High-strength plated steel sheet having excellent plating properties, workability, and delayed fracture resistance, and method for producing same

A manufacturing method and high-strength technology, applied in manufacturing tools, hot-dip galvanizing processes, chemical instruments and methods, etc., can solve the problems of poor wettability and non-plating of hot-dip galvanizing, and achieve a balance between strength and ductility , The effect of suppressing hydrogen embrittlement, bending and improving delayed fracture resistance

Inactive Publication Date: 2017-08-29

KOBE STEEL LTD

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, Si and Mn are easily oxidizable elements, and due to Si oxide, Mn oxide, Si and Mn composite oxide, etc. formed on the surface, the wettability of hot-dip galvanizing is significantly deteriorated, and non-plating, etc. question

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0130] The slab with the composition shown in Table 1 below and the balance being iron and unavoidable impurities was heated to 1250°C, and then hot rolled to 2.4 mm at a finishing temperature of 900°C, and then at the temperature shown in Table 2. The coiling was carried out under.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

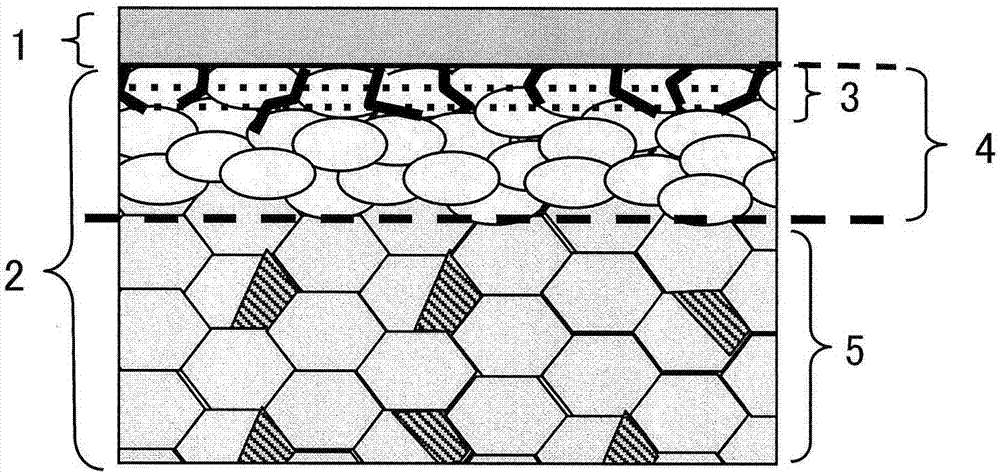

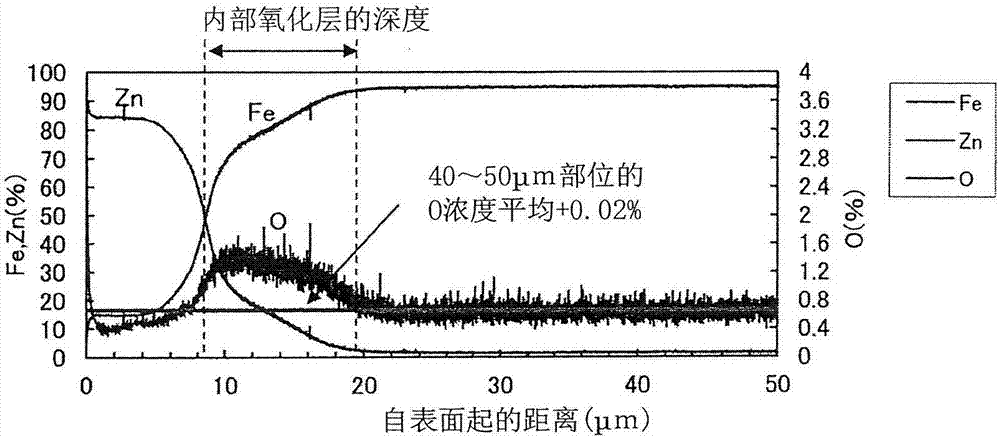

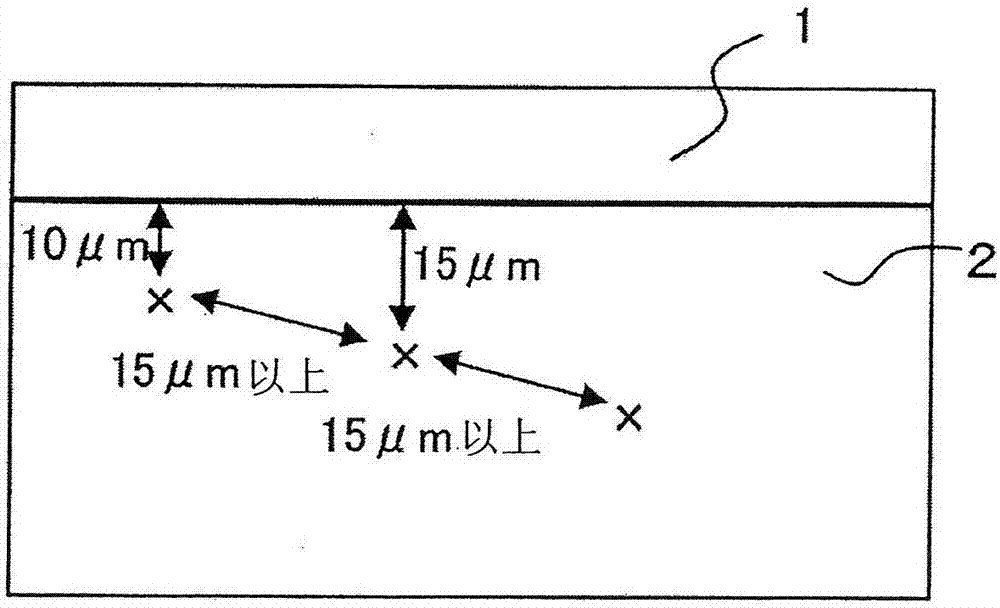

Provided are a hot-dip galvanized steel sheet and an alloyed hot-dip galvanized steel sheet having at least 980 MPa, and having excellent plating properties, workability in terms of bendability, hole expandability, and balance between strength and ductility, and delayed fracture resistance. This high-strength plated steel sheet is a plated steel sheet having a plating layer on the surface of a base material steel sheet, includes predetermined steel components, and comprises, in order from the interface between the base material steel sheet and the plating layer toward the base material steel sheet side: a soft layer having a Vickers hardness that is 90% or less of the Vickers hardness at a t / 4 position of the base material steel sheet, where t is the thickness of the base material steel sheet; and a hard layer including martensite, bainite, and ferrite in predetermined ranges. The average depth D of the soft layer is 20 [mu]m or greater, and the average depth d of an inner oxide layer is 4 [mu]m or greater and less than D.

