Patents

Literature

53 results about "Performance rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

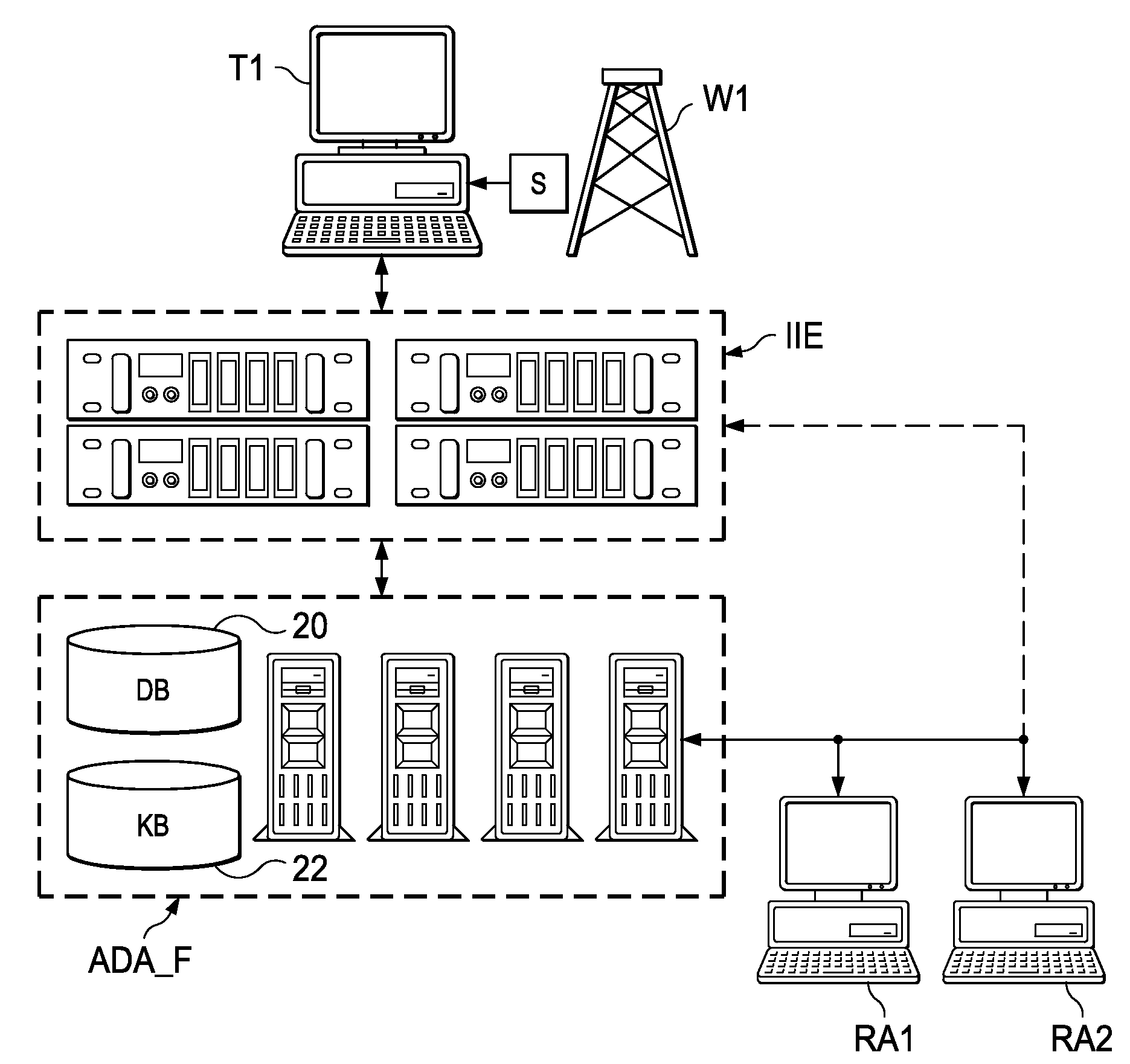

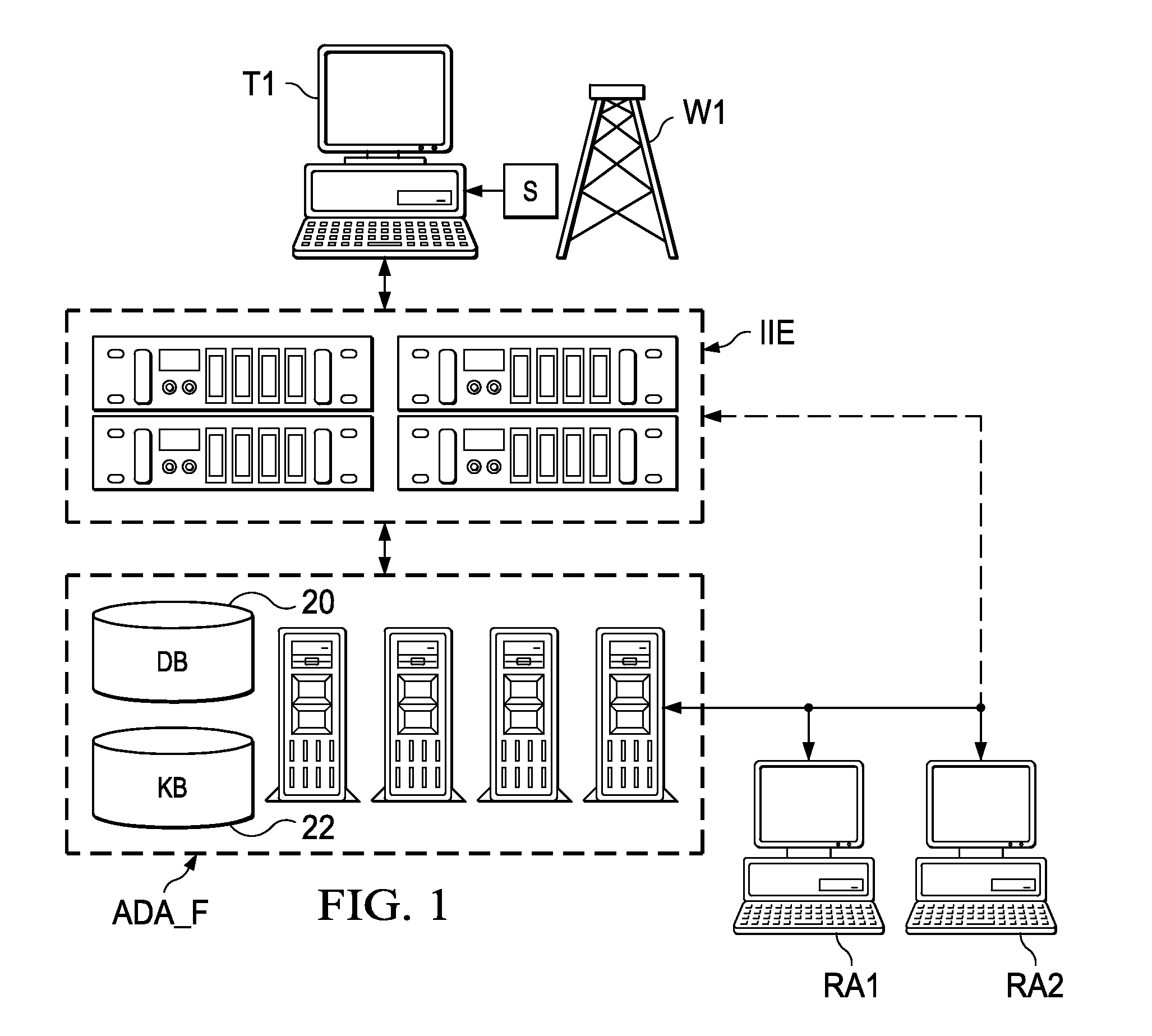

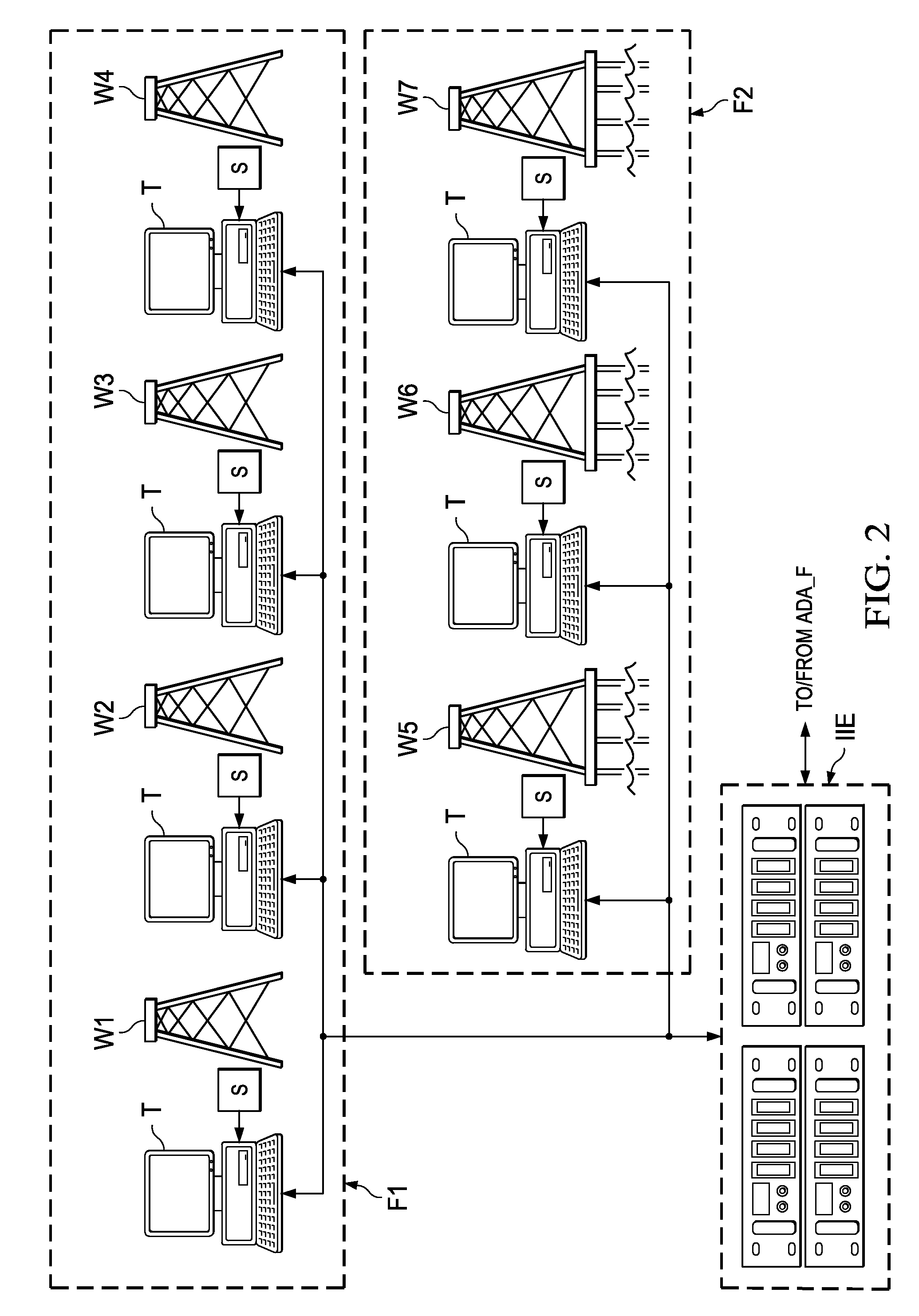

Intelligent Drilling Advisor

ActiveUS20090132458A1Loss of circulationEasy to operateElectric/magnetic detection for well-loggingKnowledge representationComputer sciencePerformance rate

A method, apparatus, and program storage device for integrating and implementing rule-based, heuristic, wellbore key performance rate of penetration indicators advising drilling operations personnel based on the situational awareness of trended earth properties and real time wellbore sensor data, is disclosed.

