High-strength pc steel wire

A high-strength, steel wire technology, applied in the furnace type, furnace, heat treatment furnace, etc., can solve the problem of reduced delayed fracture resistance, and achieve the effect of excellent delayed fracture resistance and easy manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

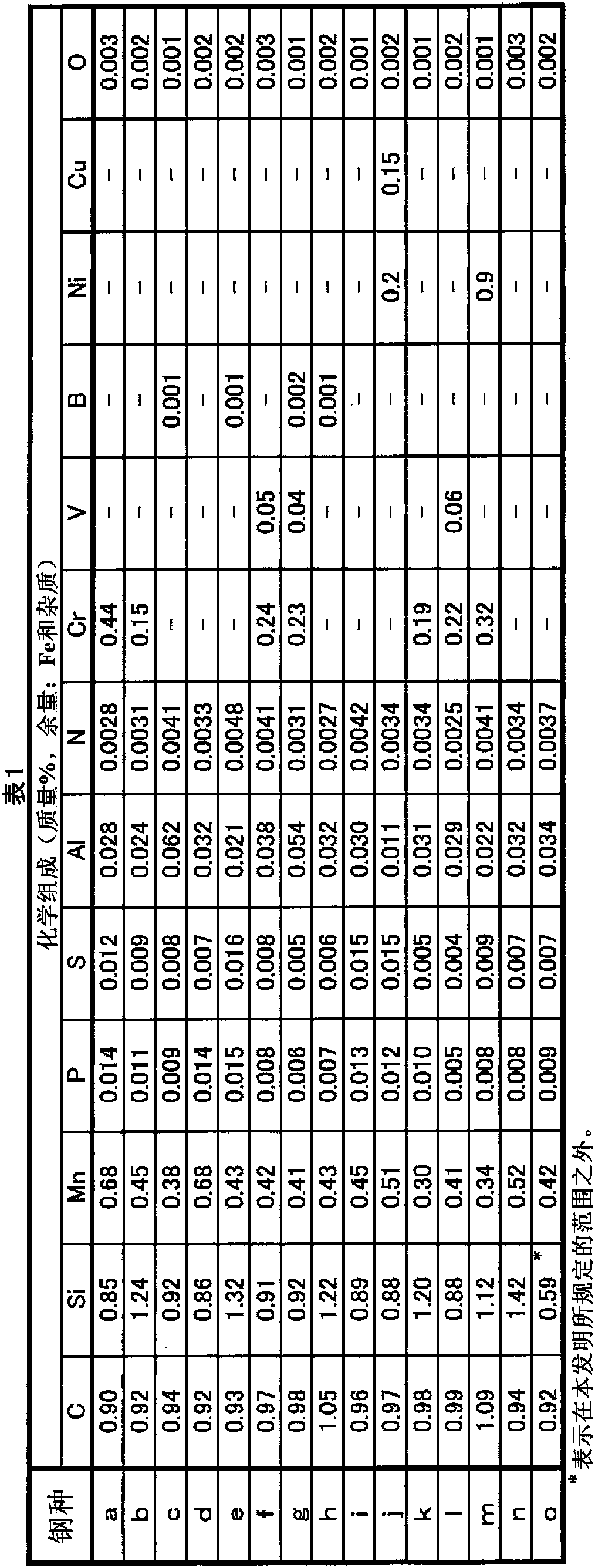

[0110] Steel grades a to o having the chemical composition shown in Table 1 were heated under the conditions shown in Table 2, hot-rolled, coiled into a ring shape, immersed in a molten salt tank behind the hot-rolling line, and subjected to a lead bath. Quenching treatment, manufacturing wire. Thereafter, the obtained wire rods were drawn into wire diameters shown in Table 2, heated after drawing, and subjected to aging treatment to manufacture high-strength PC steel wires shown in test numbers 1 to 32. Then, the following tests were carried out on these steel wires.

[0111] [Table 1]

[0112]

[0113] [Table 2]

[0114]

[0115] The tensile strength test was performed using a test piece No. 9A in accordance with JIS Z 2241. The results are shown in Table 3.

