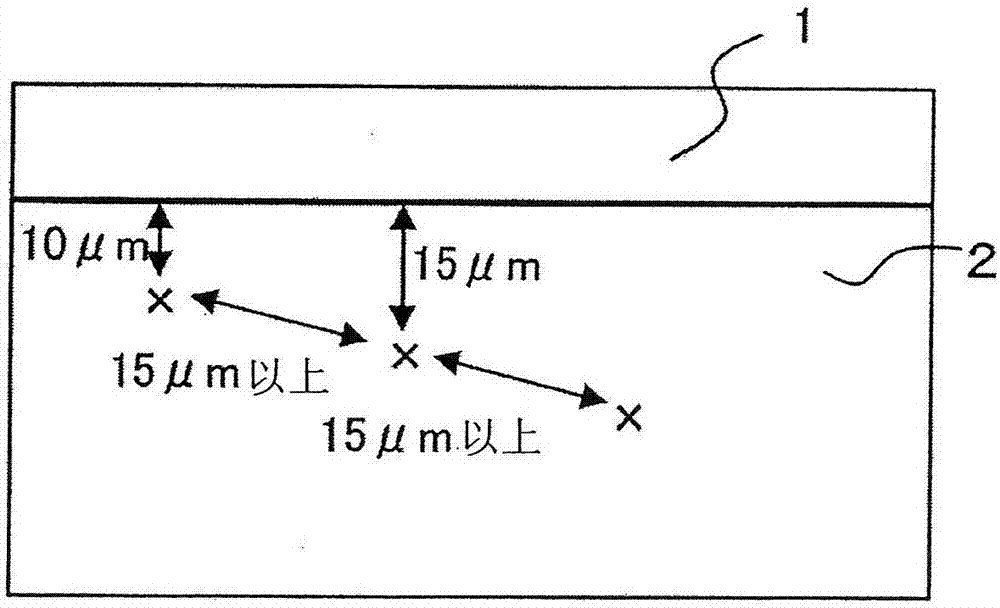

High-strength plated steel sheet having excellent plating properties, workability, and delayed fracture resistance, and method for producing same

InactiveCN107109574AInhibition of hydrogen embrittlementUniform strengthHot-dipping/immersion processesFurnace typesSoft layerInternal oxidation

Owner:KOBE STEEL LTD

A 1040mpa grade weather-resistant bolt with anti-delayed fracture

ActiveCN108070796BImproved delayed fracture resistanceReasonable regulationScrewsManufactured materialThermal treatment

Provided is a delay-fracture-resisting 1040 MPa-grade weather-proof bolt. The Delay-fracture-resisting 1040 MPa-grade weather-proof bolt is prepared from the chemical ingredients including, by mass percent, 0.21% to 0.32% of C, 0.10% to 0.50% of Si, 0.60% to 1.00% of Mn, 0.008% to 0.020% of P, not larger than 0.005% of S, 0.82% to 1.20% of Cr, 0.25% to 0.50% of Ni, 0.25 to 0.50% of Cu, 0.05% to 0.20% of Mo, 0.015% to 0.060% of Nb, 0.015% to 0.090% of V, 0.008% to 0.035% of Ti, 0.0008% to 0.0035% of B, 0.015% to 0.040% of Al, 0.003% to 0.007% of Ca, 0.015% to 0.045% of Zr, 0.010% to 0.045% of Re and the balance Fe and inevitable impurities. According to a method for preparing the bolt, the conventional high-purity smelting-continuous casting-rolling technology is mainly adopted, and metal raw materials are prepared into a steel material for the delay-fracture-resisting weather-proof bolt; and raw material acid pickling, steel pulling, blanking, end face chamfering, head cropping, head forming, head chamfering, shot blasting, semi-finished product surface treatment, hole shrinking, thread rolling, thermal treatment and finished product surface treatment are carried out according to aconventional method. The bolt is resistant to delay fractures and atmospheric corrosion and relatively low in cost.

