Method for growing titanium dioxide nano-particles on surface of titanium or titanium alloy substrate

A substrate surface and titanium dioxide technology, which is applied in the field of growing titanium dioxide nanoparticles on the surface of titanium or titanium alloy substrates, can solve the problems of repeated recycling of unfavorable catalysts, small and easy to agglomerate, and difficult to settle, and achieve strong practicability, low cost, and high processing temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of titanium dioxide nanogel layer on pure titanium surface by treating with hydrogen peroxide and hydrochloric acid

[0049] Using 25×25×3mm pure titanium as the substrate, it was polished with 400 mesh, 800 mesh, 1200 mesh, and 2000 mesh SiC sandpaper, and then ultrasonically cleaned in absolute ethanol and deionized water for 20 minutes to remove oil stains.

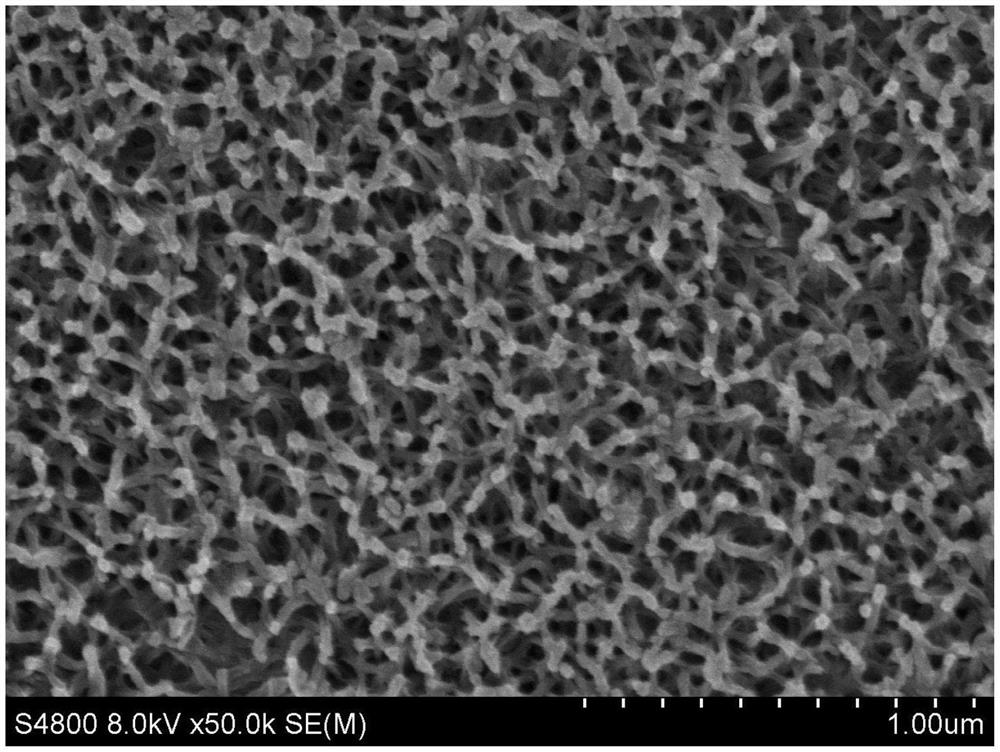

[0050] Configure 30%H 2 o 2 and 0.1M HCl mixed solution 30ml (each 15ml), put the titanium substrate into the mixed solution, and move it into an oven at 80°C, keep it warm for 40min, take it out, and wash it with deionized water. Then put the cleaned sample into an oven at 150°C and keep it warm for 1h. like figure 1 As shown, after pure titanium is etched by hydrogen peroxide and hydrochloric acid, a porous sponge-like surface structure is formed with a depth of about 200 nm.

