Martensitic steel with delayed fracture resistance and manufacturing method

一种耐延迟断裂、马氏体钢的技术,应用在耐延迟断裂性的完全马氏体级别钢领域,能够解决没有教导耐延迟断裂、耐延迟断裂性没有记载等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

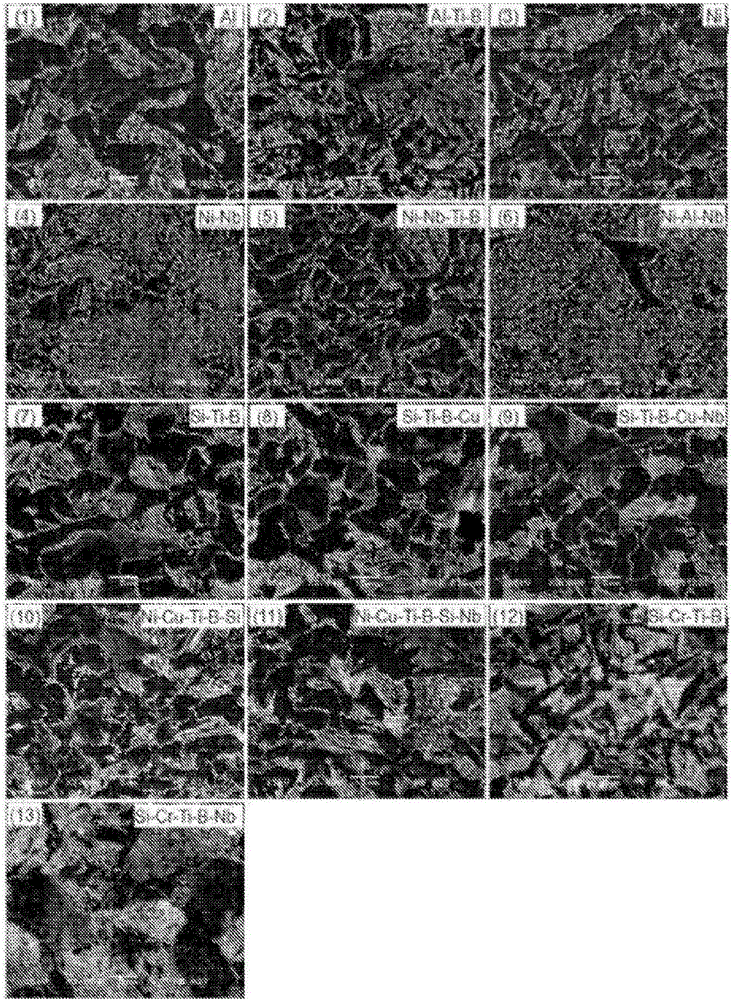

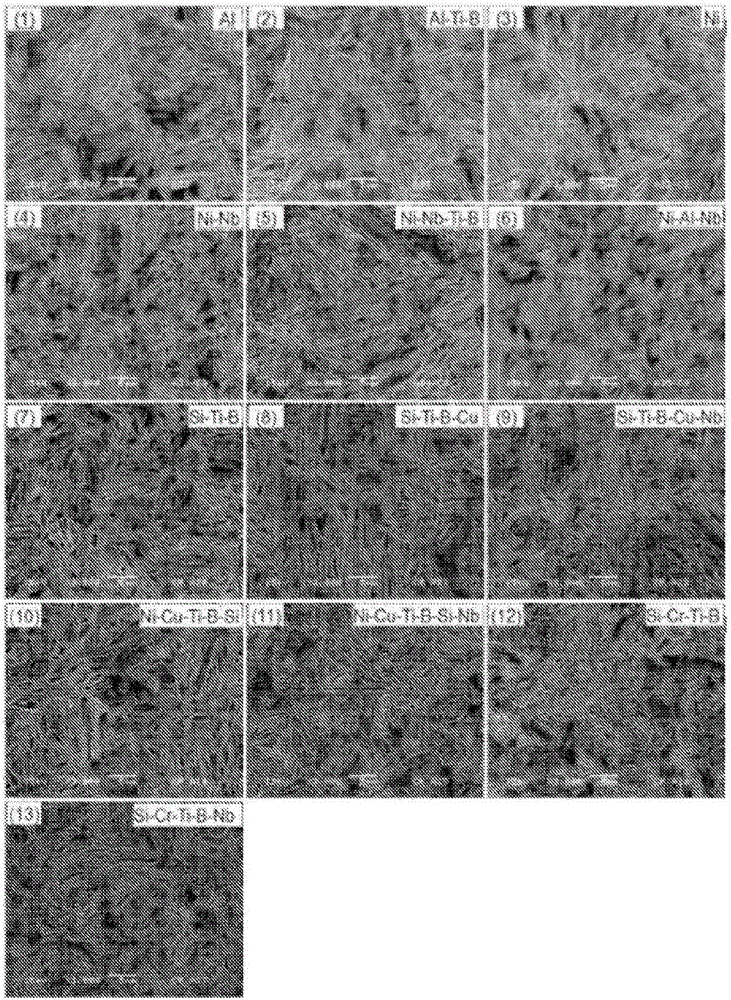

Image

Examples

Embodiment Construction

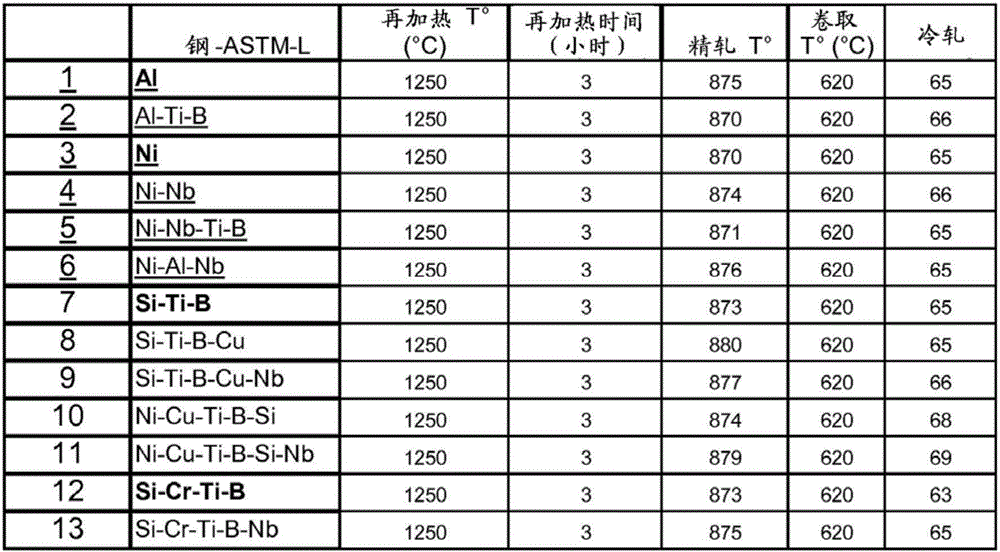

[0054] In order to obtain the martensitic steel sheet according to the invention, the chemical composition as well as the production parameters are important in order to achieve all objectives and obtain excellent delayed fracture resistance. Nickel content below 0.5% is required to reduce hydrogen embrittlement, carbon content between 0.3% and 0.5% is required for tensile properties and Si content above 0.5% is also required for improved hydrogen embrittlement resistance.

[0055] The following chemical constituent elements are given in weight percent.

[0056]Regarding carbon: increasing the content above 0.5 wt% increases the amount of grain boundary carbides, which is one of the main causes of deterioration in delayed fracture resistance of steel. However, a carbon content of at least 0.30 wt% is required to achieve the target steel strength - ie, a tensile strength of 1700 MPa and a yield strength of 1300 MPa. Therefore, the carbon content should be limited within the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| longitudinal tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com