Owner:YANSHAN UNIV +1

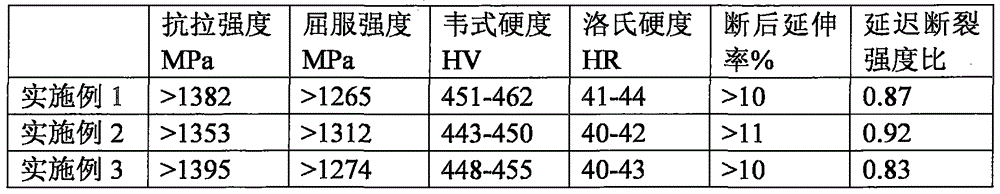

Heat-resistant 12.9-grade fastener steel for rail transit and heat treatment process thereof

ActiveCN110923580ALow notch sensitivityImproved delayed fracture resistanceQuenching agentsMechanical propertyRail transit

The invention discloses heat-resistant 12.9-grade fastener steel for rail transit. The 12.9-grade fastener steel comprises the following components in percentage by weight: C 0.25%-0.35%, Si 0.20%-0.50%, Mn 0.50%-0.70%, Cr 1.10%-1.40%, Mo 0.60%-0.80%, V 0.20%-0.40%, W 0.80%-1.20%, Al 0.015%-0.040%, Co 0.40%-0.80%, P <=0.015%, S <= 0.015%, O <= 0.0015%, N <= 0.006%, the balance Fe and other unavoidable impurities. The invention also discloses a heat treatment process of the 12.9-grade fastener steel, after heat treatment, the normal-temperature mechanical property and the 450-DEG C high-temperature mechanical property of the steel reach 12.9 grade, the steel has low notch sensitivity and good delayed fracture resistance, and is suitable for manufacturing heat-resistant 12.9-grade high-strength bolts for rail transit.

Owner:MAANSHAN IRON & STEEL CO LTD

High-strength bolt machining method

The invention discloses a high-strength bolt machining method. The method comprises the step of S1, a rod blank is prepared through a casting process, wherein the rod blank is controlled to comprisesthe following chemical components of, by weight, 0.28-0.32% of C, 0.32-0.45% of Mn, 0.05-0.15% of V, 0.15-0.25% of Si, 0.01-0.03% of W, less than or equal to 0.015% of P, less than or equal to 0.015%of S, 0.50-1.20% of Ni, 0.15-0.25% of Sn, 0.15-0.25% of Cu, 0.15-0.35% of Mo and the balance iron. A bolt produced by the high-strength bolt machining method reaches the hardness value and the strength value which are required by the high-strength bolt, the delay fracture and the fatigue fracture problems of the bolt under the high strength are solved, during use, connection is reliable, breakageis not prone to occurrence, the service life of the bolt is prolonged, and the use requirements of all industries in the society on the high-strength bolt are met.

Owner:重庆旺达汽车零部件有限公司

A kind of steel wire rod for 14.9 grade high-strength fasteners and its preparation method

The invention discloses a 14.9-grade steel wire rod for high-strength fasteners and a preparation method thereof. Its chemical composition contains: C: 0.44-0.48%, Si: ≤0.20%, Mn: 0.40-0.80% in mass percentage , P: ≤0.015%, S: ≤0.010%, Cr: 1.0‑1.5%, Mo: 0.6‑0.8%, Nb: 0.03‑0.06%, V: 0.2‑0.5%, Ti: 0.03‑0.06%, Ni: ≤0.20%, Cu: ≤0.20%, Alt: 0.010‑0.050%, N: 0.0080‑0.0160%, H: ≤0.00015%, O: ≤0.0015%, the balance is Fe and impurities; the steel wire rod can improve the finished product The tensile strength of the bolt is high, and it has excellent resistance to delayed fracture.

Owner:NANJING IRON & STEEL CO LTD

A cold-heading steel wire rod for ultra-high-strength locking rivets and its preparation method

ActiveCN111349856BEasy spheroidizing annealingImproved cold working propertiesWire rodChemical composition

The invention relates to the technical field of cold heading steel, and specifically discloses a cold heading steel wire rod for ultra-high strength locking rivets and a preparation method thereof. The weight percentage of the chemical composition of the cold heading steel wire rod is C 0.33-0.38%, Si ≤0.30%, Mn 0.80~1.10%, P≤0.020%, S≤0.020%, Cr 0.10~0.30%, Nb 0.010~0.050%, Ti 0.020~0.050%, Al 0.020~0.050%, B 0.0010~0.0035%, The rest is Fe and unavoidable impurity elements. During the preparation process, the hydrogen in the steel is removed by RH vacuum refining, and the hot-rolled billet is placed in the slow cooling pit to further reduce the hydrogen content. Through the control of heating and rolling processes, the obtained hot-rolled wire rod has easy spheroidizing annealing and good cold working Performance, good toughness and delayed fracture resistance after heat treatment.

