Steel for Warm Working, Warm Working Method Using the Steel, and Steel Material and Steel Component Obtainable Therefrom

a technology of steel and working method, which is applied in the direction of heat treatment apparatus, furnaces, manufacturing tools, etc., can solve the problems of unfavorable strengthening of steel, large reduction of ductility, and reduced ductility, etc., to improve the delay fracture resistance characteristics, improve the toughness, and improve the effect of cost efficiency and recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

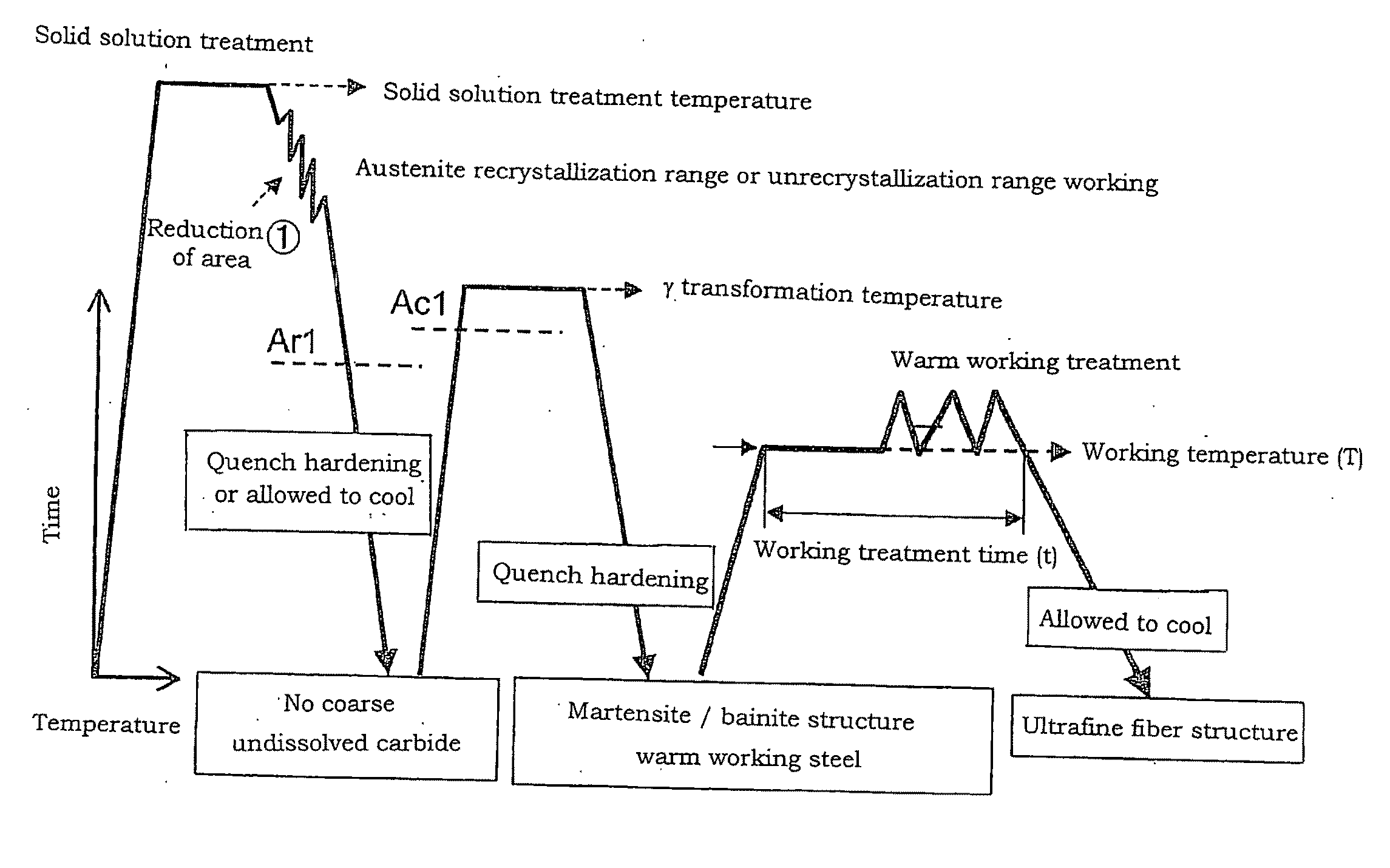

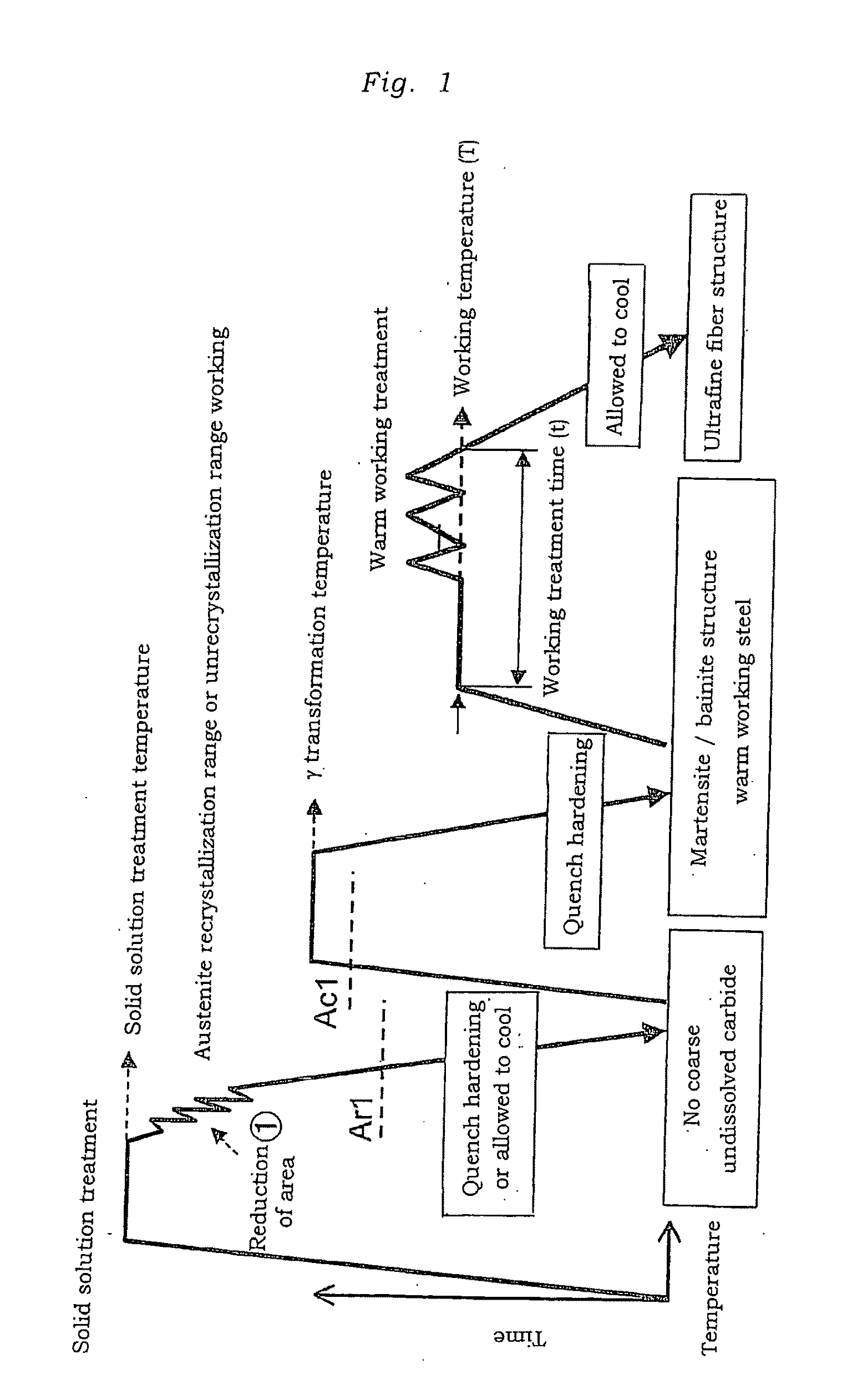