Owner:BP CORP NORTH AMERICA INC

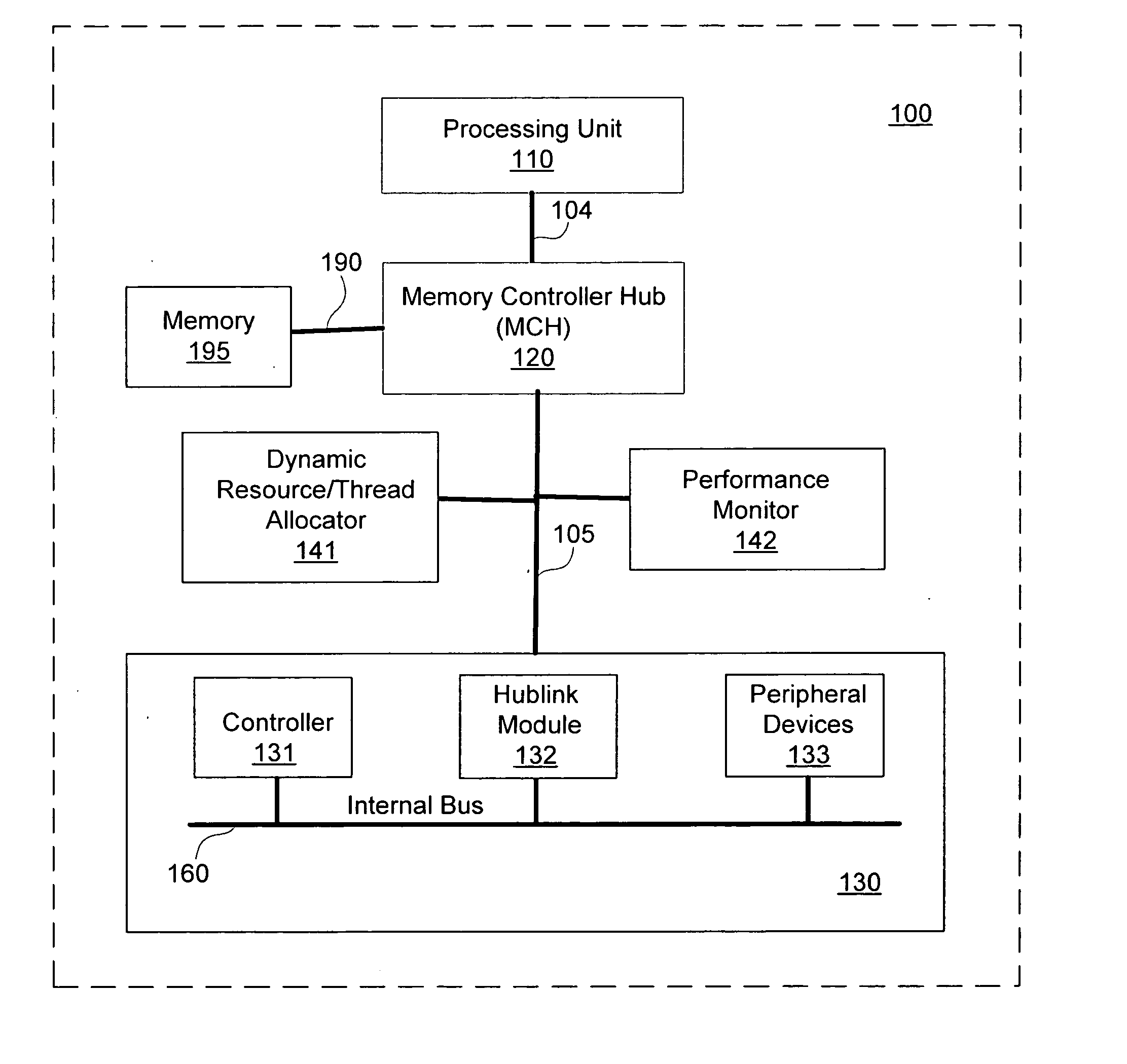

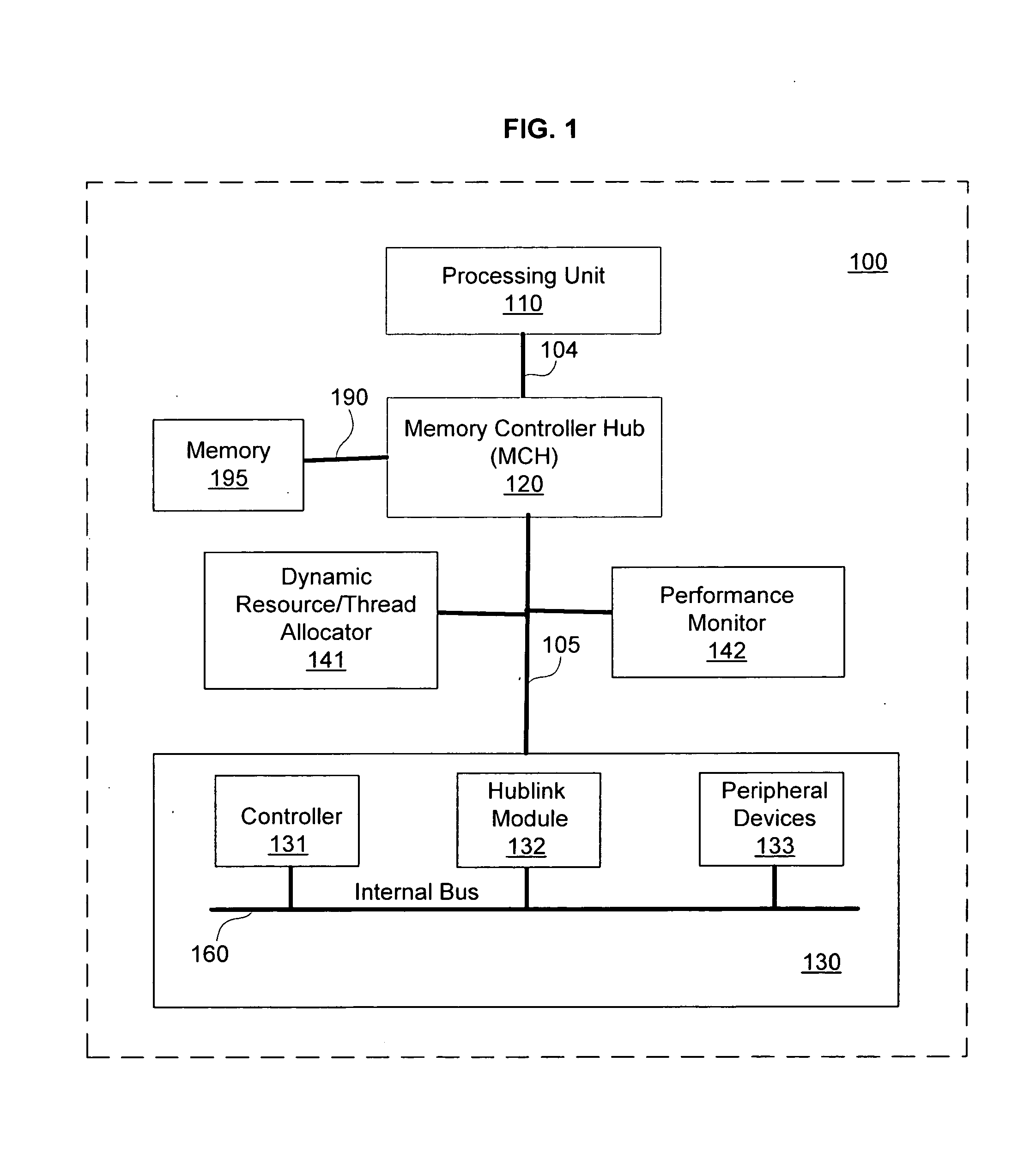

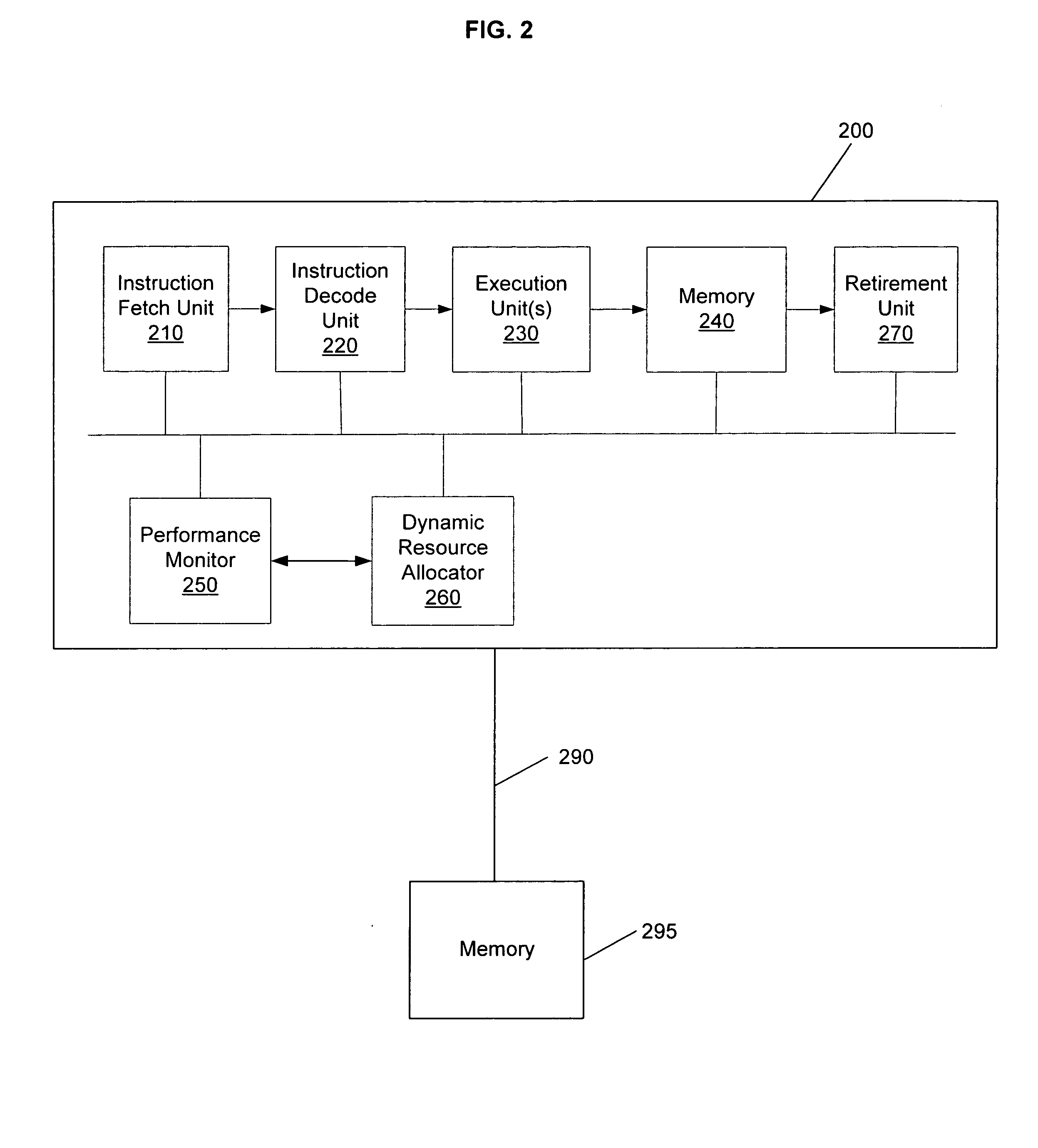

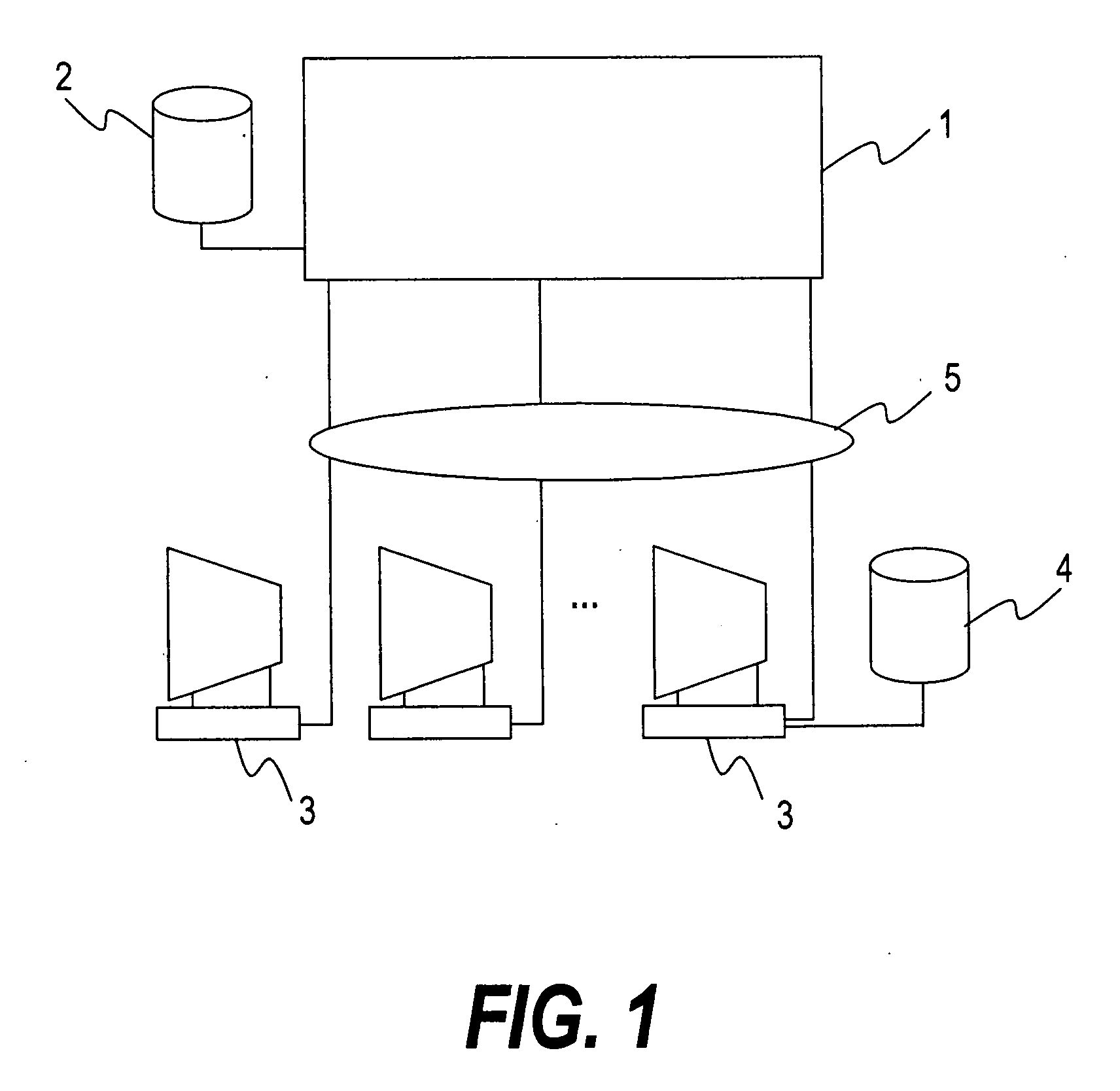

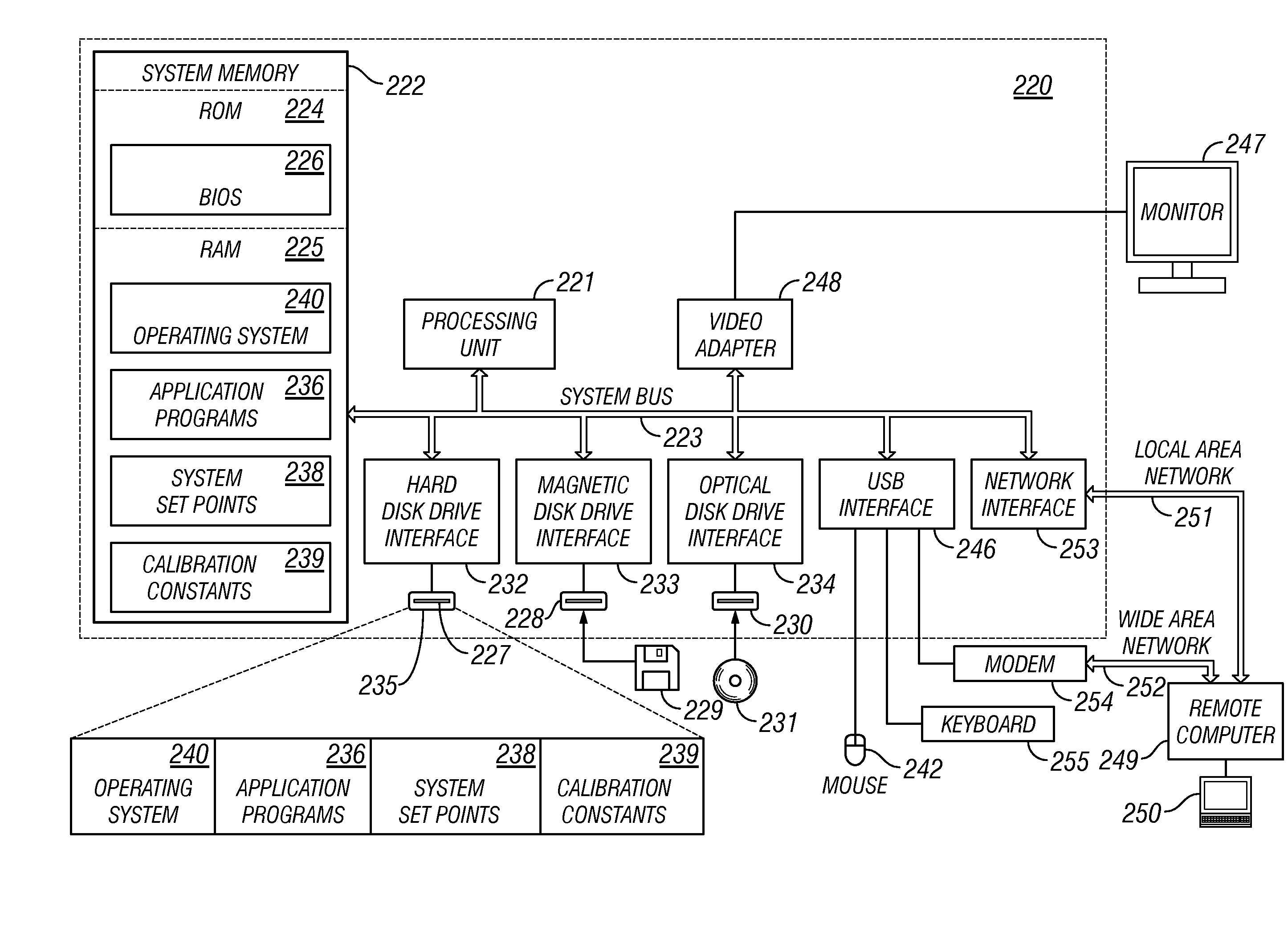

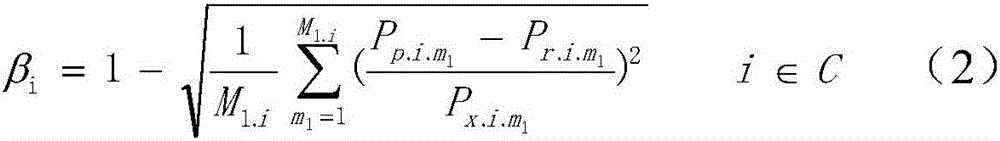

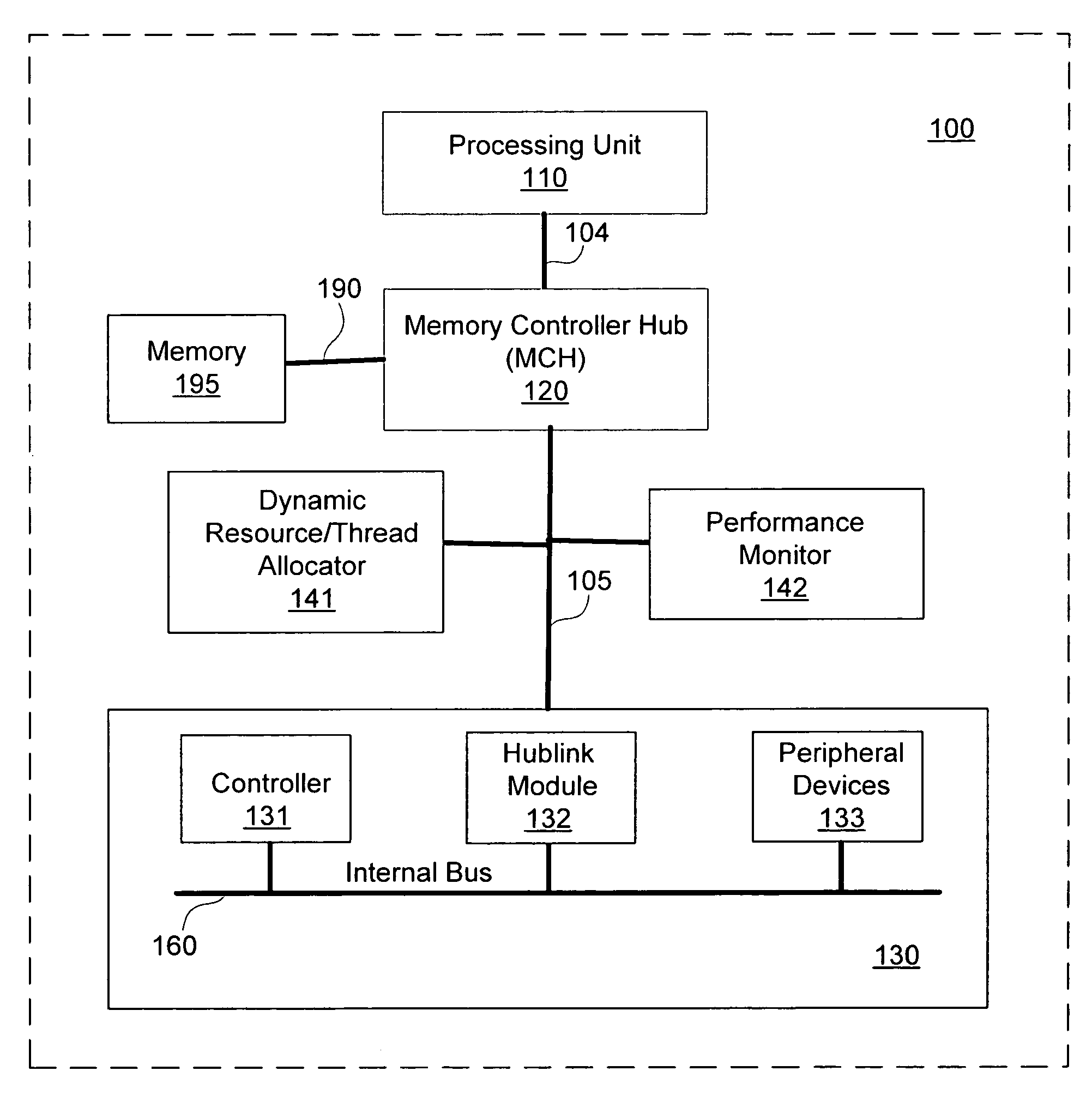

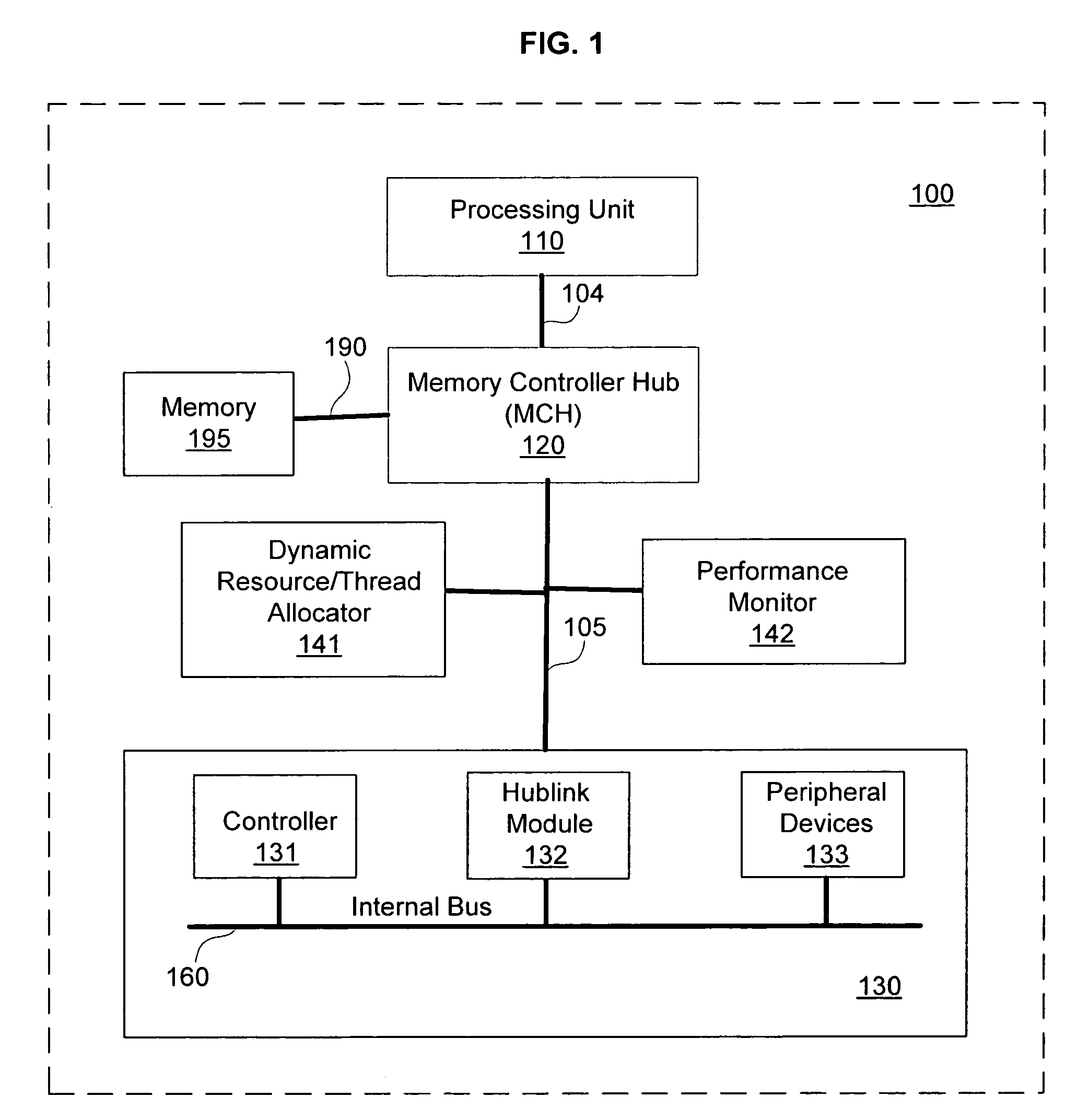

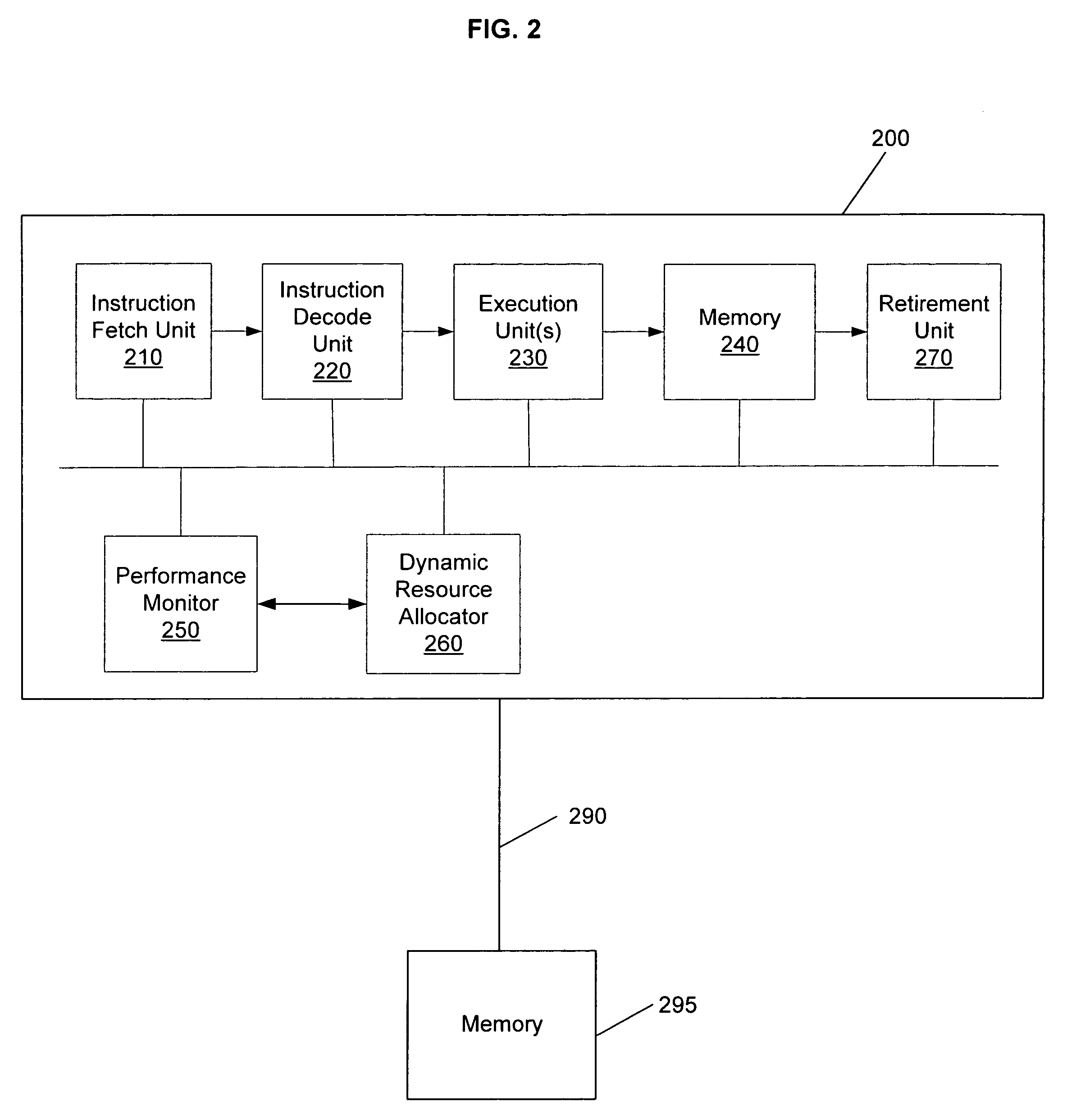

Method and system for dynamic resource allocation

InactiveUS20050141554A1Inefficiencies encountered by conventional systems may be reducedImprove performanceEnergy efficient ICTError preventionDynamic resourcePerformance rate

Embodiments of the present invention provide a dynamic resource allocator to allocate resources performance optimization in, for example, a computer system. The dynamic resource allocator to allocate a resource to one or more threads associated with an application based on a performance rate. Embodiments of the present invention may further include a performance monitor to monitor the performance rate of the one or more threads. The dynamic resource allocator to allocate an additional resource to the one or more threads, if the thread is performing above a performance threshold. In embodiments of the present invention, the dynamic resource allocation strategy may be decided based on, for example, optimizing the overall system throughput, minimizing power consumption, meeting system performance goals (e.g., real time requirements), user specified performance priorities and / or application specified performance priorities.

Owner:INTEL CORP

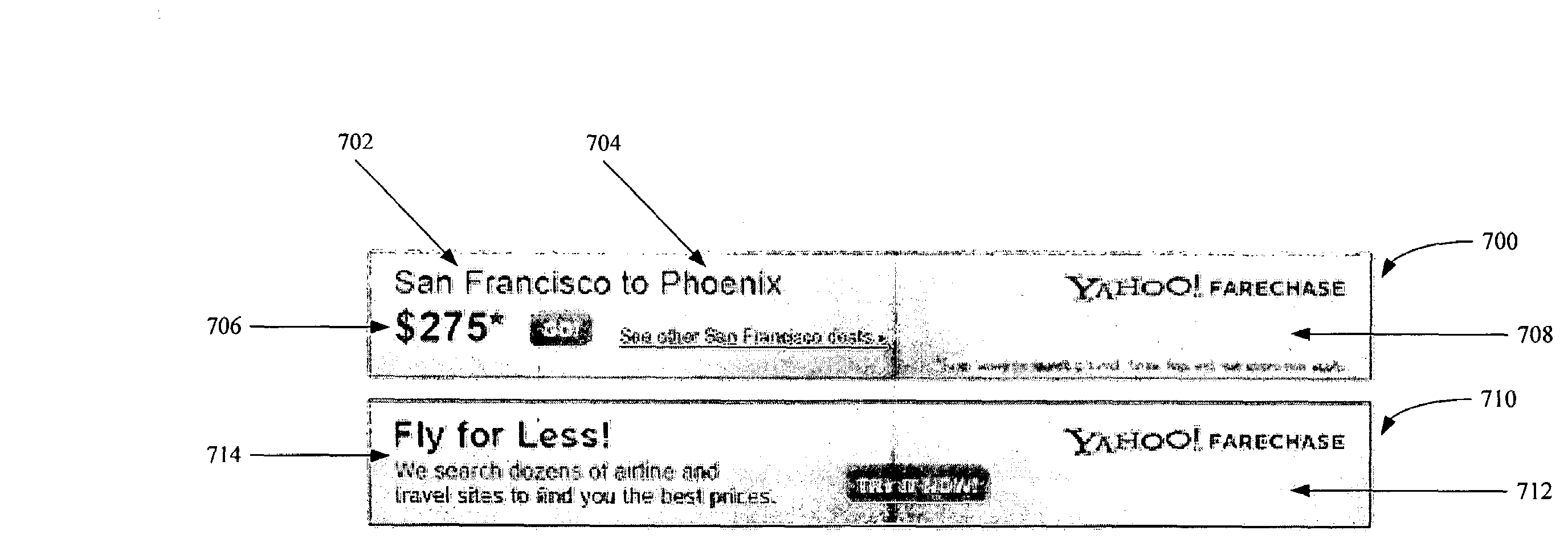

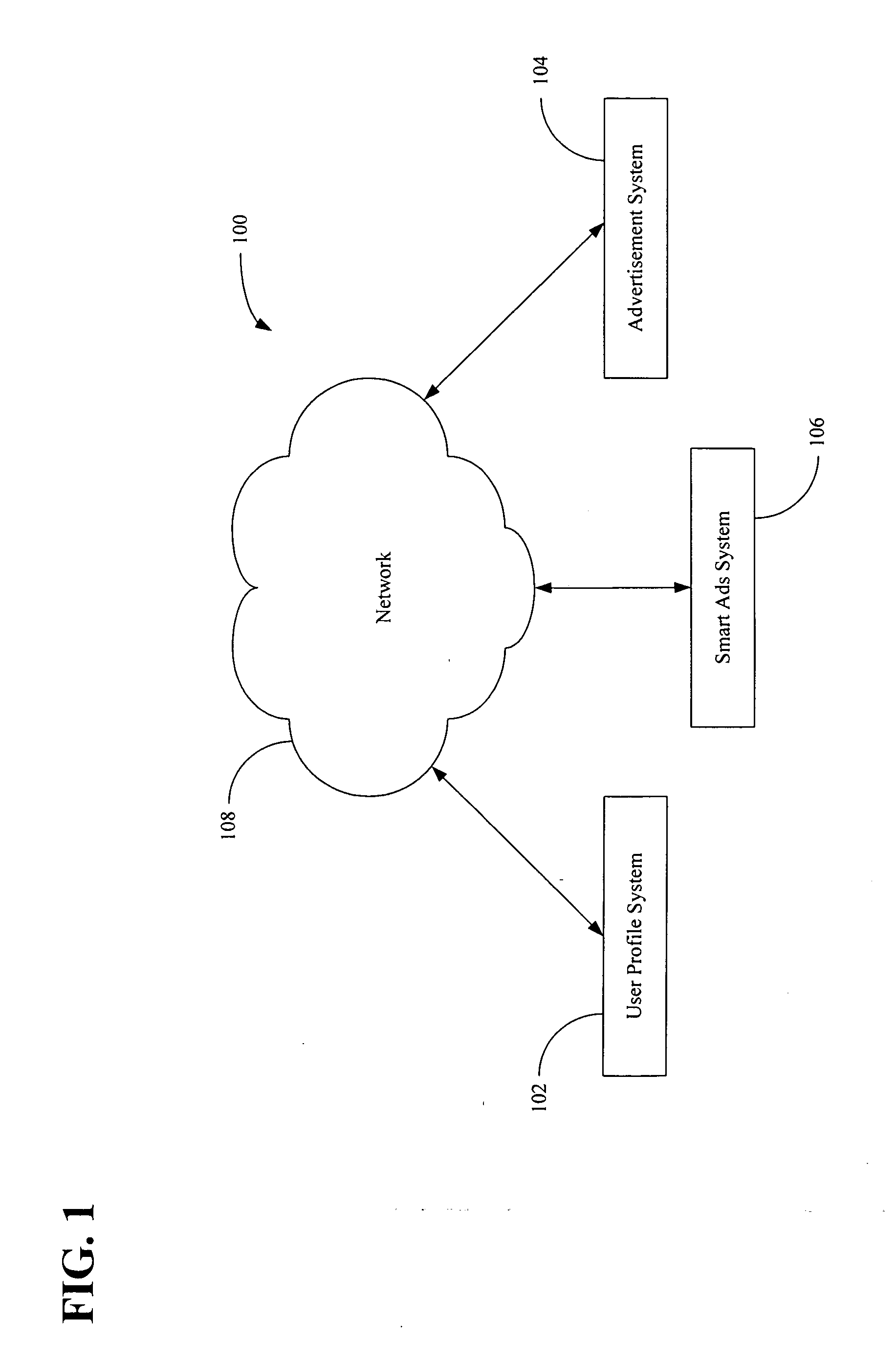

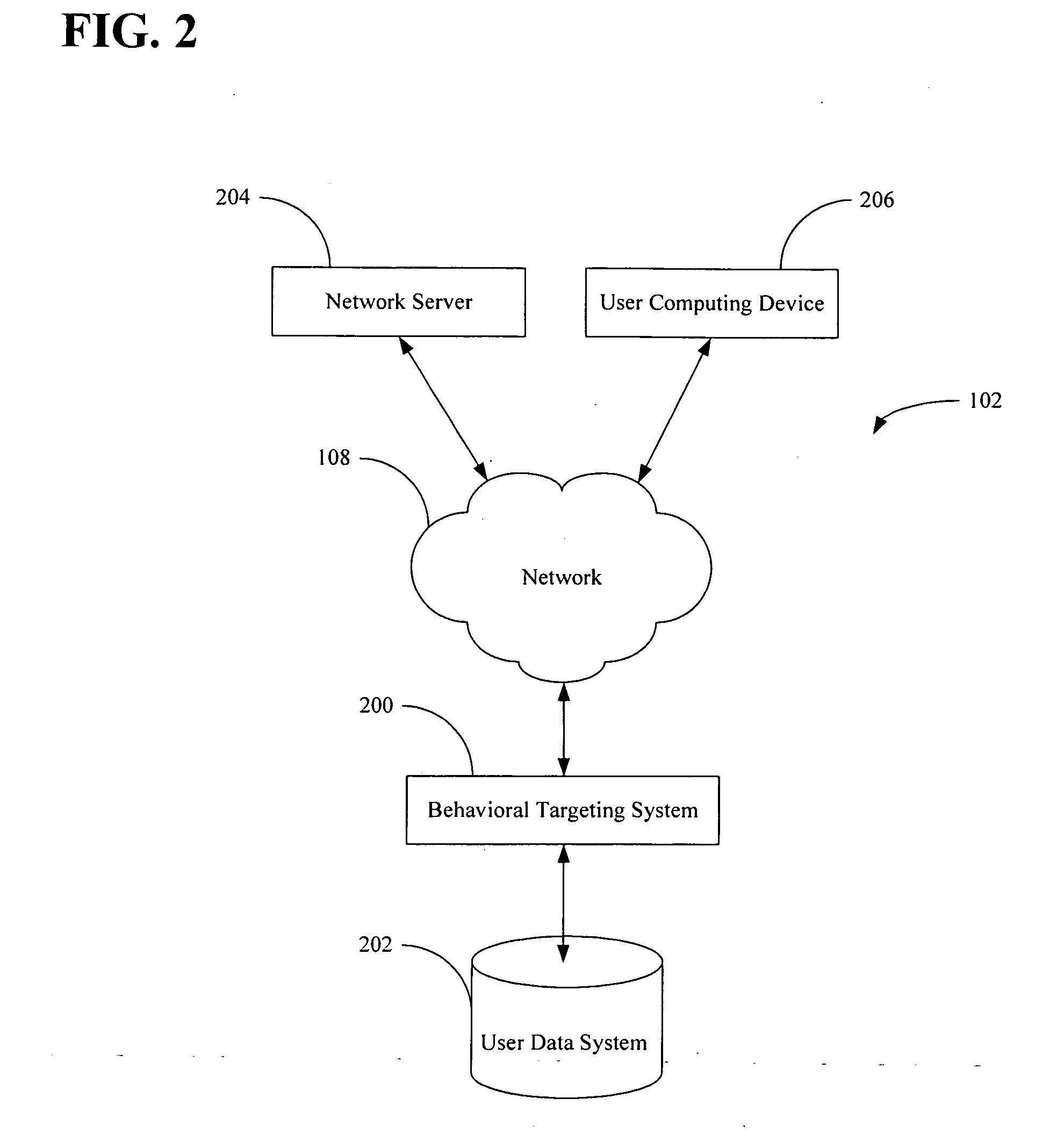

System for optimizing the performance of a smart advertisement

InactiveUS20080140508A1Improve performancePerformance rateMarket predictionsMarket data gatheringNetwork generationUser profile

A system is described for optimizing the performance of smart advertisements generated over a network for display to a user. The smart advertisements may adapt to specific user profile information and available advertising campaign information. The system may consume log data relating to previously displayed smart advertisements and compare the performance rates of the smart advertisements to determine relationships between controllable variables and the performance rates. The system may manipulate the controllable variables based on the relationships to optimize the performance of smart advertisements.

Owner:OATH INC

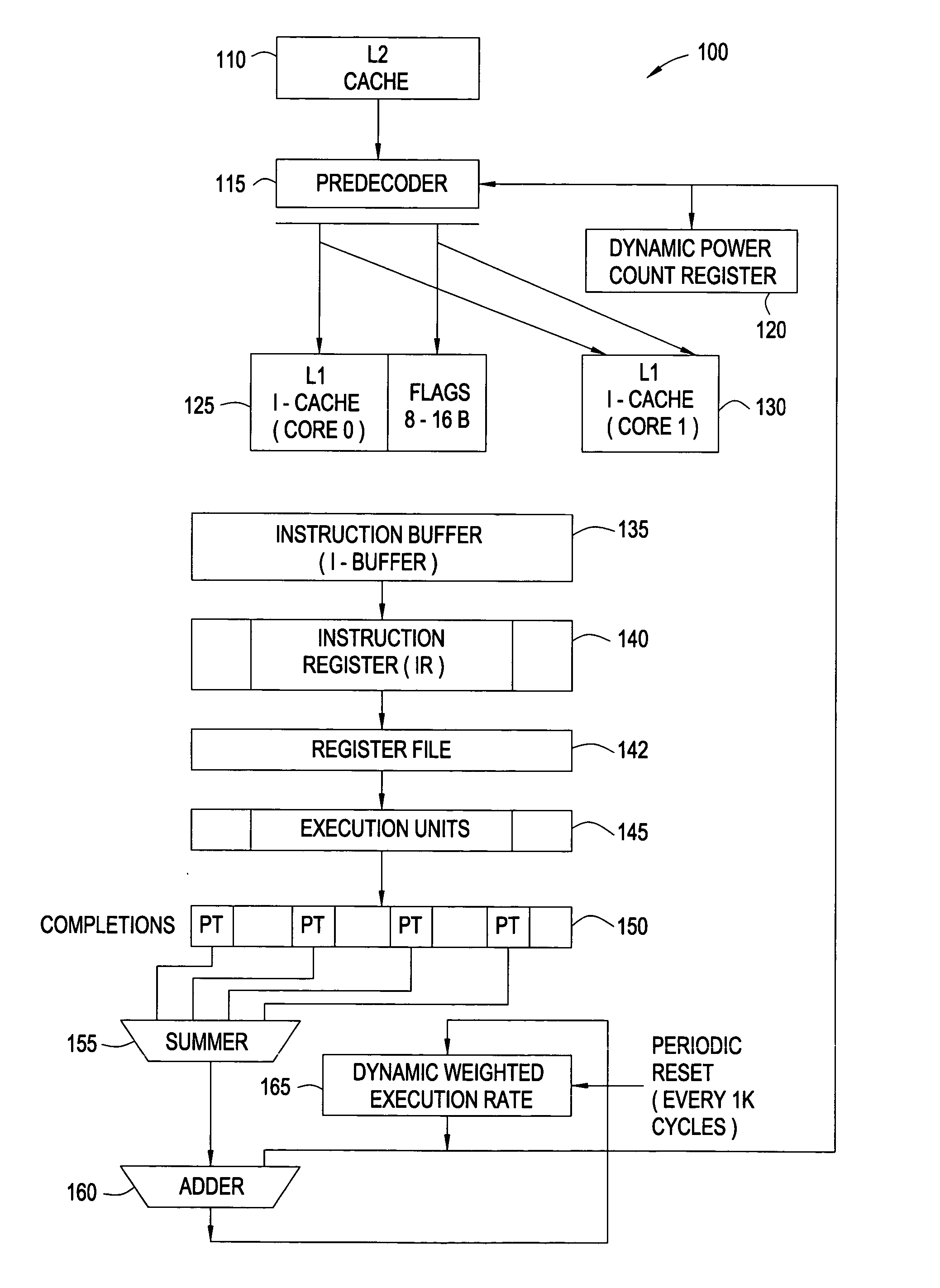

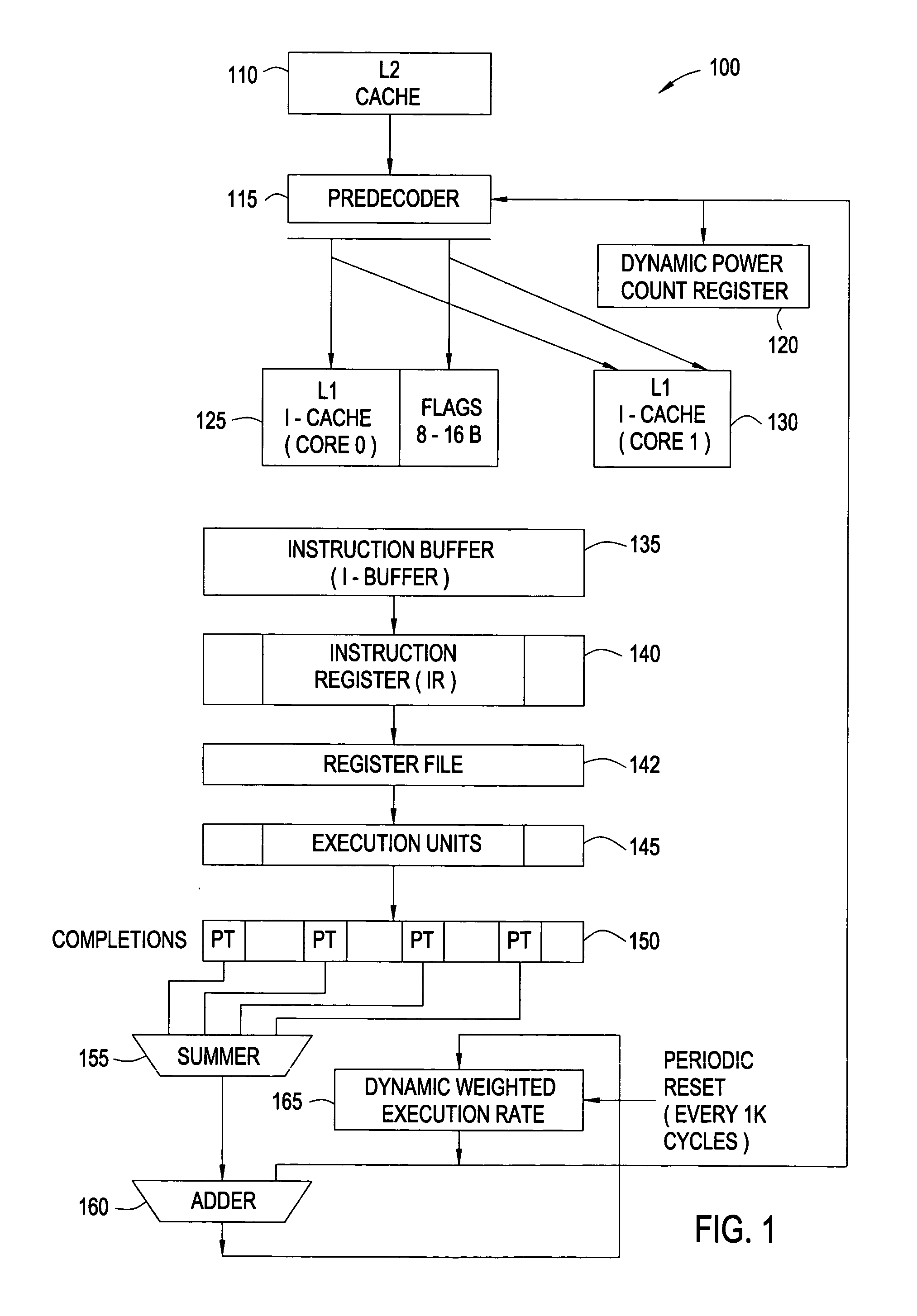

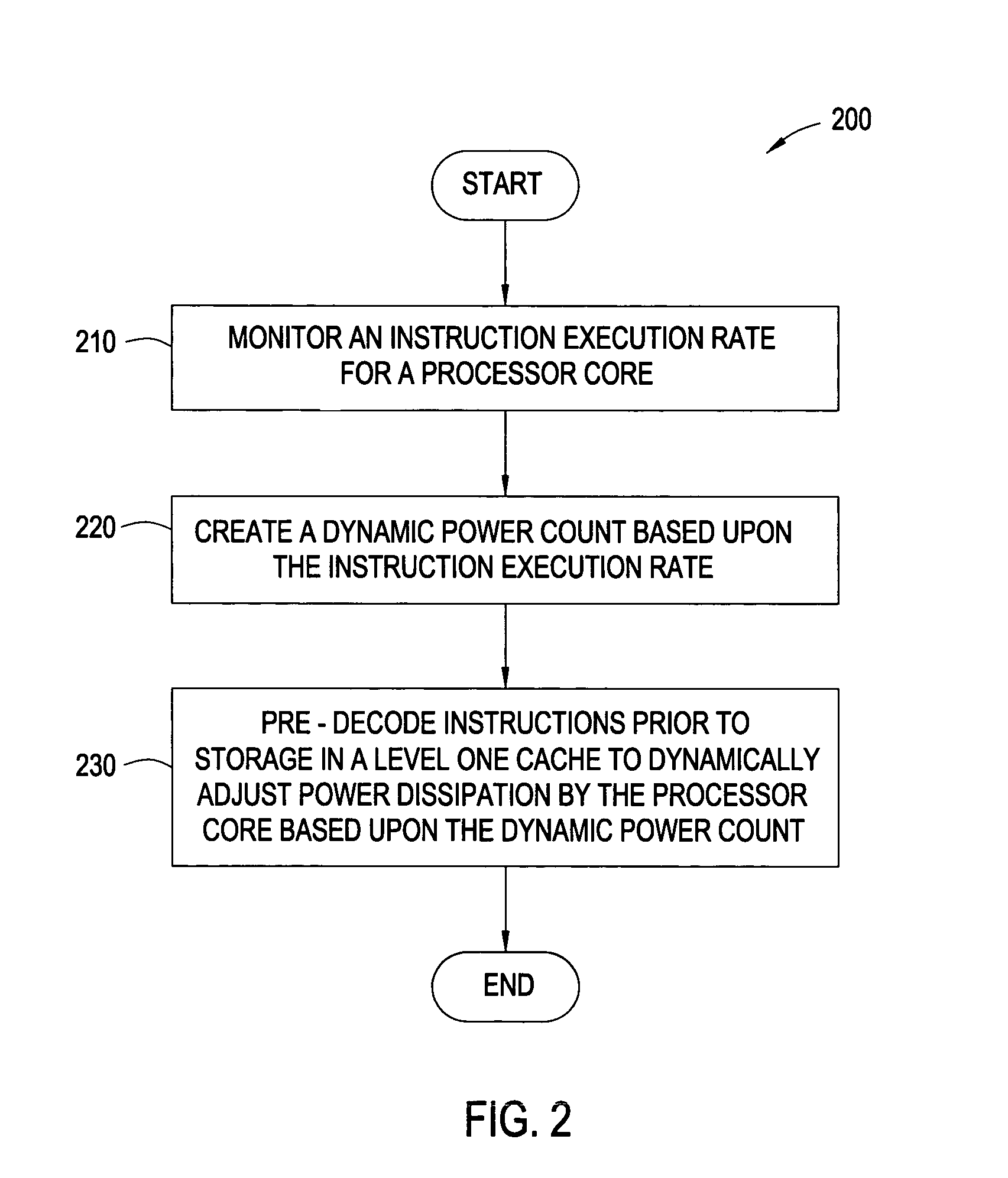

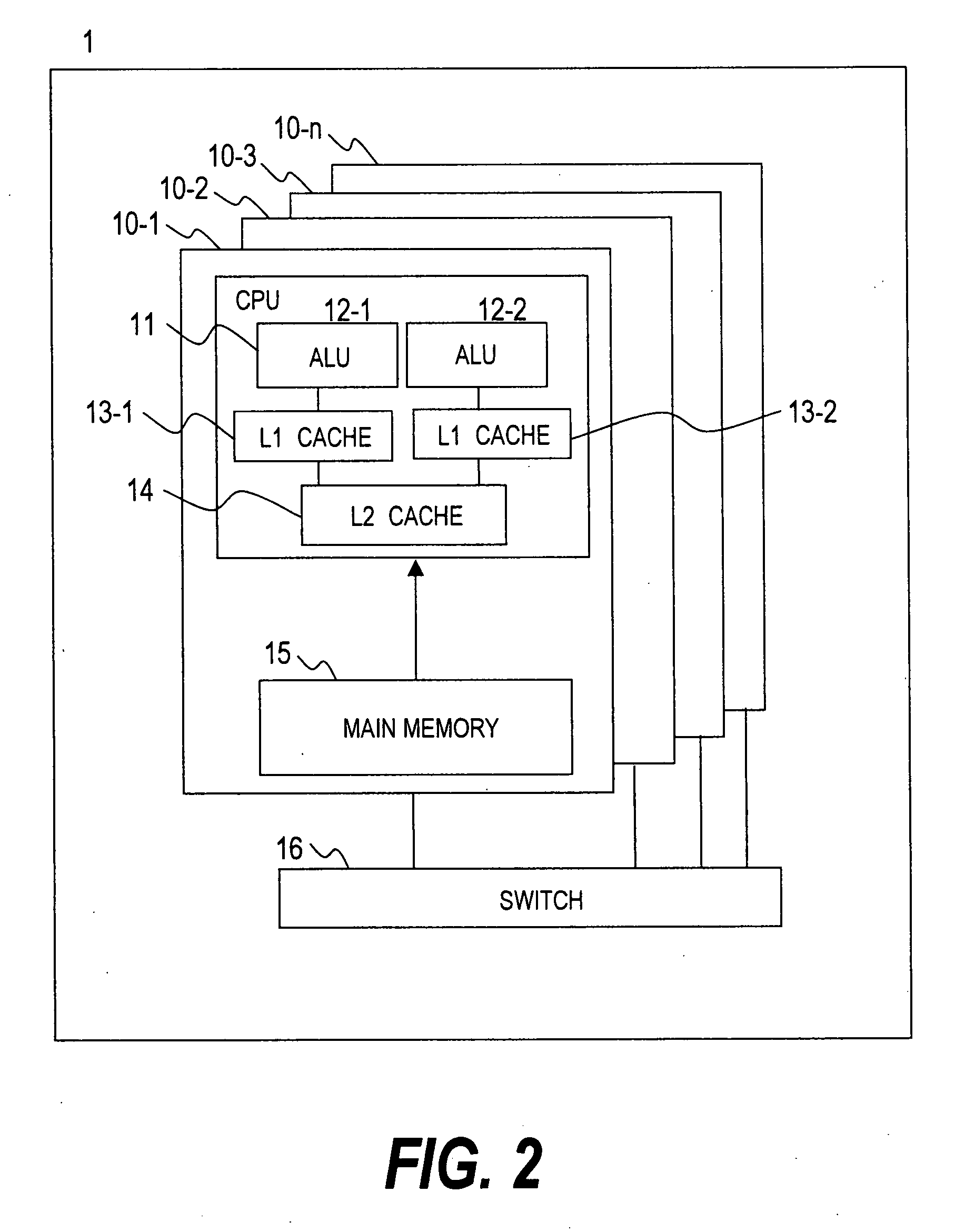

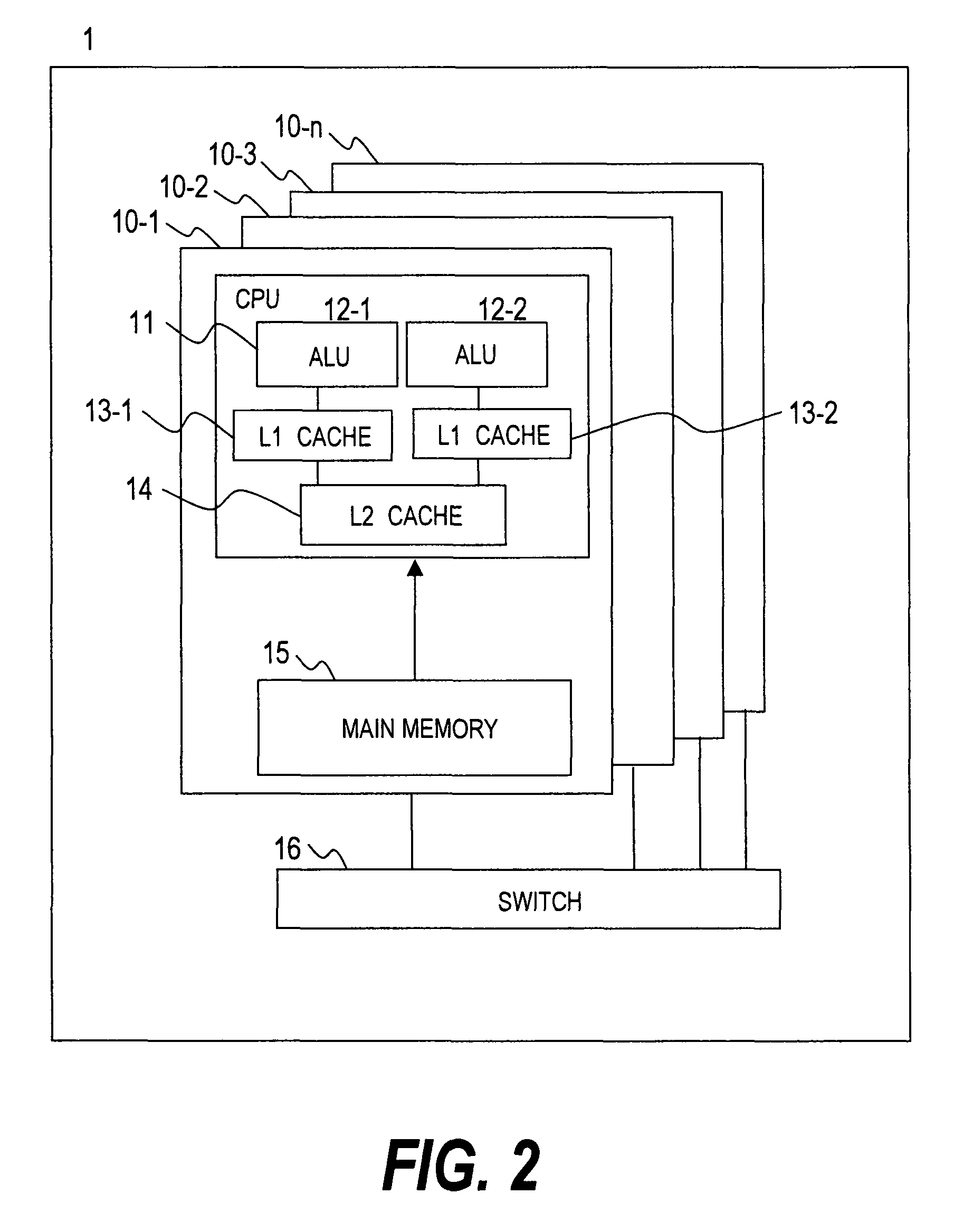

Processor power and energy management

InactiveUS20050071701A1Managing energyEnergy efficient ICTVolume/mass flow measurementParallel computingEnergy expenditure

