Anti-corrosion treatment method for inner wall of drill pipe

An anti-corrosion treatment and drill pipe technology, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of many leakage points, large porosity, thin coating, etc., to improve the ability of nitric acid resistance, ensure the anti-corrosion ability, improve the hardness of the coating and The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

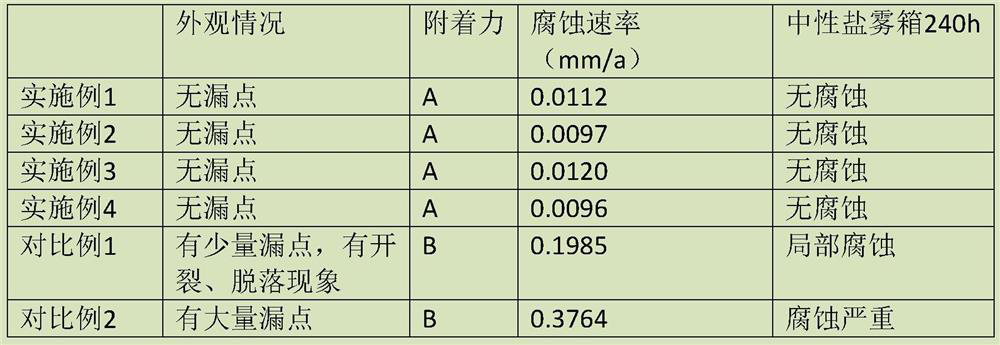

Examples

Embodiment 1

[0030] Take 30-50nm zirconia particles and rinse them with clean water, put them into a hydrochloric acid solution with a volume ratio of hydrochloric acid and water of 1:1, soak for 2 hours, wash with water, put them into 150g / L trisodium phosphate solution for 3 minutes, and then wash with water to get Surface-activated zirconia.

[0031] Sulfuric acid, citric acid, sodium citrate, phosphorous acid, sodium tungstate, and zirconia treated with surface activation as above were weighed and added to deionized water to prepare an electroplating solution. The electroplating solution is composed of: sulfuric acid 100g / L, citric acid 60g / L, sodium citrate 100g / L, phosphorous acid 45g / L, sodium tungstate 100g / L, zirconia 12g / L, and the balance is water.

[0032] Take the drill pipe and carry out electroplating anti-corrosion treatment on its inner wall. The electroplating process includes the following steps:

[0033] High temperature degreasing→installing tooling→rust removal of in...

Embodiment 2

[0046] Take 30-50nm zirconia particles and rinse them with clean water, put them in a hydrochloric acid solution with a volume ratio of hydrochloric acid and water of 1:2, soak for 1 hour, wash with water, soak in 100g / L sodium phosphate solution for 2 minutes, and then wash with water to get the surface Activated zirconia.

[0047] Sulfuric acid, citric acid, sodium citrate, phosphorous acid, sodium tungstate, and zirconia treated with surface activation as above were weighed and added to deionized water to prepare an electroplating solution. The electroplating solution is composed of: sulfuric acid 300g / L, citric acid 6g / L, sodium citrate 15g / L, phosphorous acid 7g / L, sodium tungstate 100g / L, zirconia 5g / L, and the balance is water.

[0048] Take the drill pipe and carry out electroplating anti-corrosion treatment on its inner wall. The electroplating process includes the following steps:

[0049] High temperature degreasing→installing tooling→rust removal of inner wall→rep...

Embodiment 3

[0062] Take 30-50nm zirconia particles and rinse them with clean water, put them into hydrochloric acid and water 1:1 hydrochloric acid solution and soak for 3 hours. Treated zirconia.

[0063] Sulfuric acid, citric acid, sodium citrate, phosphorous acid, sodium tungstate, and zirconia treated with surface activation as above were weighed and added to deionized water to prepare an electroplating solution. The electroplating solution is composed of: sulfuric acid 200g / L, citric acid 30g / L, sodium citrate 60g / L, phosphorous acid 25g / L, sodium tungstate 40g / L, zirconia 8g / L, and the balance is water.

[0064] Take the drill pipe and carry out electroplating anti-corrosion treatment on its inner wall. The electroplating process includes the following steps:

[0065] High temperature degreasing→installing tooling→rust removal of inner wall→replacing tooling→flowing degreasing→flowing water washing→flowing pickling→flowing water washing→flowing neutralization→installing anodes→flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com