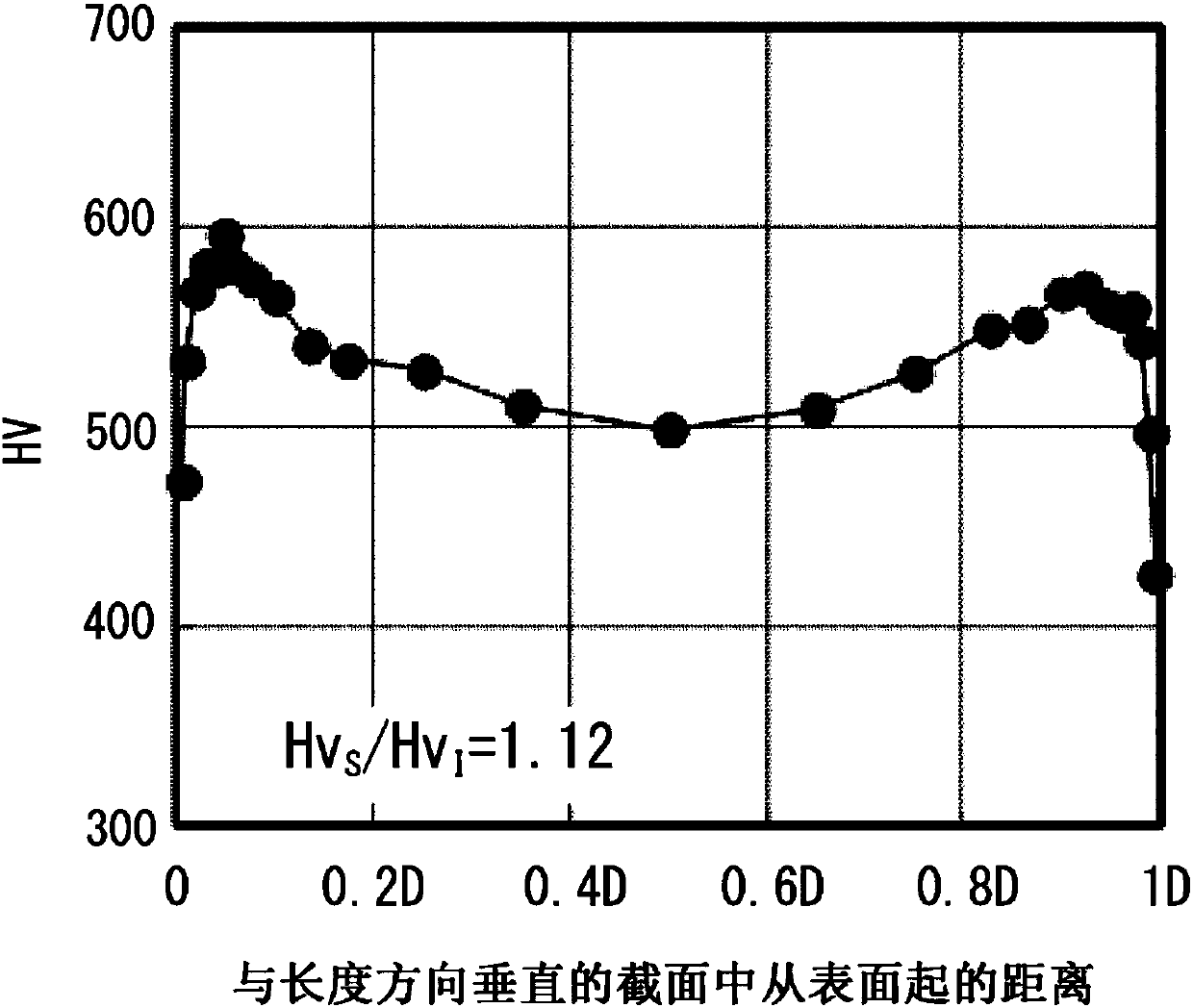

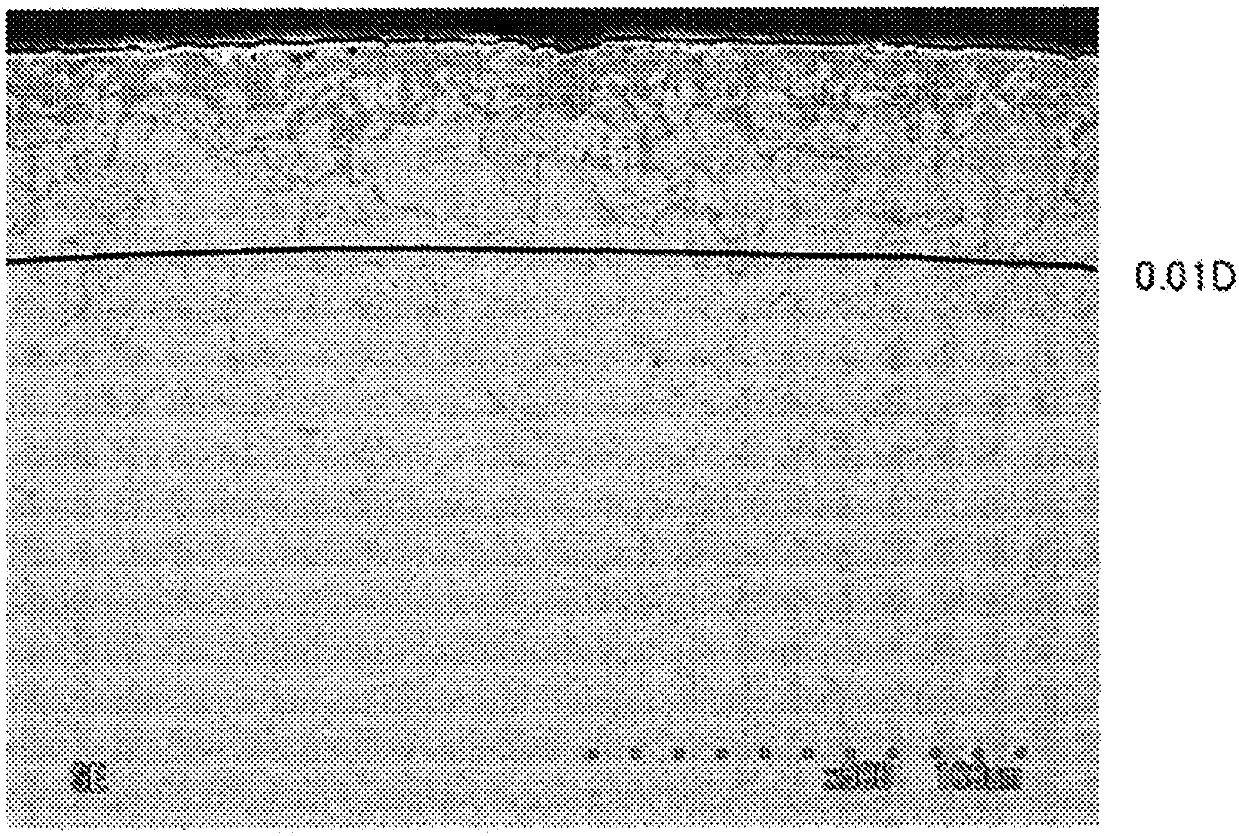

[0116] The Vickers hardness test was performed in accordance with JIS Z 2244. In calculating the Vickers hardness ratio (Hv S / Hv I ), first, the Vickers hardness (Hv S ) is measured as follows: in the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com