Delay-fracture-resisting 1040 MPa-grade weather-proof bolt

A 1040mpa, delayed fracture technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of bolt resistance to delayed fracture resistance, difficult atmospheric corrosion resistance, imbalanced content of microalloying elements, etc., to achieve resistance to industrial atmospheric corrosion. Excellent performance, excellent delayed fracture resistance, reasonable control of alloy system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

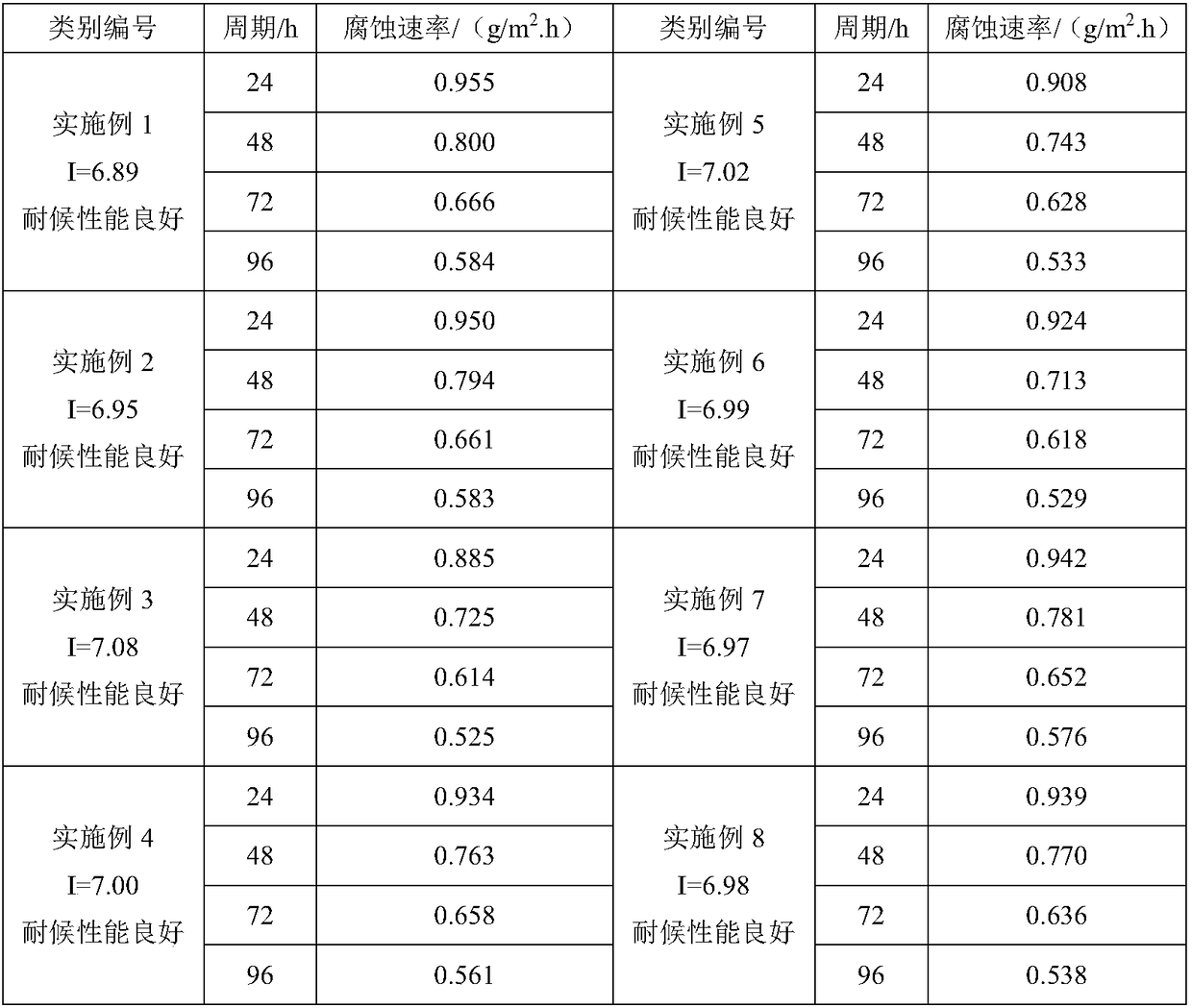

Examples

Embodiment 1

[0021] Using conventional high-purity qualitative smelting-continuous casting-rolling technology, the metal raw materials are prepared into 10.9-grade weather-resistant bolt steel materials with resistance to delayed fracture, and the chemical composition mass percentages are: C: 0.21, Si: 0.38, Mn: 1.0, P: 0.020, S: 0.004, Cr: 0.85, Ni: 0.45, Cu: 0.50, Mo: 0.10, Nb: 0.015, V: 0.015, Ti: 0.015, B: 0.0021, Al: 0.028, Ca: 0.005, Zr: 0.015, Re: 0.030, the balance is Fe and other unavoidable impurities;