Methods and systems for managing power and energy expenditures in cores of a processor to balance performance with power and energy dissipation are disclosed. Embodiments may include pre-decoder(s) between levels of cache or between main memory and a level of cache to monitor core execution rates by associating power tokens with each instruction. The power tokens include values representing the average power dissipated by the core for instructions and a sum of the power tokens may be compared with a state of management control bits for performance, energy, and power, to determine whether to increase or decrease power dissipation in the core. The power dissipation is varied by, e.g., adjusting the issue rate of instructions, adjusting the execution rate of instructions, turning off unused units within the core, controlling the frequency and voltage of the core, and switching tasks between cores.

Owner:IBM CORP

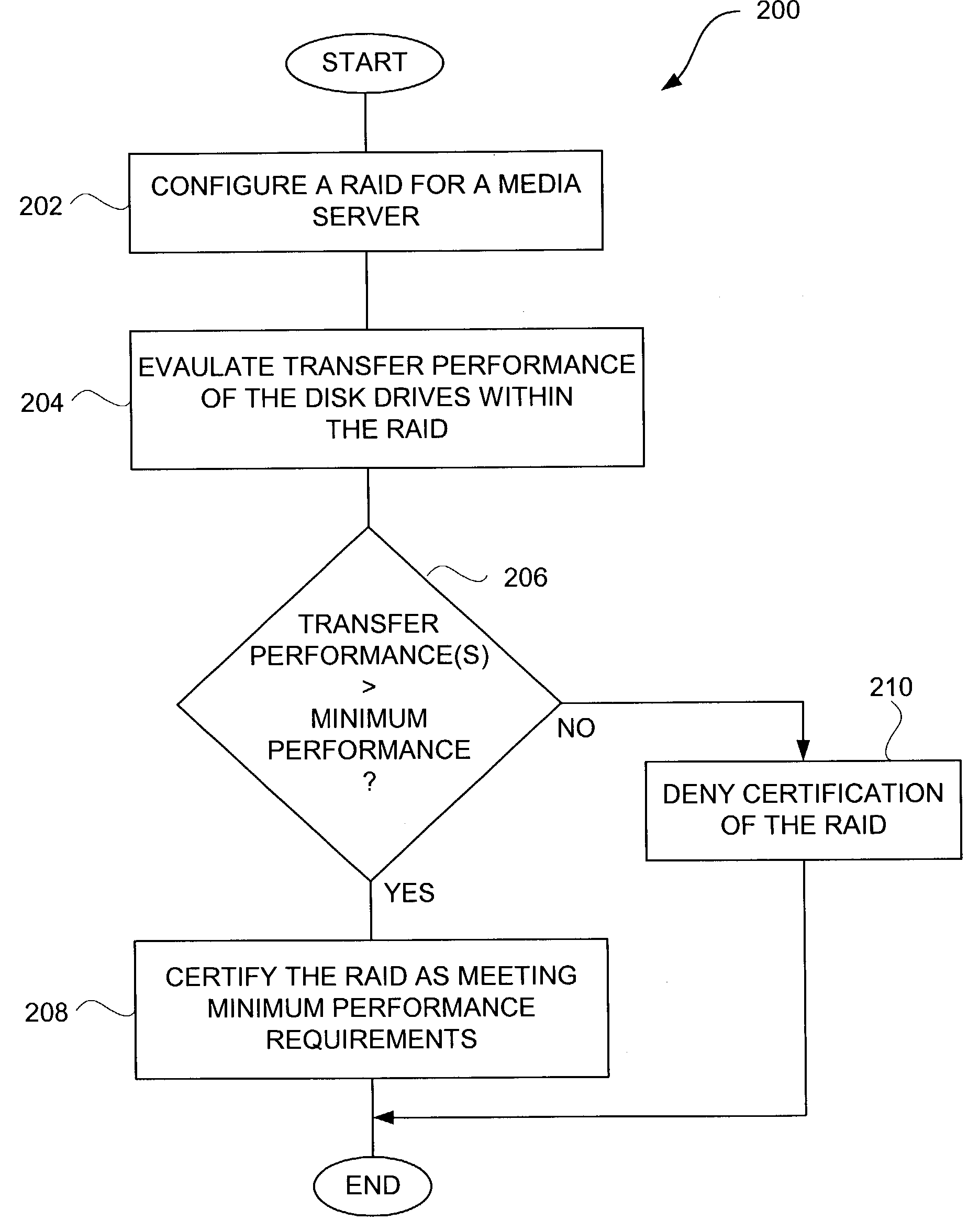

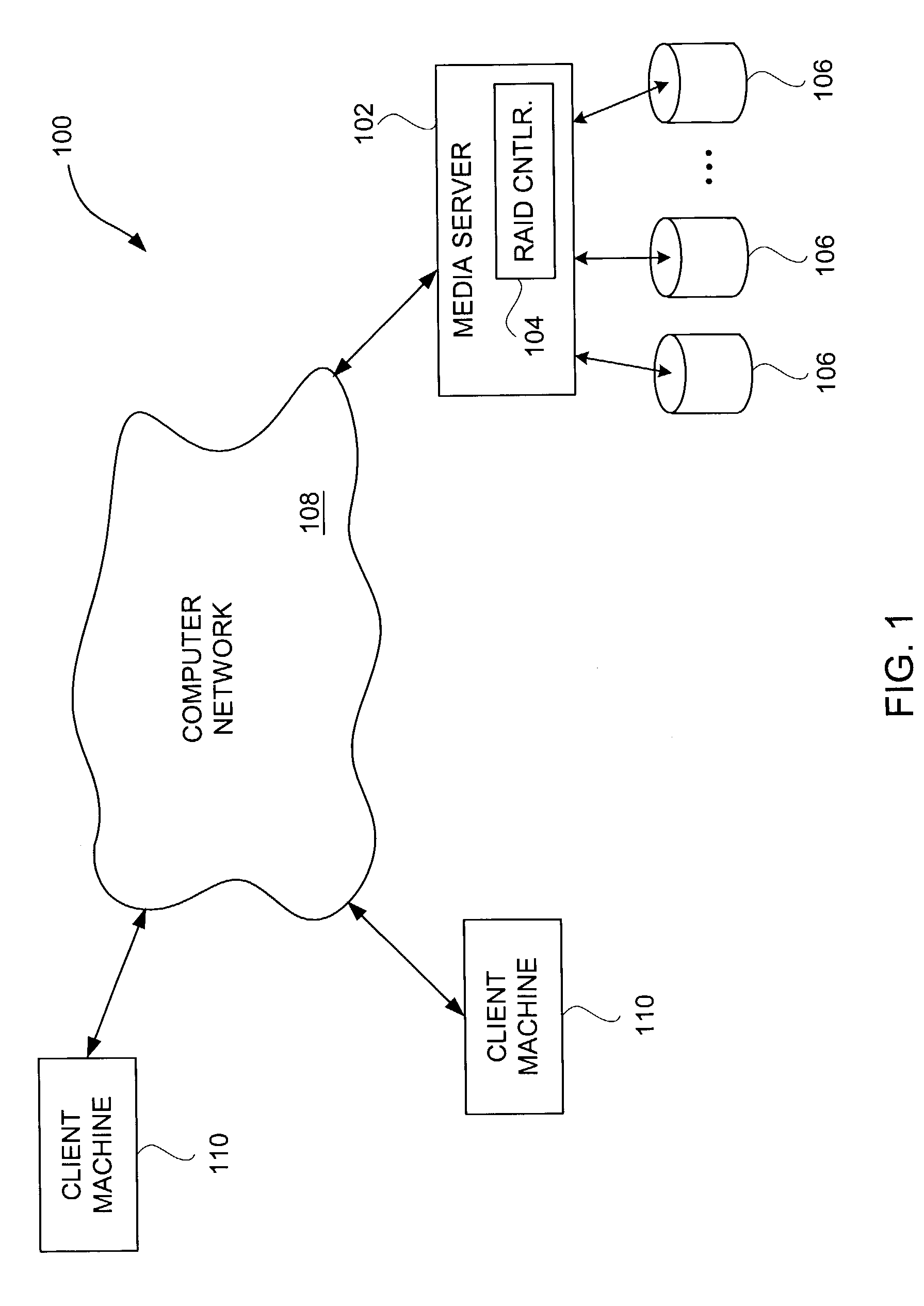

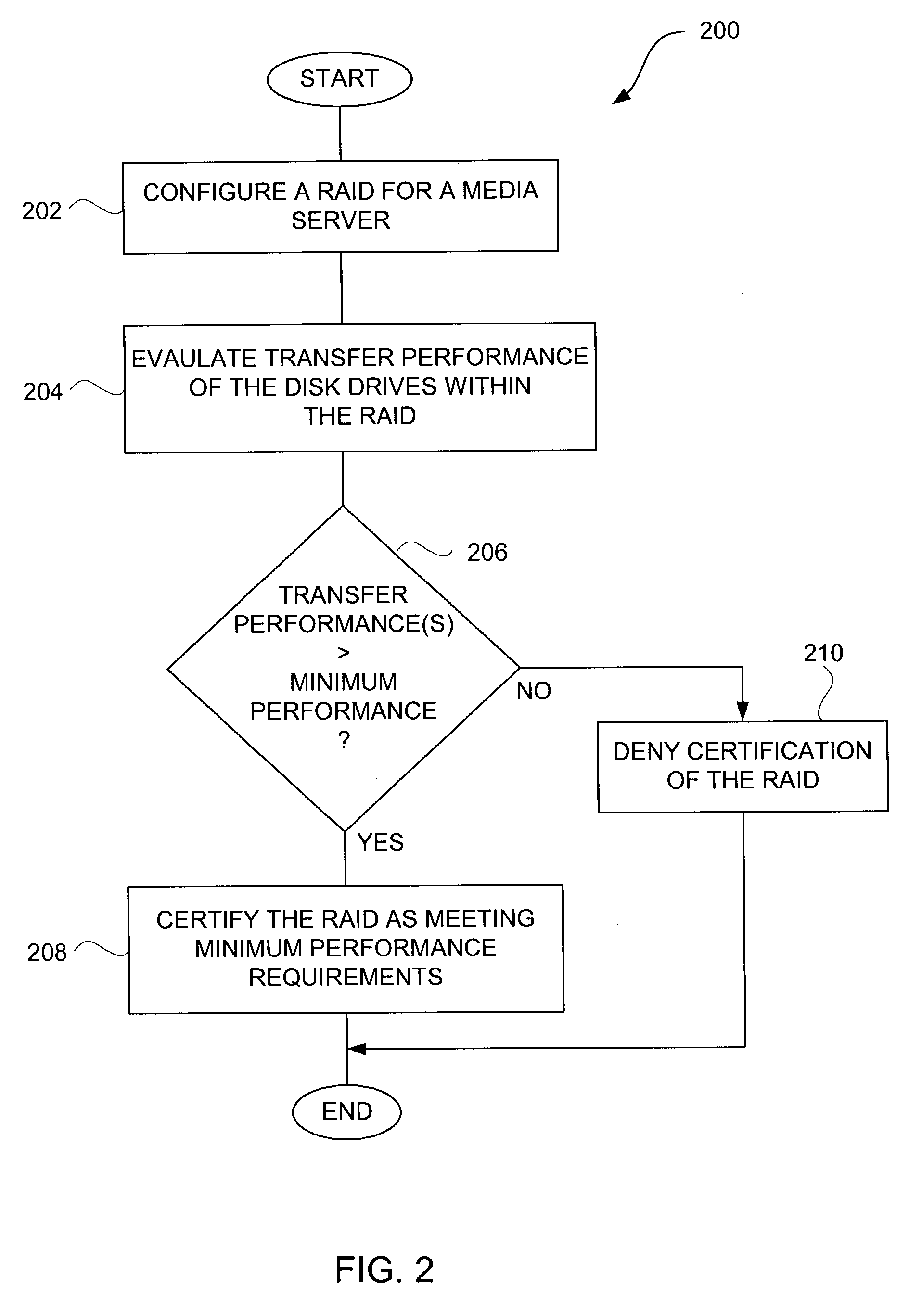

Method and apparatus for dynamic performance evaluation of data storage systems

Improved approaches for evaluating performance of data storage systems used with computers are disclosed. The performance evaluation of the data storage systems utilizes dynamic performance evaluation by use of data throughput as a diagnostic. The data storage systems include, for example, either disk drives or RAIDs. In one embodiment, the invention identifies a sustained performance rate for a disk drive or RAID.

Owner:APPLE INC

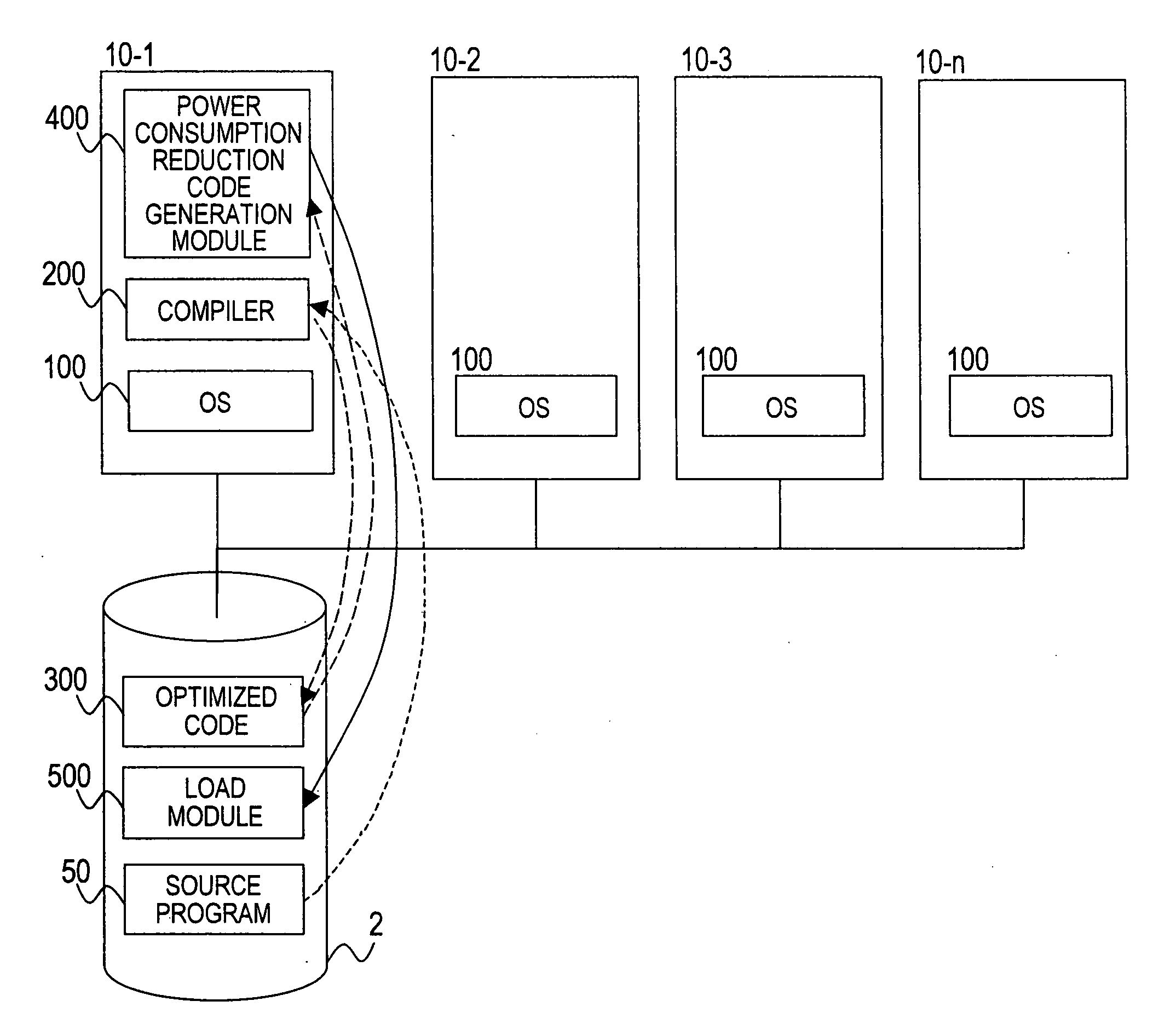

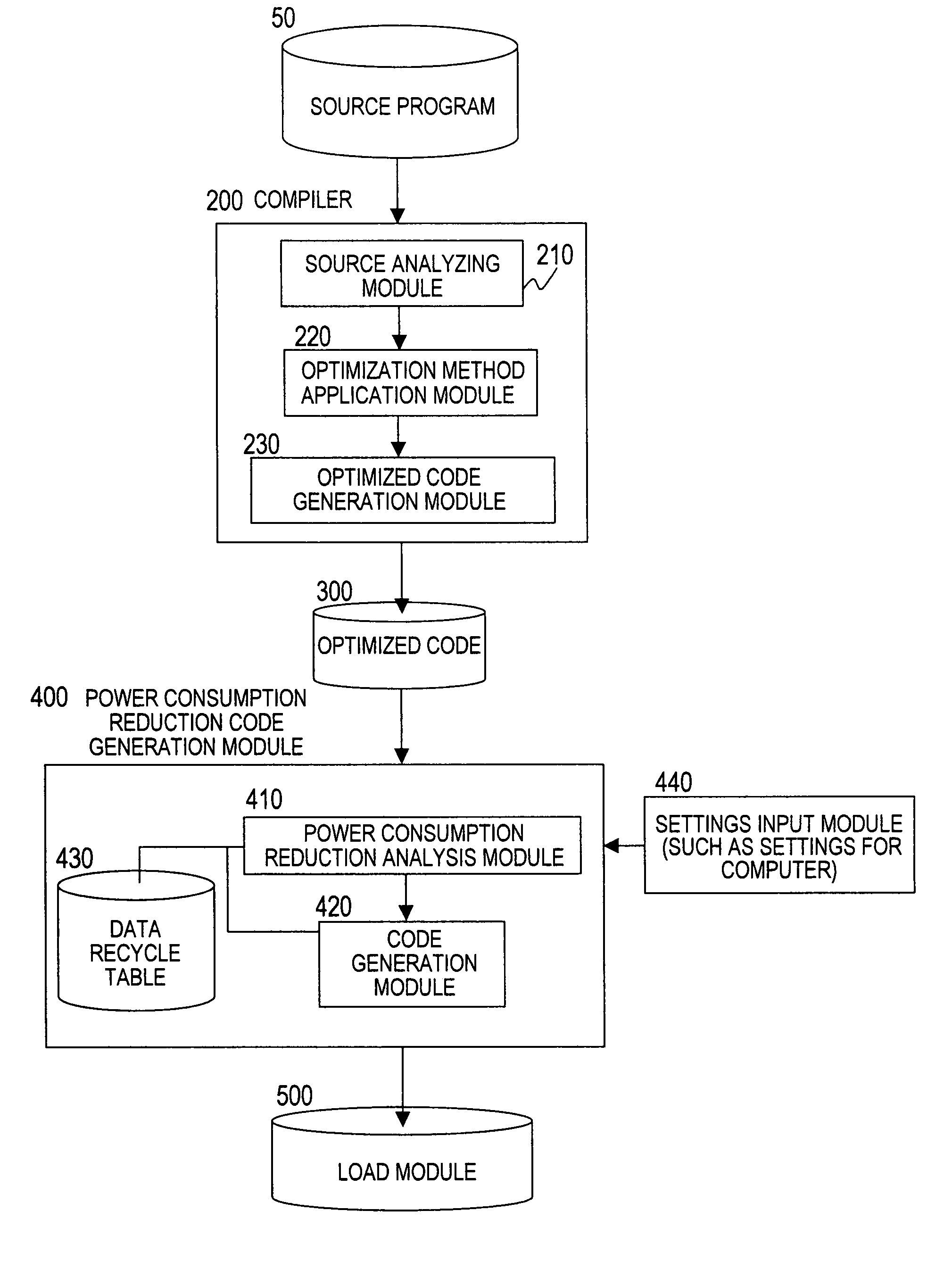

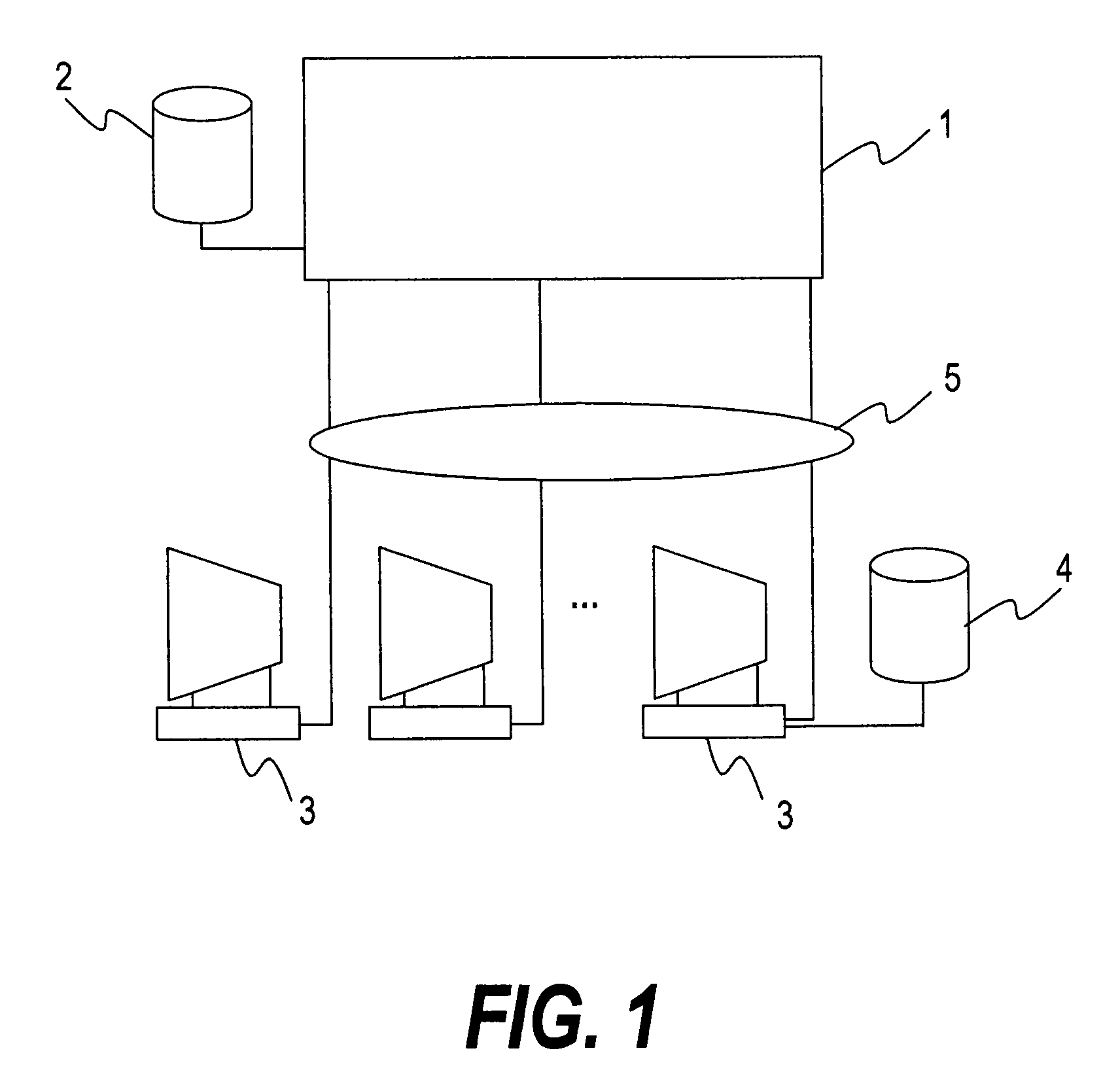

Method and program for generating execution code for performing parallel processing

InactiveUS20080034236A1Reduce clock frequencyReduce operating voltageEnergy efficient ICTSoftware engineeringParallel processingSource code

Provided is a method of reliably reducing power consumption of a computer, while promoting prompt compilation of a source code and execution of an output code. The method according to this invention includes the steps of: reading a code which is preset and analyzing an amount of operation of the CPU and an access amount with respect to the cache memory based on the code; obtaining an execution rate of the CPU and an access rate with respect to the cache memory based on the amount of operation and the access amount; determining an area in which the access rate with respect to the cache memory is higher than the execution rate of the CPU, based on the code; adding a code for enabling the power consumption reduction function to the area; and generating an execution code executable on the computer, based on the code.