Description

Technical field [0001] The present invention relates to a high-strength coated steel sheet having excellent tensile strength of 980 MPa or more, coating properties, balance of strength and ductility, workability including bendability and hole expandability, and delayed fracture resistance, and a manufacturing method thereof. The coated steel sheet of the present invention includes both hot-dip galvanized steel sheets and alloyed hot-dip galvanized steel sheets. Background technique [0002] Hot-dip galvanized steel sheets and alloyed hot-dip galvanized steel sheets commonly used in the fields of automobiles and conveyors are not only required to increase strength, but also require a balance of strength and ductility, bendability, and hole expandability (extended flange It has excellent workability such as properties, and is further required to have excellent delayed fracture resistance. [0003] In order to ensure high strength and workability, it is effective to add a large amoun...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/00C21D9/46C22C38/60C23C2/06C23C2/28C23C2/40

CPCC21D8/0226C21D1/74C21D8/0205C21D8/0247C21D8/0236C21D8/0263B32B15/013Y10T428/24967Y10T428/12667Y10T428/12799Y10T428/2495Y10T428/12611Y10T428/12583Y10T428/12792Y10T428/12972Y10T428/1259Y10T428/1266Y10T428/263Y10T428/265Y10T428/264C22C38/18C22C38/002C22C38/22C22C38/28C22C38/14C22C38/12C22C38/08C22C38/32C22C38/16C22C38/60C22C38/48C22C38/26C22C38/24C22C38/42C22C38/44C22C38/50C22C38/20C22C38/46C22C38/54C22C38/40C21D8/0278C21D9/46C22C38/001C22C38/02C22C38/04C22C38/06C23C2/0222C23C2/28C23C2/024C23C2/29C21D1/76C21D8/0257C22C38/38C23C2/06C23C2/40C21D2211/008C23G1/06B32B15/04B32B15/043C23C30/005C23G1/08C23F17/00C23C30/00B32B15/18

Inventor 池田宗朗二村裕一中屋道治

Owner KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com