Embodiment 2

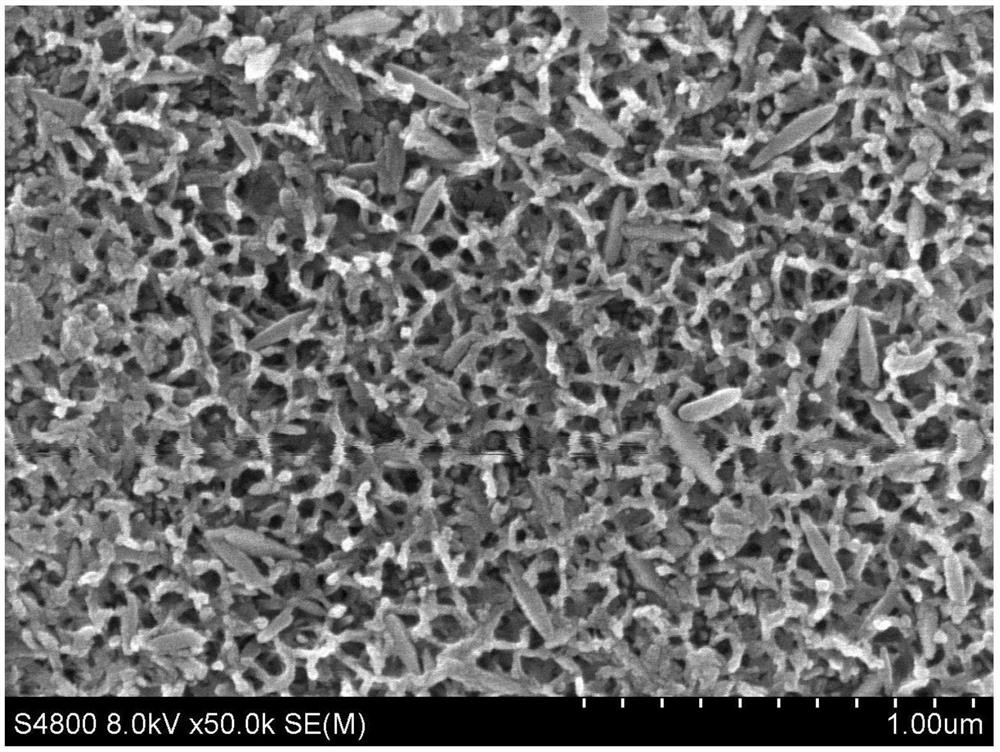

[0052] Titanium dioxide nano-films prepared by treating pure titanium surface with sodium chloride solution for 1 hour with hydrothermal treatment

[0053] In this example, the steps for preparing a titanium dioxide nanogel layer on the surface of pure titanium are shown in Example 1, and the appearance is as follows figure 1 As shown, the specific preparation steps are:

[0054] Using 25×25×3mm pure titanium as the substrate, it was polished with 400 mesh, 800 mesh, 1200 mesh, and 2000 mesh SiC sandpaper, and then ultrasonically cleaned in absolute ethanol and deionized water for 20 minutes to remove oil stains.

[0055] Configure 30%H 2 o 2 and 0.1M HCl mixed solution 30ml (each 15ml), put the titanium substrate into the mixed solution, and move it into an oven at 80°C, keep it warm for 40min, take it out, and wash it with deionized water. Then put the cleaned sample into an oven at 150°C and keep it warm for 1h.

Embodiment 3

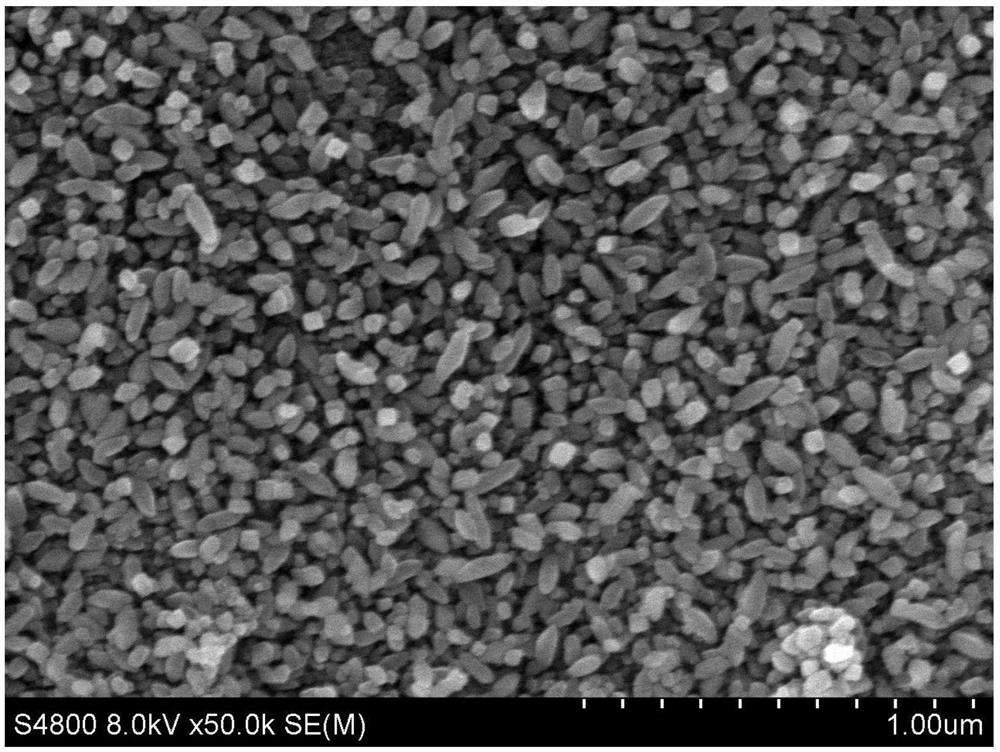

[0058] Preparation of Titanium Dioxide Nanofilms by Hydrothermally Treating Pure Titanium Surface with Sodium Chloride Solution for 5 Hours

[0059] In this example, the steps for preparing a titanium dioxide nanogel layer on the surface of pure titanium are shown in Example 1, and the appearance is as follows figure 1 As shown, the specific preparation steps are:

[0060] Using 25×25×3mm pure titanium as the substrate, it was polished with 400 mesh, 800 mesh, 1200 mesh, and 2000 mesh SiC sandpaper, and then ultrasonically cleaned in absolute ethanol and deionized water for 20 minutes to remove oil stains.

[0061] Configure 30%H 2 o 2 and 0.1M HCl mixed solution 30ml (each 15ml), put the titanium substrate into the mixed solution, and move it into an oven at 80°C, keep it warm for 40min, take it out, and wash it with deionized water. Then put the cleaned sample into an oven at 150°C and keep it warm for 1h.

[0062] Configure 5% sodium chloride solution, add it into a pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com