Preparation method of negative electrode composite current collector and product prepared by preparation method

A current collector and negative electrode technology, which is applied in the field of preparation method and its products, can solve the problems of poor binding force, many surface defects, and poor electrical conductivity, and achieve the goals of reducing internal resistance, less surface defects, and improving electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

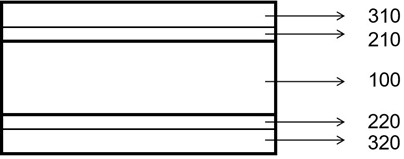

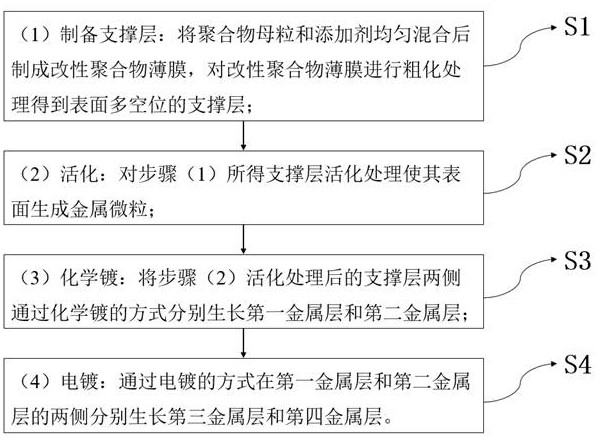

[0034] A kind of preparation method of negative electrode composite current collector of the present invention, such as figure 2 As shown, it specifically includes the following steps:

[0035] (1) Prepare the support layer 100: uniformly mix the polymer masterbatch and additives to form a modified polymer film, and roughen the modified polymer film to obtain a support layer 100 with many vacancies on the surface;

[0036] (2) Activation: activate the support layer 100 obtained in step (1) to generate metal particles on the surface;

[0037] (3) Electroless plating: the first metal layer 210 and the second metal layer 220 of a certain thickness are respectively grown on both sides of the support layer 100 after the activation treatment in step (2) by means of electroless plating;

[0038] (4) Electroplating: the third metal layer 310 and the fourth metal layer 320 are respectively grown on both sides of the first metal layer 210 and the second metal layer 220 by electroplati...

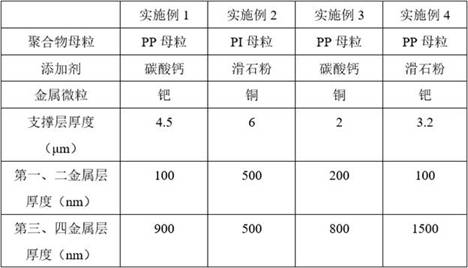

Embodiment 1

[0040] (1) Preparation of support layer 100: uniformly mix PP (polypropylene) masterbatch, calcium carbonate, and lubricant by filling, and biaxially stretch the film to form support layer 100, and soak the obtained support layer 100 in strong acid Coarsening, through the roll-to-roll method at a speed of 2-20m / min to roughen the surface of the roughening solution, the concentration of chromic acid in the roughening solution is 300-500g / L, and the concentration of sulfuric acid is 400-500g / L;

[0041] (2) Activation: the support layer 100 is activated by using a base colloidal palladium activation process, and the support layer 100 passes through the base colloidal palladium activation solution pool and then passes through an oven to solidify the activation solution to activate the support layer 100;

[0042] (3) Electroless plating: pass the support layer 100 after the activation treatment in step (2) through the electroless plating bath, and form a first metal layer 210 and a...

Embodiment 2

[0045] (1) Prepare the support layer 100: uniformly mix PI (polyimide) masterbatch and talc powder by filling, and biaxially stretch the film to form the support layer 100, and pass the obtained support layer 100 through the roll-to-roll method After femtosecond laser etching to roughen the surface, the femtosecond laser etching process parameters are: power 2.0 W, spot diameter 0.2 mm, scan rate 12 mm / s;

[0046] (2) Activation: The support layer 100 is activated by using a laser-induced activation process. The support layer 100 passes through a metal salt activation solution, the metal salt is a copper salt, and then passes through an oven to solidify the activation solution, and uses laser induction to make the support layer 100 activation;

[0047] (3) Electroless plating: pass the support layer 100 after the activation treatment in step (2) through the electroless plating bath, and form a first metal layer 210 and a second metal layer with a thickness of 500 nm on both si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com