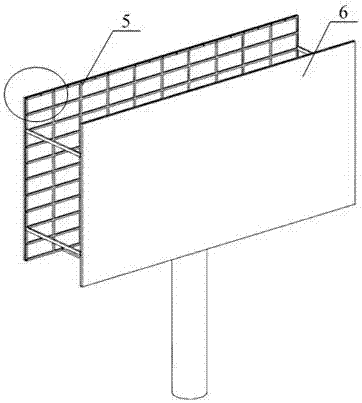

Self-piercing riveting method applied to outdoor billboard

A self-piercing riveting and billboard technology, which is applied in the field of self-piercing riveting, can solve the problems of poor sealing of joints, damage to joint strength and fatigue resistance, easy liquid intrusion, etc., and achieve good static properties and fatigue resistance , Guarantee sealing and anti-corrosion performance, and solve the effect of poor combined connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

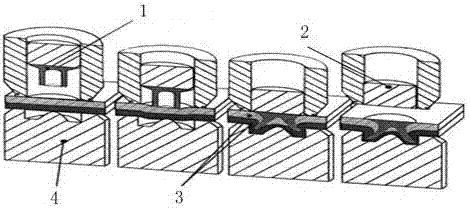

Method used

Image

Examples

Embodiment 1

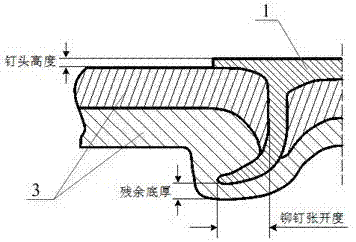

[0032] Example 1: A self-piercing riveting method applied to outdoor billboards, Q215 galvanized steel plate (1.5 mm in thickness) and AL1420 aluminum-lithium alloy plate (1.5 mm in thickness) were selected for single-lap self-piercing riveting test and joint mechanics In the performance test, the nail head height of the joint is -0.27 mm, the rivet opening is 0.81 mm, and the residual bottom thickness is 0.62 mm. The research shows that the average static failure load of AL1420-Q215 material combination single-lap self-piercing riveting joint is 5448 N, the energy absorption value is 15.3 J, and the failure mode of the joint is the separation of the lower plate and the self-piercing rivet; the shape and size of the joint used in the test are as follows Figure 7 As shown, the load-displacement curve of the joint is shown as Figure 8 shown.

example 2

[0033] Example 2: A self-piercing riveting method applied to outdoor billboards, Q215 galvanized steel plate (thickness 1.5 mm) and AA5052 aluminum alloy plate (thickness 1.5 mm) were selected for single-lap self-piercing riveting test and joint mechanical performance test , the nail head height of the joint is -0.44 mm, the rivet opening is 0.63 mm, and the residual base thickness is 0.63 mm. The research shows that the average static failure load of AA5052-Q215 material combination single-lap self-piercing riveting joint is 3303.5 N, the energy absorption value is 16.9 J, and the joint fails due to the fracture of the upper plate; the shape and size of the joint used in the test are as follows Figure 9 As shown, the load-displacement curve of the joint is shown as Figure 10 shown.

example 3

[0034] Example 3: A self-piercing riveting method applied to outdoor billboards. Q215 galvanized steel plate (1.5 mm in thickness) and 8090 aluminum-lithium alloy plate (1.5 mm in thickness) were selected for T-shaped self-piercing riveting test and joint peeling In the performance test, the nail head height of the joint is -0.15 mm, the rivet opening is 0.75 mm, and the residual bottom thickness is 0.78 mm. The research shows that the average maximum peeling load of the T-shaped self-piercing riveting joint with 8090-Q215 material is 870.5 N, and the energy absorption of the joint is 870.5 N. The value is 27.2 J, and the failure mode of the joint is that the contact area between the upper plate and the rivet head is broken, and the macroscopic fracture is V-shaped; the shape and size of the joint used in the test are as follows Figure 11 As shown, the load-displacement curve of the joint is shown as Figure 12 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com