Owner:HITACHI LTD

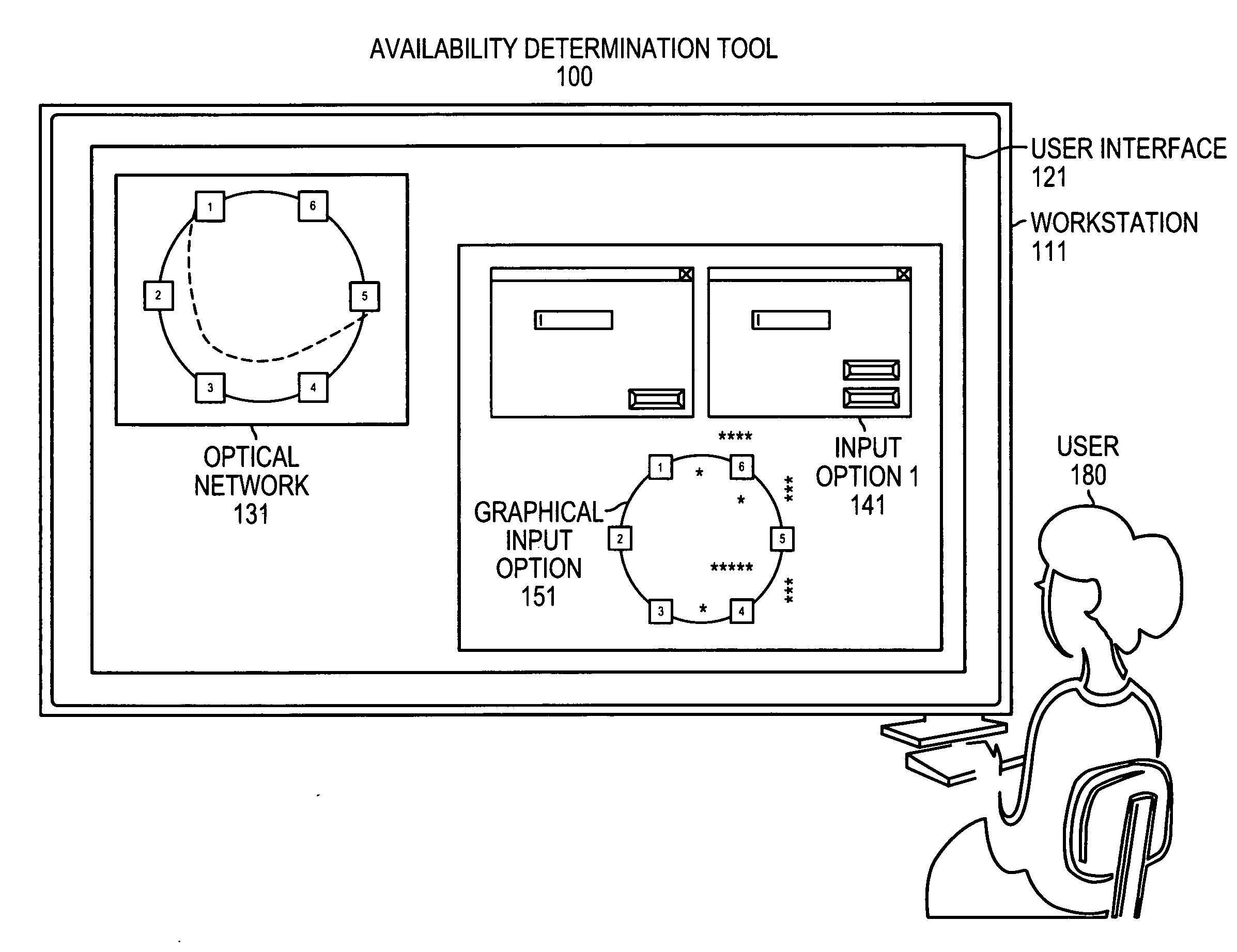

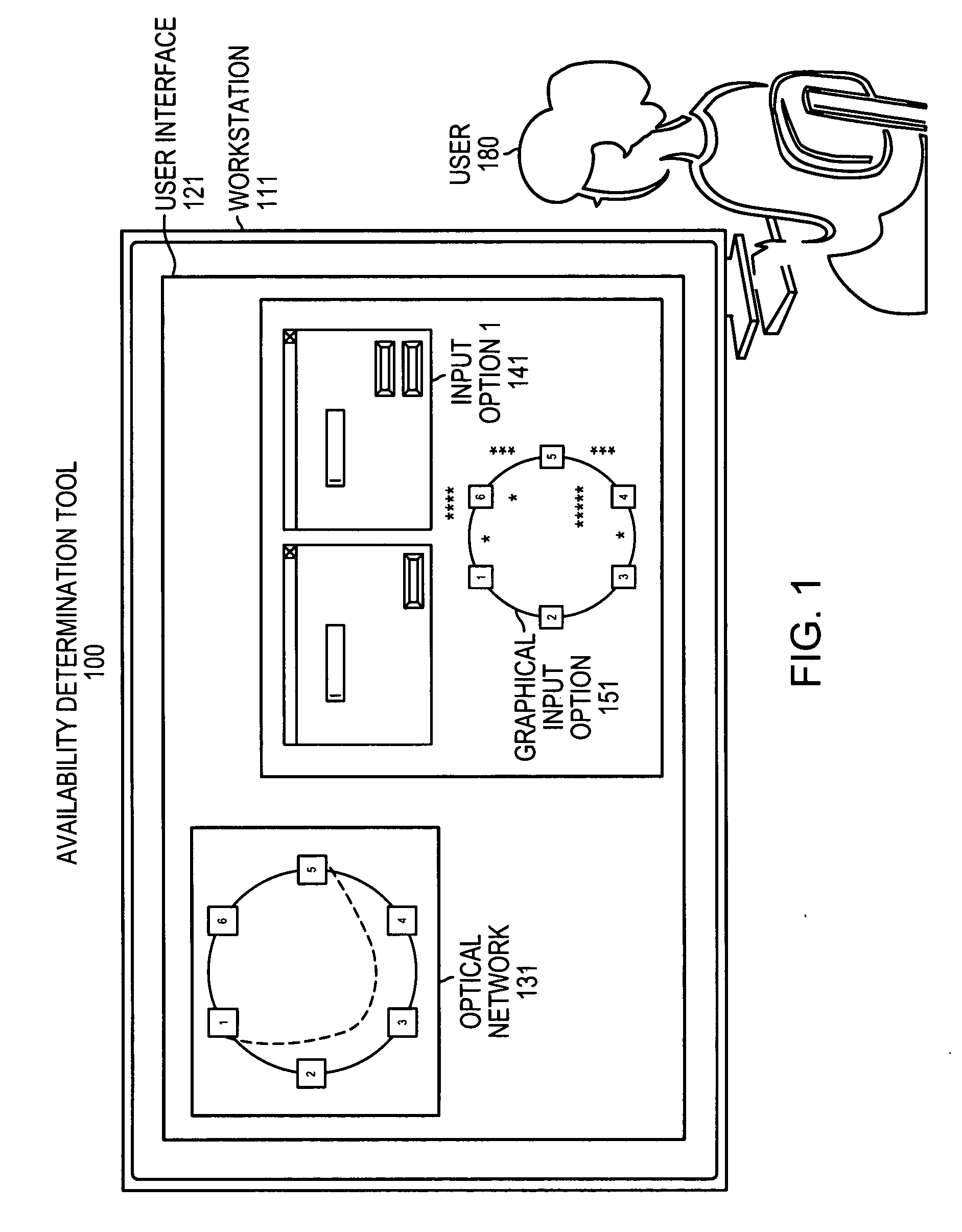

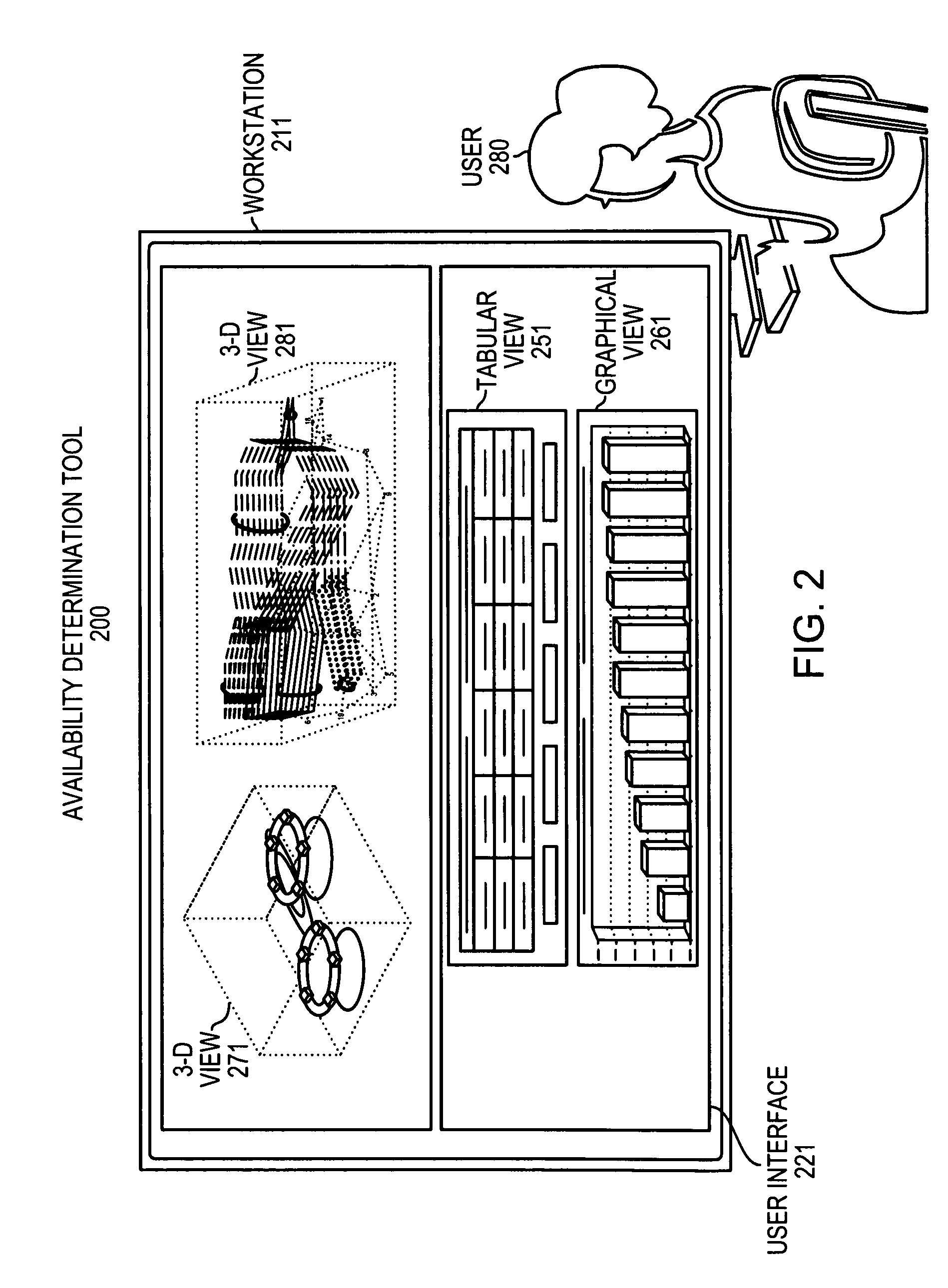

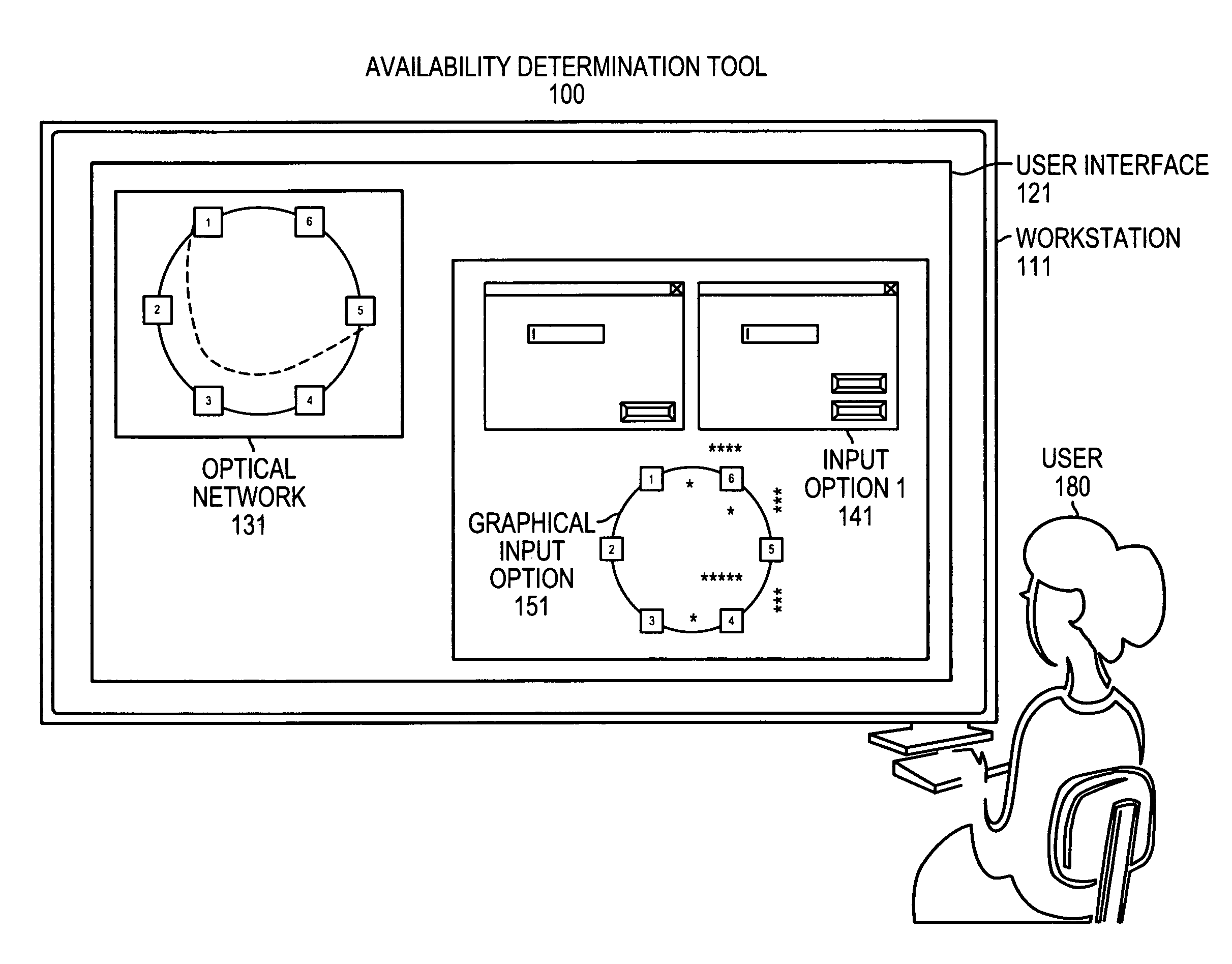

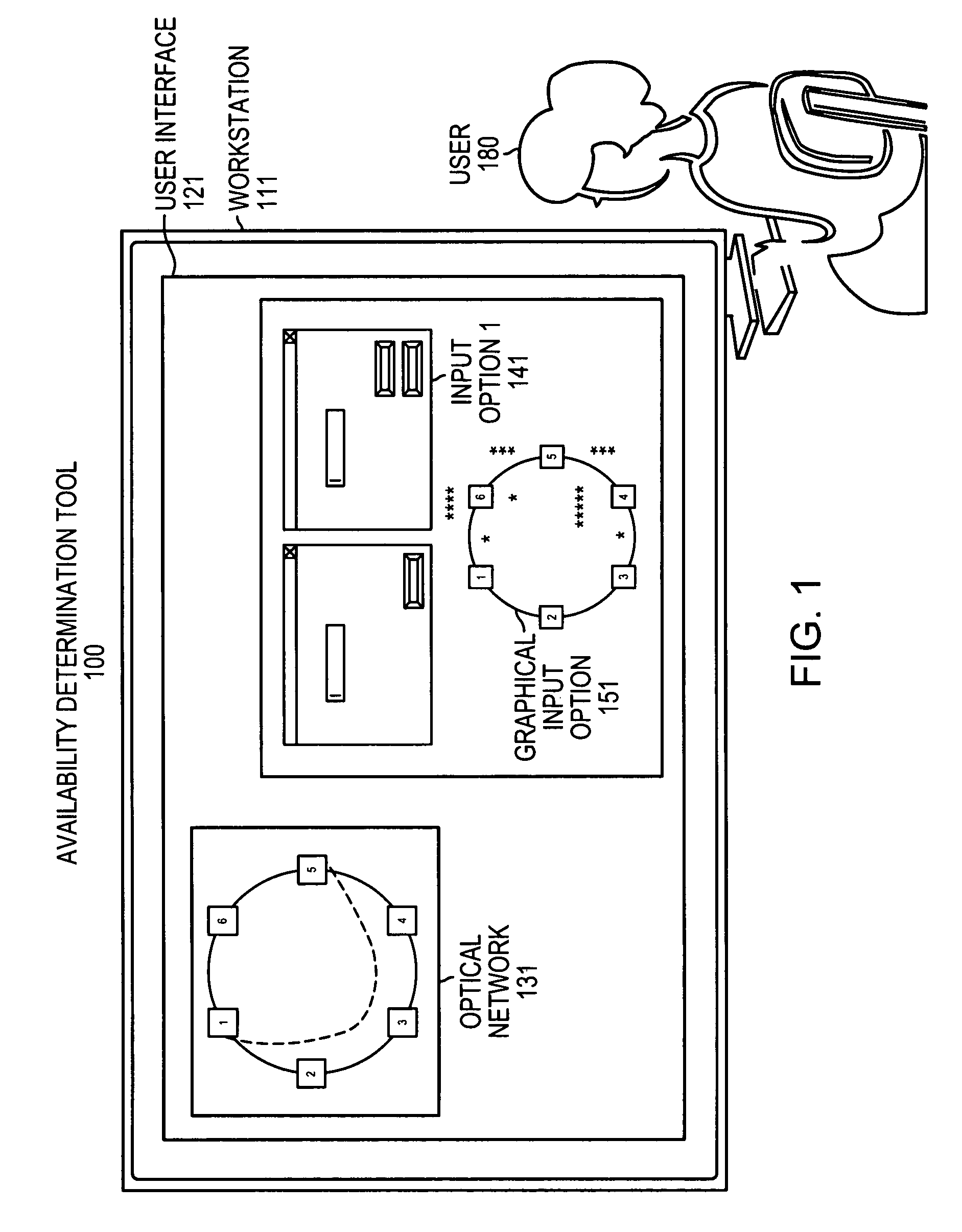

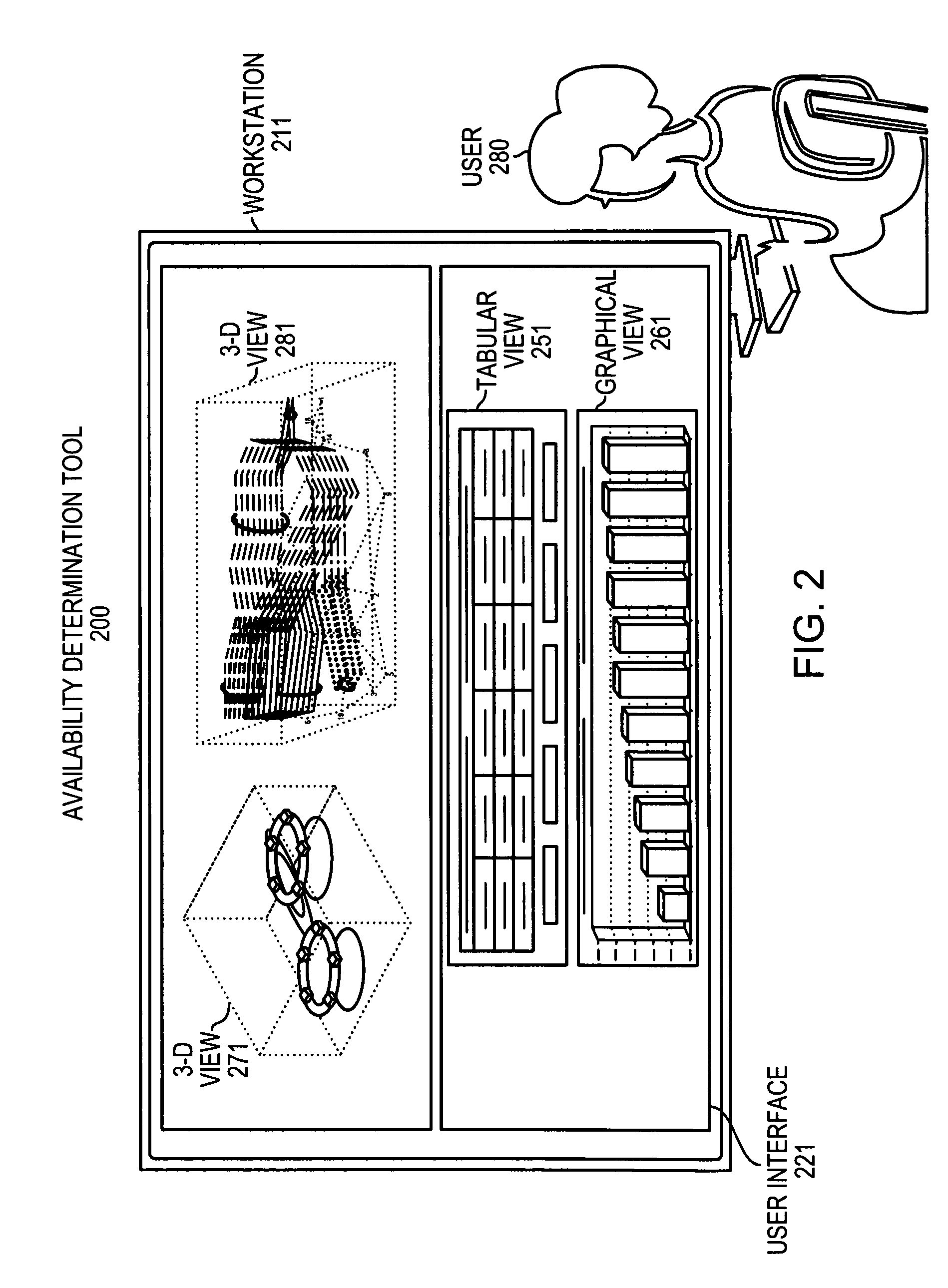

Method and apparatus for displaying and identifying available wavelength paths across a network

Due to demand for more network bandwidth, a need for multi-user optical network topologies has, and will continue to, increase. A method or corresponding apparatus in embodiments of the present invention provide for an availability determination tool for determining and displaying wavelength and subrate availabilities within a network. Benefits of embodiments of a tool include allowing a user to identify the availability and capacity of any wavelength on any network, via an interactive graphical user interface, such as by using three-dimensional representations. In one embodiment, the disclosed availability determination tool allows users to locate and view any combination of available wavelengths between nodes in an optical network topology, and generate graphical and tabular reports of the availability in order to maintain an efficient and organized method or apparatus for determining and controlling wavelengths in a network. Consequently, service providers using the tool can keep performance rates high and costs low.

Owner:TELLABS OPERATIONS

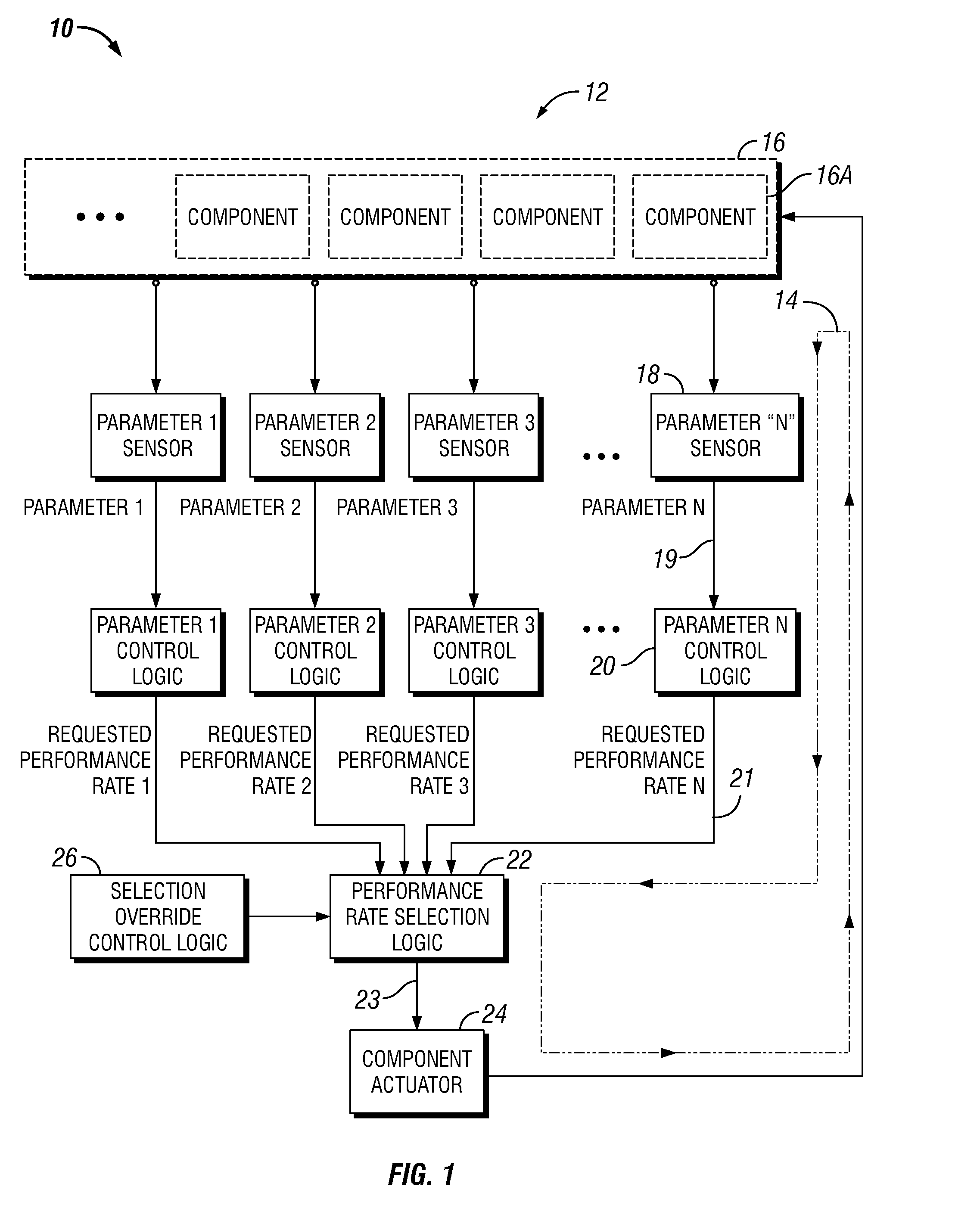

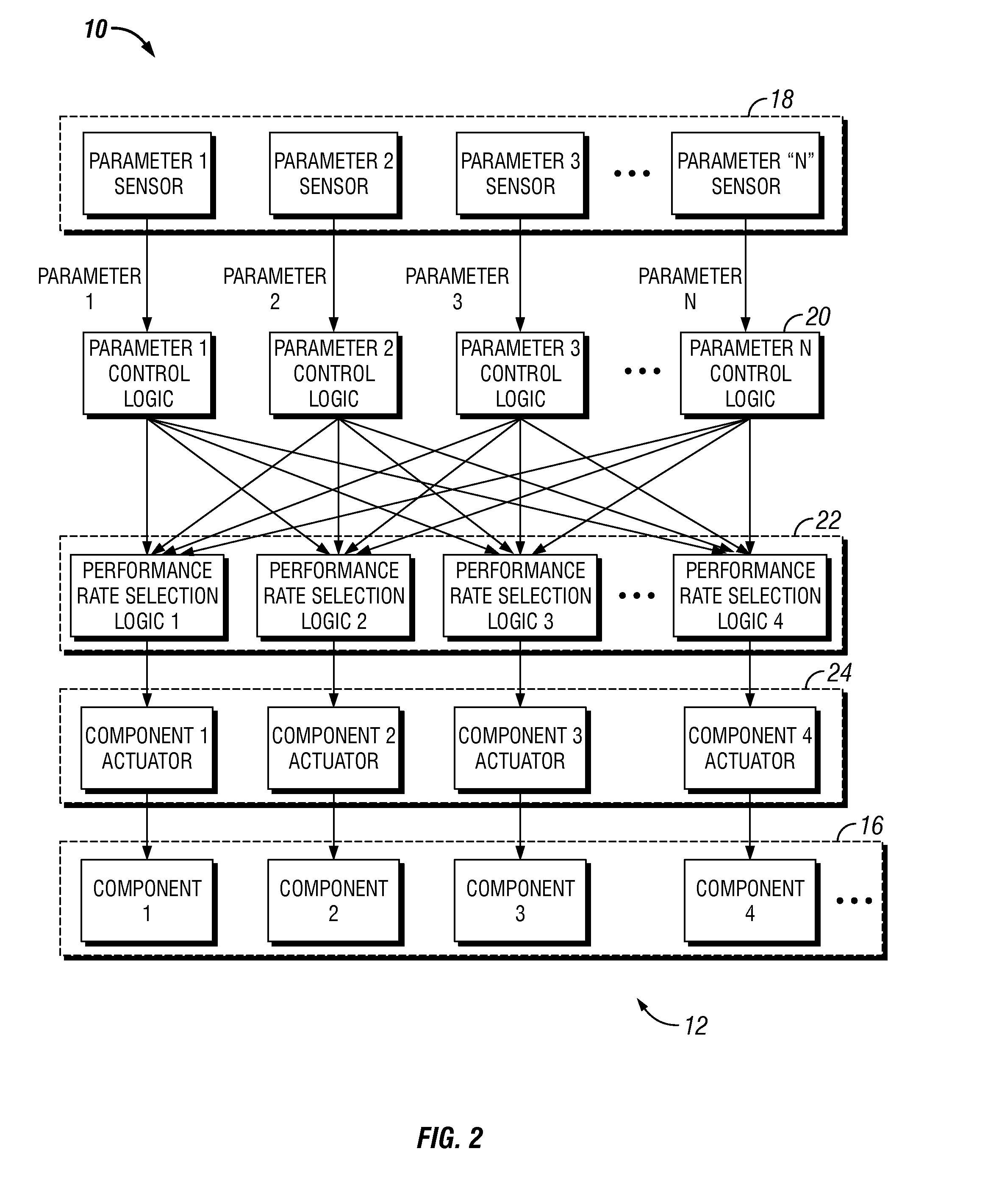

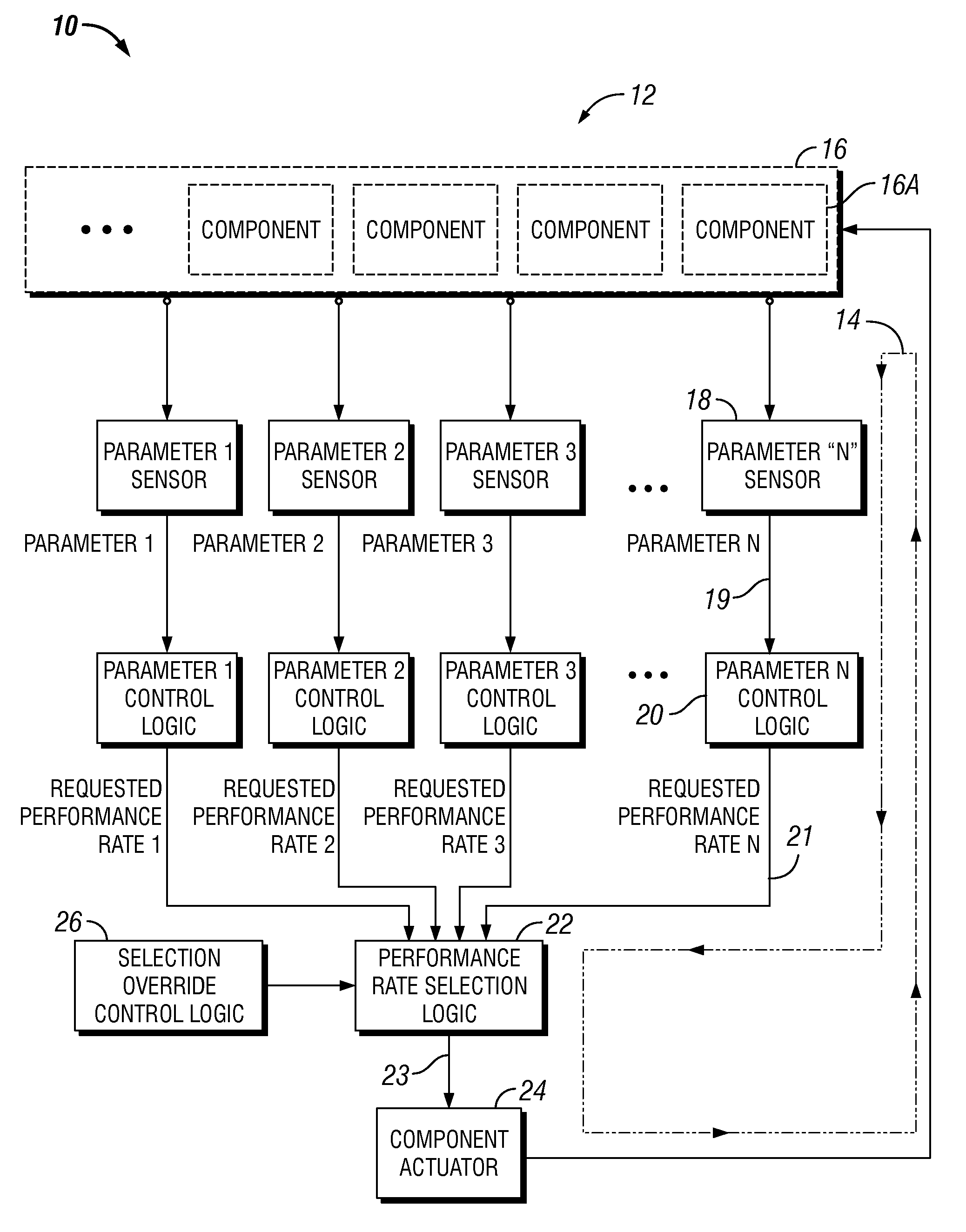

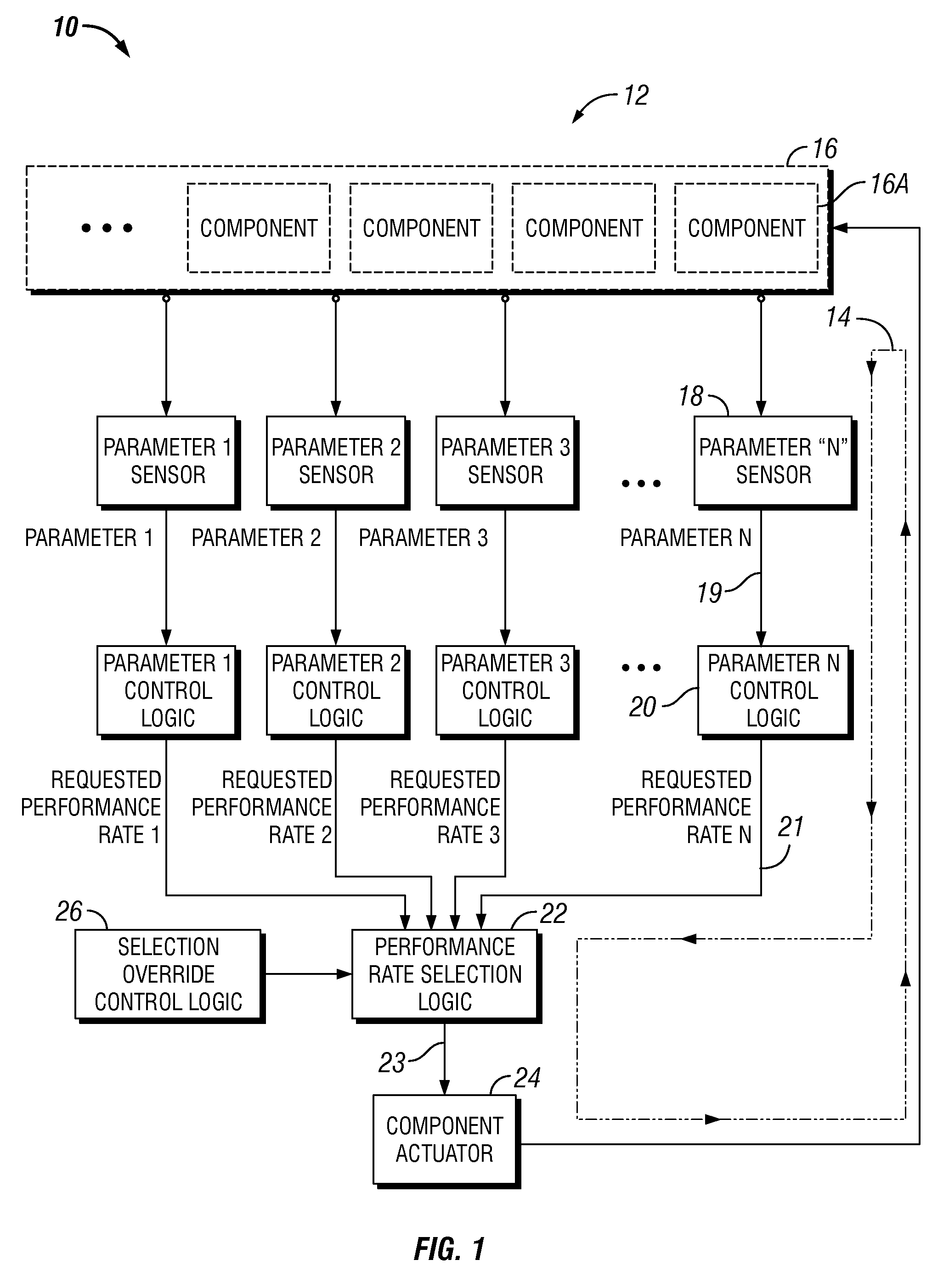

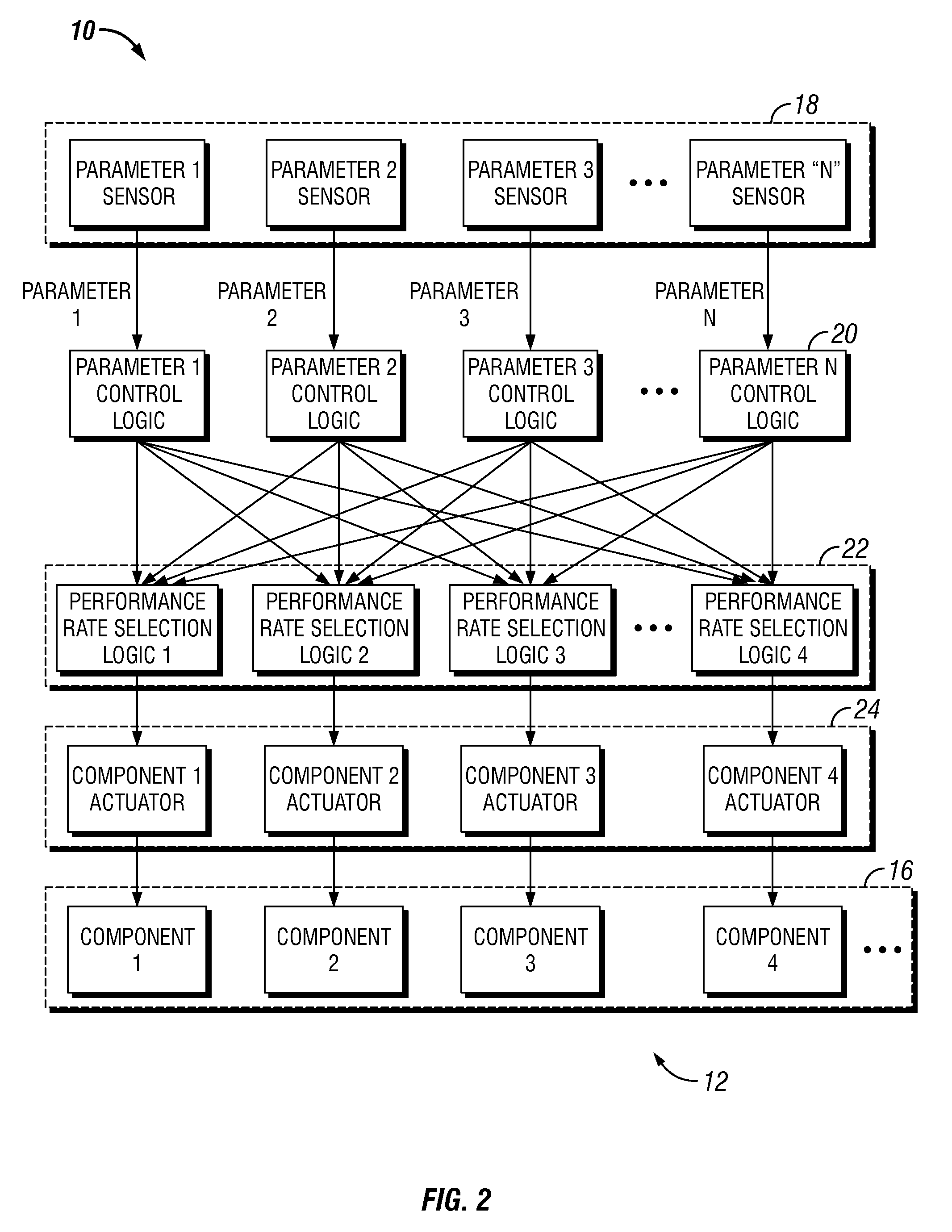

Control Systems and Method Using a Shared Component Actuator

In one embodiment, a control system supports an unlimited number of feedback control loops all sharing control of a component. A component performance rate or “speed” is used as a common metric for negotiating control of the component. Each control loop continuously monitors a system parameter it is tasked with regulating, compares it to a setpoint for that system parameter, and “requests” a speed in relation to the deviation of the associated system parameter from the corresponding setpoint. A controller receives the requested speeds as dynamic inputs and selects one of the requested speeds according to predefined selection logic. The controller communicates the selected speed to an actuator, which causes the component to operate at the selected speed. In this manner, the control system in effect negotiates control of the component in a way that ensures that all of the system parameters are being managed within safe limits.

