Nano/superfine medium-manganese TRIP (transformation induced plasticity) steel plate and warm-rolling preparation method thereof

A nano and steel plate technology, which is applied in the field of nano/ultrafine medium manganese TRIP steel plate and its warm rolling preparation, can solve the problems of difficult plate shape control, large instantaneous elastic modulus, increased production cost, etc., and achieve cooling rate Less sensitivity, improved strength and plasticity, and lower hot stamping temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

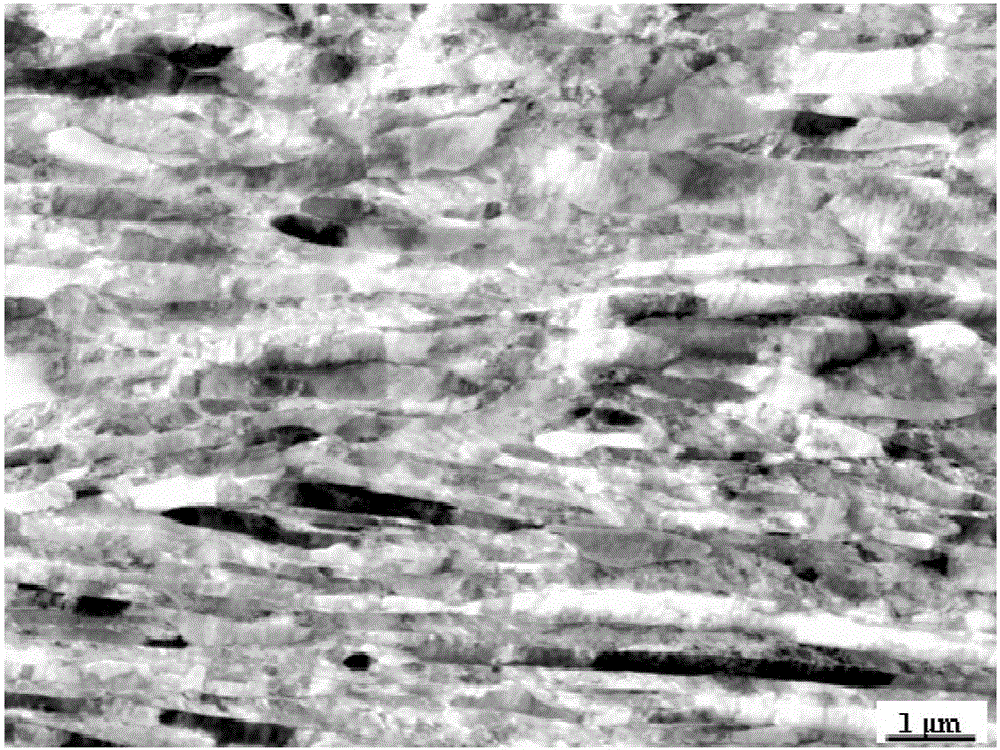

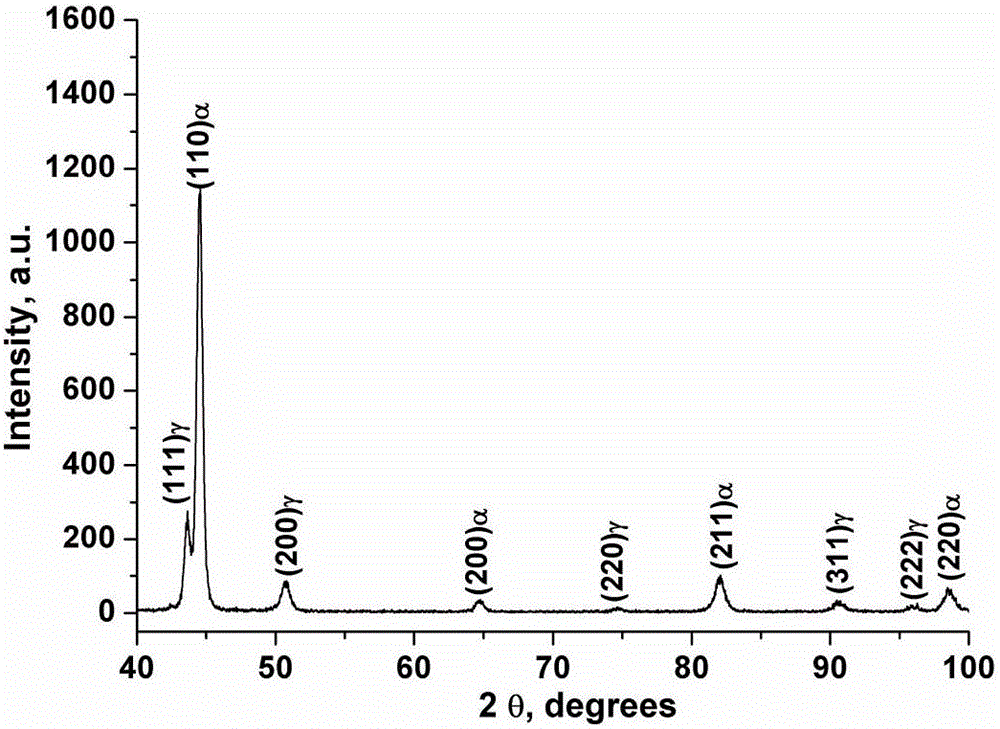

Embodiment 1

[0042] A nano / ultrafine medium manganese TRIP steel plate, its chemical composition and content are: C is 0.20wt.%, Si is 0.05wt.%, Mn is 5.59wt.%, Al is 1.22wt.%, N is 0.014wt.%, Nb is 0.06wt.%, Mo is 0.22wt.%, and the balance is Fe and unavoidable impurities.