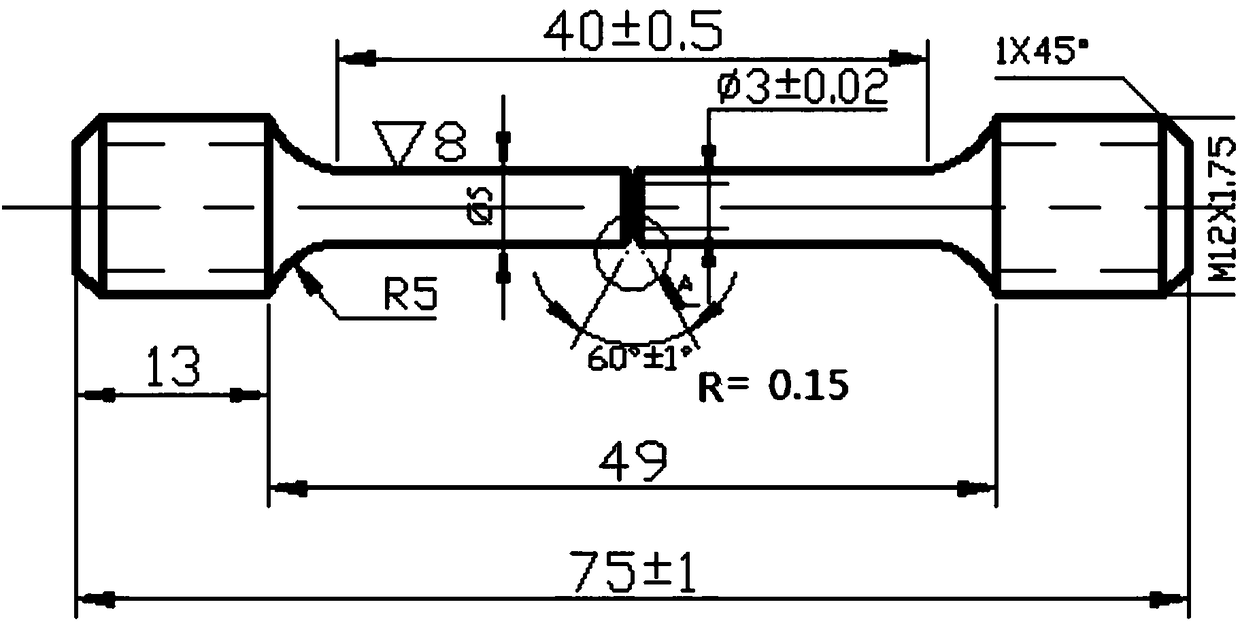

[0022] The ingot is billeted and rolled into Bars, pickling of raw materials, steel drawing, blanking, end chamfering, flat head, head forming, head chamfering, shot blasting, semi-finished surface treatment, diameter reduction, thread rolling according to conventional methods;

[0023] Heat treatment, quenching temperature 950°C, holding time 1h, water cooling; tempering temperature 450°C, holding time 40min, air cooling;

[0024] Finished product surface treatment, made of M...

Embodiment 2

[0026] Using conventional high-purity qualitative smelting-continuous casting-rolling technology, the metal raw materials are prepared into 10.9-grade weather-resistant bolt steel materials with resistance to delayed fracture, and the chemical composition mass percentages are: C: 0.29, Si: 0.18, Mn: 0.68, P: 0.014, S: 0.002, Cr: 0.96, Ni: 0.42, Cu: 0.26, Mo: 0.08, Nb: 0.020, V: 0.025, Ti: 0.008, B: 0.0015, Al: 0.018, Ca: 0.004, Zr: 0.030, Re: 0.040, the balance is Fe and other unavoidable impurities;

[0027] The ingot is billeted and rolled into Bars, pickling of raw materials, steel drawing, blanking, end chamfering, flat head, head forming, head chamfering, shot blasting, semi-finished surface treatment, diameter reduction, thread rolling according to conventional methods;

[0028] Heat treatment, quenching temperature 925°C, holding time 1h, water cooling; tempering temperature 540°C, holding time 40min, air cooling;

[0029] Finished product surface treatment, made of ...

Embodiment 3

[0031] Using conventional high-purity qualitative smelting-continuous casting-rolling technology, the metal raw materials are prepared into 10.9-grade weather-resistant bolt steel materials with resistance to delayed fracture, and the chemical composition mass percentages are: C: 0.25, Si: 0.30, Mn: 0.80, P: 0.010, S: 0.003, Cr: 0.88, Ni: 0.32, Cu: 0.38, Mo: 0.18, Nb: 0.042, V: 0.055, Ti: 0.022, B: 0.0020, Al: 0.032, Ca: 0.005, Zr: 0.030, Re: 0.030, the balance is Fe and other unavoidable impurities;

[0032] The ingot is billeted and rolled into Bars, pickling of raw materials, steel drawing, blanking, end chamfering, flat head, head forming, head chamfering, shot blasting, semi-finished surface treatment, diameter reduction, thread rolling according to conventional methods;

[0033] Heat treatment, quenching temperature 935°C, holding time 1h, water cooling; tempering temperature 500°C, holding time 40min, air cooling;

[0034] Surface treatment of the finished product to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com