Owner:XINGTAI IRON & STEEL

Bolt and fastened structure

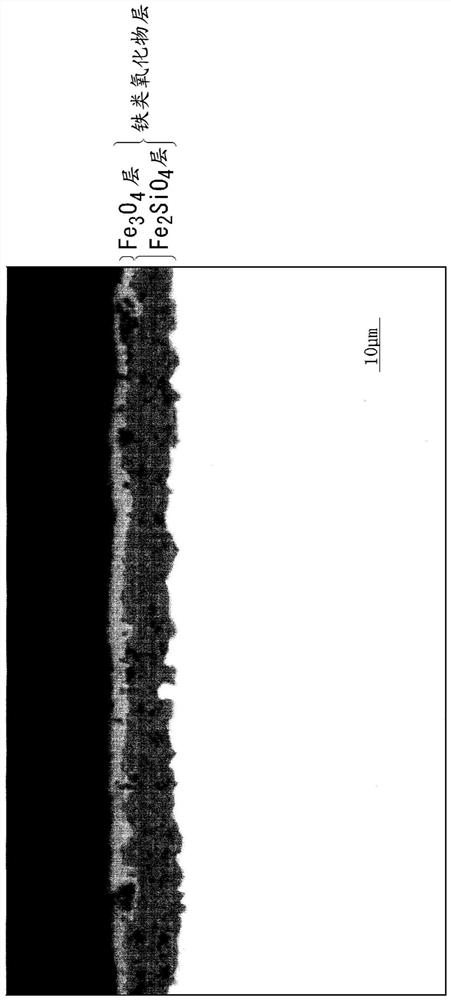

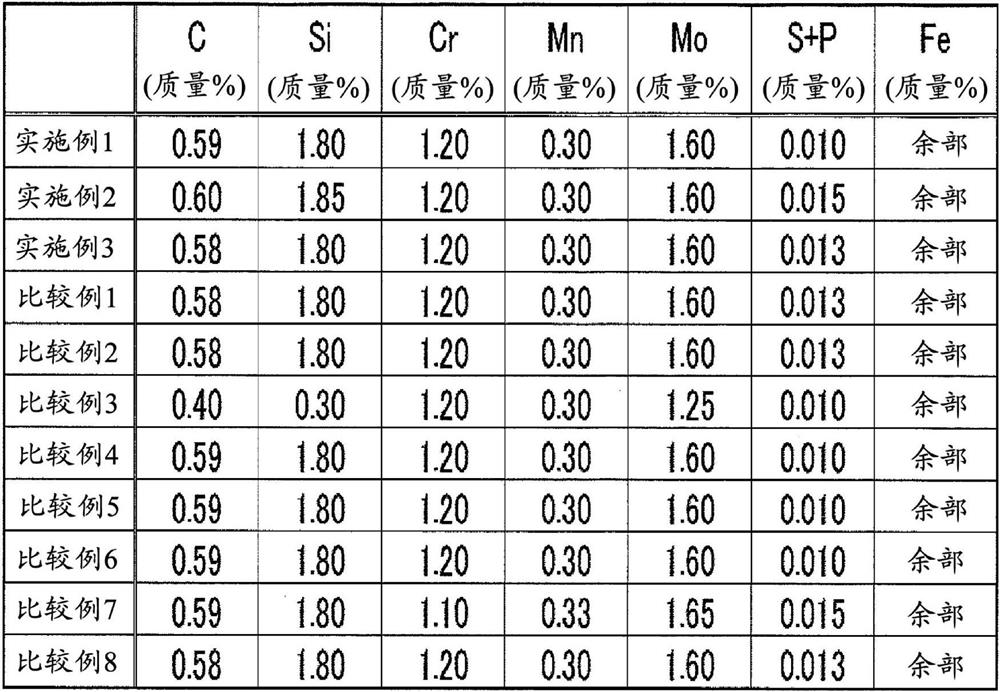

A bolt according to the present invention has such a chemical composition in which 0.50 to 0.65% by mass inclusive of carbon (C), 1.5 to 2.5% by mass inclusive of silicon (Si), 1.0 to 2.0% by mass inclusive of chromium (Cr), 0.2 to 1.0% by mass inclusive of manganese (Mn) and 1.5 to 5.0% by mass inclusive of molybdenum (Mo) are contained, the total amount of phosphorus (P) and sulfur (S) which areimpurities is 0.03% by mass or less and the remainder is made up from iron (Fe), and the bolt has, formed on the surface thereof, an iron-based oxide film having a thickness of 3 to 20 [mu]m inclusive, has excellent delayed fracture resistance, and can achieve a stable tightening axial force.

