Coating roller, preparation method and application thereof and copper-clad plate

A technology of coating rollers and copper clad laminates, which is applied in the direction of surface coating liquid devices, coatings, and printed circuit manufacturing, which can solve the problems of easy loss of coatings and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

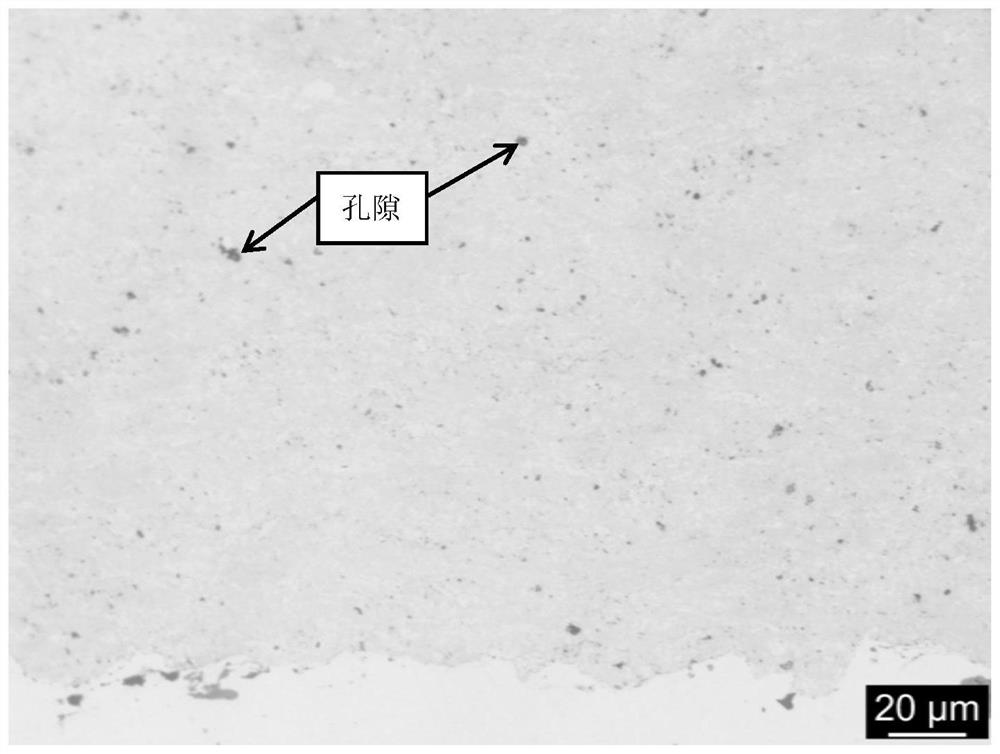

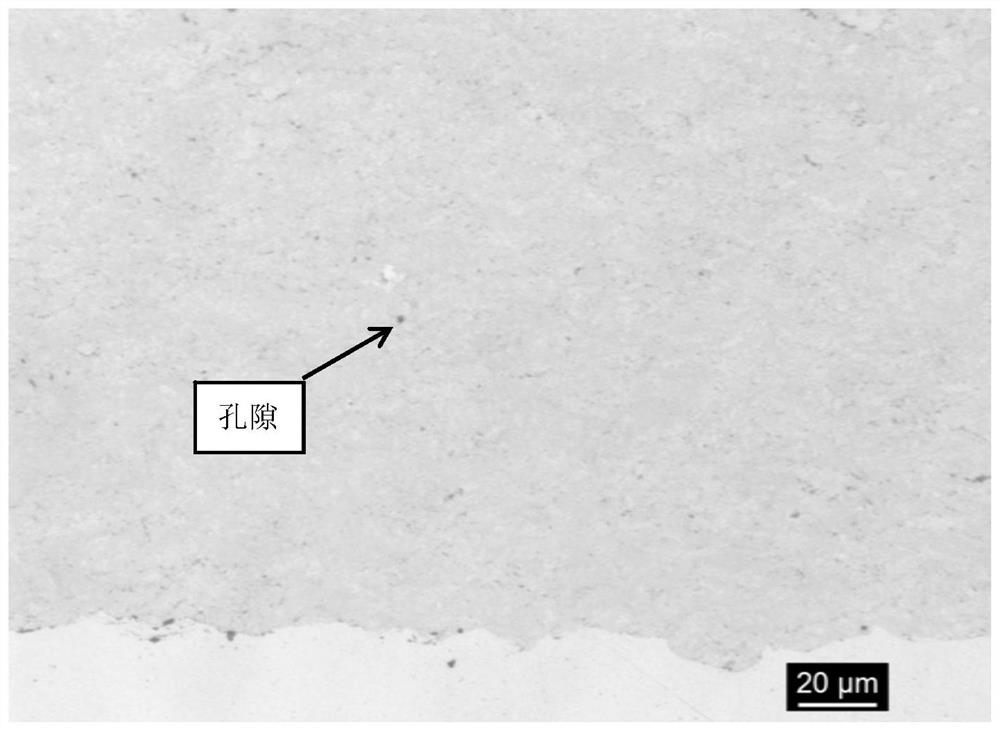

[0079] Through the above preparation method, the nano tungsten carbide coating on the surface of the coating roller can reach a thickness of 100-350 μm. In some preferred embodiments, the nano-tungsten carbide coating in the coating roller is 200-300 μm.

