Manufacturing method of forged products

A manufacturing method and hot forging technology are applied in the manufacturing field of forged products, which can solve the problems of reducing manufacturing cost and difficulty in obtaining target strength, and achieve the effects of reducing manufacturing cost, suppressing hydrogen embrittlement, and achieving good strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

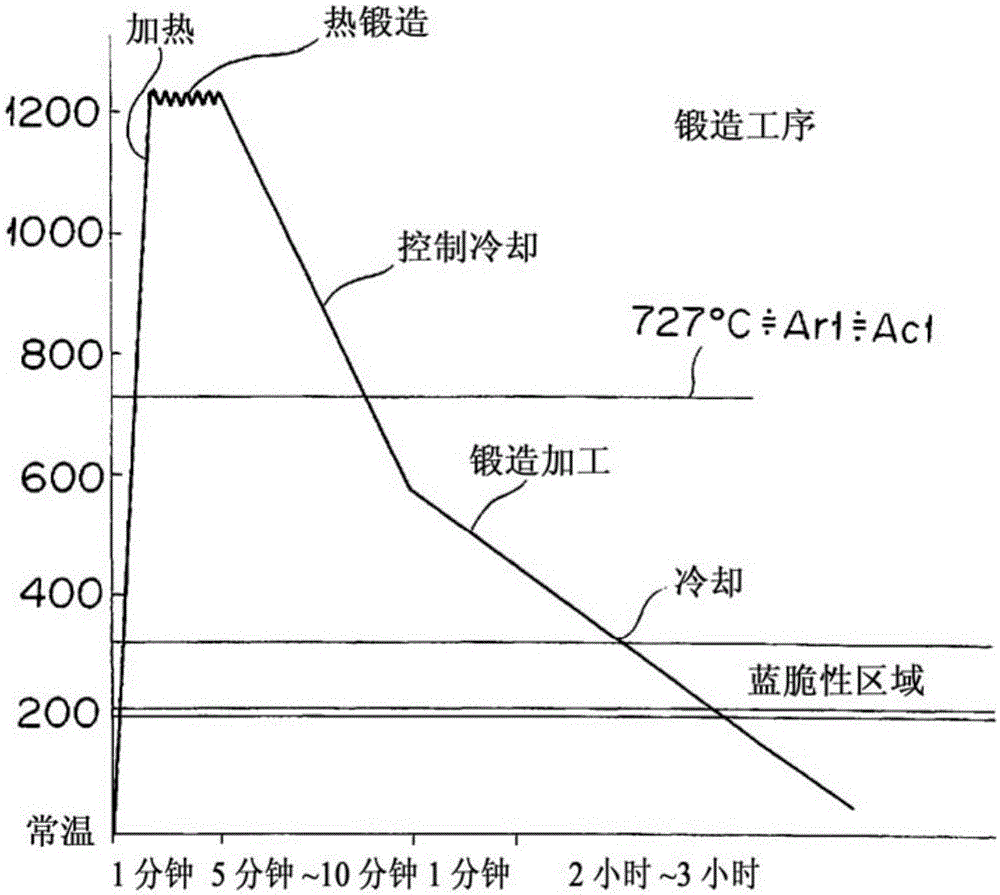

[0021] In the method of manufacturing a forged product according to an embodiment of the present invention, the temperature of 350 to 600° C. The forging process is performed in the area, and instead of using steel containing N as a chemical composition as shown in the existing manufacturing method, using steel with N less than or equal to the unavoidable solid solution amount is based on a completely different from the existing technology. based on technical ideas.

[0022] In the technical field of conventional forged products, steel materials containing N are easily age-hardened, and although high-strength forged products can be obtained, there is a possibility that hydrogen adheres to the age-hardened N to cause hydrogen embrittlement. If the number of hydrogen embrittlement sites on the forged product increases, it will be easily cracked and damaged.

[0023] In addition, for example, in the case of adding Al as a deoxidizing material, since the Al combines with N to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com