Hot-press member and method for manufacturing same, and cold-rolled steel sheet for hot pressing and method for manufacturing same

A technology of cold-rolled steel plate and manufacturing method, which is applied in the field of hot-pressed components and its manufacture, as well as cold-rolled steel plate for hot-pressing and its manufacture, can solve problems such as liquid metal brittle steel plate cracks, zinc melting, etc., and achieve high tensile strength, Excellent resistance to resistance welding cracking and delayed fracture resistance, excellent resistance to resistance welding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0176] Hereinafter, examples of the present invention will be described.

[0177] It should be noted that the present invention is not limited to the following examples, and can also be appropriately modified within the scope of the gist of the present invention, and all of them are included in the technical scope of the present invention.

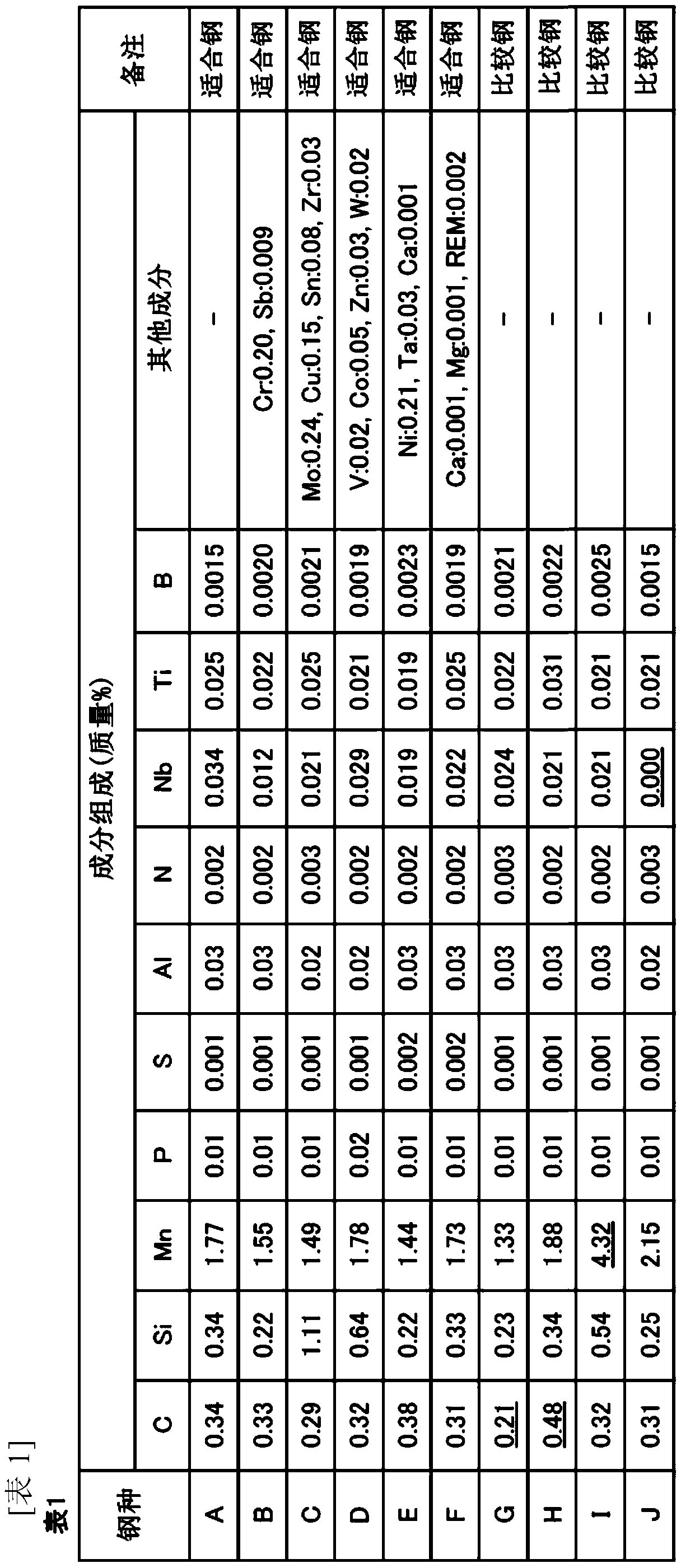

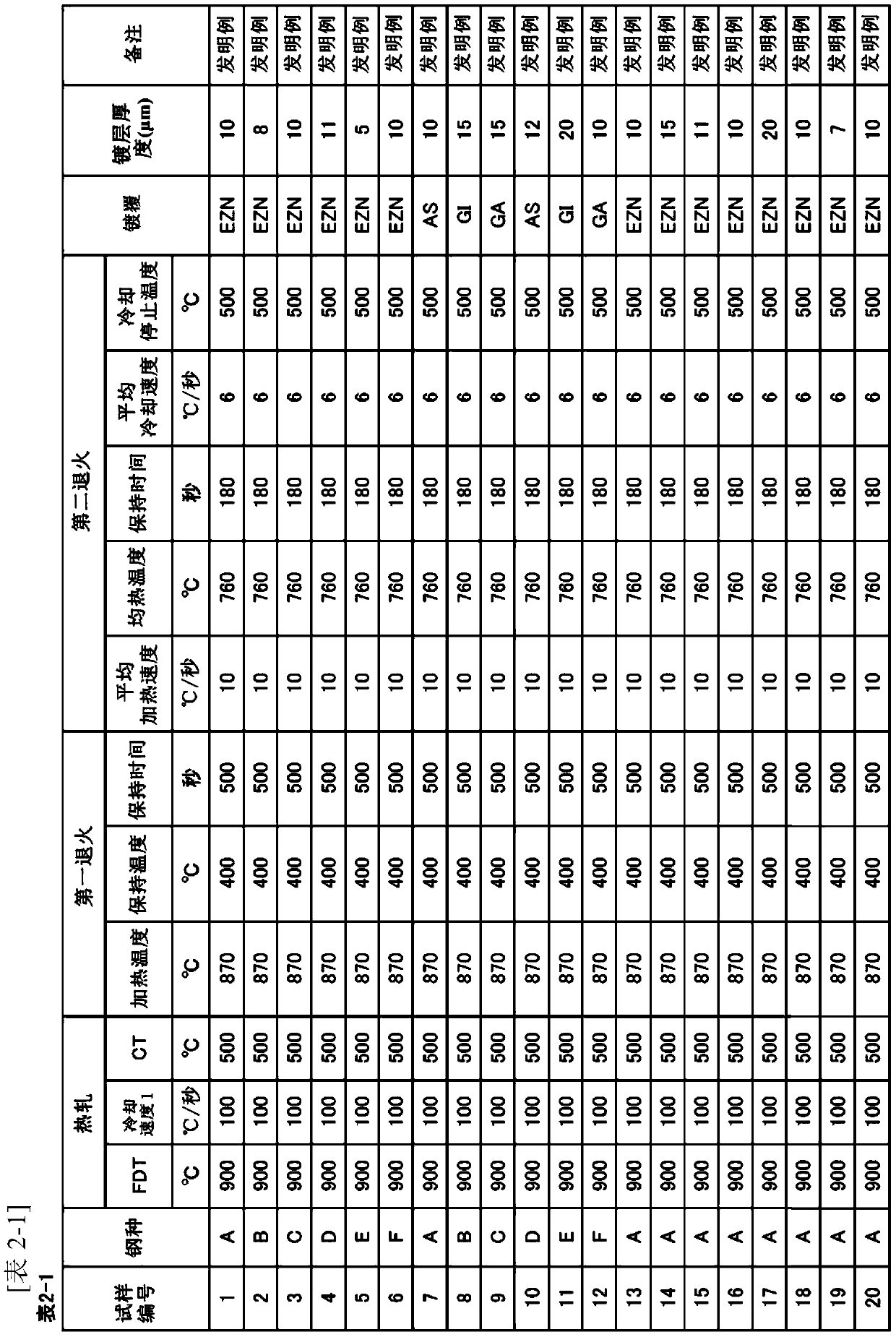

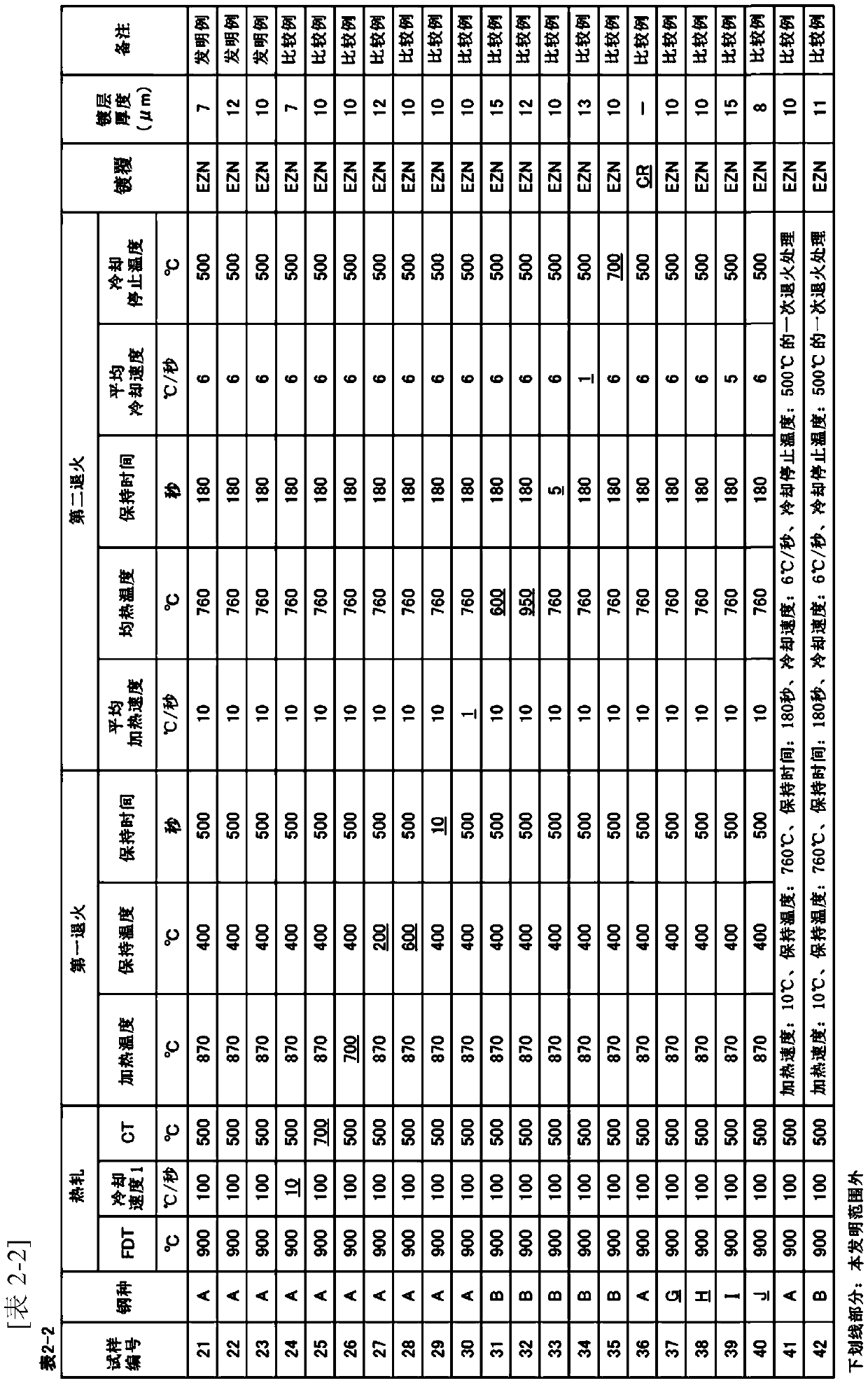

[0178] Steel with the composition shown in Table 1 was melted and cast to form a slab, heated to 1250° C., and then hot-rolled at the finish rolling finish temperature (FDT) as shown in Table 2. Next, the hot-rolled steel sheet was cooled to the coiling temperature (CT) at the first average cooling rate (cooling rate 1) shown in Table 2, and coiled into a coil.

[0179] Next, after pickling the obtained hot-rolled sheet, it cold-rolled by 50% of rolling reduction, and it was set as the cold-rolled sheet (sheet thickness: 1.4 mm).

[0180] Next, the cold-rolled steel sheet obtained in this way is subjected to the first and second annealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com