Method for preparing high-performance molybdenum-based hydrogen evolution electrode by phosphatizing molybdate precursor

A phosphide molybdate, hydrogen evolution electrode technology, applied in electrodes, electrolysis components, electrolysis process and other directions, can solve the problems of low catalytic activity and poor stability of molybdenum-based hydrogen evolution electrodes, and achieve excellent hydrogen evolution activity and stability, cost Low, high reserve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Pretreatment of nickel foam substrate

[0034] Put the nickel foam substrate into the acetone solution and ultrasonically vibrate for 15 minutes for chemical degreasing, then soak it in the aqueous hydrochloric acid solution with a molar concentration of 3 mol / L for 30 minutes to remove the oxides on the surface of the substrate, and finally clean it with deionized water, and then Store in absolute ethanol solution until use.

[0035] (2) Preparation of molybdate precursor

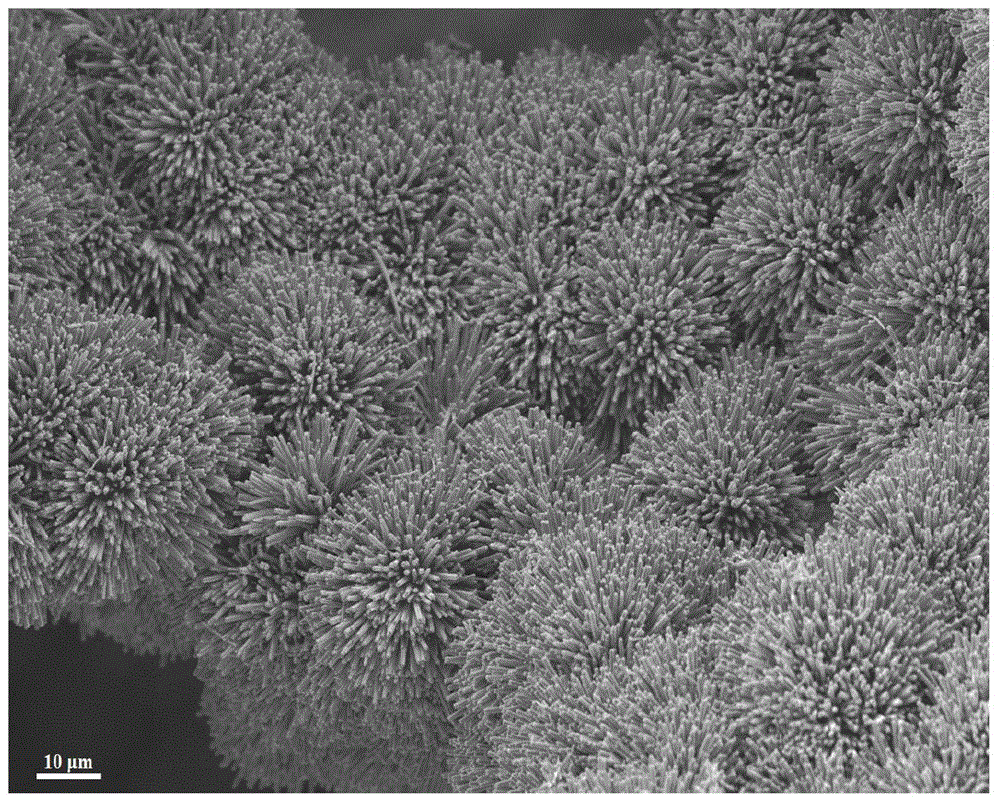

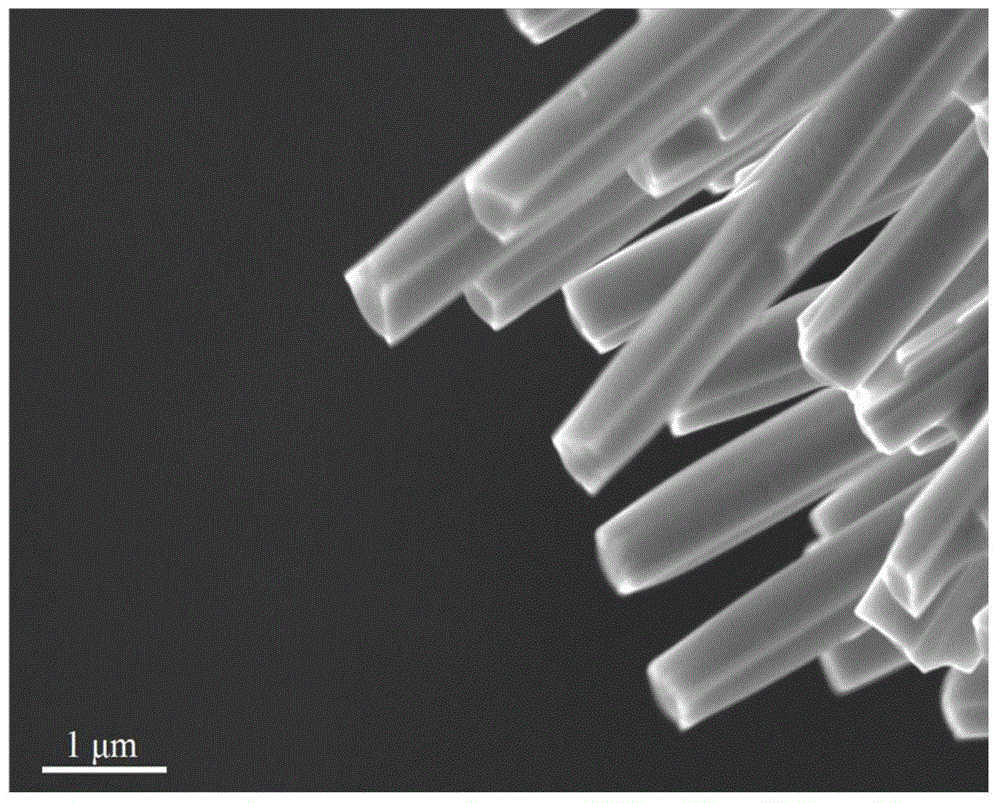

[0036] Take deionized water as solvent, prepare the mixed solution of nickel nitrate, ammonium molybdate, wherein the molar concentration of nickel ion is 0.05 mole / liter, and the molar concentration of molybdenum is 0.05 mole / liter; The substrate was put into a reaction kettle containing a mixed solution of nickel nitrate and ammonium molybdate, and reacted at a temperature of 150°C for 6 hours; after the reaction was completed, it was rinsed with deionized water and dried to obtain a nickel m...

Embodiment 2

[0046] Step (1) is the same as step (1) in Example 1.

[0047] (2) Preparation of molybdate precursor

