a scaly g-c 3 no 4 Nanosheet and its preparation method

A technology of g-c3n4 and nanosheets, which is applied in the fields of chemical instruments and methods, chemical/physical processes, hydrogen/synthesis gas production, etc., can solve the problems of amorphous shape, difficult shape control, and limited photocatalytic performance, and achieve high Effect of crystallinity, expansion of light absorption range, and reduction of recombination probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A scaly g-C 3 N 4 A method for preparing nanosheets, comprising the following steps:

[0024] (1) Melamine is mixed with three kinds of salts by 1:1 mass ratio (wherein, three kinds of salts are BaCl 2 , KCl and NaCl are mixed in a mass ratio of 5:3:2), mixed and poured into a beaker containing distilled water, then stirred and evaporated to dryness (wherein, the stirring time is 1 to 10 hours, preferably 5 hours, evaporated to dryness The temperature is 60-90°C, preferably 80°C);

[0025] (2) Put the evaporated mixture in a box furnace, heat it to 565°C, and keep it warm for 4 hours to prepare g-C with scaly characteristics 3 N 4 Nanosheets.

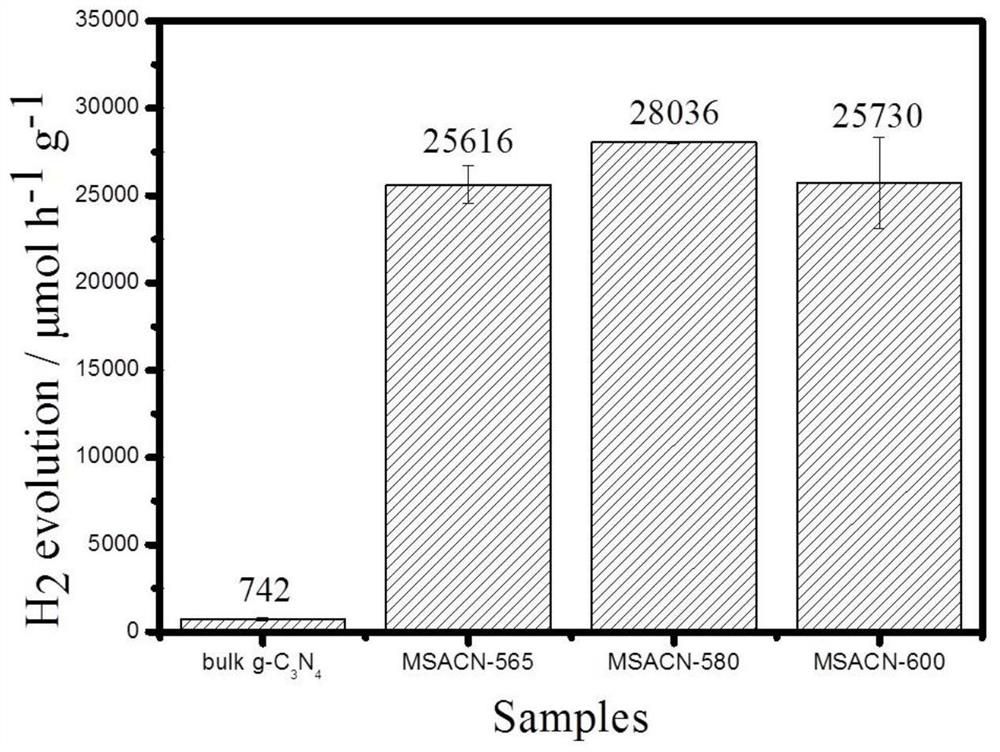

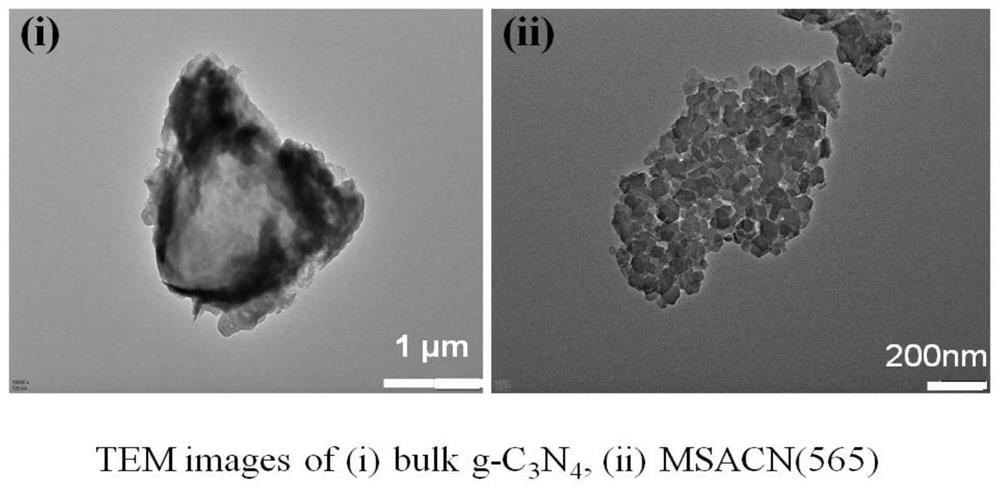

[0026] After testing, g-C prepared according to the above steps 3 N 4 Nanosheets, under visible light irradiation, photocatalyzed water splitting hydrogen at a rate of 25616 μmol h -1 g -1 , which is about 34.5 times that of the photocatalytic hydrogen evolution performance of the coarse powder calcined from the nitrogen...

Embodiment 2

[0028] The preparation method of this embodiment is the same as that of Example 1, except that the heating temperature in step (2) is 580°C.

[0029] The sample obtained in this embodiment, g-C 3 N 4 The surface of the nanosheets is evenly distributed, there is no amorphous agglomeration phenomenon, and it has a unique microscopic morphology. After testing, the g-C prepared according to the above steps 3 N 4 Nanosheets, under visible light irradiation, photocatalyzed water splitting hydrogen at a rate of 28036 μmol h -1 g -1 , which is about 37.8 times that of the photocatalytic hydrogen evolution performance of the coarse powder calcined from the nitrogen-containing organic raw material without adding the three kinds of salts.

Embodiment 3

[0031] The preparation method of this example is the same as Example 1, except that the heating temperature in step (2) is 600°C.

[0032] The sample obtained in this embodiment, g-C 3 N 4 The surface of the nanosheets is evenly distributed, there is no amorphous agglomeration phenomenon, and it has a unique microscopic morphology. After testing, the g-C prepared according to the above steps 3 N 4 Nanosheets, under visible light irradiation, photocatalyzed water splitting hydrogen at a rate of 25730 μmol h -1 g -1 , which is about 34.6 times that of the photocatalytic hydrogen evolution performance of the coarse powder calcined from the nitrogen-containing organic raw material without adding the three kinds of salts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com