Bolt and fastened structure

A technology for fastening structures and bolts, which is applied in the direction of threaded fasteners, bolts, nuts, etc., can solve the problems of brittle fracture and high risk, and achieve the effect of excellent delayed fracture resistance and stable fastening axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited to the following examples.

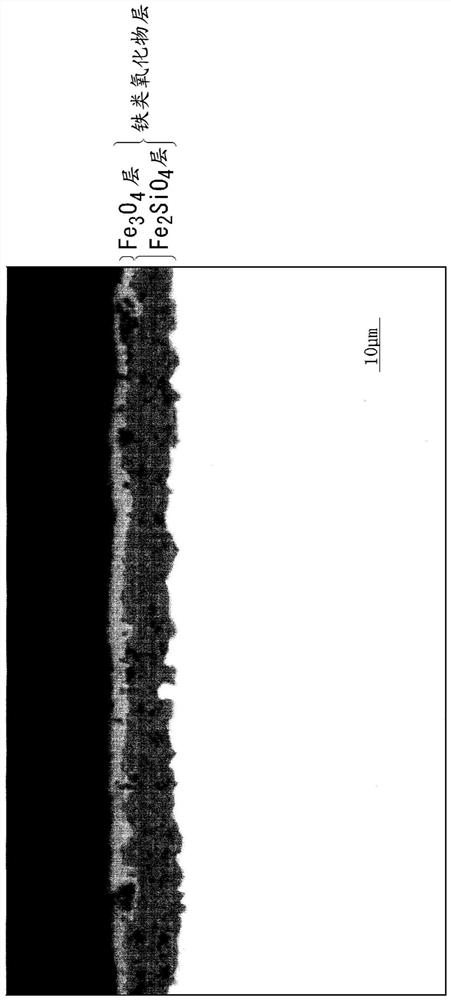

[0066] Carbon steel for high-strength bolts with the composition shown in Table 1 below is quenched at a temperature of 900°C or higher after cold forging and screw rolling, and introduced so that the oxygen concentration becomes 3%. N 2 In an atmosphere, tempering was performed under the conditions shown in the following Table 2 to obtain high-strength bolts.

[0067] It should be noted that Comparative Examples 2 and 3, Comparative Examples 6 and 8 did not introduce N 2 If necessary, temper in air.

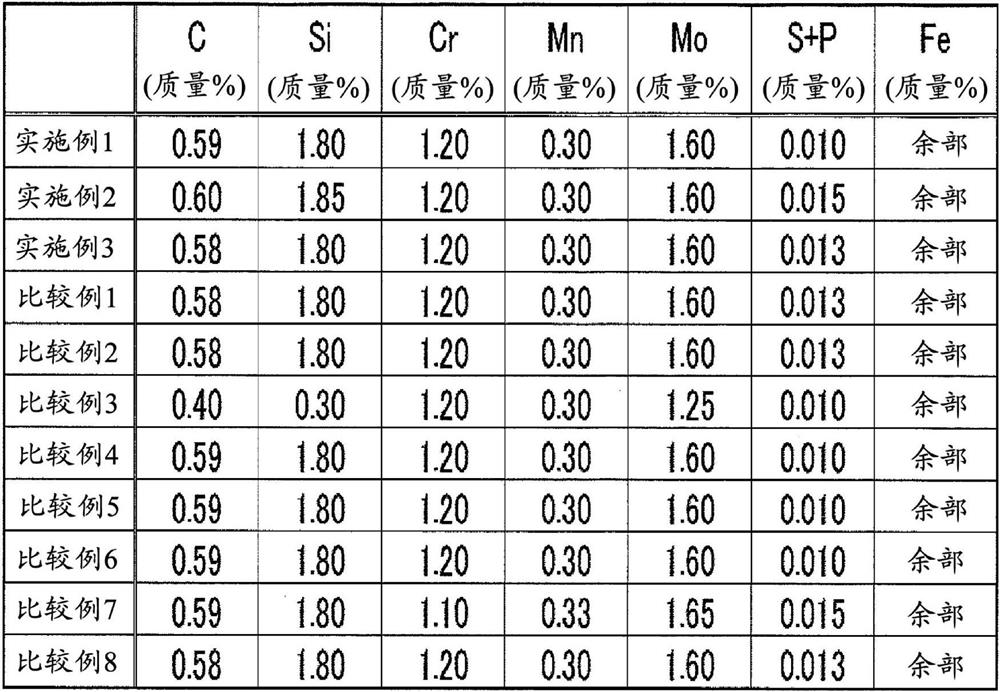

[0068] [Table 1]

[0069]

[0070] [Table 2]

[0071] tempering temperature tempering time tempered vibe Example 1 580℃ 100min N2+air Example 2 590℃ 100min N2+air Example 3 620℃ 100min N2+air Comparative example 1 570℃ 100min N2+air Comparative example 2 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com