[0048] Take deionized water as solvent, prepare the mixed solution of cobalt nitrate, ammonium molybdate, wherein the molar concentration of cobalt ion is 0.03 mole / liter, and the molar concentration of molybdenum is 0.03 mole / liter; Put the substrate into a reaction kettle containing a mixed solution of cobalt nitrate and ammonium molybdate, and react at a temperature of 150°C for 12 hours; after the reaction is completed, rinse it with deionized water and dry it to obtain a cobalt molybdate precursor .

[0049] (3) Preparation of molybdenum-based hydrogen evolution electrode

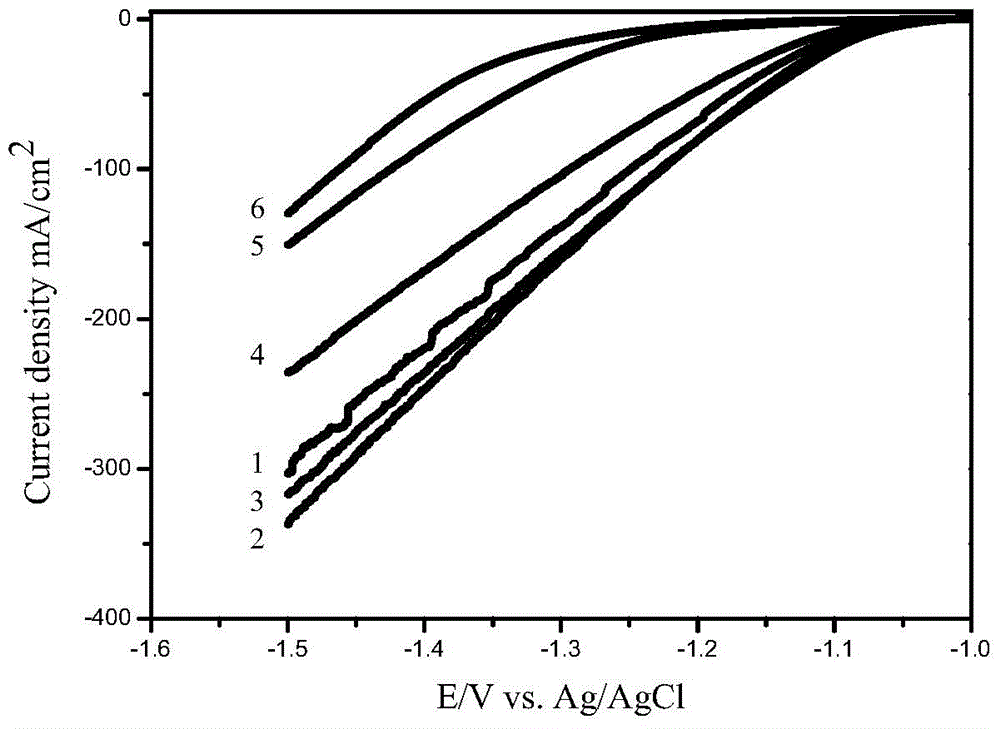

[0050] Place the precursor prepared in step (2) together with sodium hypophosphite in a tube furnace, where the position of sodium hypophosphite is close to the inlet end of the tube furnace, where the molar ratio of Mo:P is 1:10; In an inert atmosphere, the temperature was raised to 400°C and mai...

Embodiment 3

[0052] Step (1) is the same as step (1) in Example 1.

[0053] (2) Preparation of molybdate precursor

[0054] Take deionized water as solvent, prepare the mixed solution of ferrous sulfate, potassium molybdate, wherein the molar concentration of ferrous ion is 0.005 mole / liter, and the molar concentration of molybdenum is 0.01 mole / liter; Step (1) pretreated The nickel foam substrate was placed in a reaction kettle containing a mixed solution of ferrous sulfate and potassium molybdate, and reacted at a temperature of 60°C for 72 hours; after the reaction was completed, it was rinsed with deionized water and dried; then the hydrothermal reaction The finished nickel foam substrate was placed in a hydrogen atmosphere at a temperature of 300° C. for 5 hours, cooled to room temperature, and taken out to obtain a ferrous molybdate precursor.

[0055] (3) Preparation of molybdenum-based hydrogen evolution electrode

[0056] The precursor prepared in step (2) is placed in a tube fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com