Owner:IBM CORP

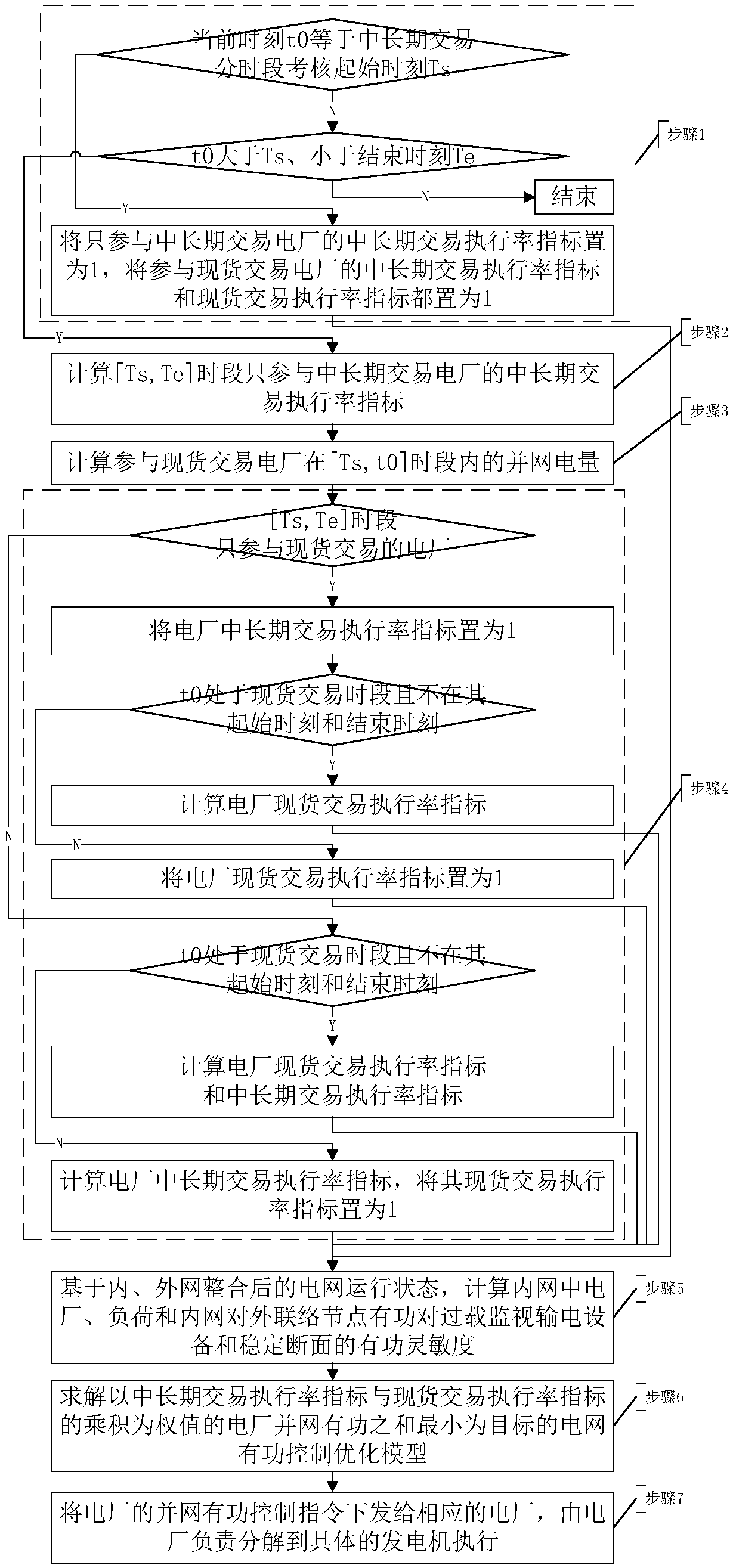

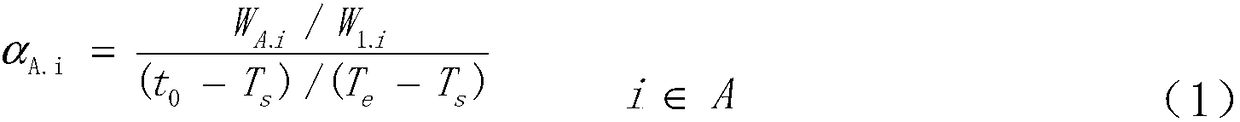

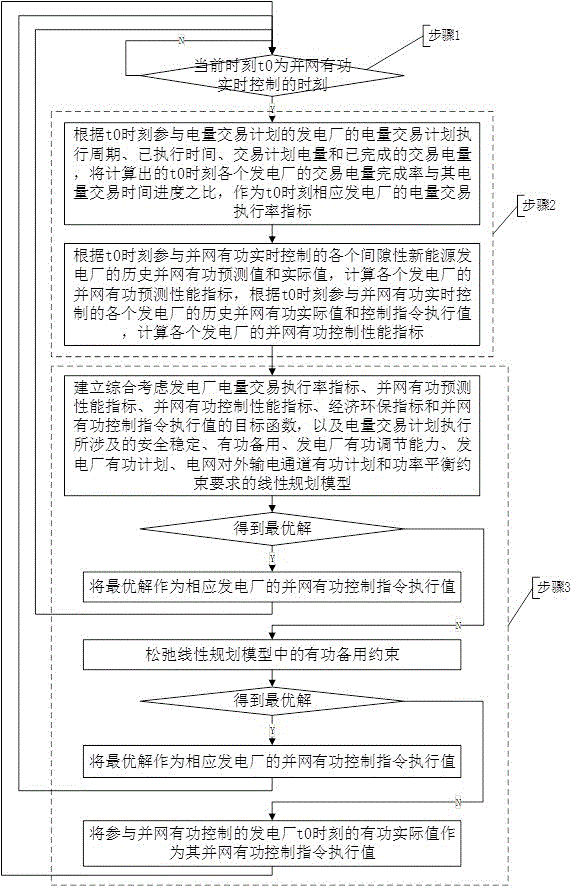

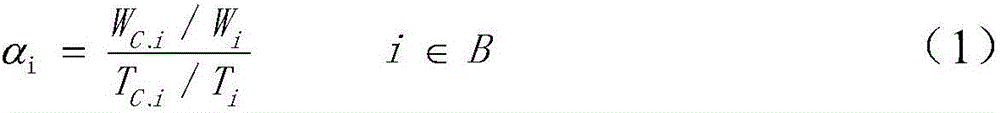

Power grid active real-time control method considering medium and long term transaction and spot transaction constraints

ActiveCN108520315ATo achieve overall coordinationIncreased transaction powerForecastingSingle network parallel feeding arrangementsElectric power systemElectricity market

The invention discloses a power grid active real-time control method considering medium and long term transaction and spot transaction constraints, and belongs to the technical field of electric powersystem operation and control. Aiming at the grid-connected active real-time control of a power plant in an electric power market environment with coexistence of medium and long term transactions andspot transactions, according to the method, a spot transaction electric quantity execution rate index is adjusted through introduction of a parameter less than 1 by regarding a ratio of the transaction electric quantity completion progress to the transaction time progress as a transaction electric quantity execution rate index, the grid-connected active adjusting speed and the adjustable space ofthe power plant, electric power balance, power transmission channel capability, and frequency modulation and peak regulation constraints are considered, a power grid active control optimization modelregarding a minimum grid-connected active sum of the power plant which regards a product of the medium and long term transaction electric quantity execution rate index and the spot transaction electric quantity execution rate index as the weight as the target is established, and power grid active control which simultaneously satisfies requirements of medium and long term transaction constraints and spot transaction constraints is realized.

Owner:NARI TECH CO LTD +3

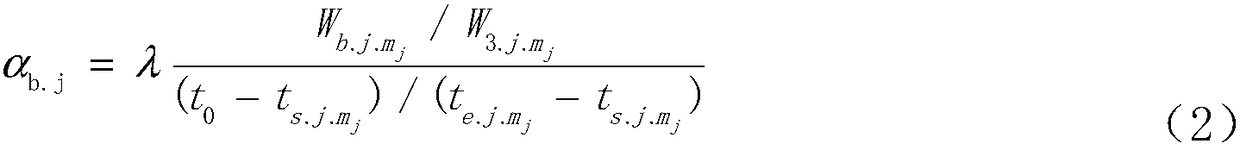

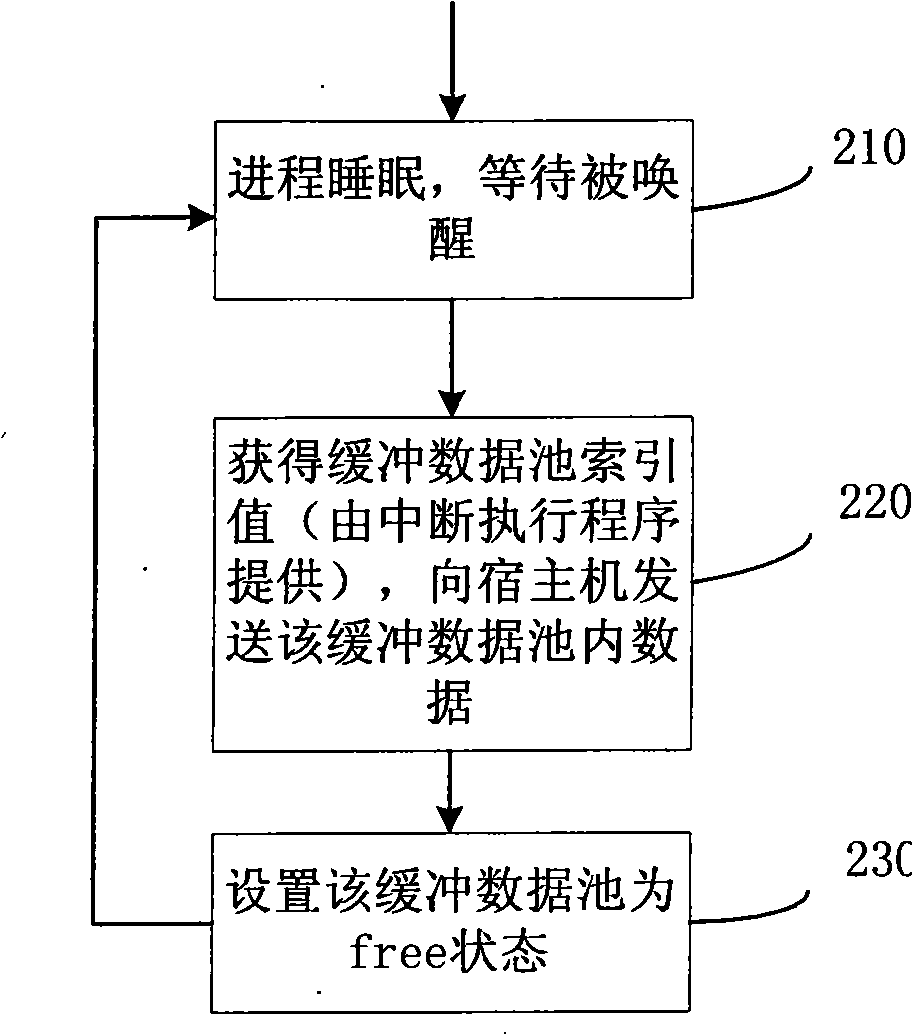

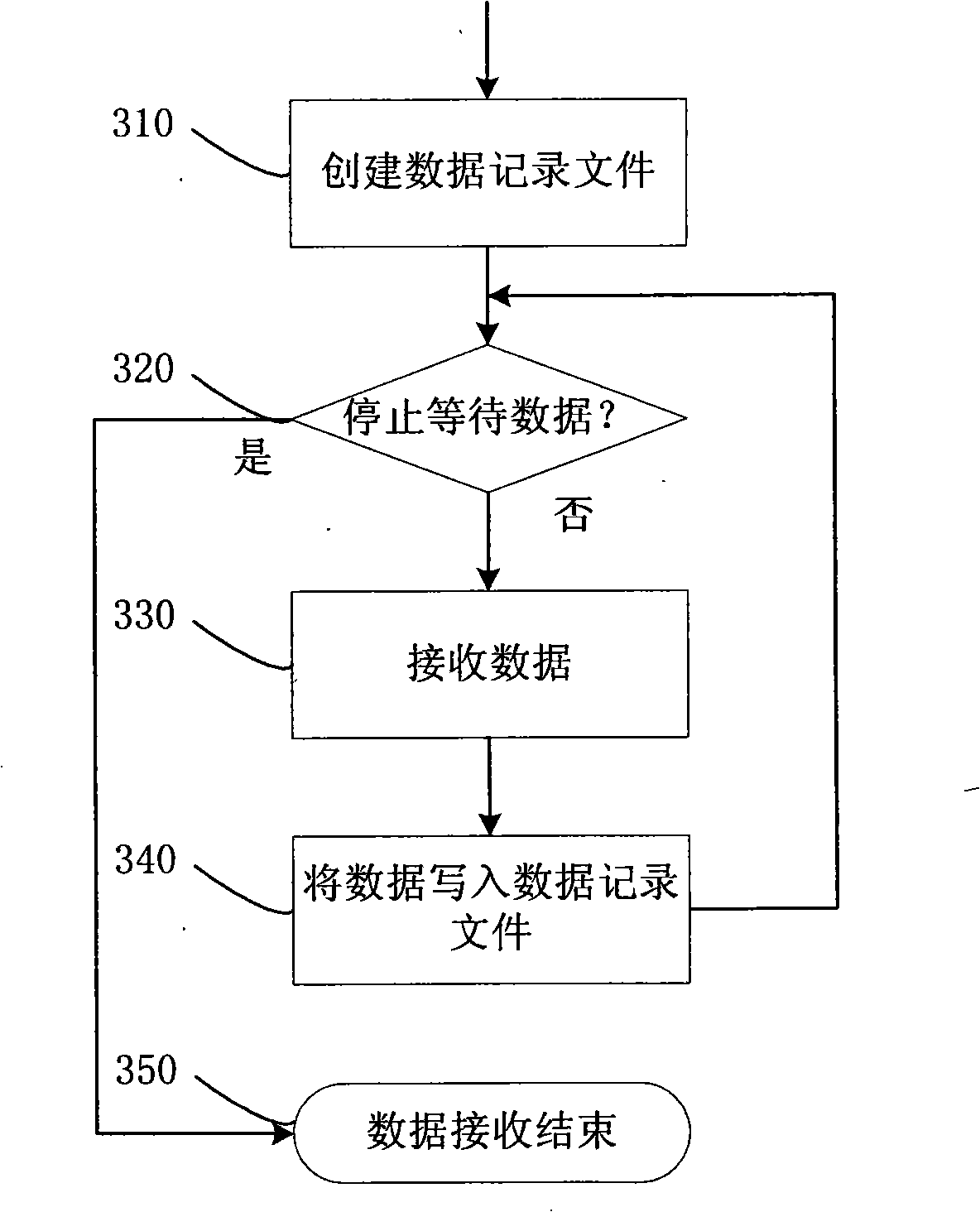

CPU occupancy rate measuring method and apparatus

InactiveCN101344865AEasy to optimizeImprove performanceHardware monitoringMultiprogramming arrangementsOccupancy rateOperational system

The invention discloses a method and a device for CPU occupation rate measurement and relates to the field of computer operation systems. The method of the invention comprises the following steps of: generating timed interruption by using a hardware timer; sampling and saving the values recorded by the program counters of the interrupted functions; carrying out function name resolution, counting times of function use and analyzing execution rate of each function of the system according to the saved data. The method provides a more precise CPU occupation rate measurement method and therefore offers a more effective basis for system execution efficiency acquisition.

Owner:ZTE CORP

Power plant grid-connection active power real time control method taking electric quantity transaction plan into consideration

ActiveCN106655279AFulfill the execution requirementsLow comprehensive cost of economy and environmental protectionSingle network parallel feeding arrangementsNew energyElectric power system

The invention discloses a power plant grid-connection active power real time control method taking an electric quantity transaction plan into consideration, and belongs to the electric power system operation and control field. A ratio between a power plant electric quantity transaction completion rate and a transaction plan implementation progress is taken as an electric quantity transaction implementation rate index, a power plant low in electric quantity transaction implementation rate index, an intermittent new energy power station high in grid-connection prediction performance index, a power plant high in grid-connection active control performance index and an economical and environment-friendly power plant low in comprehensive cost per generating capacity get priority during grid-connection active real-time control, the above factors are taken as a target function, and a linear plan model considering safety and stability, active standby, power plant active adjusting capability, a power plant active plan, a power grid external power transmission channel active plan and a power balance constraint requirement that are related to electric quantity transaction plan implementation is built. The method of the invention helps to improve practicality of power plant grid-connection active power real time control.

Owner:NARI TECH CO LTD +4

Method and system for dynamic resource allocation

InactiveUS7688746B2Inefficiencies encountered by conventional systems may be reducedImprove performanceEnergy efficient ICTError preventionDynamic resourceComputerized system

Owner:INTEL CORP

Method for reducing converter hot metal single consumption

ActiveCN102399932AEasy to useIncrease economic benefitsManufacturing convertersFerrosiliconPerformance rate

The present invention provides a method for reducing converter hot metal single consumption. According to the present invention, the following conditions are adopted as the standard conditions: the Si content in the hot metal is more than or equal to 0.4%, the actual hot metal temperature T is more than or equal to 1380 DEG C; each ton of the iron is added with 180-200 kg of scrap steel; when theT is more than or equal to 1320 DEG C and less than 1380 DEG C, the treatment of silicon preparing is firstly performed, then the treatment of carbon preparing is performed, and the scrap steel is added according to the ratio when the ratio of the hot metal meets the standard conditions; when the T is more than or equal to 1280 DEG C and less than 1320 DEG C, each ton of the iron is added with 150-175 kg of the scrap steel after the ratio of the hot metal meets the standard conditions by the silicon preparing treatment and the carbon preparing treatment,. With the present invention, the combined temperature compensation manner of the ferrosilicon and the coke is adopted, such that the converter carbon temperature at the end point is basically coordinated so as to ensure the stability of the final quality of the hot metal; the use amount of the scrap steel is 20% of the total amount of the converter hot metal, such that the hot metal single consumption of the converter can be substantially reduced, the production cost is reduced when the price of the scrap steel is less than the price of the hot metal; the resource shortage can be effectively released during the hot metal shortage process, the production scale and the performance rate of the contract can be ensured.

Owner:ANGANG STEEL CO LTD

Method and apparatus for displaying and identifying available wavelength paths across a network

Due to demand for more network bandwidth, a need for multi-user optical network topologies has, and will continue to, increase. A method or corresponding apparatus in embodiments of the present invention provide for an availability determination tool for determining and displaying wavelength and subrate availabilities within a network. Benefits of embodiments of a tool include allowing a user to identify the availability and capacity of any wavelength on any network, via an interactive graphical user interface, such as by using three-dimensional representations. In one embodiment, the disclosed availability determination tool allows users to locate and view any combination of available wavelengths between nodes in an optical network topology, and generate graphical and tabular reports of the availability in order to maintain an efficient and organized method or apparatus for determining and controlling wavelengths in a network. Consequently, service providers using the tool can keep performance rates high and costs low.

Owner:TELLABS OPERATIONS

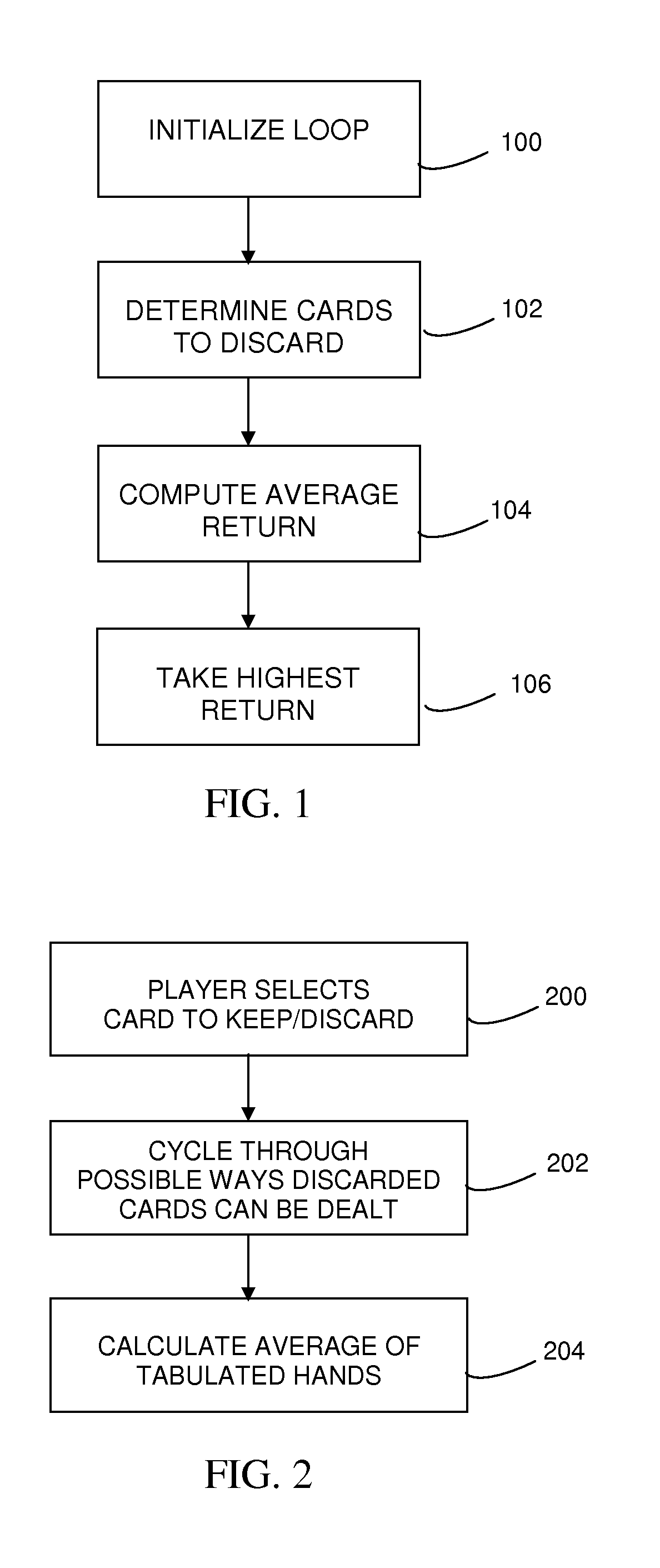

Player comping system and method

Owner:DRAFTKINGS INC

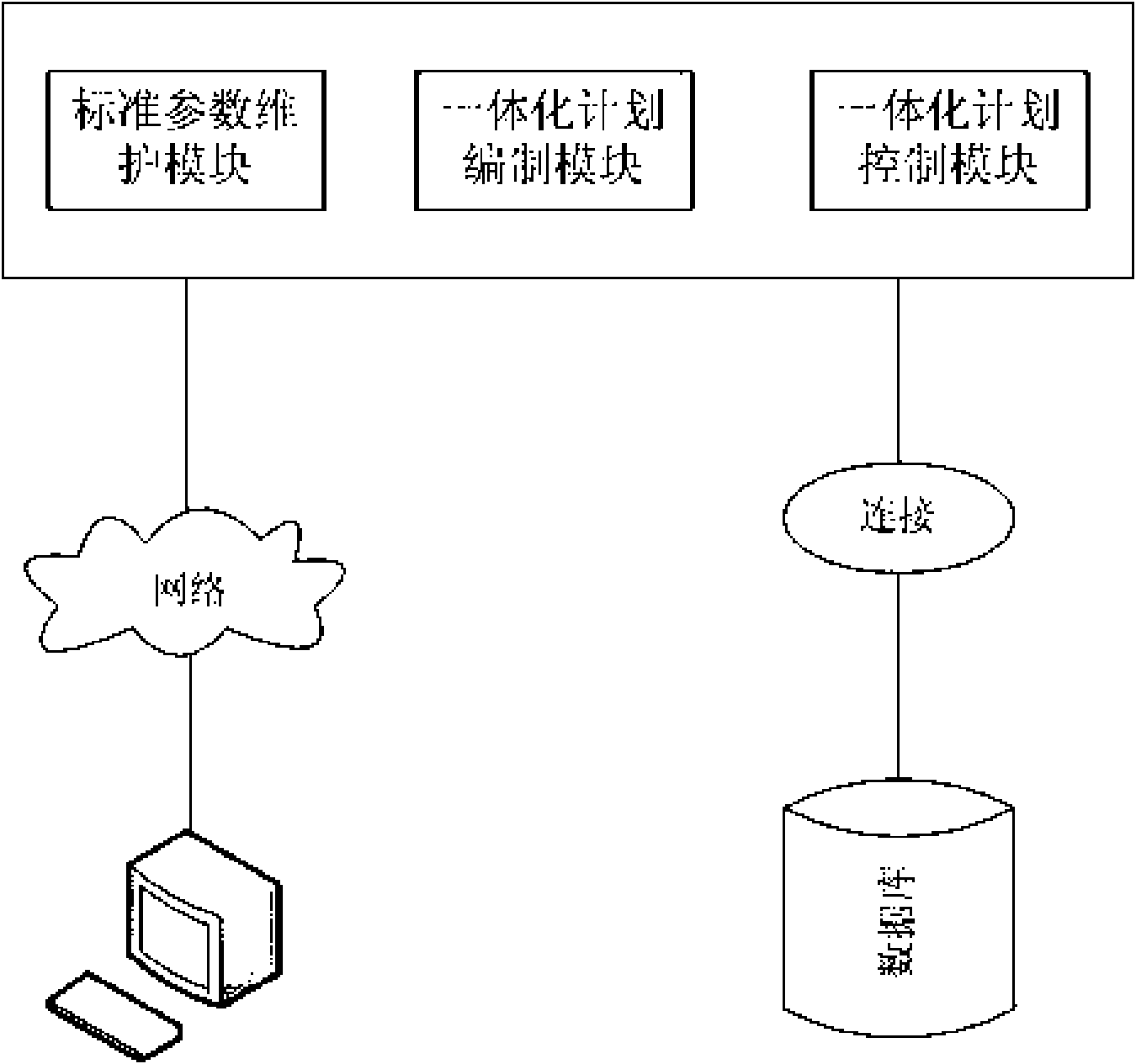

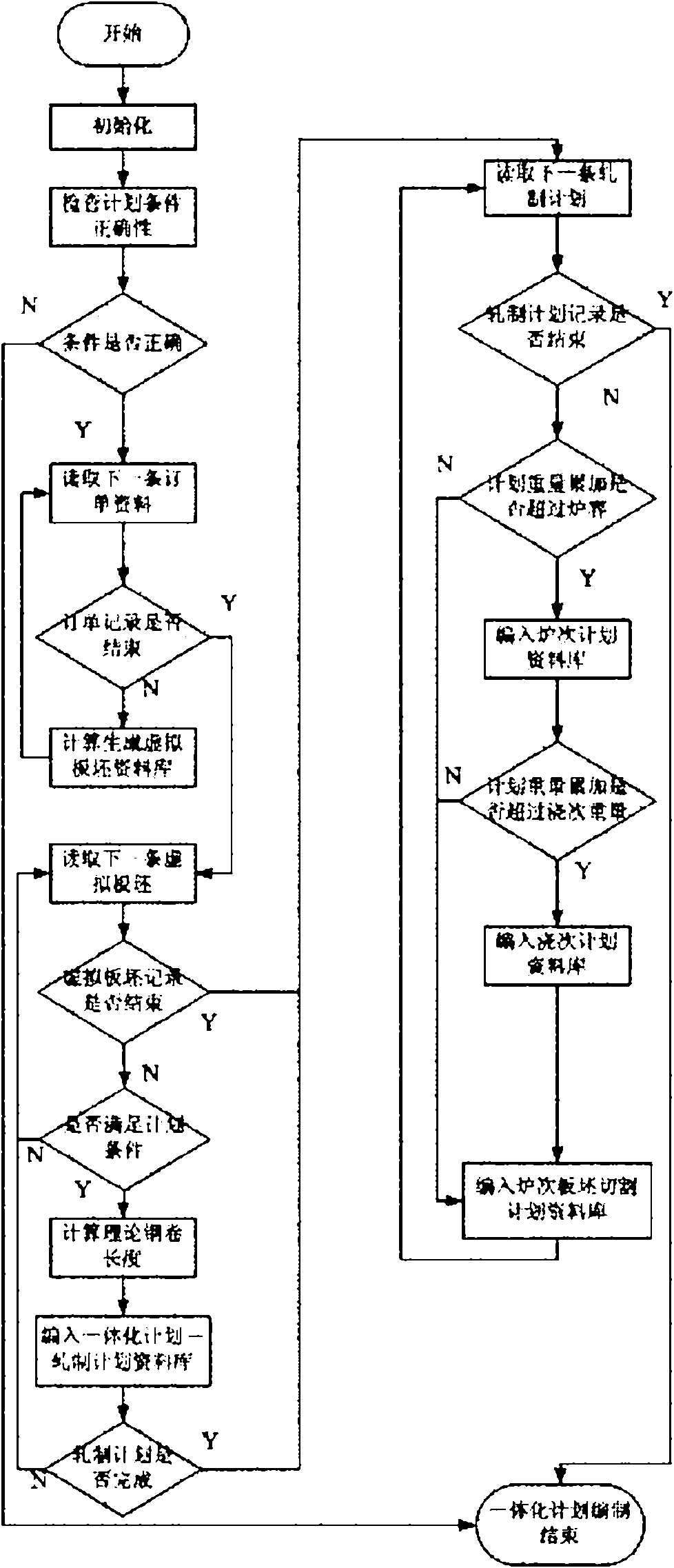

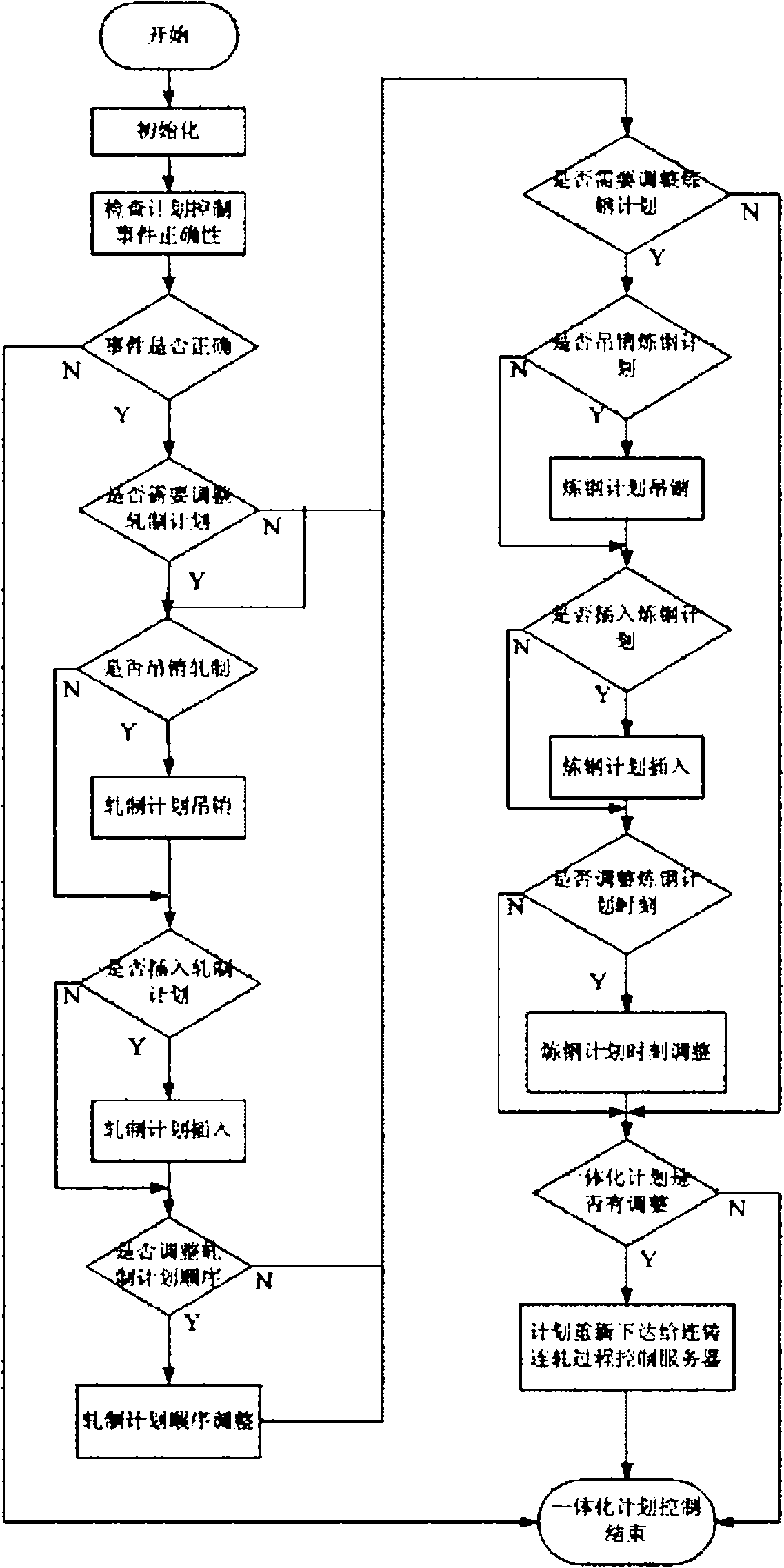

Continuous casting and continuous rolling integration control method

InactiveCN101634839AImprove execution rateEasy to implementRoll mill control devicesProgramme control in sequence/logic controllersSteelmakingContinuous rolling

The invention provides a continuous casting and continuous rolling integration control method comprising the following steps: ensuring a rolling plan; ensuring a steelmaking plan according to the rolling plan; and executing the steelmaking plan and the rolling plan. The continuous casting and continuous rolling integration control method is especially suitable for uniformly weaving and controlling a steelmaking and steel rolling production plan of an enterprise which is oriented to a production organization mode of an order to produce. Compared with the prior art, the continuous casting and continuous rolling integration control method has plan integration, easy realization, high efficiency and dynamic regulation, realizes the unity and the compatibility of the metallurgy continuous casting and continuous rolling production plan, completely satisfies the requirement of a technical constraint condition and increases the production plan executing rate and the order hanging rate, thereby increasing the product rate and reducing the production cost.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Control systems and method using a shared component actuator

In one embodiment, a control system supports an unlimited number of feedback control loops all sharing control of a component. A component performance rate or “speed” is used as a common metric for negotiating control of the component. Each control loop continuously monitors a system parameter it is tasked with regulating, compares it to a setpoint for that system parameter, and “requests” a speed in relation to the deviation of the associated system parameter from the corresponding setpoint. A controller receives the requested speeds as dynamic inputs and selects one of the requested speeds according to predefined selection logic. The controller communicates the selected speed to an actuator, which causes the component to operate at the selected speed. In this manner, the control system in effect negotiates control of the component in a way that ensures that all of the system parameters are being managed within safe limits.