Owner:NISSAN MOTOR CO LTD

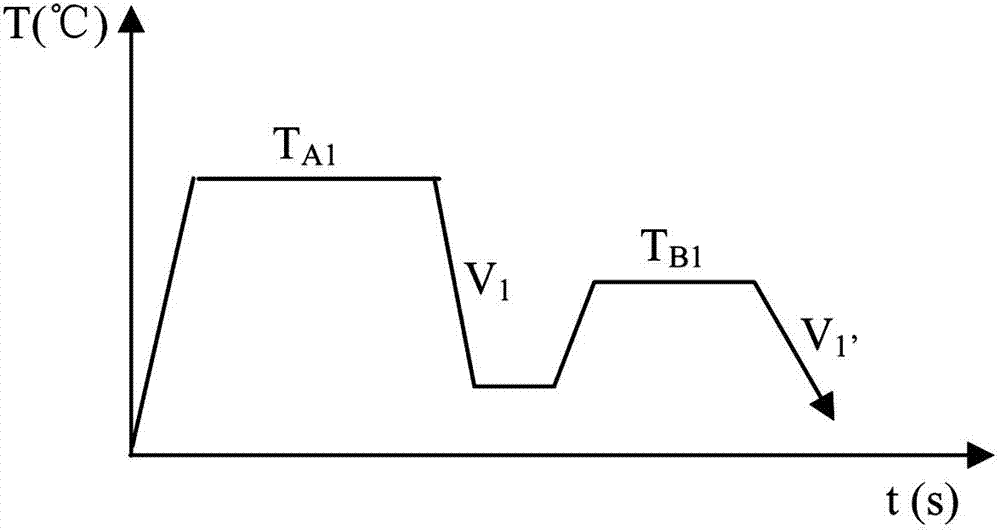

High-strength heat-treated steel bar and manufacturing method thereof

ActiveCN102851467BReduce slackImproved delayed fracture resistanceIncreasing energy efficiencyStress relaxationRebar

The invention discloses a high-strength heat-treated steel bar and a manufacturing method thereof. The steel bar is processed through an induction heating process. During cooling, the steel bar is first annealed to a two-phase region, and then rapid cooling treatment is carried out. The steel bar satisfies mechanical performances of: a tensile strength of 1200-1800MPa, an elongation rate higher than 10%, and a yield strength ratio no higher than 0.9. The relaxation performance of the steel bar satisfies that: when initial stress is 70% of a nominal tensile strength, a stress relaxation rate of 1000h is no higher than 2%.

