Anti-rust nanocrystal alloy and fabrication method thereof

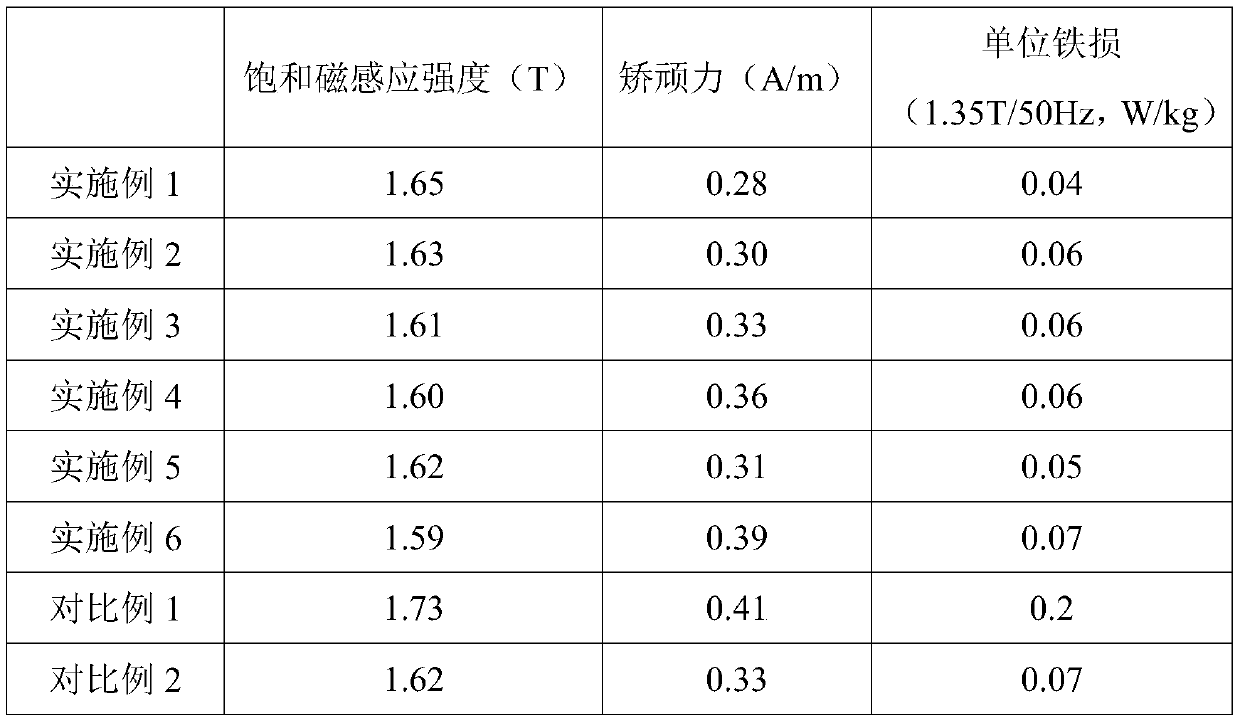

A nanocrystalline alloy and alloy technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of complex polishing process, damage to the performance indicators of flaky nanocrystalline alloys, etc., and achieve improved amorphous formation. capacity, low iron loss, low coercivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

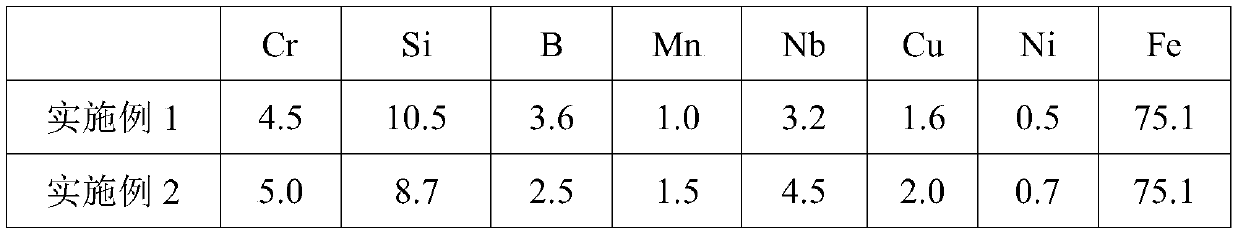

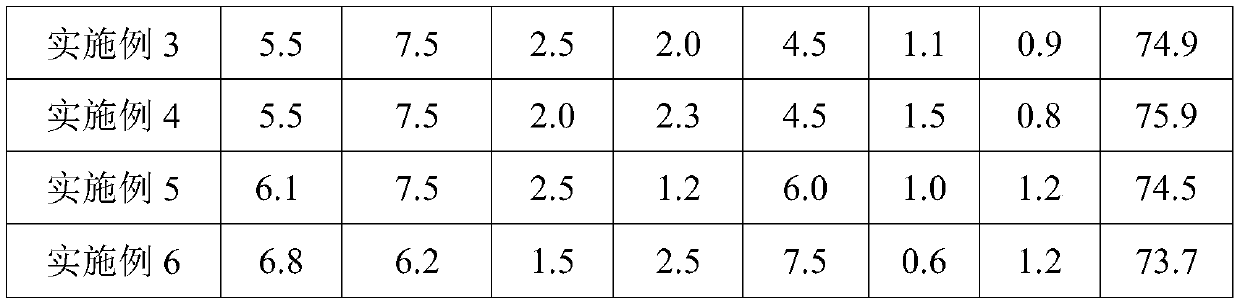

Embodiment 1~6

[0027] (1) Put the raw materials into the smelting furnace according to the mass ratio shown in Table 1. After melting, keep the temperature at about 1540°C for about 20 minutes, add the purifying agent, stand still for several times to remove slag, and finally make the components in the alloy mother liquor evenly distributed. The respective contents of Al, O and N are below 10ppm; the purifying agent is composed of 55% silicon dioxide, 35% calcium oxide and 10% iron scale;

[0028] (2) Import the alloy mother liquid in the smelting furnace into the tundish, seal the nozzle with a stopper rod, and let it stand for about 30 minutes to make the temperature of the mother liquid even;

[0029] (3) Then lift the plug rod, the mother liquor enters the nozzle bag, and shoots through the nozzle onto the high-speed rotating cooling roller (using water-cooled copper roller), so that the alloy mother liquor 6 ~10 7 Cooling and forming at the speed of ℃ / sec, the spray casting pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com