High-strength cold-rolled steel plate and method for producing same

A cold-rolled steel sheet and a technology for a manufacturing method, which are applied in the field of high-strength cold-rolled steel sheets and their manufacturing, can solve problems such as delayed fracture of steel sheets, and achieve the effects of excellent delayed fracture resistance and excellent delayed fracture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

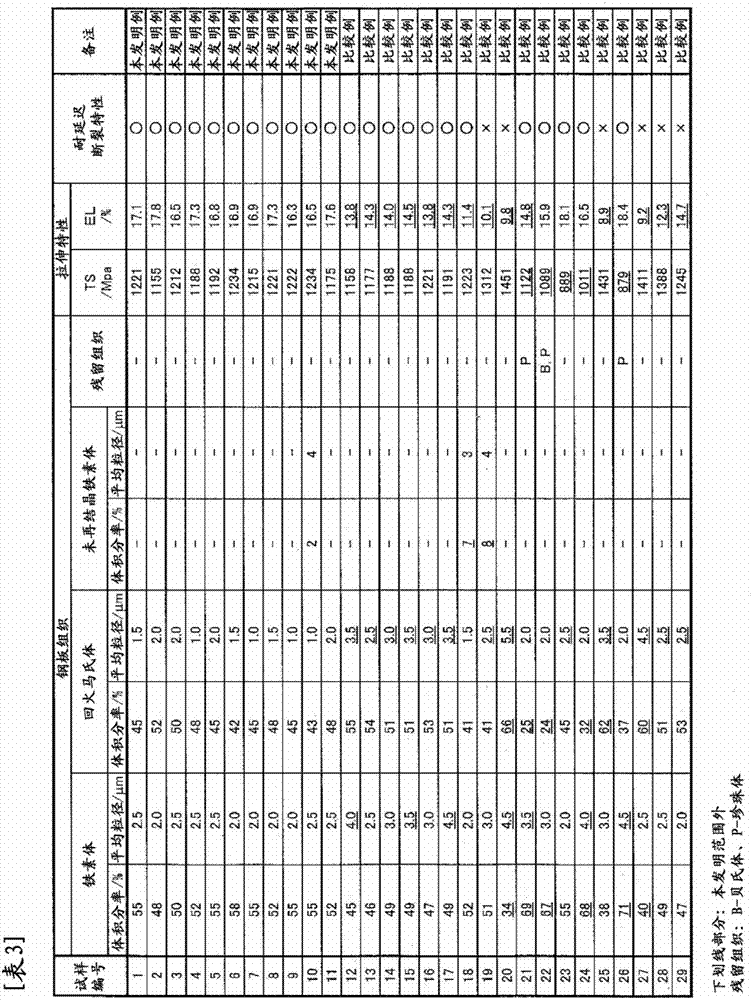

[0125] Hereinafter, examples of the present invention will be described. However, the present invention is not limited to the following examples, and may be implemented by appropriately adding changes within the scope of the gist of the present invention, and these are included in the technical scope of the present invention.