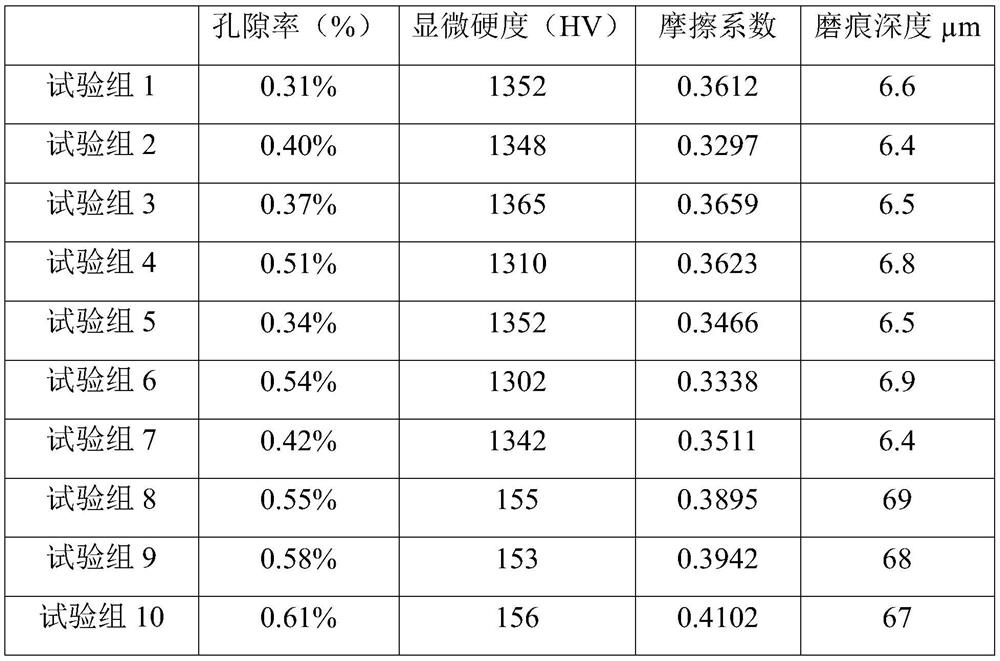

[0080] In a preferred embodiment, the porosity of the nano-tungsten carbide coating of the coating roller prepared by the above method is less than 1%. Under the condition that the load is 50g and the load is maintained for 15s, the microhardness of the nano-tungsten carbide coating of the coating roller is 1300-1500HV. When the load is 1000g, the rotation speed is 400r / min, the rotation radius is 3mm, the rotation time is 30min, and the grinding ball is Si 3 N 4 Under the condition of rotating friction, the friction coefficient of the nano-tungsten carbide coating of the coating roller is 0.3338-0.3659, and the wear scar depth is 6.4-6.9 μm.

[0081] In addition, the present application also provides the application of t...

Embodiment 1

[0087] by The 45# steel roll body is used as the substrate for preparing the copper-clad laminate coating roll, and the roll surface is cleaned with alcohol and acetone; the zirconium corundum is sandblasted on the roll surface under a pressure of 0.6MPa; the sandblasting nozzle is 90 degrees from the roll surface. Select the WC powder with a particle size of 15-30nm (nano WC), and dry it in a constant temperature 70°C oven for 30 minutes. Use the HVOF supersonic flame spray gun to preheat the roller surface first, preheat twice, the preheating temperature is 110 °C, and the preheating time is 12 minutes. On the surface of the 45# steel roller body, use HVOF supersonic flame spraying to deposit a nano-WC coating with a thickness of 200 μm; the process parameters of HVOF supersonic flame spraying are: the flow rate of oxygen is 900L / min, and the flow rate of kerosene is 25L / h , the combustion chamber pressure is 8.6bar, the powder delivery rate is 100g / min, and the spraying d...

Embodiment 2

[0089] by The stainless steel roll body is used as the substrate for preparing the copper-clad laminate coating roll, and the roll surface is cleaned with alcohol and acetone; the zirconium corundum is used to sandblast the roll surface under a pressure of 0.5 MPa; the sandblasting nozzle is at 90 degrees to the roll surface. Select the WC powder with a particle size of 15-30nm (nano WC), and dry it in a constant temperature 80°C oven for 30 minutes. Use the HVOF supersonic flame spray gun to preheat the roller surface first, preheat twice, the preheating temperature is 120 °C, and the preheating time is 15 minutes. A nano-WC coating with a thickness of 260 μm was sprayed with HVOF supersonic flame spraying on the surface of the stainless steel roller body; the process parameters of the HVOF supersonic flame spraying: the oxygen flow rate was 920L / min, the kerosene flow rate was 26L / h, the combustion chamber The pressure is 8.8bar, the powder delivery rate is 110g / min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com