A Sampling and Analysis System for Measuring Hydrogen Concentration in Containment Vessel

A sampling analysis and containment technology, applied in sampling, analyzing materials, measuring devices, etc., can solve the problems of increasing the difficulty of nuclear power plant operators, time, errors, deviations, etc., to improve the degree of informatization automation, improve accuracy, The effect of eliminating systematic errors

Active Publication Date: 2013-08-28

718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The 225CM hydrogen monitor adopts the "dry state" concentration measurement after cooling the gas in the containment vessel. Although the device has many advantages, with the deepening of research, the shortcomings of dry measurement are gradually exposed, that is, as mentioned in the previous analysis, The "dry" hydrogen concentration deviates from the real hydrogen concentration in the containment under high temperature and high humidity conditions

Nuclear power plants will only continuously monitor the hydrogen content in the containment under accident conditions. If accurate and reliable hydrogen concentration signals cannot be provided, it will increase the difficulty and time for nuclear power plant operators to make correct judgments and control, and even make wrong decisions. decision, it is very dangerous

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

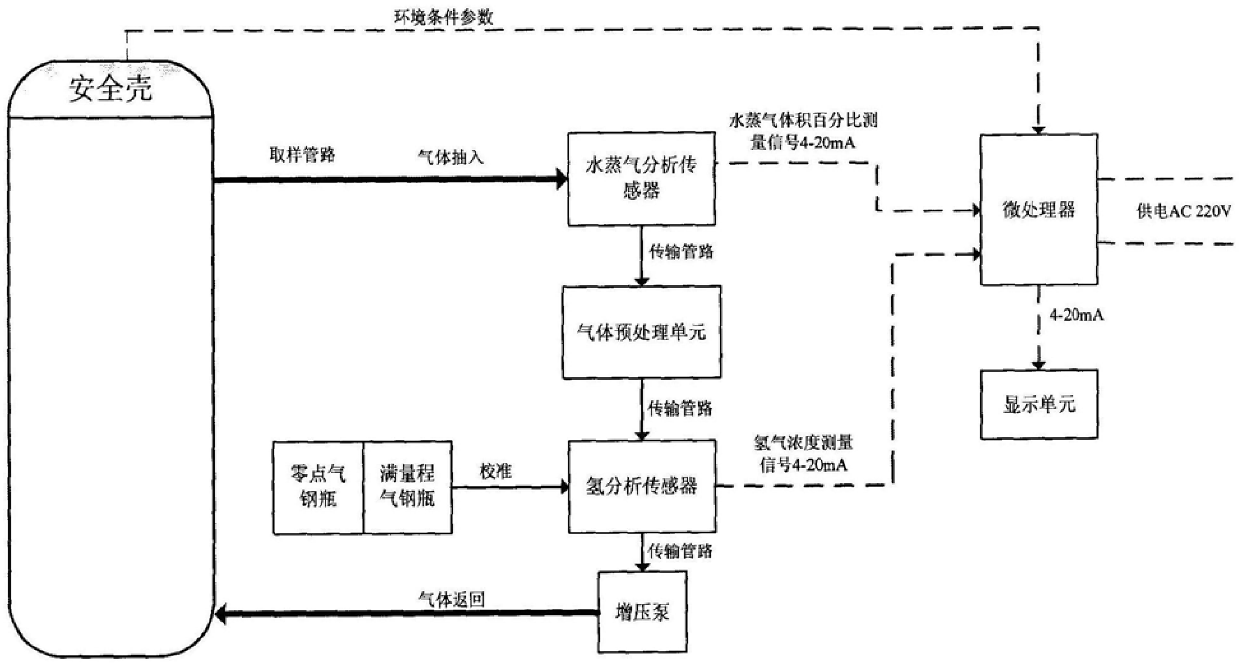

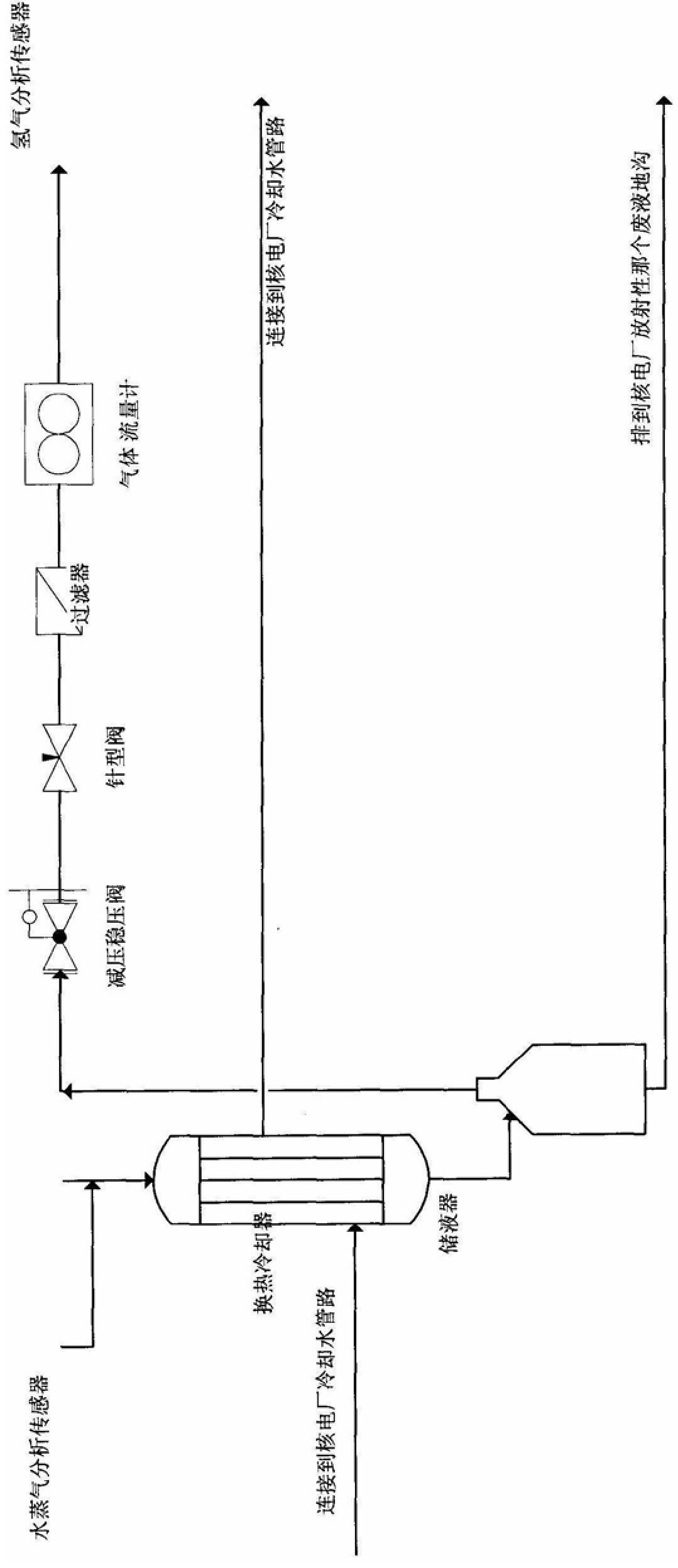

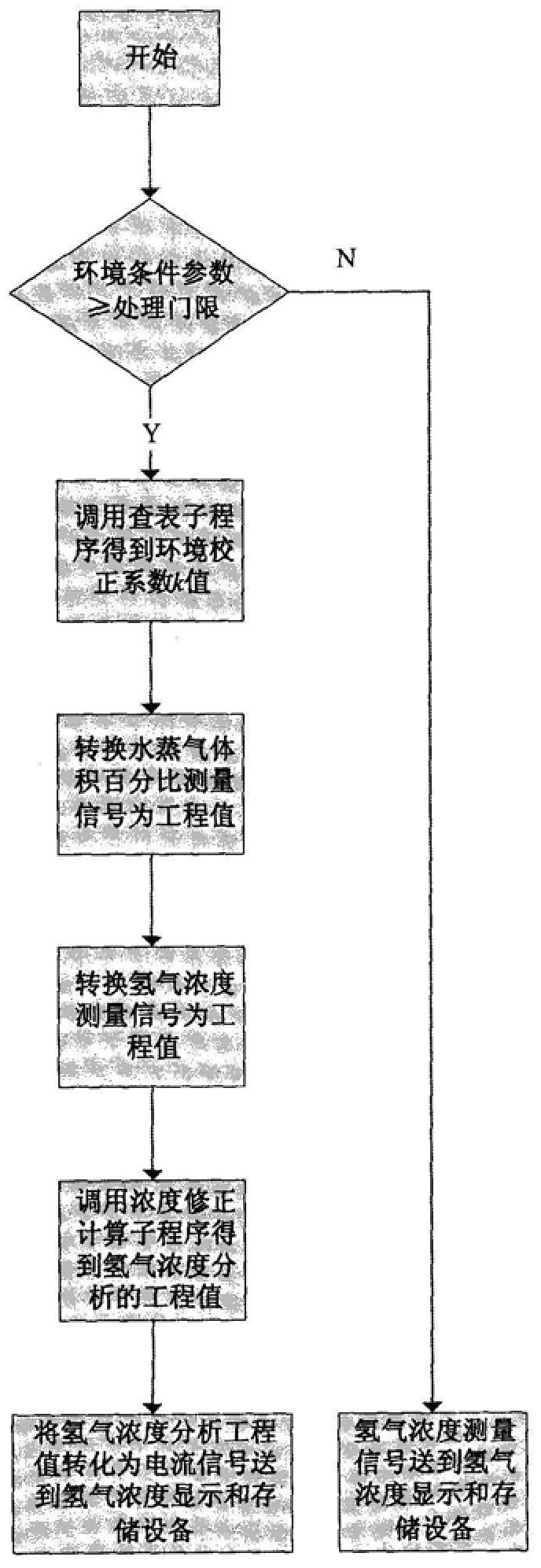

A sampling analysis system for measuring the concentration of hydrogen in the containment vessel, comprising: a sampling pipeline, a transmission pipeline, a water vapor analysis sensor, a gas pretreatment unit, a hydrogen analysis sensor, a booster pump, a microprocessor, and a display unit; The gas in the containment is extracted by the sampling pipeline with thermal insulation treatment function, and the gas is processed to normal temperature and pressure by the pretreatment unit after passing through the water vapor analysis sensor, and the hydrogen volume in the pretreated gas is measured by the hydrogen analysis sensor Concentration, the microprocessor determines the current hydrogen volume concentration in the containment according to the measurement results of the sensor and outputs and displays it. It adapts to the use requirements of common gas analysis sensors and eliminates the influence of water vapor on the gas extraction measurement method in the containment by preprocessing the measured gas and combining with the preset algorithm program in the microprocessor. It is especially suitable for accurate measurement of the volume concentration of hydrogen or other explosive gas components in the containment under accident conditions of nuclear power plants.

Description

A Sampling and Analysis System for Measuring Hydrogen Concentration in Containment Vessel technical field The invention relates to a sampling analysis system for measuring hydrogen concentration, belonging to the technical field of gas concentration analysis and measurement. Background technique The gas composition in the containment of the nuclear power plant beyond the benchmark accident conditions and severe accidents is mainly air and water vapor, containing hydrogen and other gases, high-temperature and high-humidity mixed gas. Sources of hydrogen: 1) In the early stage of the accident, zirconium-water reaction produced hydrogen at a high rate; 2) In the middle and late stages of the accident, a large amount of hydrogen was also produced by the radiation decomposition of water, the reaction of core melt and concrete. Under accident conditions, the reactor emits a large amount of heat, and the temperature inside the containment vessel can reach as high as 180°C, and a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N5/04G01N1/00G21C17/00

CPCY02E30/30

Inventor 罗沙黄永生董强牛立宏冯海波袁晓燕

Owner 718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com