Owner:北京钢研新冶工程技术中心有限公司

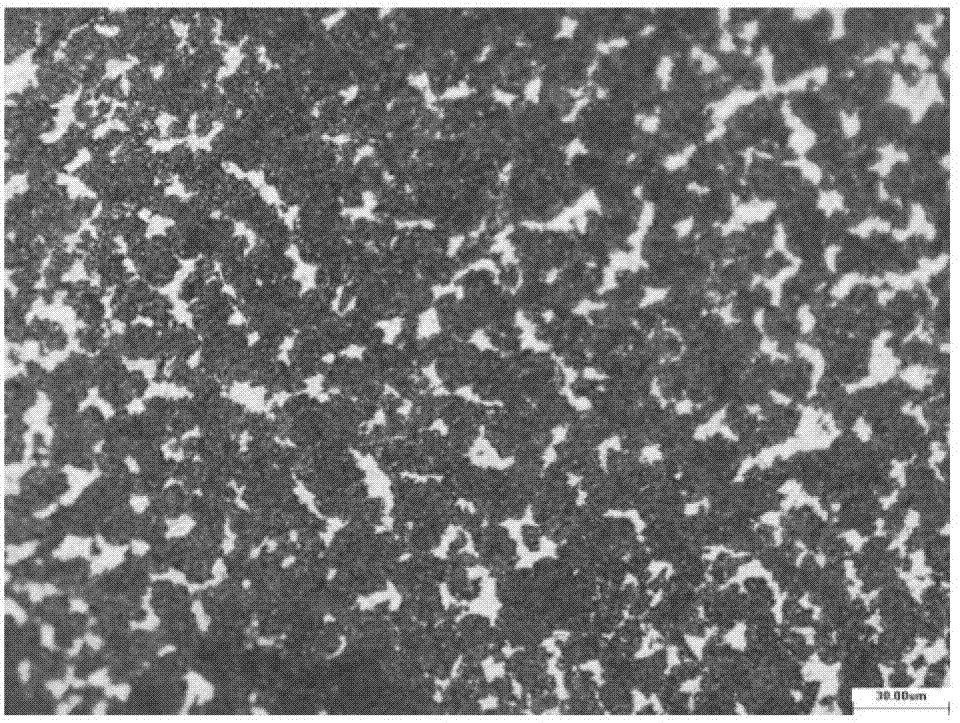

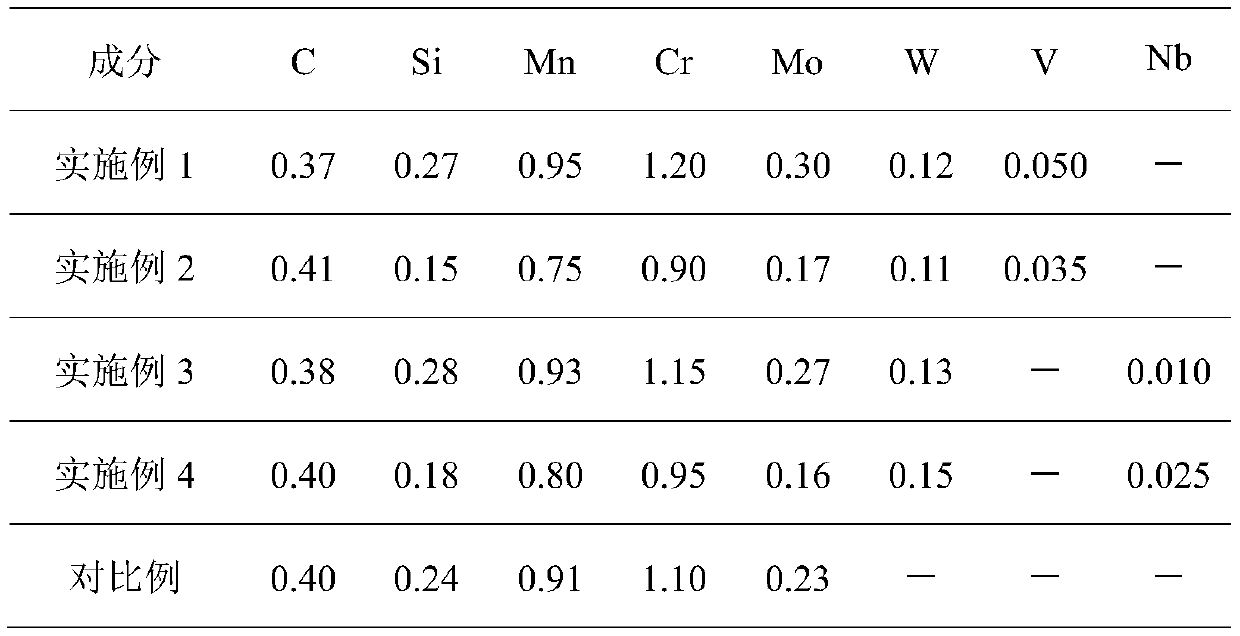

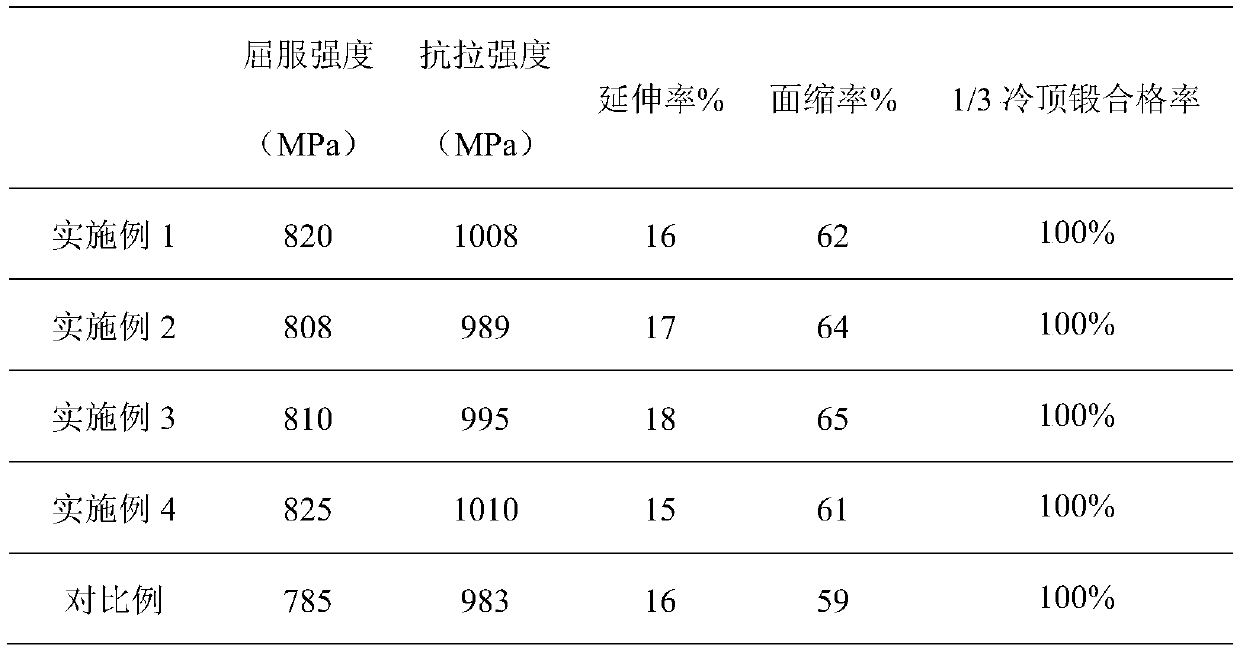

A kind of delayed fracture resistant alloy cold heading steel wire rod and its production method

The invention relates to a delay-fracture-resistant alloy cold-upset steel coil strip and a production method thereof. The alloy cold-upset steel coil strip comprises the following chemical componentsof, by weight, 0.37 %-0.41 % of C, 0.15 %-0.30 % of Si, 0.75 %-0.95 % of Mn, 0.90 %-1.20 % of Cr, 0.15 %-0.30 % of Mo, 0.05 %-0.15 % of W, V or Nb, wherein 0.030 %-0.060 % of V, 0.010 %-0.030 % of Nb, the balance Fe and inevitable impurities. According to the alloy cold-upset steel coil strip and the production method, through reasonable design of chemical components, production processes of continuous casting continuous rolling, heating, rolling control and cold control are adopted, a ferrite and pearlite structure is produced, a medium-carbon chromium-molybdenum alloy cold-upsetting steel coil strip without a full-decarburized layer, and the alloy cold-upset steel coil strip has good delay fracture resistance.

Owner:ANGANG STEEL CO LTD

1400mpa grade delayed fracture resistant high-strength bolt steel and manufacturing method

ActiveCN110423954BPromote formationPlay a role in precipitation strengtheningRare-earth elementHydrogen

The invention discloses a 1400MPa grade delayed fracture resistant high-strength bolt steel and a manufacturing method. The high-strength bolt steel has a relatively high Cu element content, and the Cu element can play a role of precipitation strengthening in the steel, and can also promote passivation film formation. When Cu element precipitates and Cu element segregates, it can induce the precipitation of Mo, V, Nb and other elemental carbides, enhance its hydrogen trapping effect, and at the same time prevent crack propagation, so that the tensile strength of the finished bolt is not less than 1400MPa. The reduction of area is not less than 40%, and it has excellent resistance to delayed fracture. The bolt steel does not add rare earth elements, and at the same time strictly controls the addition of other microalloying elements, on the one hand, the production cost is reduced, and on the other hand, the relatively simple process is conducive to mass production.

Owner:NANJING IRON & STEEL CO LTD

High-strength bolt alloy material resistant to delayed fracture and manufacturing method of bolt

ActiveCN105177463BImproved delayed fracture resistanceImprove mechanical propertiesAlloyNeodymium iron boron

Owner:NINGBO ZHENHAI YONGDING FASTENER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com