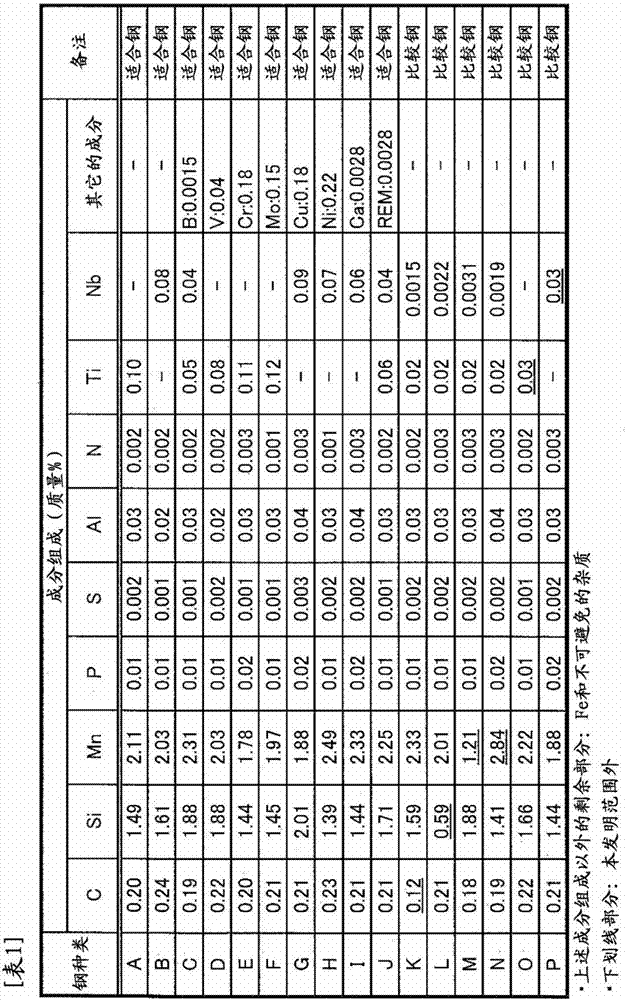

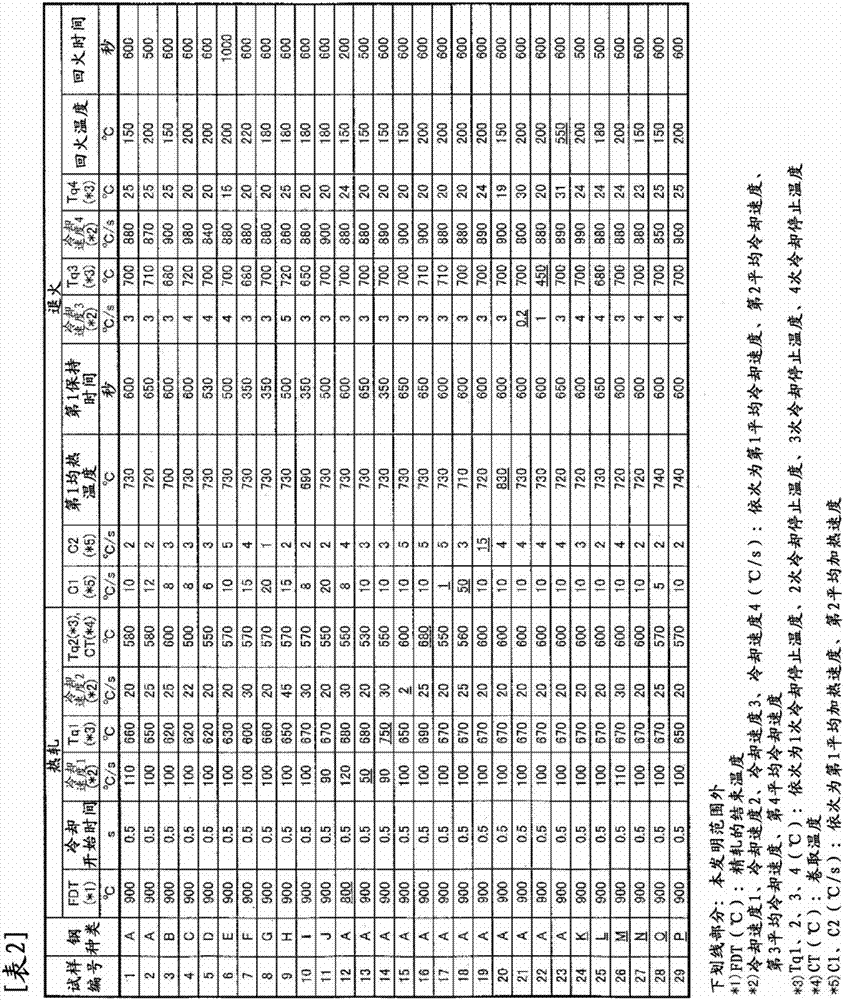

[0126] The steel with the composition shown in Table 1 and the rest is composed of Fe and unavoidable impurities is smelted in a converter, and made into a slab by continuous casting. After cooling to room temperature, the obtained slab is reheated to make the hot rolled The starting temperature is 1250°C, and the hot rolling is carried out at the finishing temperature (FDT) shown in Table 2. After making a hot-rolled steel sheet, cooling is started at the cooling start time shown in Table 2. Under the conditions, as the first cooling, after cooling to the primary cooling stop temperature (Tq1) at the first average cooling rate (cooling rate 1) (primary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com