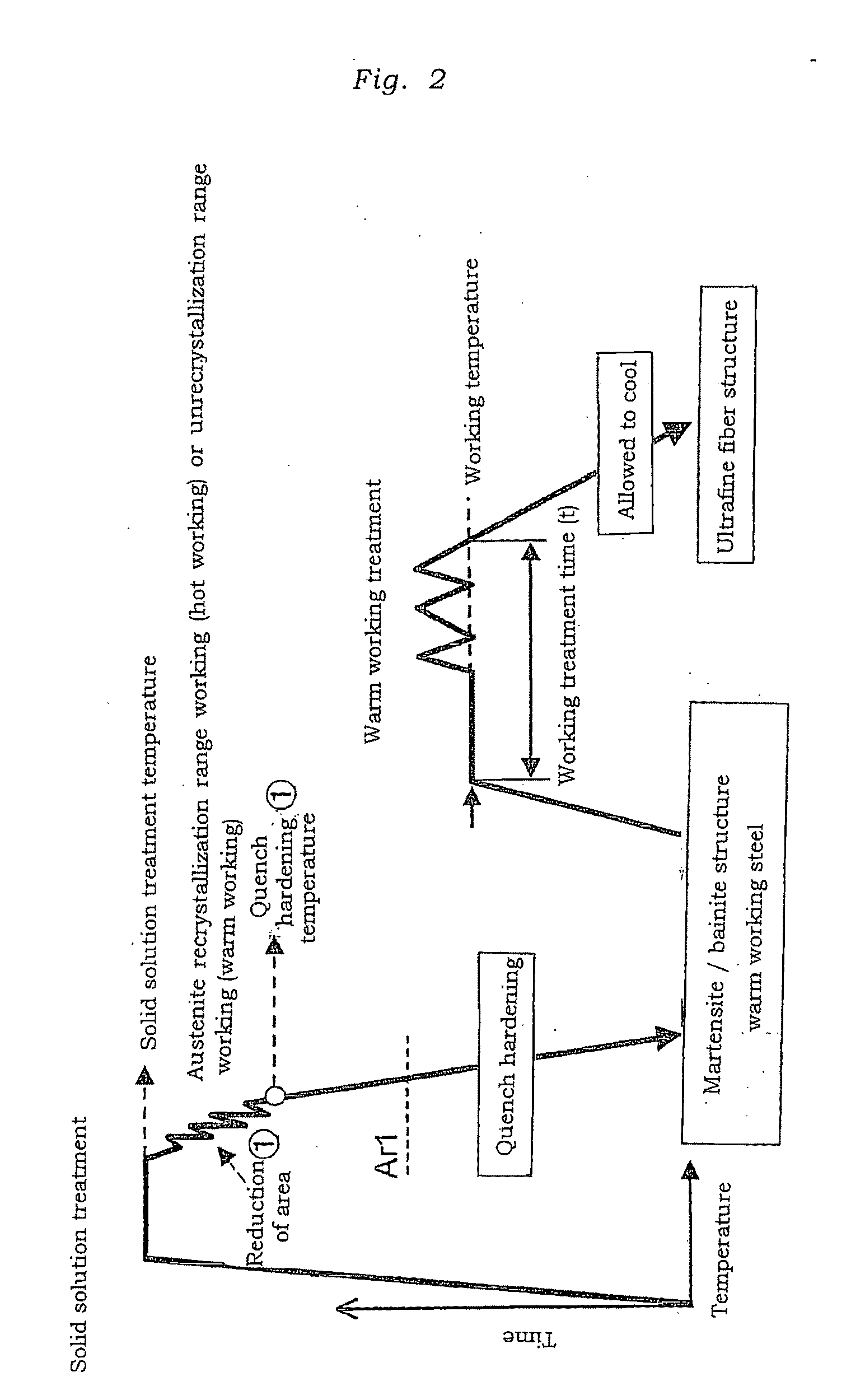

Method used

Image

Examples

examples

[0142]Table 1 shows the steel components (A to K, M, N, and O) within the scope of the invention and the steel component (L) outside the scope. Incidentally, in examples, carbides are used as the dispersed second-phase particles. Table 2 shows the volume fractions of alloy carbides dispersible as the dispersed second-phase particles and cementites for the steels of the compositions of Table 1. The steels of the examples cover martensitic steels of from SCM435 to 2 GPa class secondary hardened steels except for Co-added maraging steels.

TABLE 1Chemical composition (wt %)SteeltypeCSiCrMnNiMoCuNbPST-AlT-NOA0.201.951.010.21—1.02——0.0010.00100.0100.00220.0007B0.391.981.040.21—1.05——0.0410.0020C0.591.990.980.20—1.01——0.00070.0040.00160.0005D0.210.092.010.212.021.01——0.0100.00200.011E0.220.092.000.202.001.00—0.0340.0090.00200.007F0.400.082.000.202.011.03——0.0100.00200.009G0.571.961.020.16—0.002——0.0410.0018H0.350.201.100.700.250.200.053—0.0060.00200.0090.00700.0040I0.400.201.030.770.070.170...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain diameter | aaaaa | aaaaa |

| grain diameter | aaaaa | aaaaa |

| grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com