Owner:INT BUSINESS MASCH CORP

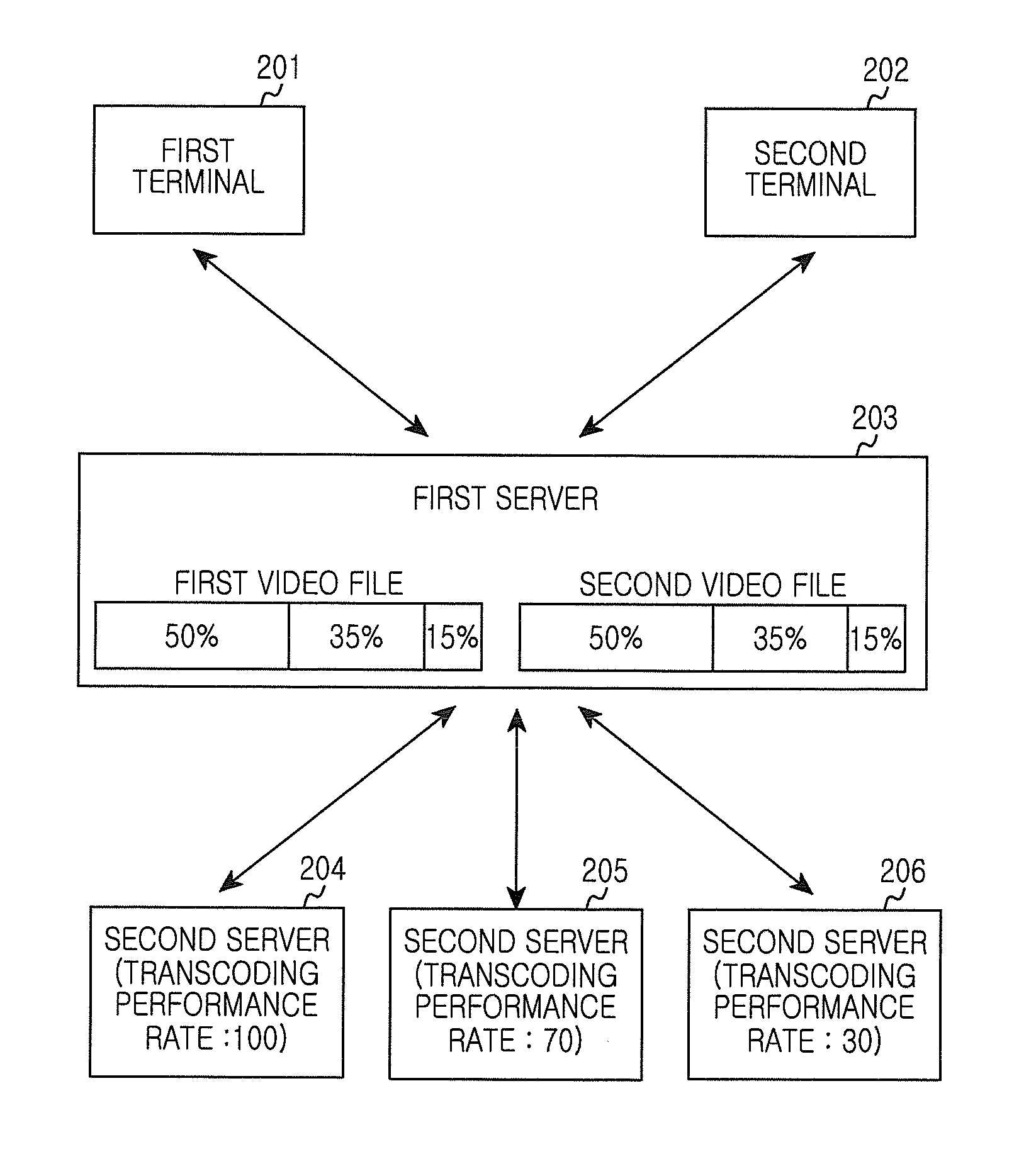

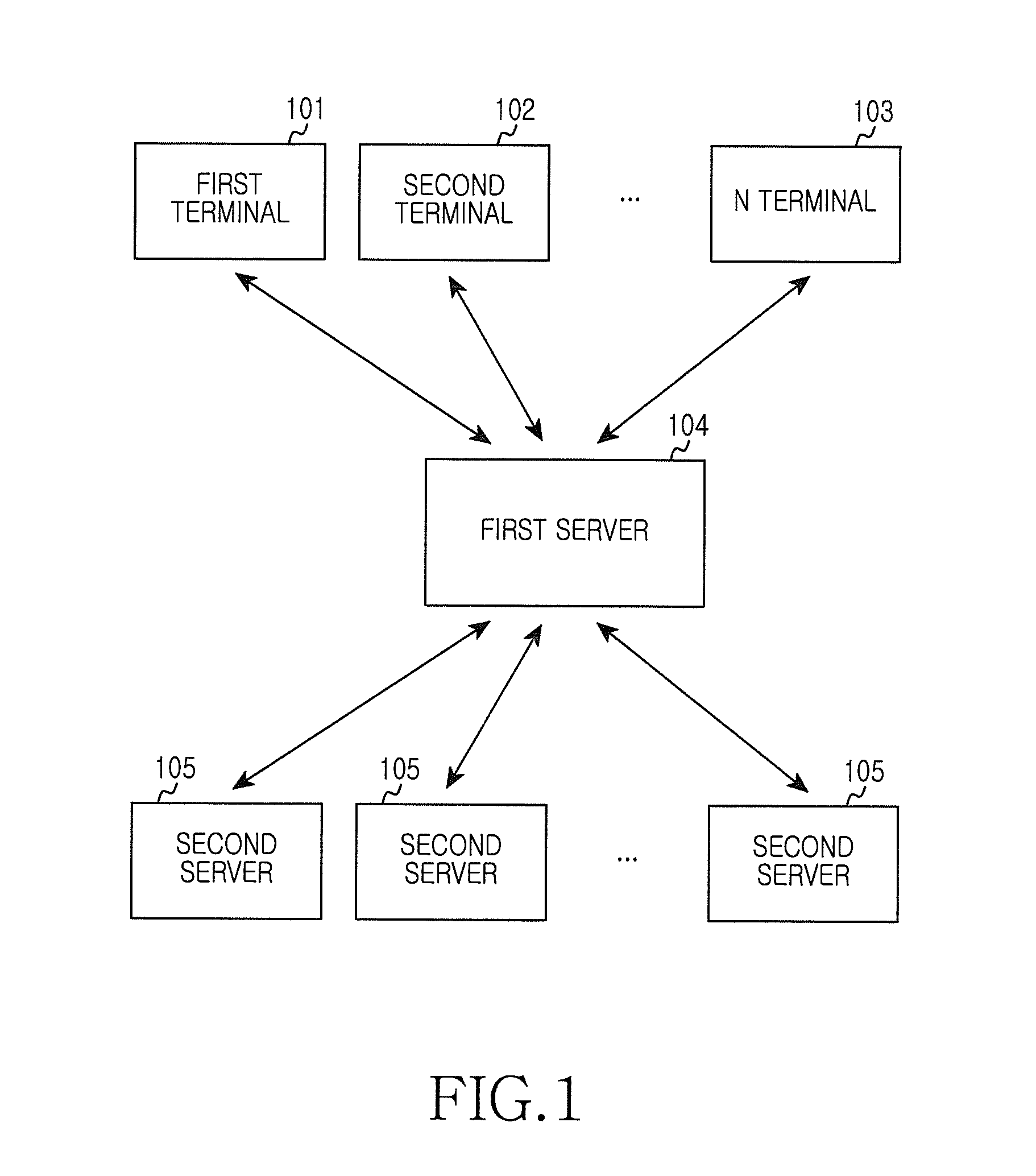

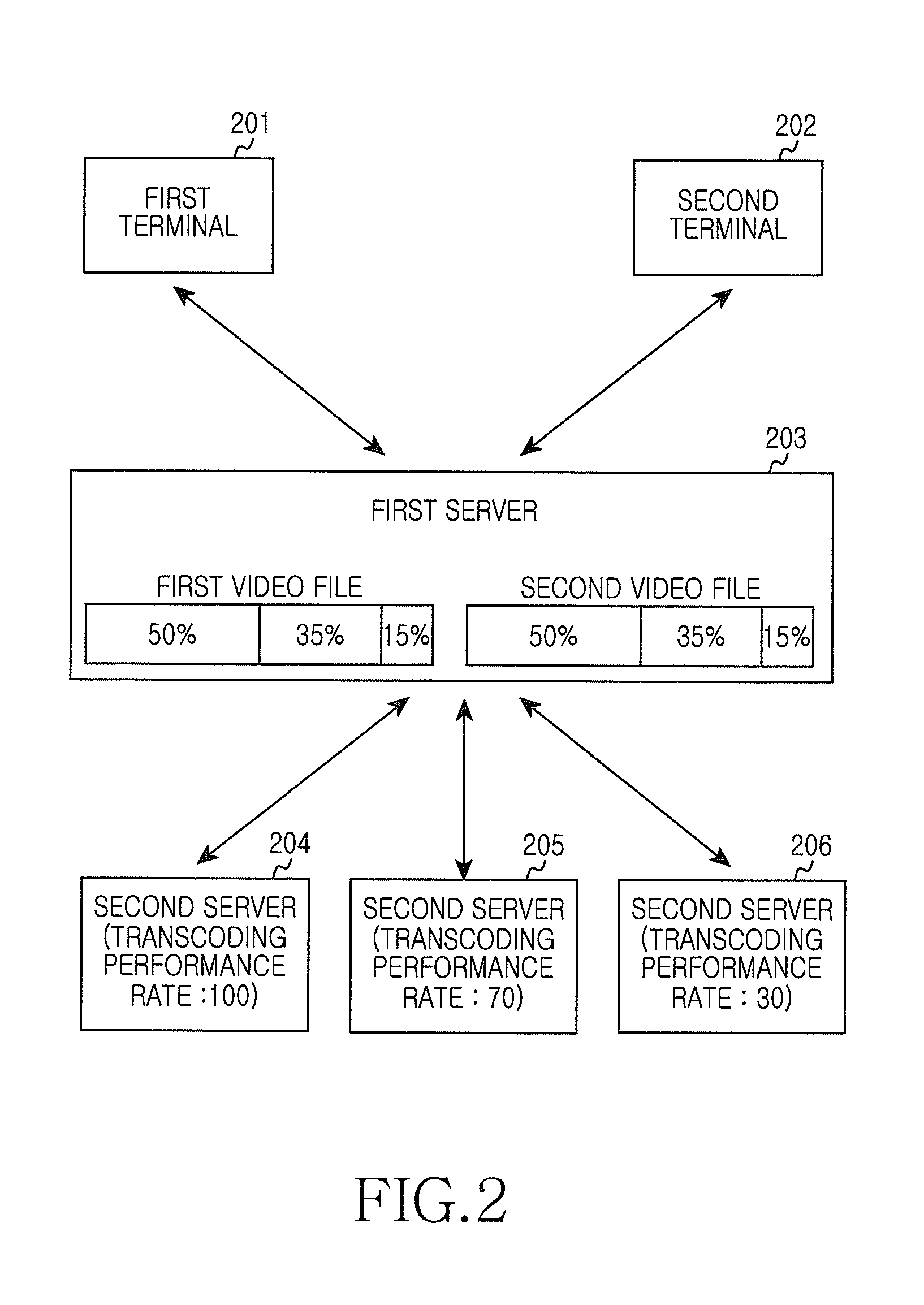

Distributed transcoding apparatus and method using multiple servers

ActiveUS20130297679A1Save powerMultiple digital computer combinationsTransmissionTranscodingPerformance rate

In one embodiment, a distributed transcoding method using a plurality of servers includes receiving a request for a first video file from a first terminal, distributing and requesting a first transcoding of the first video file to at least two second servers according to performance rates of the second servers, before receiving the first video file with the completed first transcoding completed from the second server, receiving a request for a second video file from a second terminal, and distributing and requesting a second transcoding of the second video file to the second servers according to the performance rates of the second servers.

Owner:OMNISLASH DIGITAL LLC

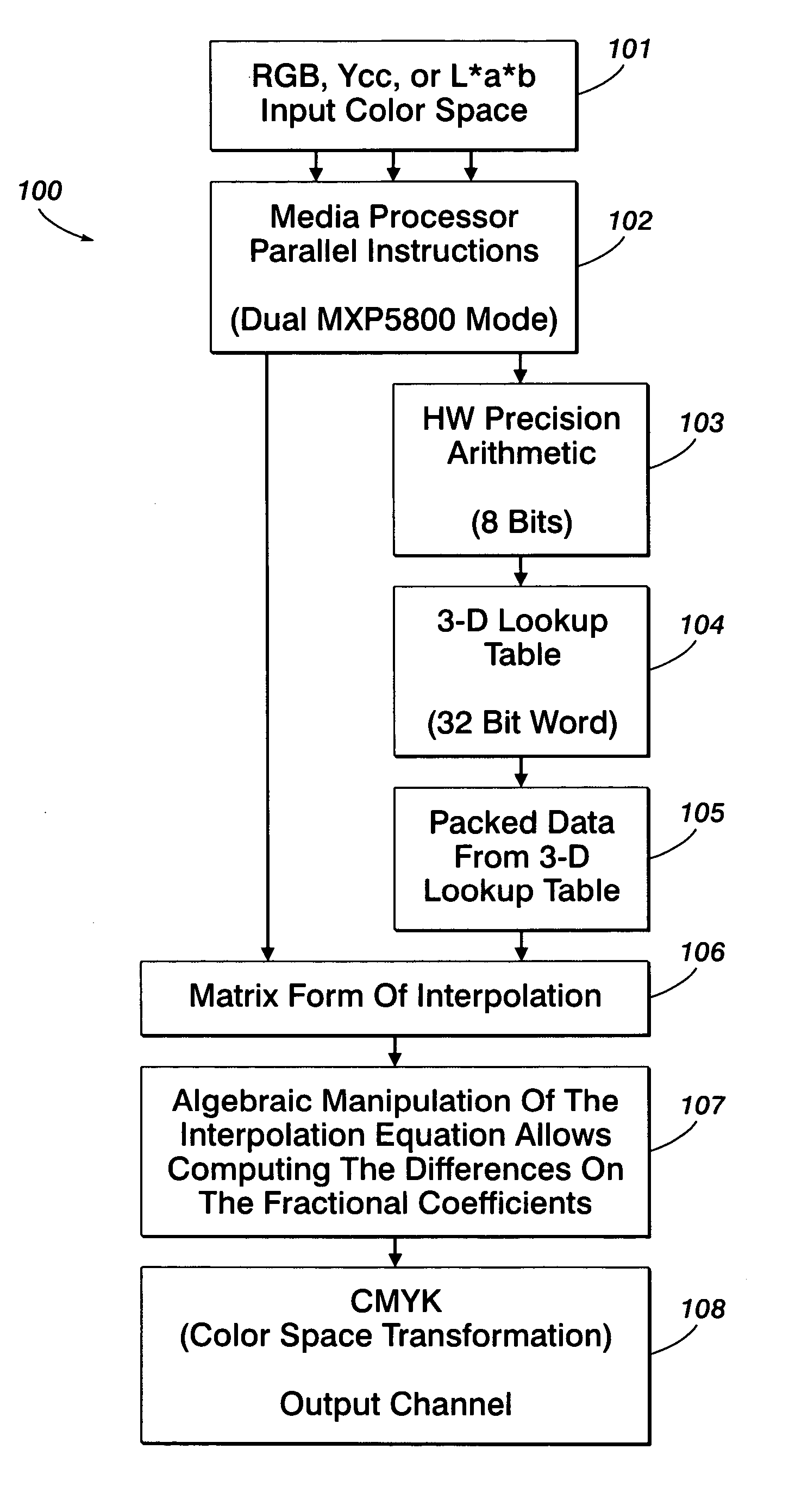

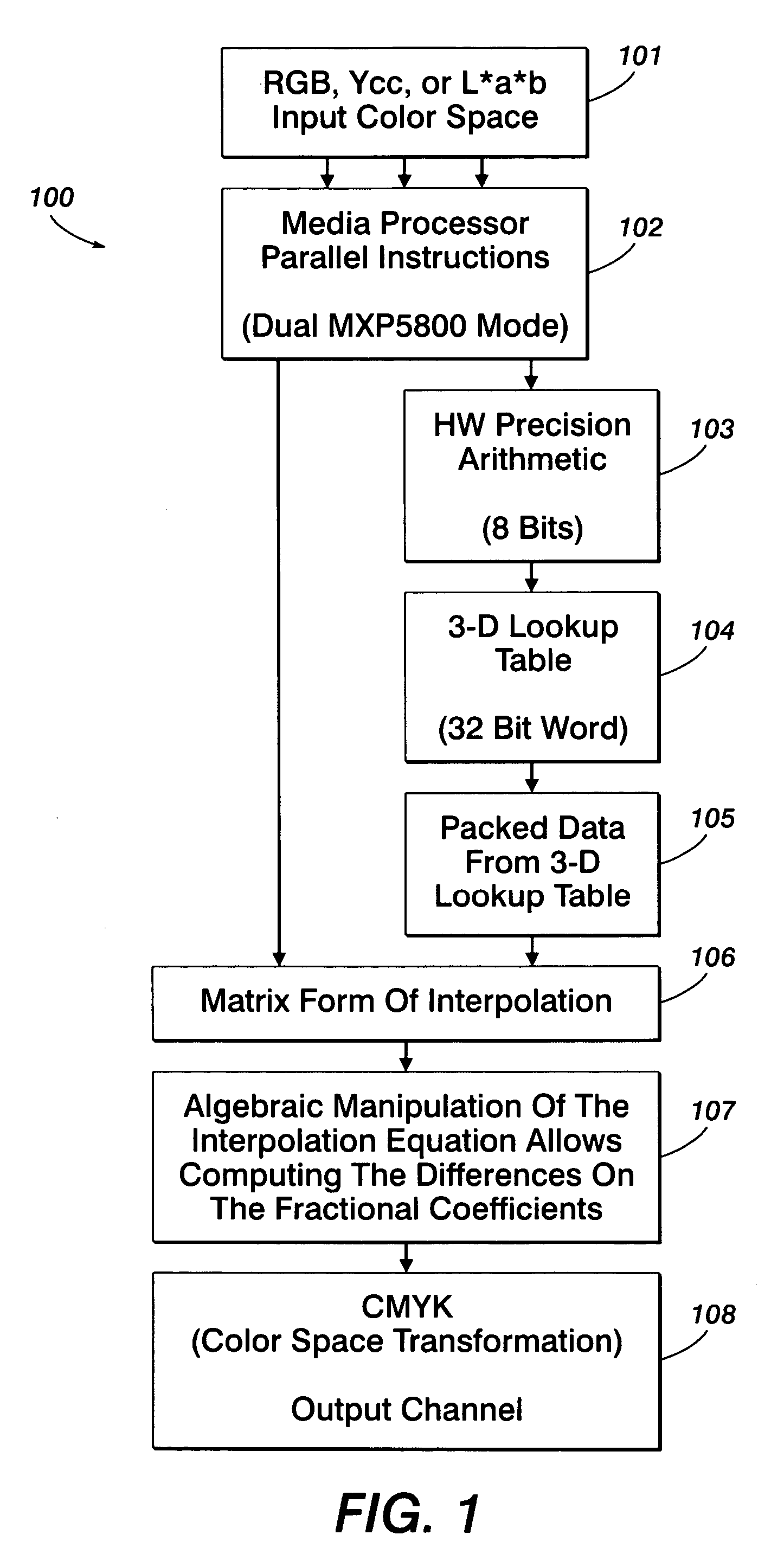

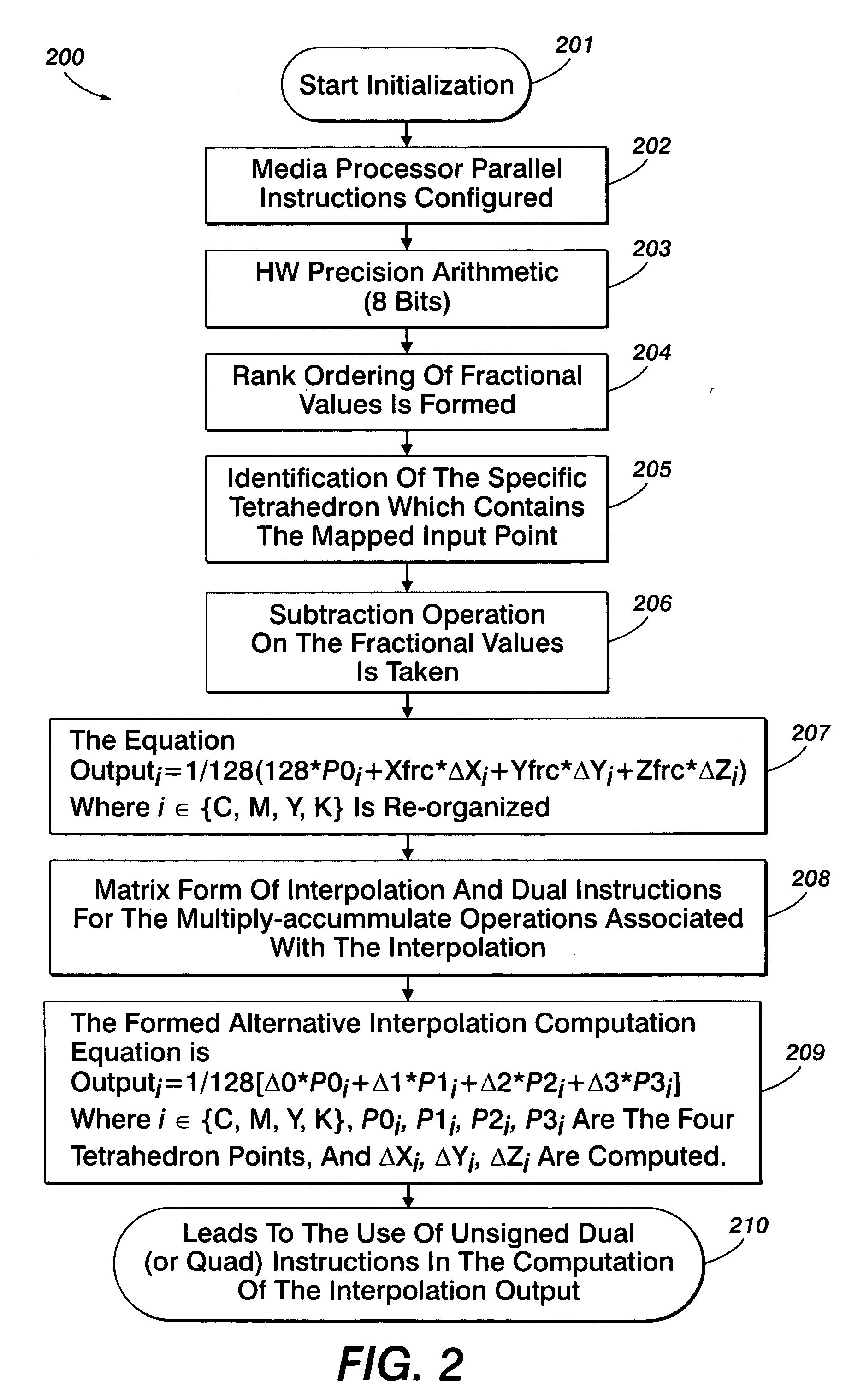

Method for tetrahedral interpolation computations using data-level parallelism

InactiveUS20070247648A1Effective calculationQuick implementationDigitally marking record carriersColor signal processing circuitsParallel computingPerformance rate

A system and method for tetrahedral interpolation computations using data-level parallelism that takes advantage of data-level parallelism in media processors. If the tetrahedron points in a 3D lookup table are packed together in a memory, the interpolation computation can be implemented without extra instructions to unpack them. An algebraic manipulation of the interpolation equation allows computing the difference on the fraction coefficients instead of the tetrahedron node values. Not only will this technique preserve the full precision without over or underflow, but the packed data from the 3D lookup can be used directly, thereby allowing a faster implementation of the color space transformation overall and implementing as part of a direct-copy image path on a media processor. Such a system and method allows the implementation of the direct copy pipeline to function at the required performance rate as requested by a customer specification while obtaining the required product design speed.

Owner:XEROX CORP

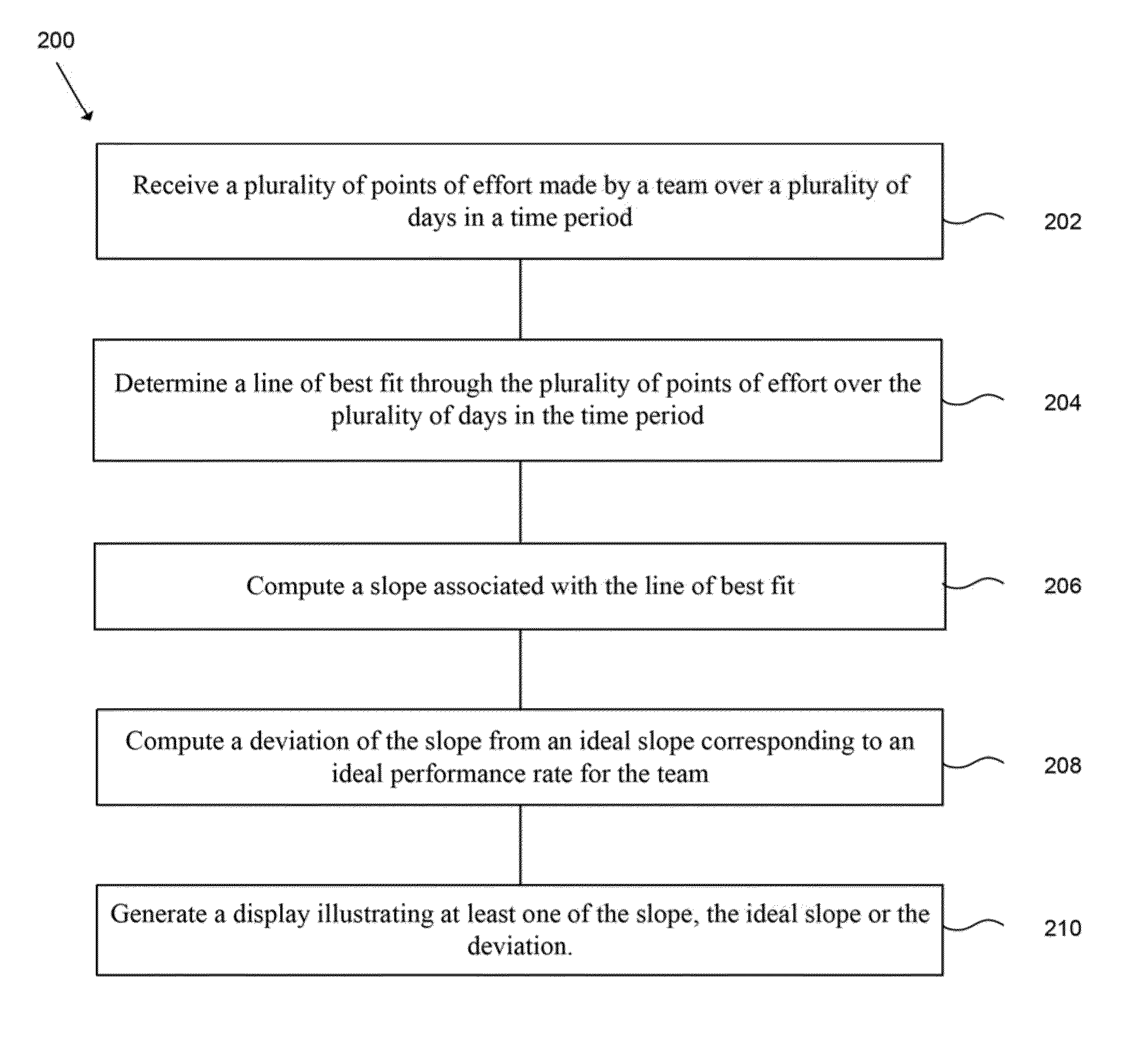

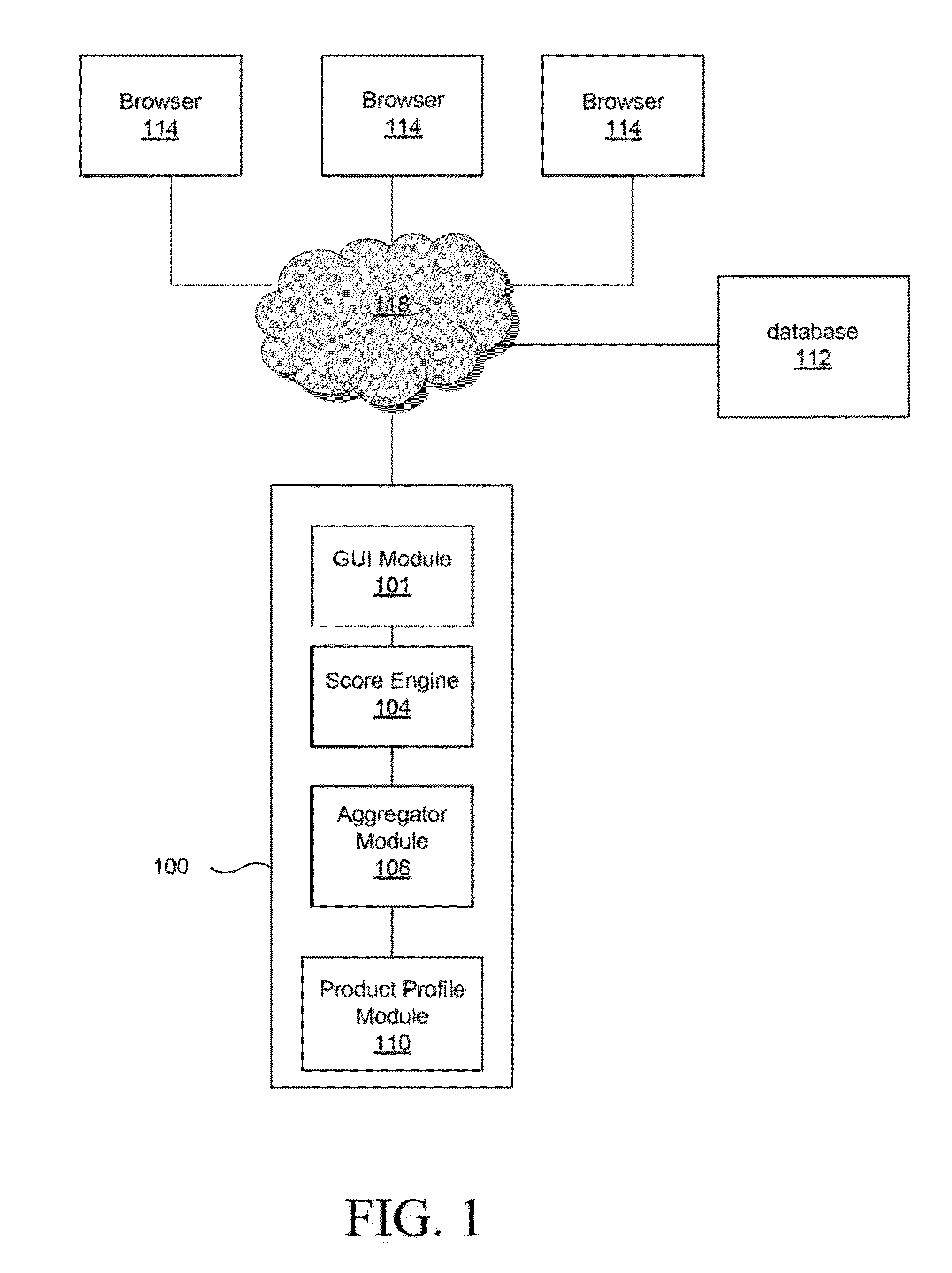

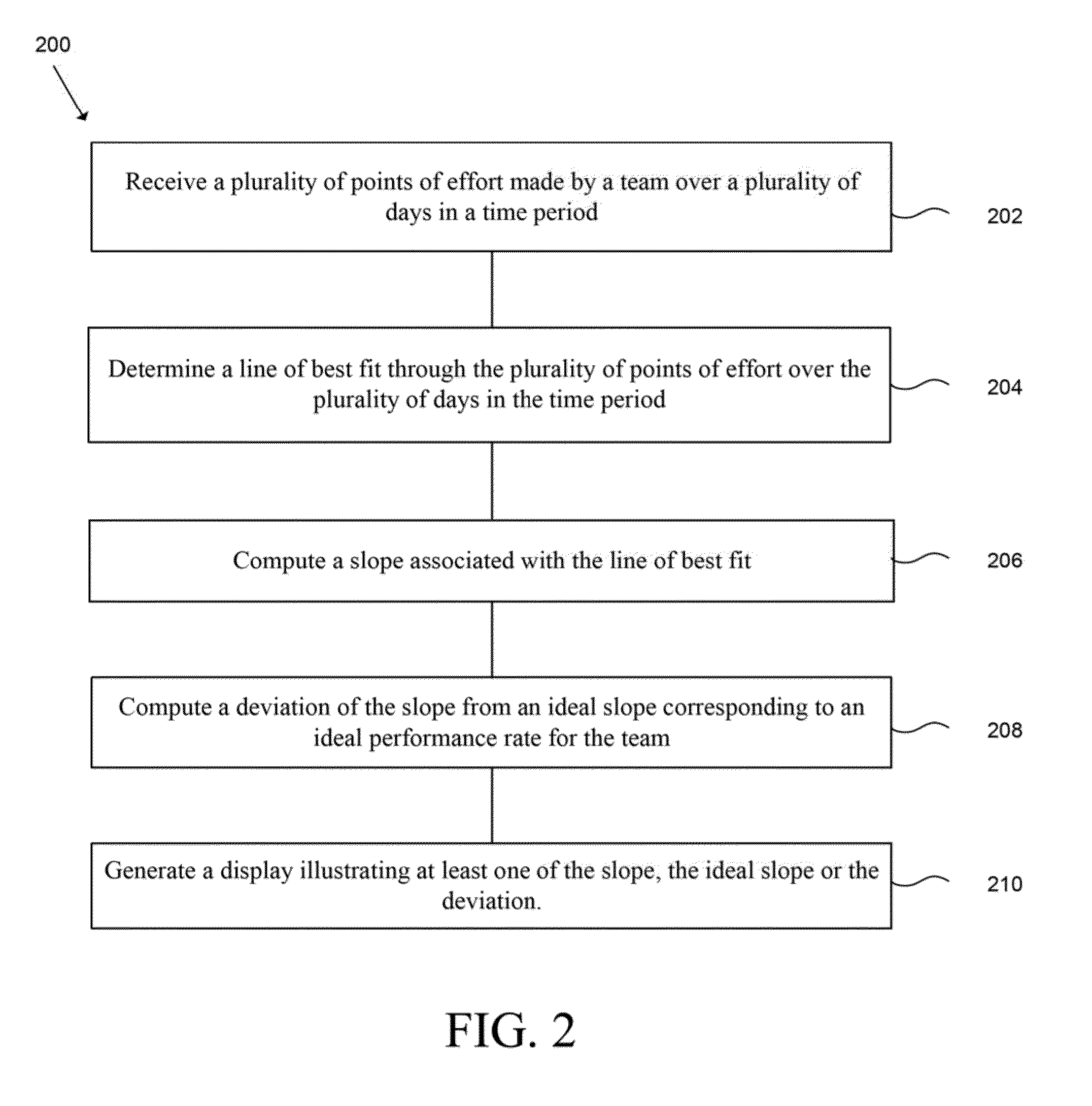

Systems and methods for monitoring product development

ActiveUS9043745B1Measure and track ongoing team performancePerformanceSoftware maintainance/managementResourcesEngineeringPerformance rate