[0043] The warm rolling preparation method of the nano / ultrafine medium manganese TRIP steel plate comprises the following steps:

[0044] (1) Melting: According to the chemical composition and ingredients of the nano / ultrafine medium manganese TRIP steel plate, add it to the vacuum induction melting furnace, melt it at 1650°C, and cast it to obtain a 50kg round ingot;

[0045] (2) Forging: heat a 50kg round ingot at 1150°C for 2 hours, forge it, and air-cool it to room temperature to obtain a 100mm×100mm square ingot, and cut the square ingot into 30mm×100mm×100mm;

[0046] (3) Hot rolling: After heating the cut square ingot to 1200°C and keeping it warm for 0.5h, hot rolling is carried out 6 times on a two-roll hot...

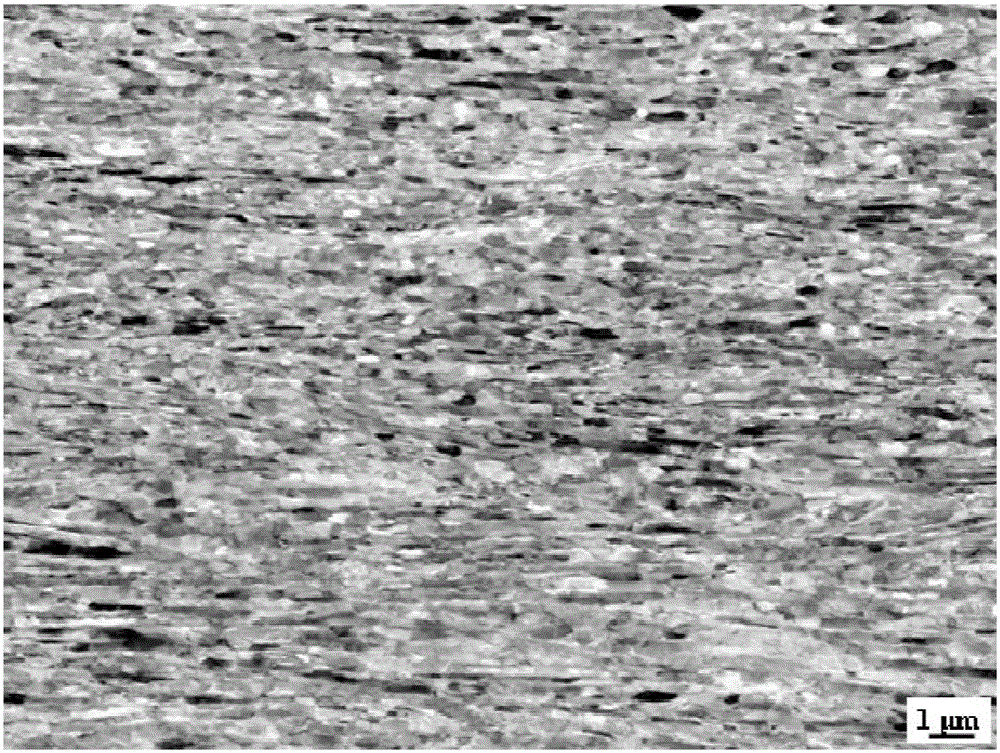

Embodiment 2

[0050] A kind of nano / ultrafine medium manganese TRIP steel plate, after the same smelting, forging, hot rolling, and warm rolling steps as in Example 1, then the nanometer / ultrafine medium manganese TRIP steel plate is heat treated, heated to 650°C, Keep warm for 30min, then air-cool to room temperature to prepare nano / ultrafine medium manganese TRIP heat-treated steel plate. %.

Embodiment 3

[0052] A nano / ultrafine medium manganese TRIP steel plate, its chemical composition and content are: C is 0.25wt.%, Si is 0.50wt.%, Mn is 5.00wt.%, Al is 1.00wt.%, N is 0.03wt.%, Nb is 0.06wt.%, Mo is 0.25wt.%, and the balance is Fe and unavoidable impurities.

[0053] The warm rolling preparation method of the nano / ultrafine medium manganese TRIP steel plate comprises the following steps:

[0054] (1) Melting: According to the chemical composition and ingredients of the nano / ultrafine medium manganese TRIP steel plate, add it to the vacuum induction melting furnace, melt it at 1600°C, and cast it to obtain a 50kg round ingot;

[0055] (2) Forging: heat a 50kg round ingot at 1250°C for 1 hour, forge it, and air-cool it to room temperature to obtain a 100mm×100mm square ingot, and cut the square ingot into 40mm×100mm×100mm;

[0056] (3) Hot rolling: After heating the cut square ingot to 1100°C and keeping it warm for 1.5 hours, hot rolling is carried out 6 times on a two-roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com