Analysis method of oil-rich coal

An analysis method and oil-rich technology, applied in the petroleum industry, special forms of dry distillation, coke ovens, etc., can solve problems such as insufficient understanding of concepts, backward systemic supporting technologies, lack of systematic processes in testing and analysis methods, etc., and achieve an increase in tar yield , Improve the effect of pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present embodiment provides a method for analyzing oil-rich coal, comprising the following steps:

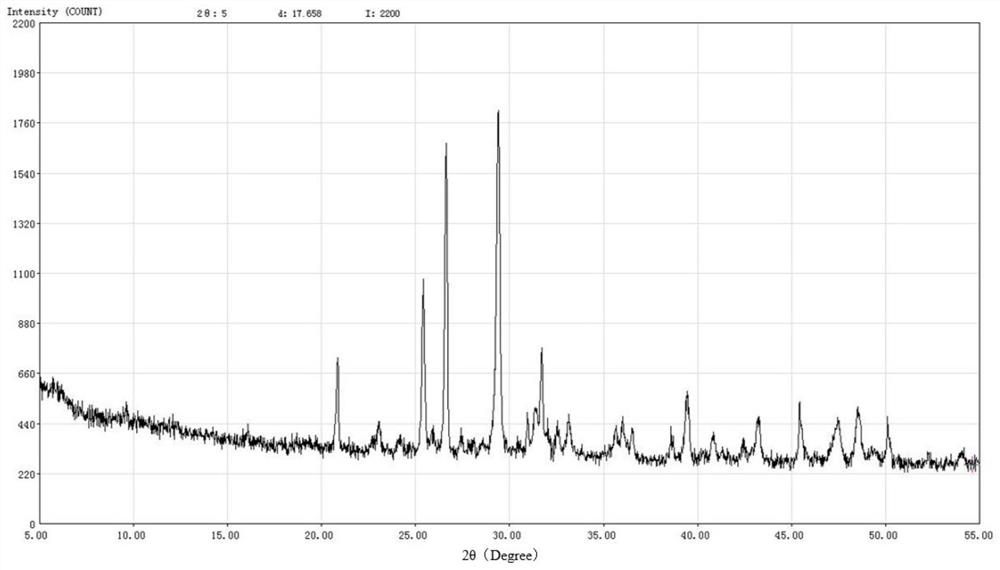

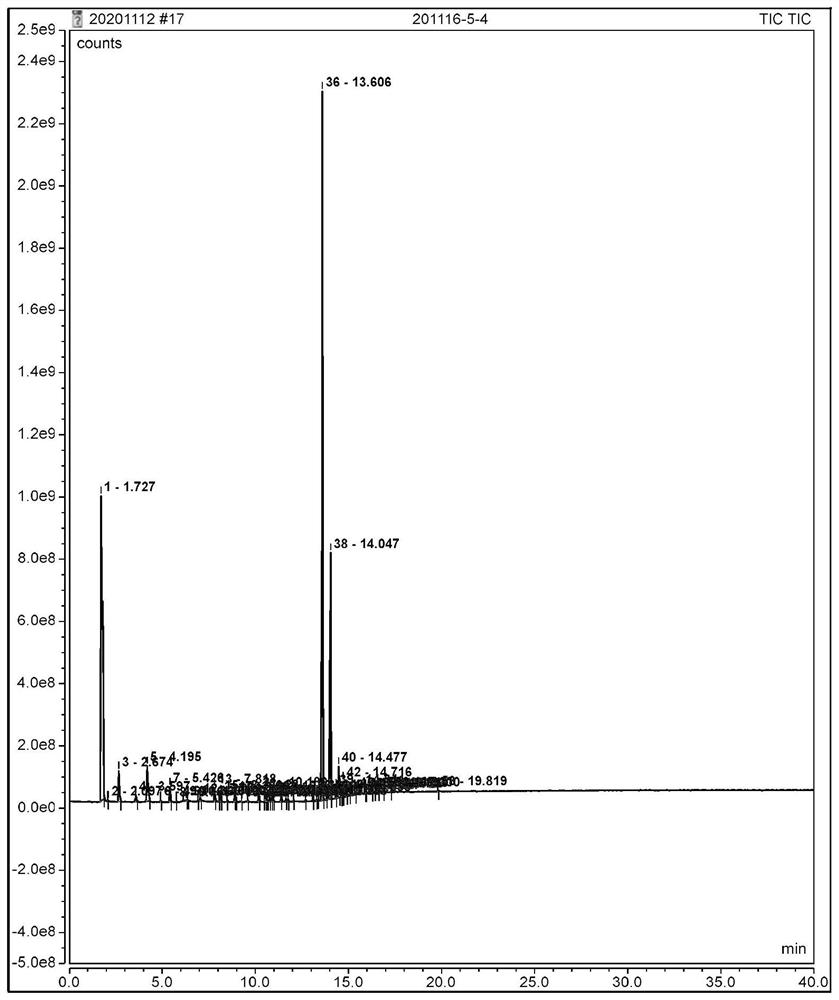

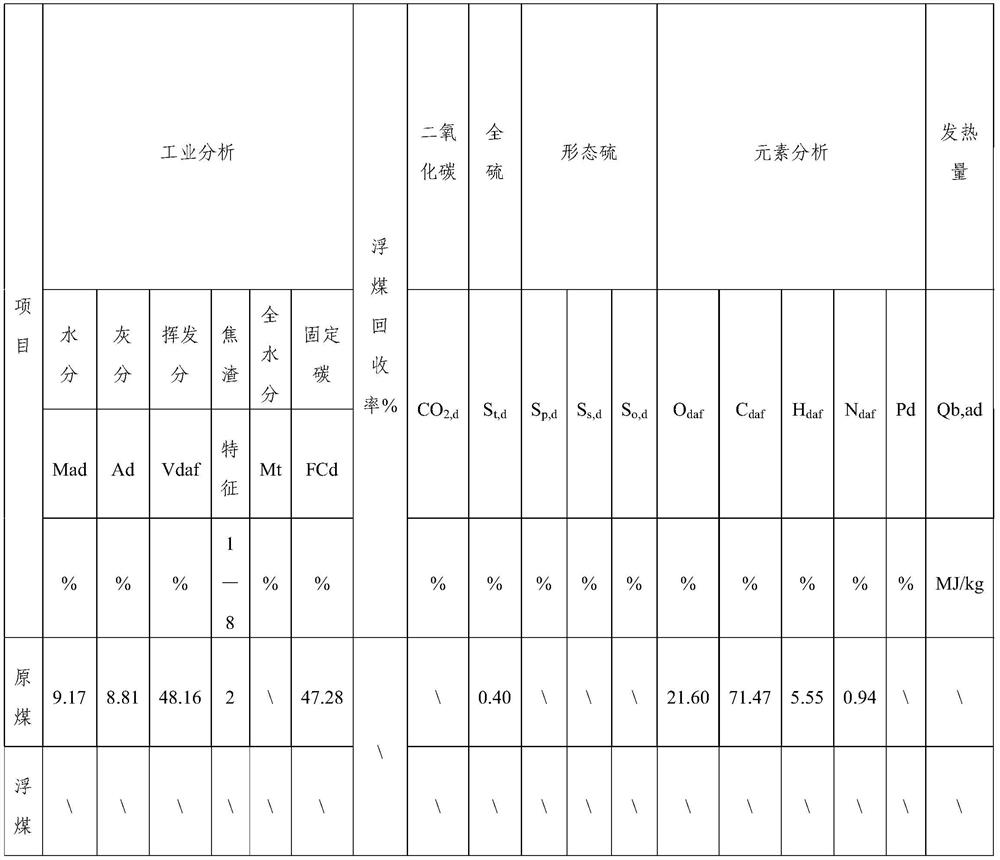

[0040](1) Industrial analysis of oil-rich coal (according to GB / T212-2008), total sulfur analysis (according to GB / T214-2007), hydrocarbon analysis (according to GB / T476-2008), ash component analysis ( According to GB / T1574-2007), nitrogen analysis (according to GB / T19227-2008), Gejin low temperature dry distillation analysis (according to GB / T1341-2007), vitrinite reflectance analysis (according to GB / T6948-2008 ), microscopic component classification analysis (according to GB / T15588-2013), scanning electron microscope analysis (according to SY / T5162-2014), energy spectrum quantitative analysis (according to SY / T6189-2018), X-ray diffraction Rock analysis (according to SY / T5163-2018);

[0041] Wherein, the analysis results are shown in Table 1, Table 2, Table 3, Table 4 and Table 5;

[0042] Table 1

[0043]

[0044] Table 2

[0045]

[0046] table 3

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com