A computer-implemented method is provided for evaluating team performance in a product development environment. The method includes receiving a plurality of points of effort made by a team over a plurality of days in a time period, computing a slope associated with a line of best fit through the plurality of points of effort over the plurality of days, computing a deviation of the slope from an ideal slope corresponding to a desired performance rate for the team, and generating a display illustrating at least one of the slope, the ideal slope or the deviation.

Owner:FMR CORP

Method and program for generating execution code for performing parallel processing

InactiveUS7739530B2Reduce power consumptionEasy to compileEnergy efficient ICTSoftware engineeringParallel processingSource code

Provided is a method of reliably reducing power consumption of a computer, while promoting prompt compilation of a source code and execution of an output code. The method according to this invention includes the steps of: reading a code which is preset and analyzing an amount of operation of the CPU and an access amount with respect to the cache memory based on the code; obtaining an execution rate of the CPU and an access rate with respect to the cache memory based on the amount of operation and the access amount; determining an area in which the access rate with respect to the cache memory is higher than the execution rate of the CPU, based on the code; adding a code for enabling the power consumption reduction function to the area; and generating an execution code executable on the computer, based on the code.

Owner:HITACHI LTD

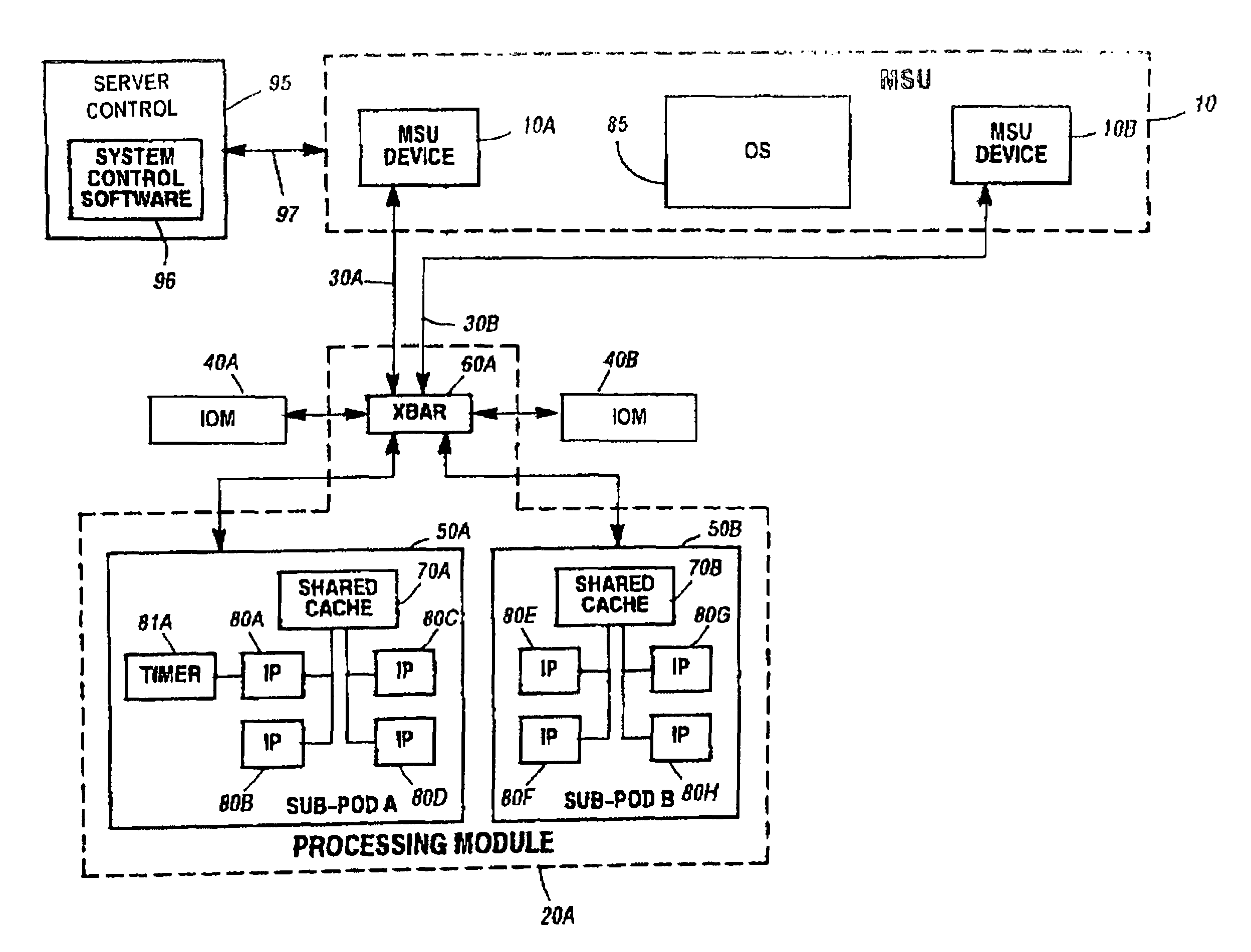

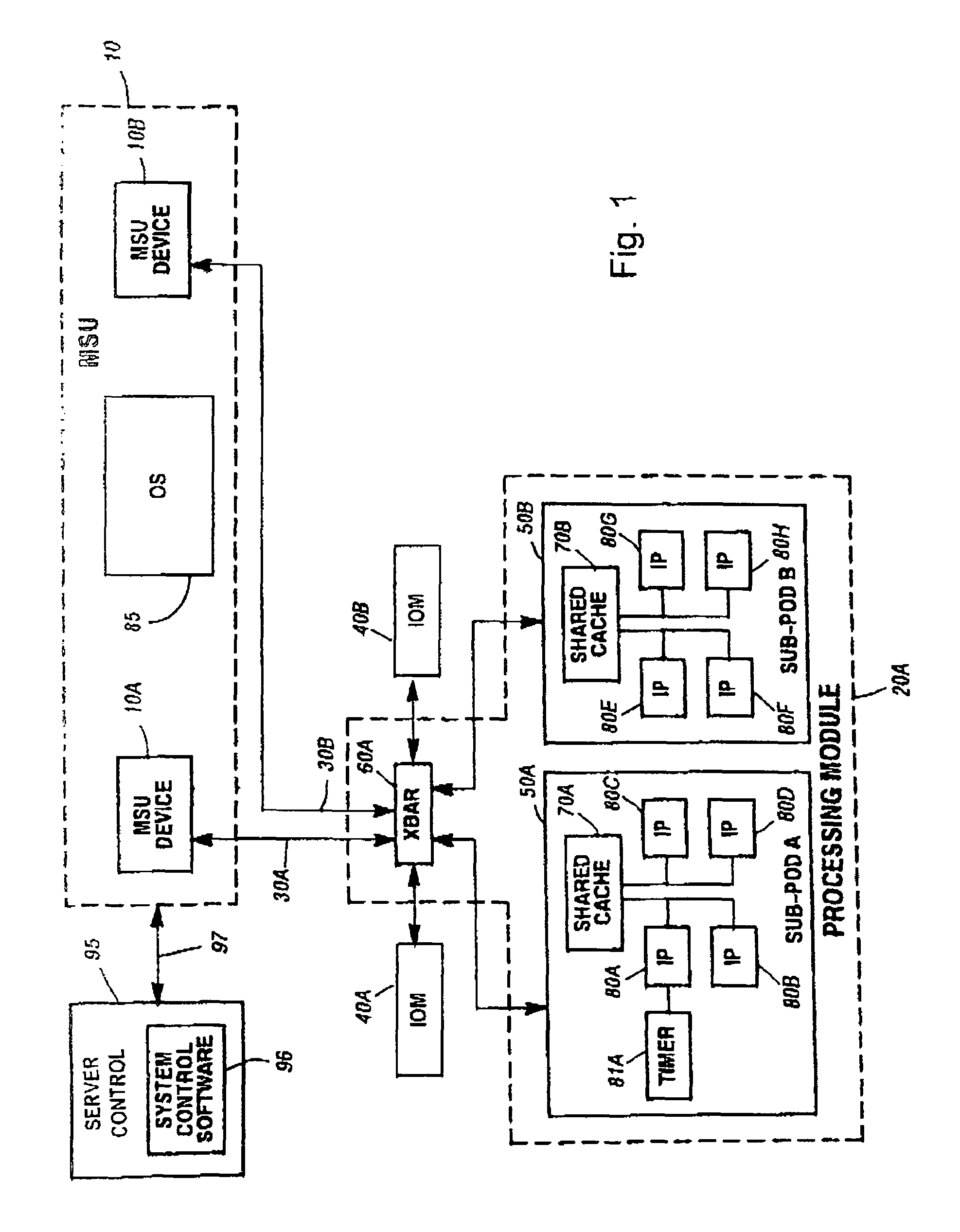

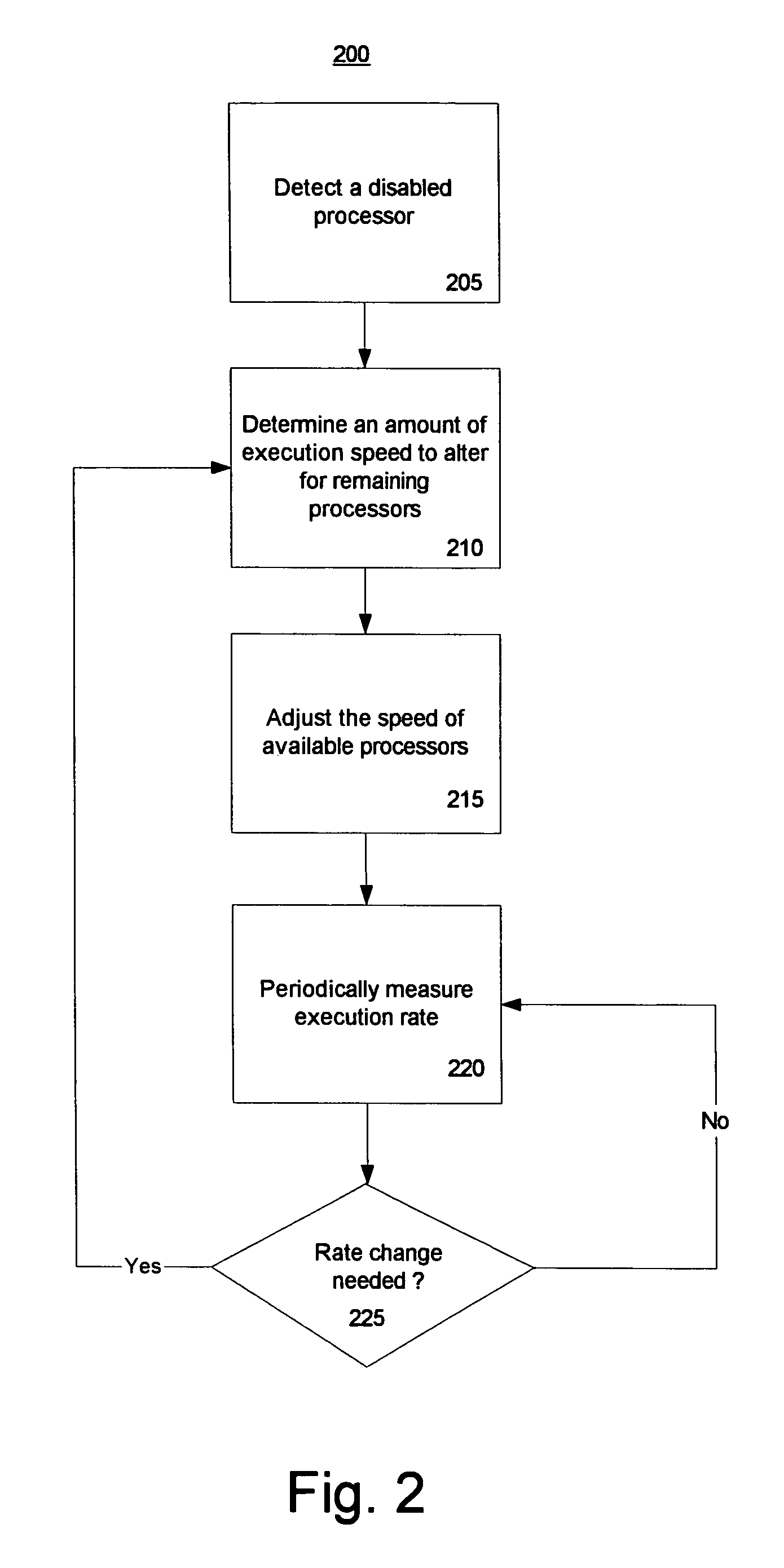

System and method for maintaining a constant processor service level in a computer

ActiveUS7734952B1Maintaining processor performanceError detection/correctionRecovery methodMulti processor

A method and system for maintaining the execution speed of a multiprocessor computer system includes automatically detecting a change in instruction execution rate in a disabled processor by a threshold amount and determining an amount of change in instruction execution rate to adjust an actual system-level instruction execution rate to approximate a target system-level instruction execution rate. The target system-level execution rate being pre-determined. Thereafter, the method adjusts one or more instruction processor execution rates such that the actual system-level instruction execution rate approximates the target system-level instruction execution rate to overcome the loss of the disabled processor. One embodiment of the invention involves the use of a processor key for licensing of processor resources within the computer system and offers the option of enabling a dynamic processor recovery method as well as an automatic execution rate regulation method.

Owner:UNISYS CORP

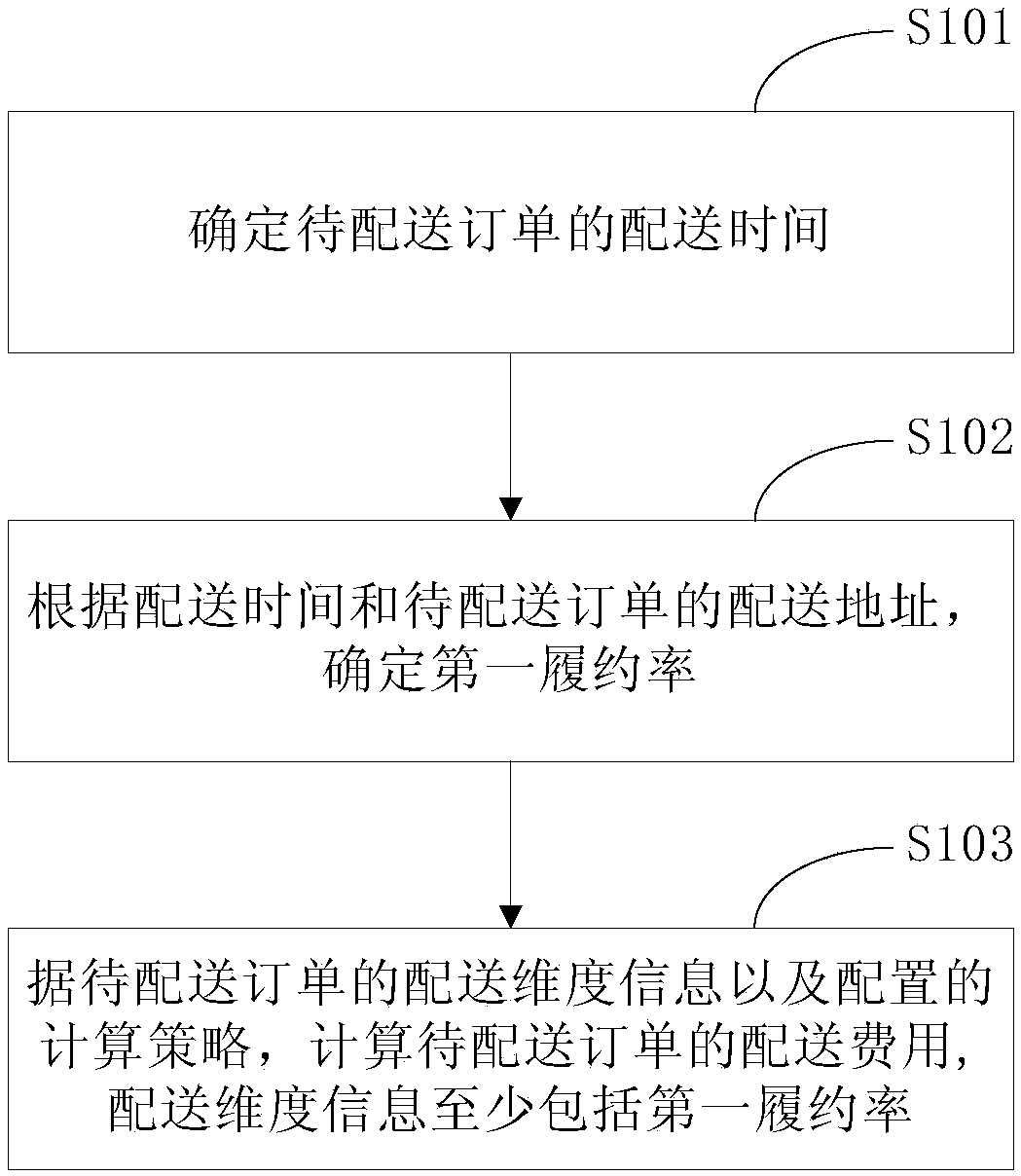

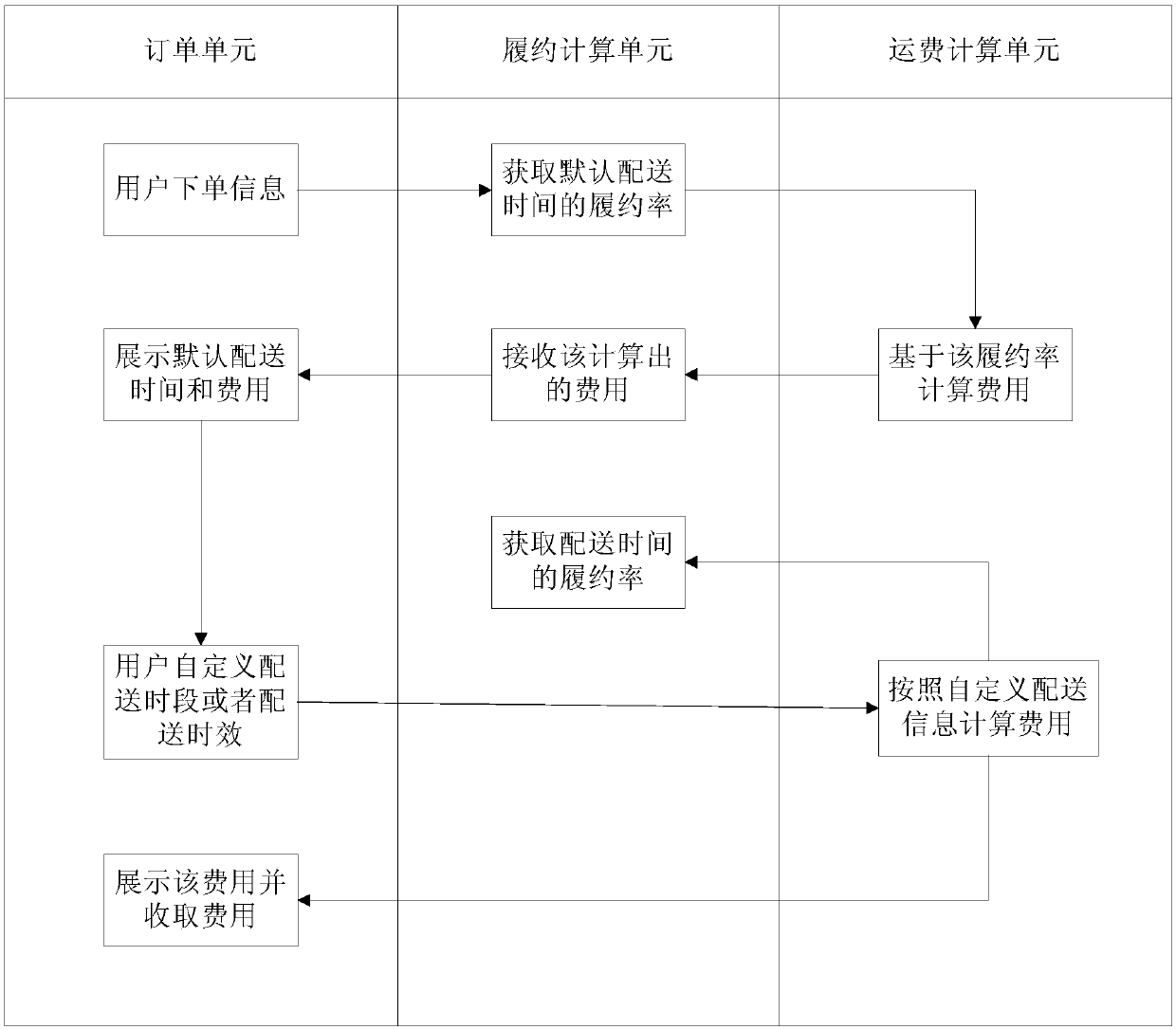

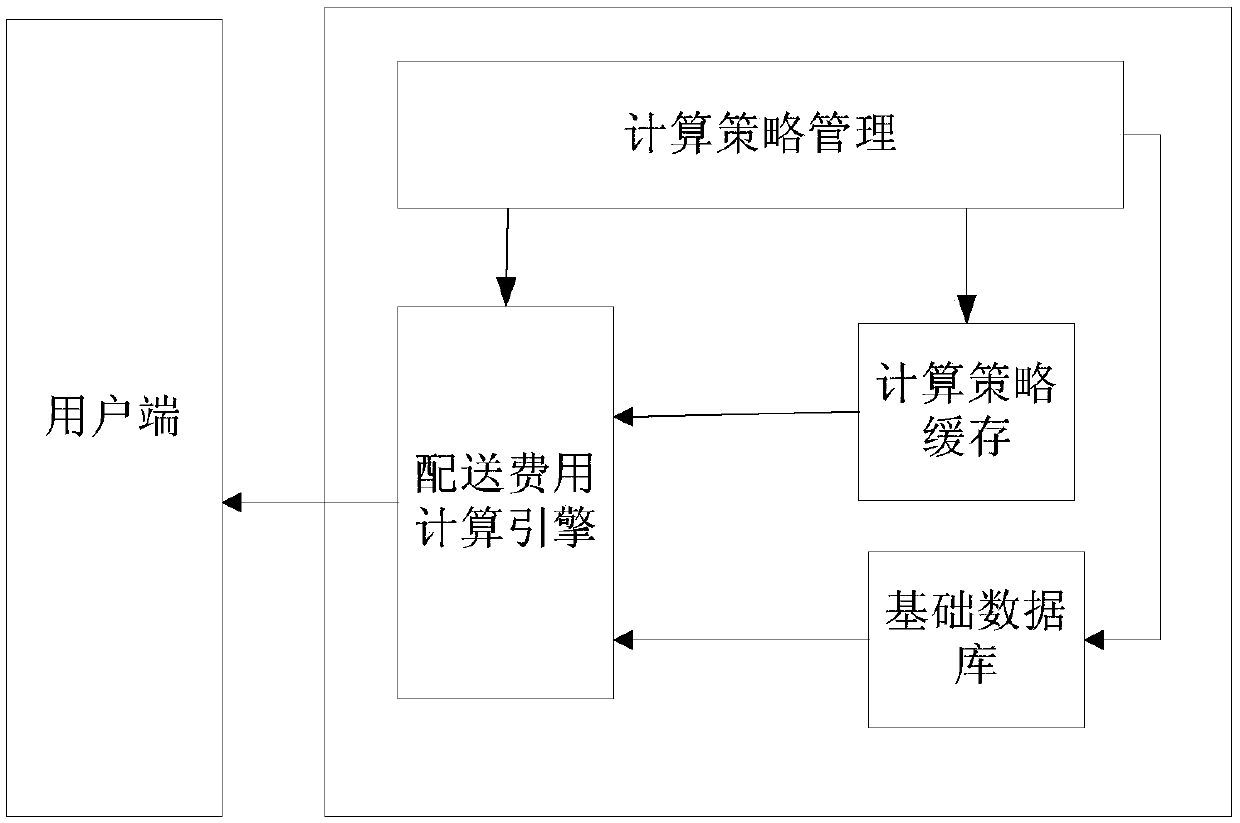

Method and device for determining logistics distribution cost

PendingCN111047243AImprove experienceBalance delivery order quantityLogisticsLogistics managementDelivery cost

The invention discloses a method and device for determining logistics distribution cost, and relates to the field of logistics distribution. A specific embodiment of the method comprises the steps ofdetermining delivery time of a to-be-delivered order; determining a first fulfillment rate according to the delivery time and the delivery address of the to-be-delivered order; calculating the delivery cost of the to-be-delivered order according to the delivery dimension information of the to-be-delivered order and a configured calculation strategy; wherein the distribution dimension information at least comprises the first performance rate. According to the method, the delivery cost of the order can be dynamically calculated according to the delivery dimension information including the fulfillment rate. The user experience is improved, the user can be further guided to select the time with the high performance rate for delivery by setting the calculation strategy, and the delivery order quantity in the logistics system is balanced.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

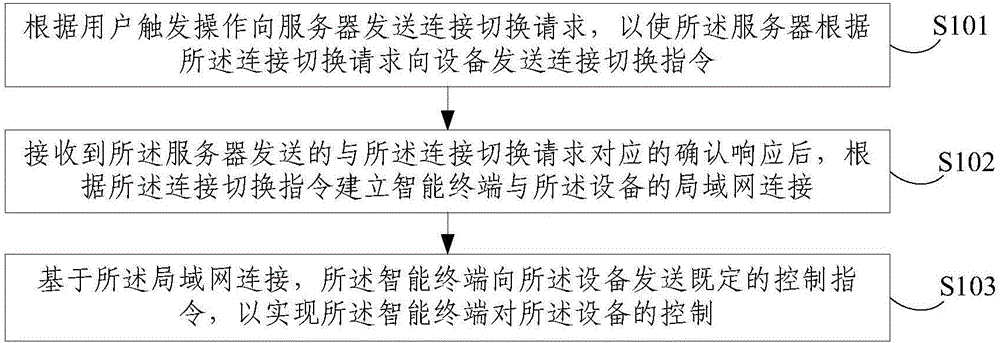

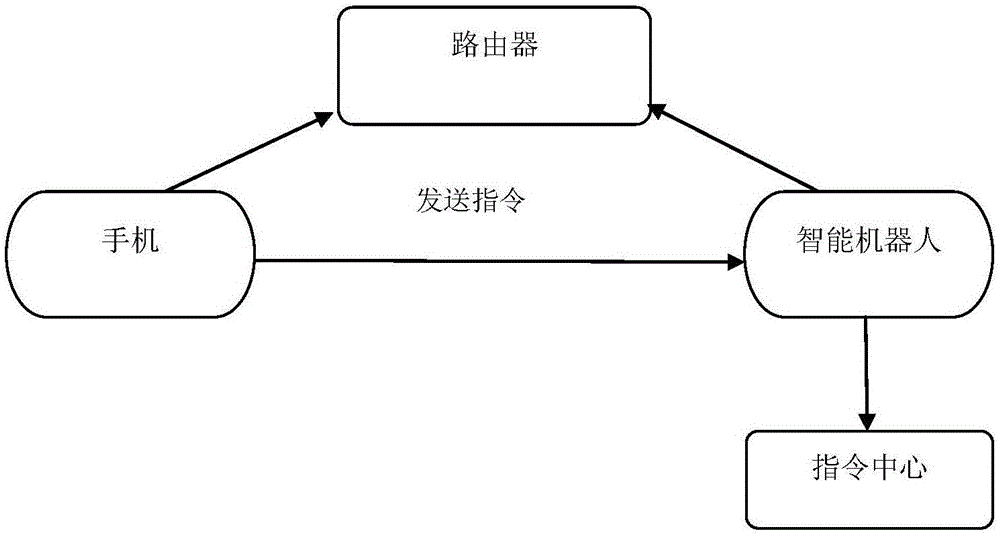

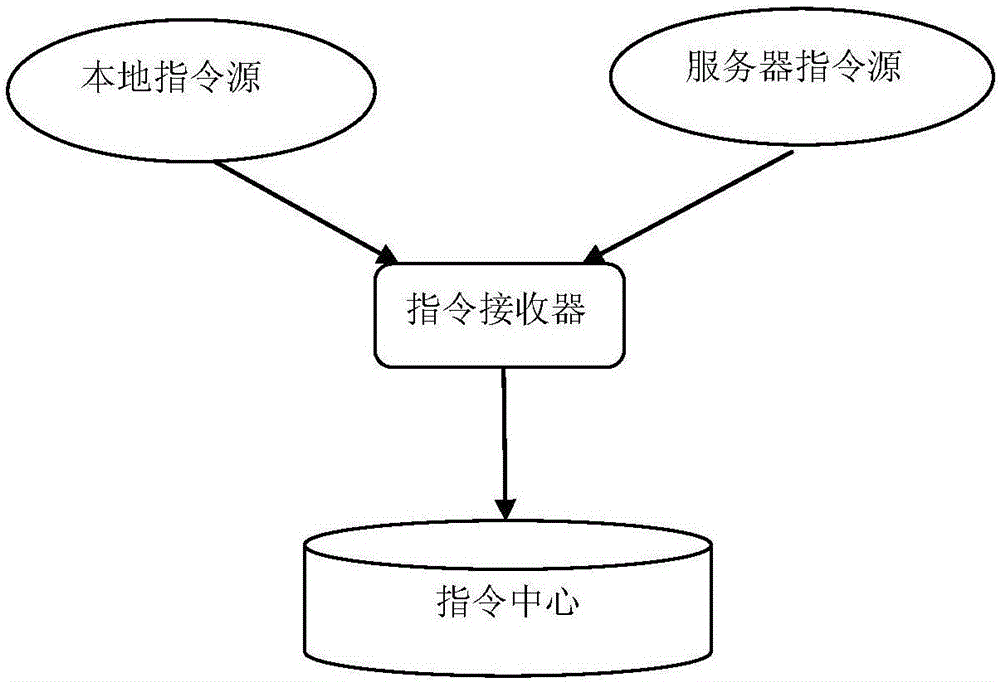

Device control method and apparatus

InactiveCN106452994AImprove effective execution rateAvoid timeout conditionsData switching by path configurationTTEthernetThe Internet

The embodiment of the invention discloses a device control method and apparatus. The method comprises the following steps: sending a connection switching request to a server according to a user trigger operation, so that the server sends a connection switching instruction to a device according to the connection switching request; after acknowledgement response corresponding to the connection switching request sent by the server is received, establishing a local area network connection between an intelligent terminal and the device according to the connection switching instruction; based on the local area network connection, sending a set control instruction to the device by the intelligent terminal, so that the intelligent terminal controls the device. After the server sends the connection switching request, the local area network connection between the intelligent terminal and the device is established, therefore the communication speed is improved, the communication between the intelligent terminal and the device is not affected by the network speed of the Internet, and the communication timeout situation is avoided; and meanwhile, the control of the intelligent terminal to the device is realized in a local area network, thereby improving the effective execution rate of the instruction and avoiding the identification error situation caused by inaccurate pickup during voice control in a noisy environment.

