A cold-heading steel wire rod for ultra-high-strength locking rivets and its preparation method

An ultra-high-strength, cold-heading steel technology, applied in the field of cold-heading steel wire rods for ultra-high-strength lock rivets and its preparation, can solve the problem that the delayed fracture resistance of wire rods cannot meet the production requirements of lock rivets, and the hardness is difficult to guarantee , unable to produce ultra-high-strength rivets and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

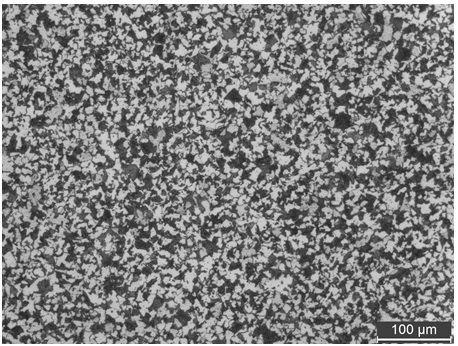

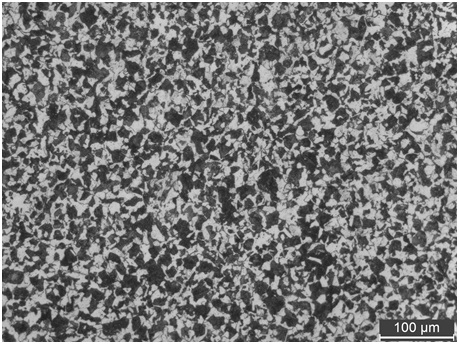

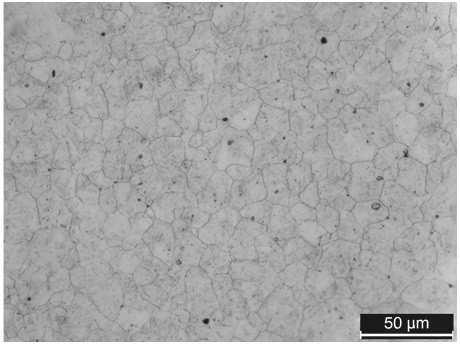

Image

Examples

Embodiment 1

[0038] The embodiment of the present invention provides a cold heading steel wire rod for ultra-high strength locking rivets, the composition of which is: C 0.33%, Mn 1.10%, Si 0.24%, P 0.020%, S 0.005%, Cr 0.30%, Nb 0.030%, Al 0.023%, Ti0.020%, B 0.0020%, and the rest are iron and unavoidable impurity elements.

[0039] The preparation steps of the cold heading steel wire rod for the above-mentioned ultra-high-strength locking rivets are as follows:

[0040] (1) The molten steel smelted by the converter is refined outside the LF furnace and then subjected to RH vacuum refining. The vacuum degree of the vacuum tank in the RH process is 70pa, and the pure degassing time of the RH refining is 20min. The molten steel refined by RH is prepared into a bloom through the continuous casting process.

[0041] (2) After blooming the bloom obtained in step (1), place the hot-rolled billet in a slow cooling pit for 48 hours;

[0042] (3) Steel slab heating: heat the hot-rolled slab after...

Embodiment 2

[0045] The embodiment of the present invention provides a cold heading steel wire rod for ultra-high strength locking rivets, the composition of which is: C 0.35%, Mn 0.95%, Si 0.17%, P 0.012%, S 0.010%, Cr 0.20%, Nb 0.020%, Al 0.041%, Ti0.027%, B 0.0022%, and the rest are iron and unavoidable impurity elements.

[0046] The preparation steps of the cold heading steel wire rod for the above-mentioned ultra-high-strength locking rivets are as follows:

[0047] (1) The molten steel smelted by the converter is refined outside the LF furnace and then subjected to RH vacuum refining. The vacuum degree of the vacuum tank in the RH process is 67pa, and the pure degassing time of the RH refining is 15 minutes. The molten steel refined by RH is prepared into a bloom through the continuous casting process.

[0048] (2) After blooming the bloom obtained in step (1), place the hot-rolled billet in a slow cooling pit for 49 hours;

[0049] (3) Steel slab heating: heat the hot-rolled slab ...

Embodiment 3

[0052] The embodiment of the present invention provides a cold heading steel wire rod for ultra-high strength locking rivets, the composition of which is: C 0.38%, Mn 0.87%, Si 0.01%, P 0.009%, S 0.008%, Cr 0.27%, Nb 0.035%, Al 0.033%, Ti0.034%, B 0.0010%, and the rest are iron and unavoidable impurity elements.

[0053] The preparation steps of the cold heading steel wire rod for the above-mentioned ultra-high-strength locking rivets are as follows:

[0054] (1) The molten steel smelted by the converter is refined outside the LF furnace and then subjected to RH vacuum refining. The vacuum degree of the vacuum tank in the RH process is 70pa, and the pure degassing time of the RH refining is 17 minutes. The molten steel refined by RH is prepared into a bloom through the continuous casting process.

[0055] (2) After the bloom obtained in step (1) is opened, the hot-rolled billet is placed in a slow cooling pit for 52 hours;

[0056] (3) Steel slab heating: heat the hot-rolled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com