Copper-bearing titanium-based wear-resisting laser cladding layer on surface of titanium alloy and preparation method of copper-bearing titanium-based wear-resisting laser cladding layer

A laser cladding and surface coating technology, which is applied in the coating process and coating of metal materials, can solve the problems of reduced mechanical properties of the cladding layer, unfavorable cladding layer forming quality, stress concentration of the cladding layer, etc., and achieves good results. Effects of metallurgical bonding, increasing fluidity of molten pool, and dense and uniform distribution

Inactive Publication Date: 2020-05-08

CIVIL AVIATION UNIV OF CHINA

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

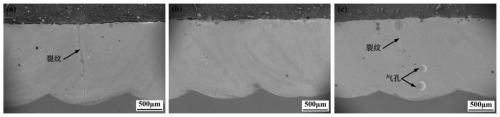

The cladding layer prepared by using nickel-based self-fluxing alloy can effectively improve the hardness and wear resistance of the titanium alloy surface, but the cladding layer often produces a hard phase with a coarse structure, and the process characteristics of rapid heating and cooling of laser cladding, It is easy to cause stress concentration and pore defects in the cladding layer, and cracks are easily initiated from the coarse hard phase generated in the cladding layer, and then spread to the entire cladding layer, which is not conducive to the forming quality of the cladding layer, making the cladding layer The mechanical properties are greatly reduced, which limits its industrial application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

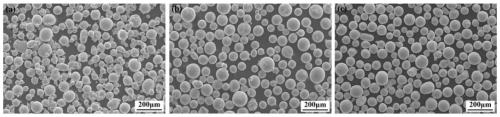

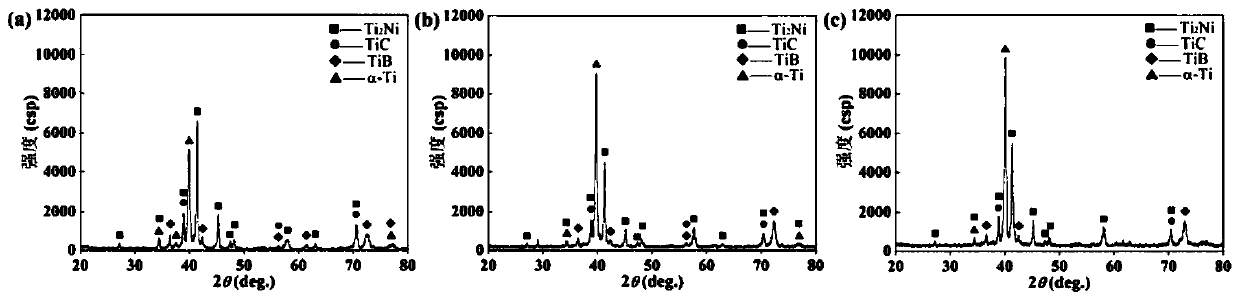

[0046] The specific scheme of this case is 65wt% TC4+35wt% Ni60, and the laser cladding layer is prepared according to the above steps.

Embodiment 2

[0048] The specific scheme of this case is 65wt% TC4 + 30wt% Ni60 + 5wt% Cu, and the laser cladding layer is prepared according to the above steps.

Embodiment 3

[0050] The specific scheme of this case is 65wt%TC4+25wt%Ni60+10wt%Cu, and the laser cladding layer is prepared according to the above steps.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of titanium alloy surface engineering, and particularly relates to a copper-bearing titanium-based wear-resisting laser cladding layer on the surface of a titanium alloy and a preparation method of the copper-bearing titanium-based wear-resisting laser cladding layer. Cladding layer comprises 65wt% of TC4 powder, 25-35wt% of Ni60 powder and 0-10wt% of Cu powder.The TC4 powder comprises 6.36wt% of Al, 4.06wt% of V, 0.011wt% of N, 0.05wt% of Fe, 0.077wt% of O and the balance Ti. The Ni60 powder comprises 15.5wt% of Cr, 0.8wt% of C, 3.5wt% of B, 4.0wt% of Si, 5.0wt% of Fe, 3.0wt% of W and the balance Ni. The purity of the Cu powder is larger than 99%. The forming quality of the laser cladding layer is improved, the friction and wear performance of the surface of the titanium alloy can be obviously improved, and the service life of the titanium alloy can be prolonged.

Description

technical field [0001] The invention belongs to the field of titanium alloy surface engineering, in particular to a copper-containing titanium-based wear-resistant laser cladding layer on the surface of a titanium alloy and a preparation method thereof. Background technique [0002] Ti-6Al-4V (TC4) alloy has the characteristics of high specific strength, excellent medium and low temperature performance and low density, which can meet the requirements of high thrust-to-weight ratio, high reliability and long life of advanced aero-engines. It is the engine blade, compressor disk, One of the important materials for casing and aircraft structural parts. However, titanium alloys have low hardness and poor wear resistance. Under high-speed aerodynamic loads and harsh environments, titanium alloy parts such as compressor blades, fan blades and casings will inevitably be scratched and worn due to inhalation of foreign matter in the air , destroying the structural strength and aerod...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C24/10C22C14/00

CPCC22C14/00C23C24/103

Inventor 张志强肖海强张天刚姚波杨凡张倩

Owner CIVIL AVIATION UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com