Owner:BEIJING INTELLIGENT STEWARD CO LTD

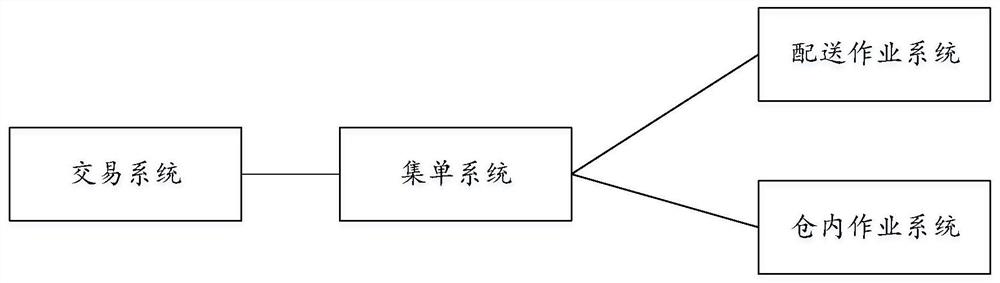

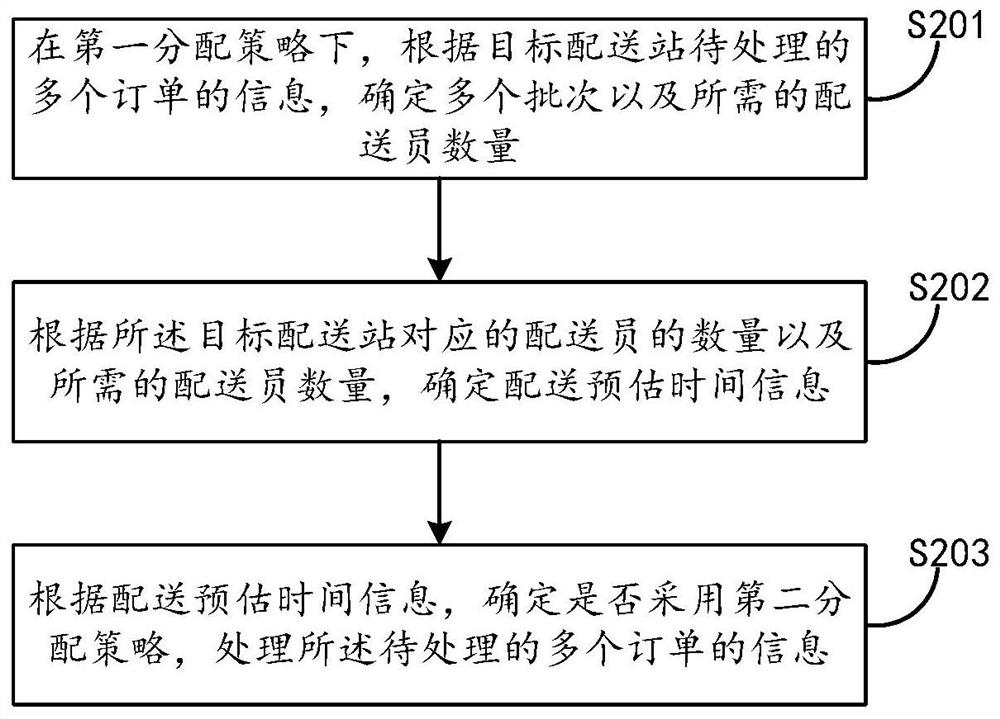

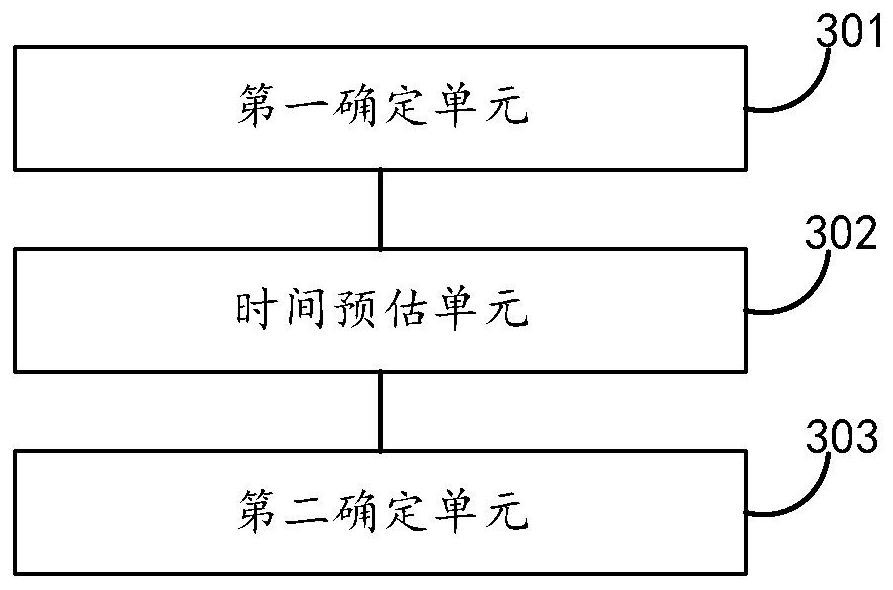

Order batch processing method and device and computer system

PendingCN111985748AImprove on-time performanceReduce backlogBuying/selling/leasing transactionsResourcesTime informationBatch processing

The embodiment of the invention discloses an order batch processing method and device and a computer system. The method comprises the steps: determining a plurality of batches and the number of neededdeliverymen according to the information of a plurality of to-be-processed orders of a target delivery station under a first distribution strategy; determining estimated delivery time information according to the number of deliverymen corresponding to the target delivery station and the required number of deliverymen; and determining whether to adopt a second allocation strategy or not accordingto the distribution estimation time information, and processing the information of the to-be-processed multiple orders. Through the embodiment of the invention, the on-time performance rate of the order can be improved.

Owner:ALIBABA GRP HLDG LTD

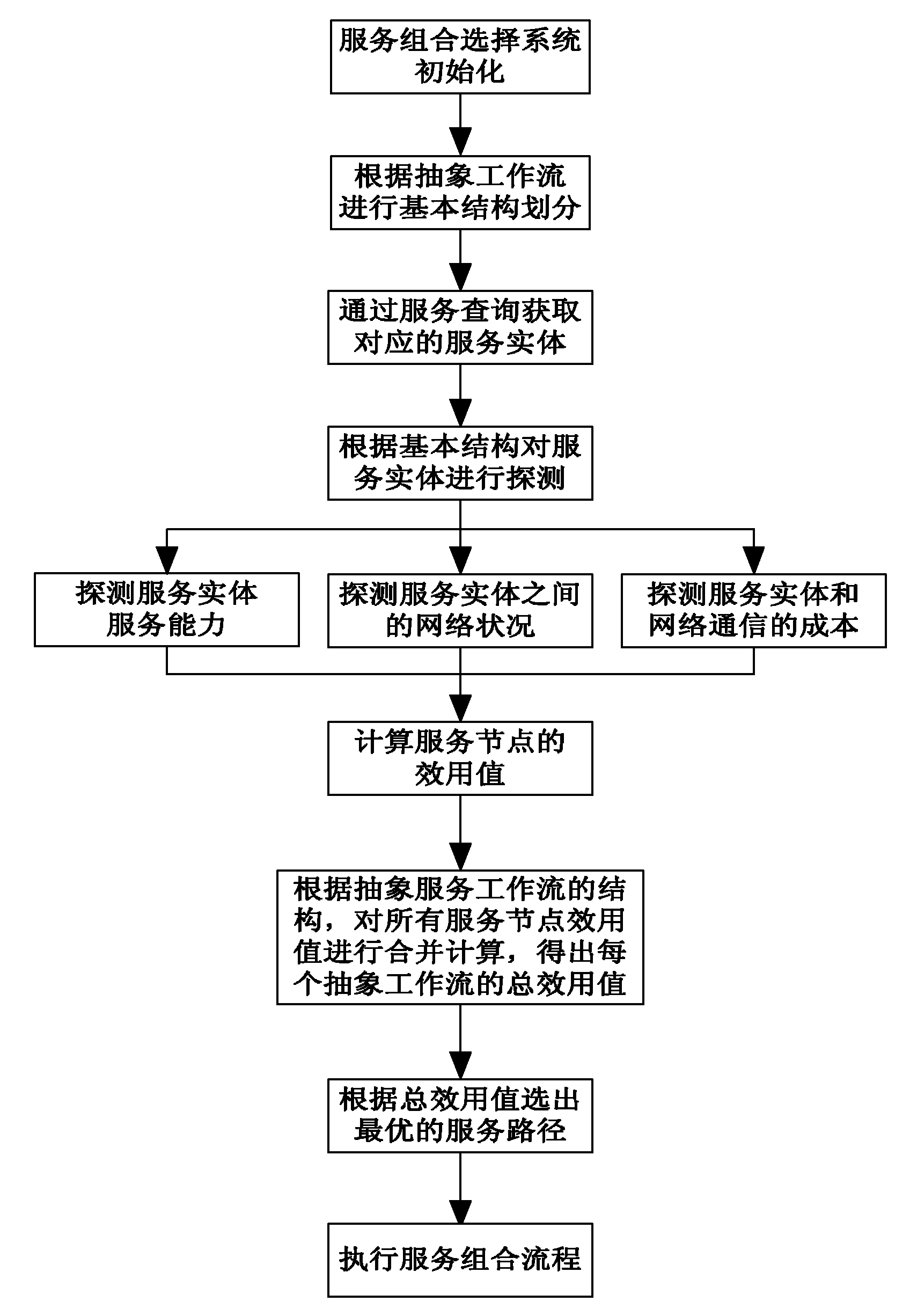

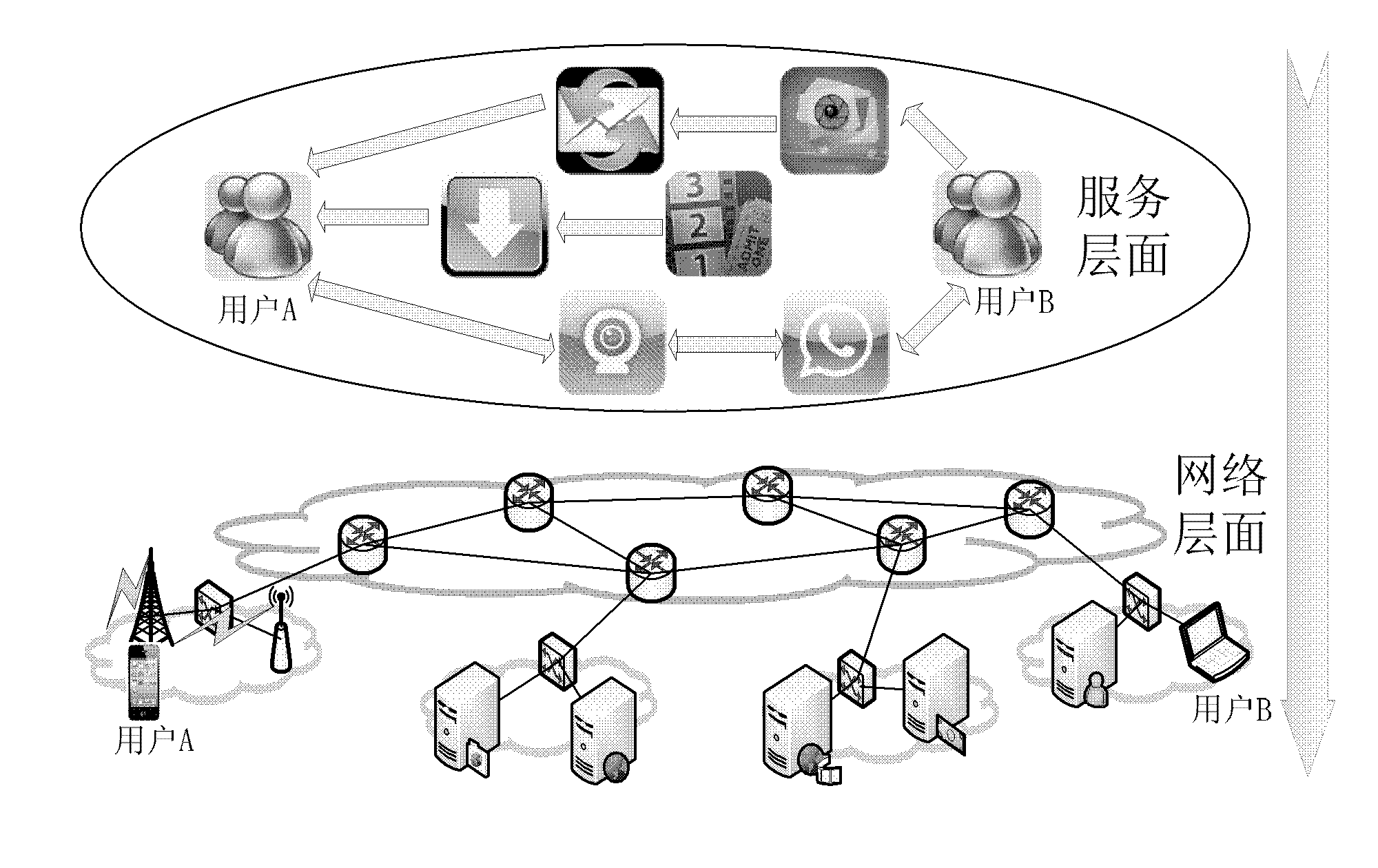

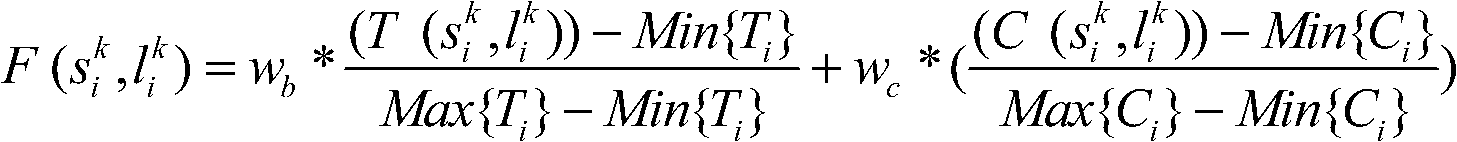

Resource-oriented service composition selection method

ActiveCN102143087AIncrease profitImprove satisfactionData switching networksService compositionComputer network

The invention provides a resource-oriented service composition selection method. A service composition system can comprehensively take the actual conditions of bottom-layer resources such as network resources, computing resources and the like into account and realize negotiation about serving nodes and a serving process in a process from abstract service composition planning to specific service composition mapping. Resource optimal matching is performed according to dynamic network resources and dynamic computing resources, and a service composition sequence developing the highest efficiency is selected so as to increase the utilization rate of the resources, the success rate of service composition execution and the satisfaction degree of a user.

Owner:BEIJING JIAOTONG UNIV

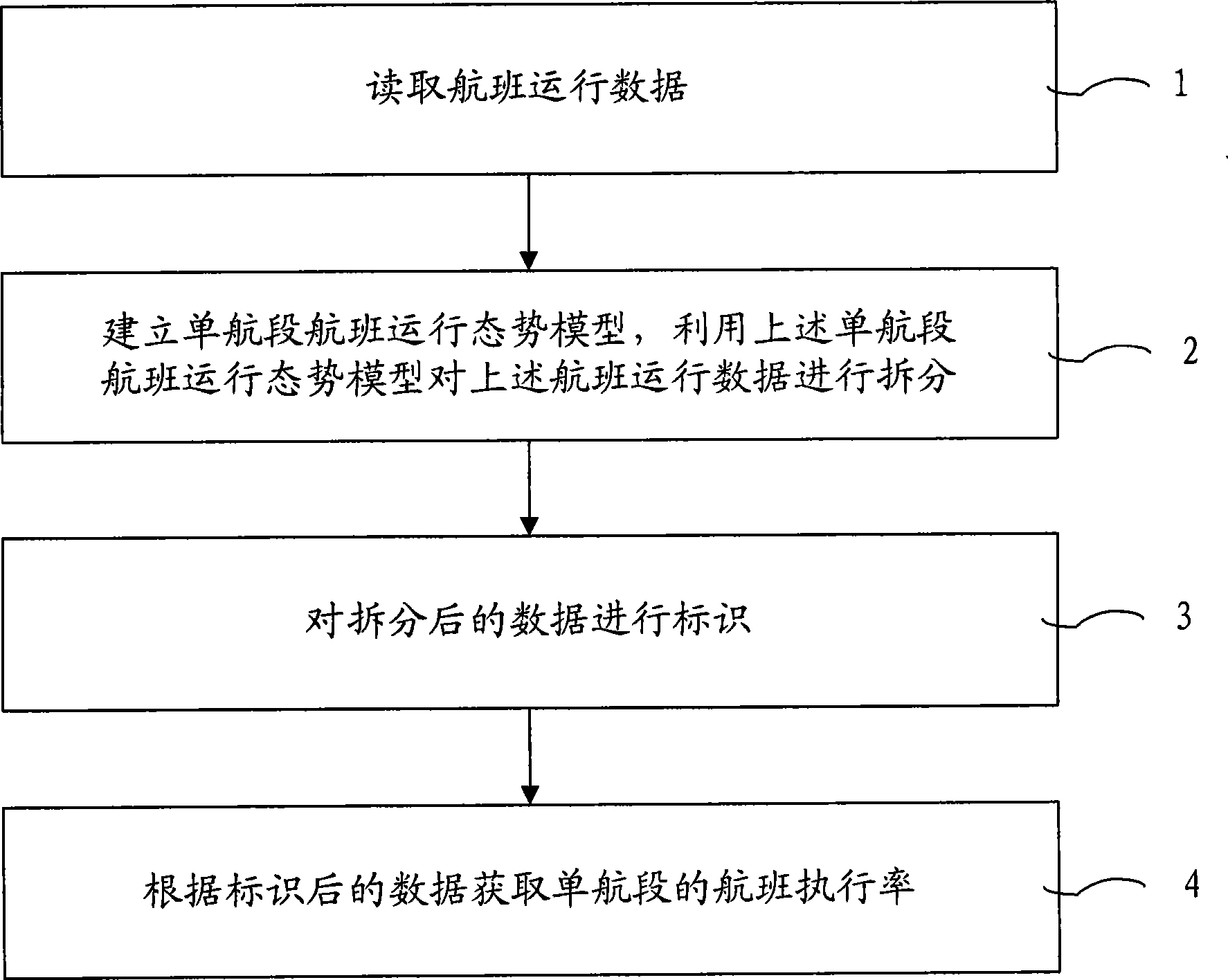

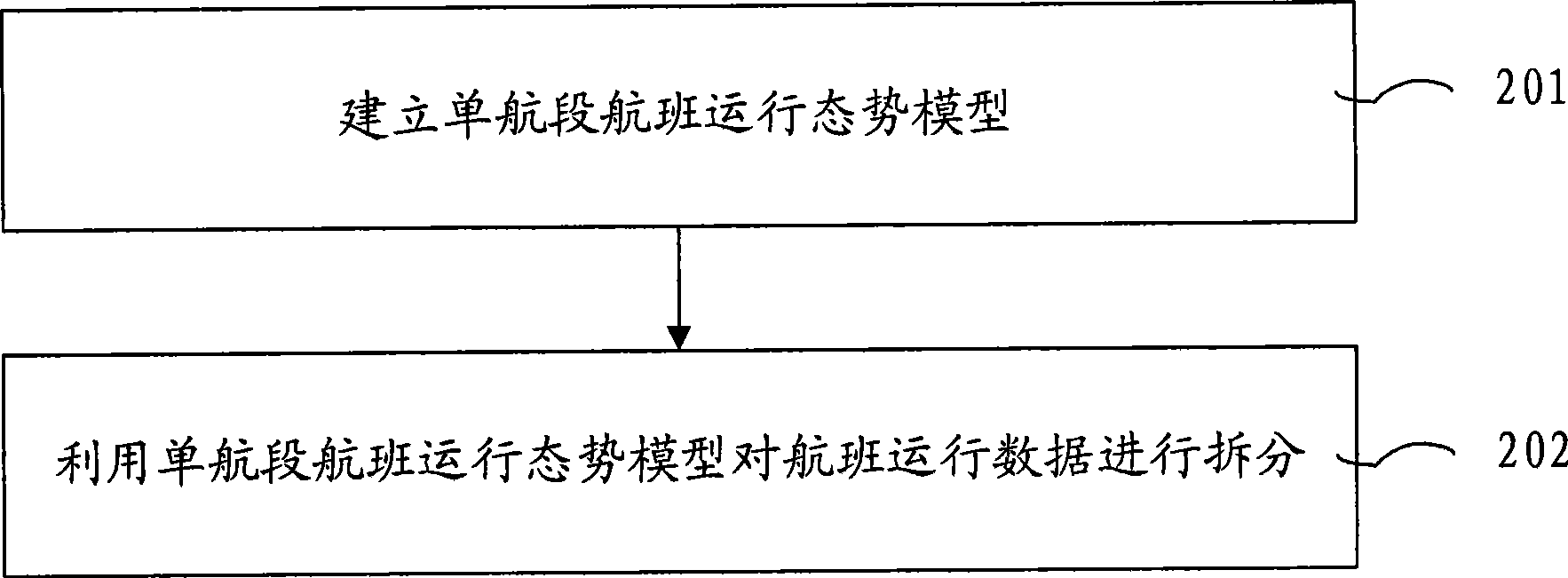

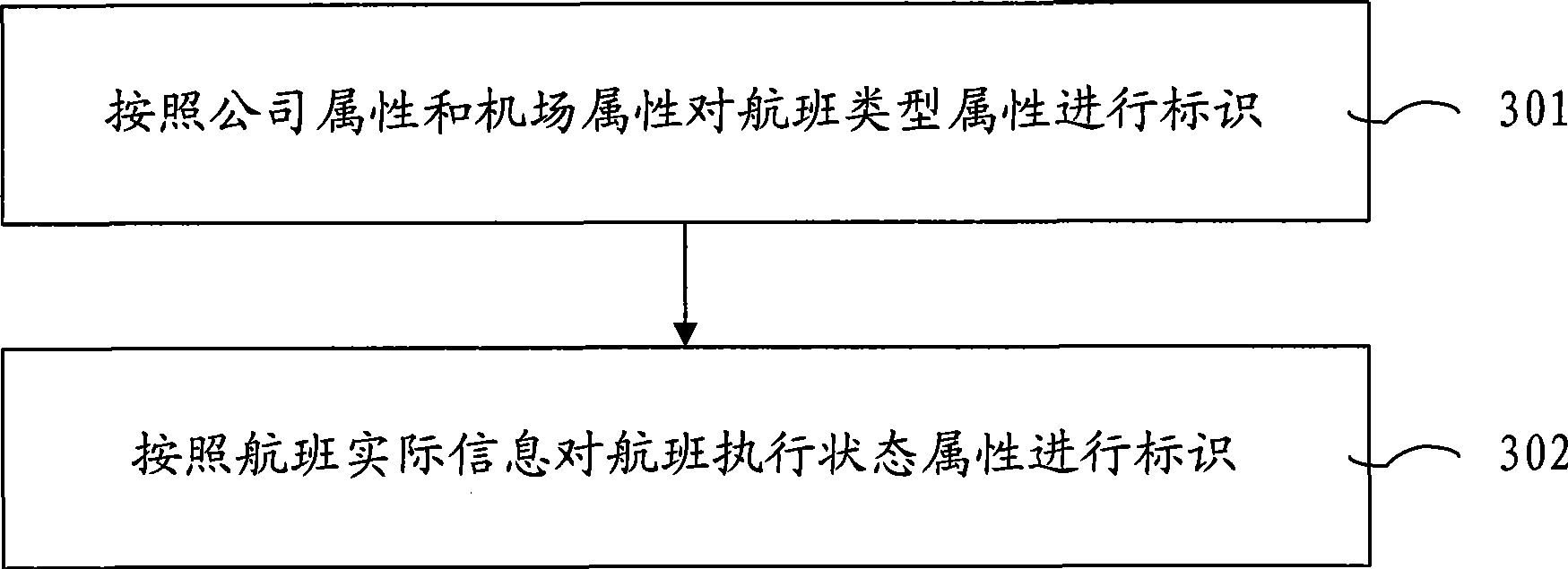

Method for obtaining flight execution rate and device thereof

The invention relates to a method for obtaining flight execution rate and a device thereof, wherein, the method for obtaining the flight execution rate comprises: reading flight service data; establishing a flight operation situation model of a single-trip flight segment, using the flight operation situation model of the single-trip flight segment to split the flight service data; marking the split data; obtaining the flight execution rate of the single-trip flight segment according to marked data The method for obtaining flight execution rate and the device thereof establish the flight operation situation model of the single-trip flight segment, split the read flight service data by employing the flight operation situation model of the single-trip flight segment, mark the split data and accurately obtain the flight execution rate of the single-trip flight segment according to marked data, thus improving accuracy of the statistic of the flight execution rate.

Owner:AVIATION DATA COMM +1

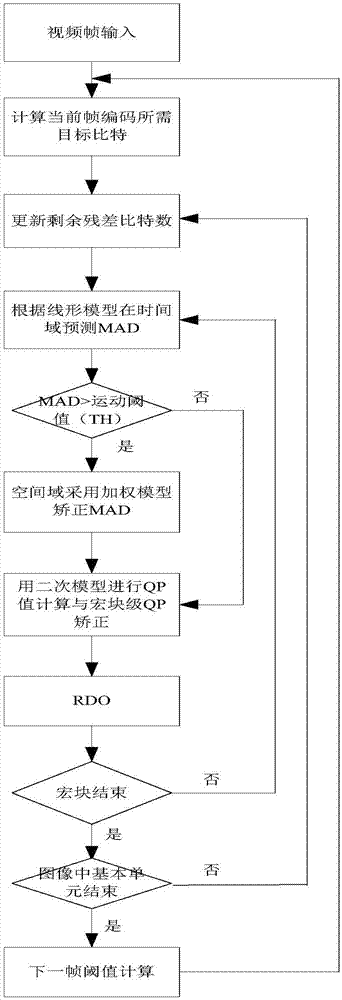

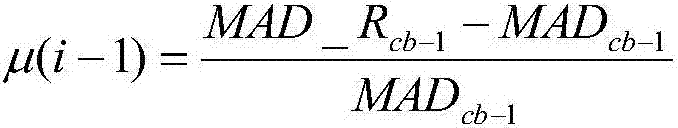

Code rate control method in video coding

ActiveCN108012149AEasy to predictAccurate predictionDigital video signal modificationTime domainComputer architecture

The invention discloses a code rate control method in video coding. The method comprises the following steps: dividing an input video signal into serial video frame images; updating the number of remaining encoding bits of the current encoding frame; calculating an MAD value of a current basic unit according to a time domain linear prediction model; if MADcb is greater than TH, performing airspacecorrection; if MADcb is less than TH, not performing the airspace correction; calculating the number of coding bits used by a current macro block; calculating and correcting a quantization parameterQP value of the current macro block; executing rate distortion optimization to obtain an actual MAD value of the current macro block; performing circular execution until the macro blocks in the current basic unit are completely processed; and calculating the next basic unit, and performing circular execution until the basic units in the video frames are completely processed. The movement conditions of the current processing unit on time and space can be well predicted to accurately predict and process the video coding quantization parameter.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

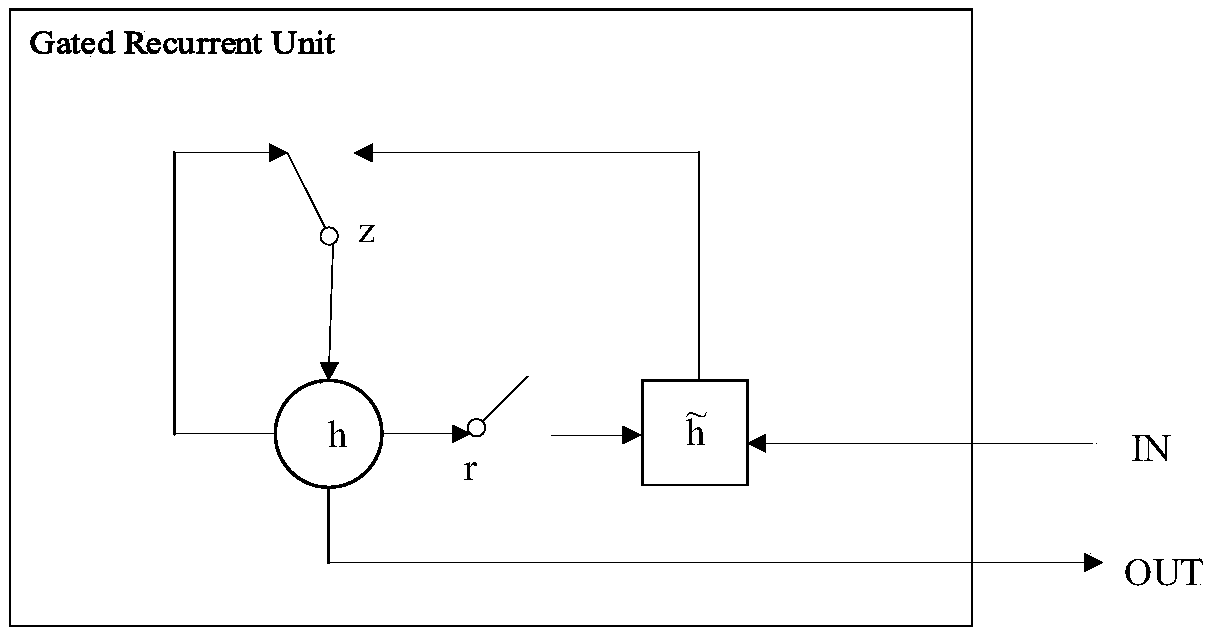

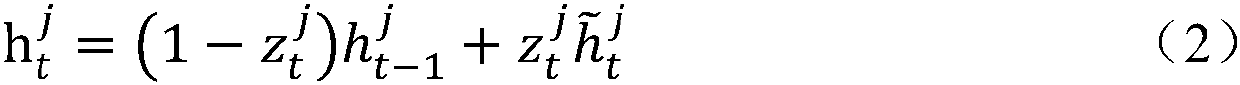

Periodic prediction neural network based industrial data fault prediction method

InactiveCN109656236AImprove forecast qualityIncrease training speedProgramme controlElectric testing/monitoringNerve networkPredictive methods

The invention provides a periodic prediction neural network based industrial data fault prediction method. The method includes steps: (1) designing mode exploration branch rings, and establishing an equipment operating state mode for storage and representation of various operating states and time-series relationships of equipment; (2) designing a periodic prediction neural network for predicting anext state and fault probability according to time series of a current period in a cloud environment; (3) in the cloud environment, performing dynamic node selection and data duality in an operatingprocess to iteratively explore new faults which are not occurred, and establishing a data experiment mechanism to realize fault prediction in a real-time cloud environment. The periodic neural networkprediction based industrial data fault prediction method has the advantage that by combination of industrial data fault prediction and the neural network and design of a periodic prediction neural network model, algorithm prediction precision is improved while the algorithm execution rate is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

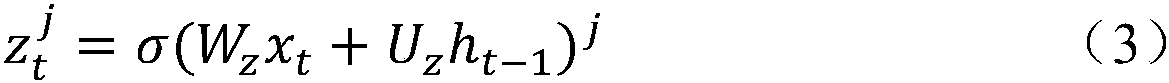

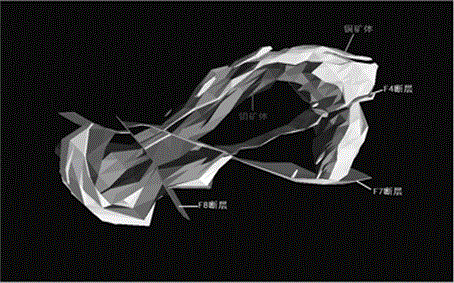

Mining geological logging data three dimensional processing method

InactiveCN106530396AImprove accuracyImprove design execution rate3D modellingEntity modelComputer science

The invention discloses a mining geological logging data three dimensional processing method. The mining geological logging data three dimensional processing method includes the following steps: 1) geological logging; 2) establishing a three dimensional entity model; and 3) estimating the grade of ore blocks. The mining geological logging data three dimensional processing method relates to the geological logging technical flow, the three dimensional entity modeling technical flow and the ore block grade estimation technical flow, thus having comprehensiveness and scientificity. The mining geological logging data three dimensional processing method can accurately acquire the truth of the ore body, the constructed space occurrence state, the grade distribution, and the ore rock boundary, and improves the accuracy of the ore body estimation result, achieves the aim of improving the execution rate of mining and planning and the execution rate of individual design and reducing the loss dilution rate, and has remarkable effect on reducing the loss dilution rate, wherein the loss dilution rate is respectively reduced by 0.47% and 1.11%; and at the same time the execution rate of mining and planning, and the execution rate of individual design are improved to 98% from 85%.

Owner:CHINA GOLD INNER MONGOLIA MINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com