1400mpa grade delayed fracture resistant high-strength bolt steel and manufacturing method

A technology for resistant to delayed fracture and high-strength bolts, applied in the field of steel and its manufacturing, can solve problems such as easy delayed fracture, and achieve the effects of reducing production costs, preventing crack propagation, and excellent resistance to delayed fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: The chemical composition of 42CrMoVNb high-strength bolt steel contains C: 0.43%; Si: 0.14%; Mn: 0.30%; P: 0.003%; S: 0.010%; Cr: 1.10%; Mo: 0.55%; V: 0.33%; Nb: 0.04%; Cu: 0.65%; Al: 0.012%; N: 0.009%;

[0037] The preparation process scheme of table 1 embodiment 1

[0038]

[0039]

[0040] The test results of the technical indicators of the finished products prepared by the above preparation scheme are shown in Table 2.

[0041] Table 2 Example 1 high-strength bolt steel technical index detection results

[0042]

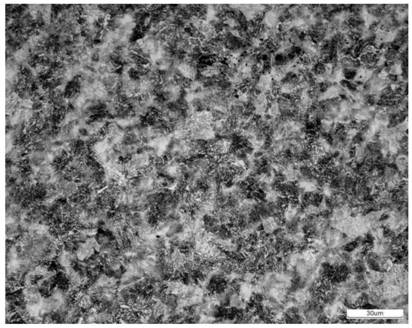

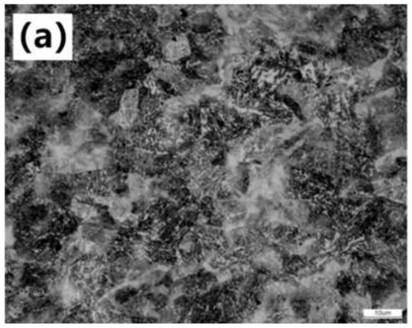

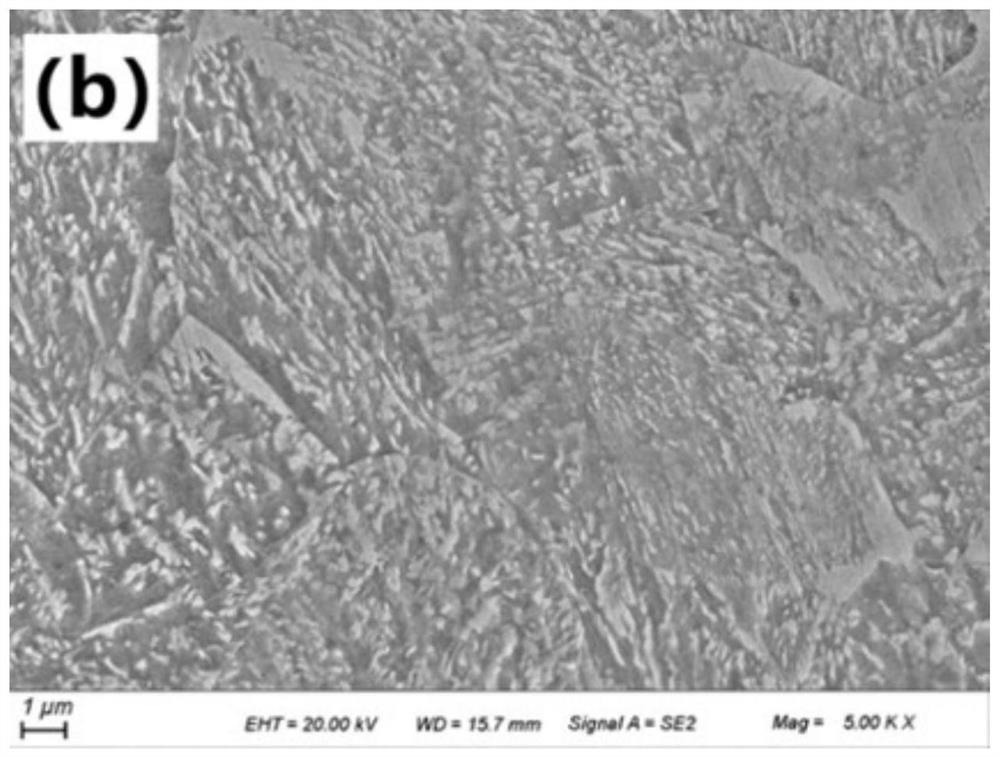

[0043] Such as Figure 1-3 As shown, the cross-sectional metallographic structure and scanning electron microscope of the 42CrMoVNb high-strength bolt steel in the hot-rolled state of Example 1, the structure is mainly bainite and a small amount of martensite, and the Vickers hardness of the test steel in the hot-rolled state is 373-387HV .

Embodiment 2

[0056] Example 2: The chemical composition of high-strength bolt steel contains C: 0.44%, Si: 0.13%, Mn: 0.32%, P: 0.005%, S: 0.009%, Cr: 1.0%, Mo: 0.50 in mass percentage %, Nb: 0.03%, V: 0.31%, Cu: 0.7%, Al: 0.015%, N: 0.018%, and the balance is Fe and impurities. The specific preparation process scheme is shown in Table 6.

[0057] The preparation process scheme of table 6 embodiment 2

[0058]

[0059]

[0060] The test results of the technical indicators of the finished high-strength bolt steel products prepared by the above preparation scheme are shown in Table 7.

[0061] Table 7 Example 2 high-strength bolt steel technical index testing results

[0062]

[0063]

Embodiment 3

[0064] Example 3: The chemical composition of high-strength bolt steel contains C: 0.38%; Si: 0.25%; Mn: 0.60%; P: 0.015%; S: 0.010%; Cr: 0.90%; Mo: 0.60 %; V: 0.35%; Nb: 0.02%; Cu: 0.50%; Ti: 0.01%; N: 0.009%; the balance is Fe and unavoidable impurities. The specific preparation process scheme is shown in Table 8.

[0065] The preparation process scheme of table 8 embodiment 3

[0066]

[0067]

[0068] The test results of the technical indicators of the finished high-strength bolt steel products prepared by the above preparation scheme are shown in Table 9.

[0069] Table 9 Example 3 high-strength bolt steel technical index detection results

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com