Lignin sizing agent and method for preparing same

A technology of lignin and sizing agent, which is applied in the direction of water-repellent addition, etc., can solve the problems of high cost, large amount of sizing agent, and difficult to improve the grade, so as to be suitable for large-scale industrial production and improve the surface environment. Compressive strength, effect of improving Cobb value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

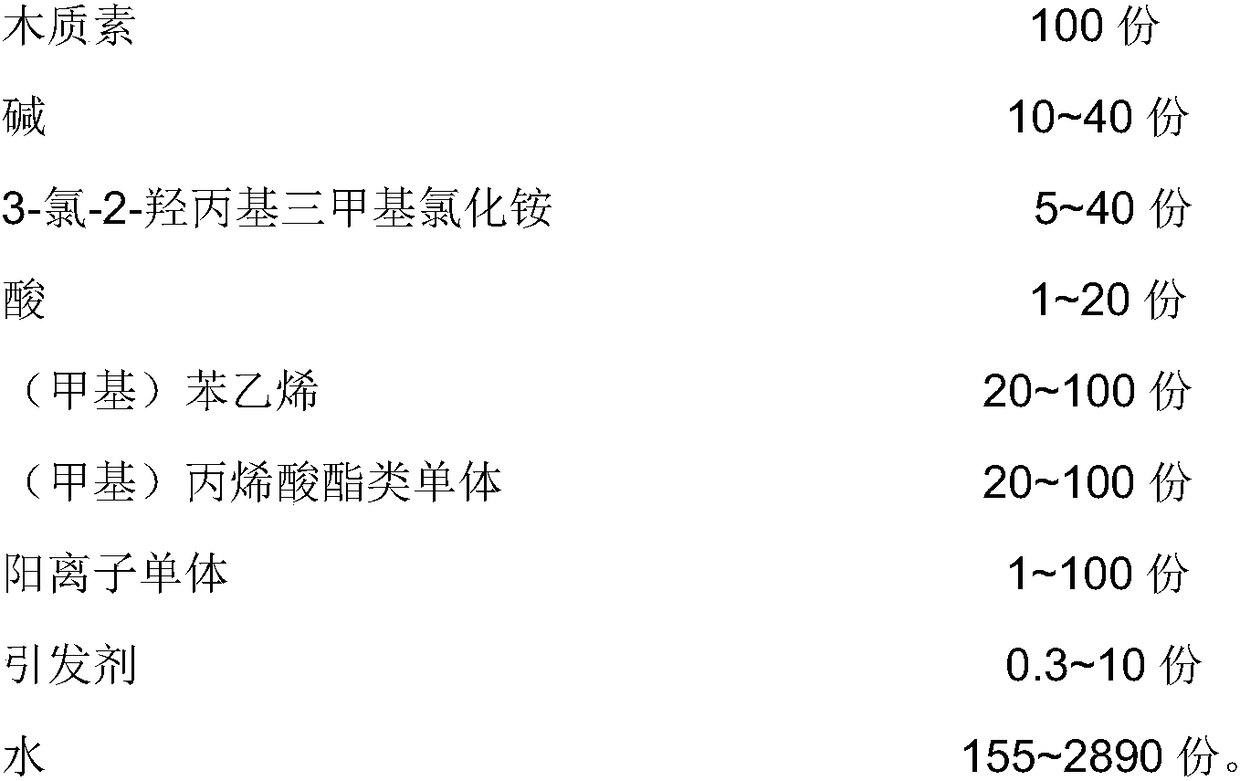

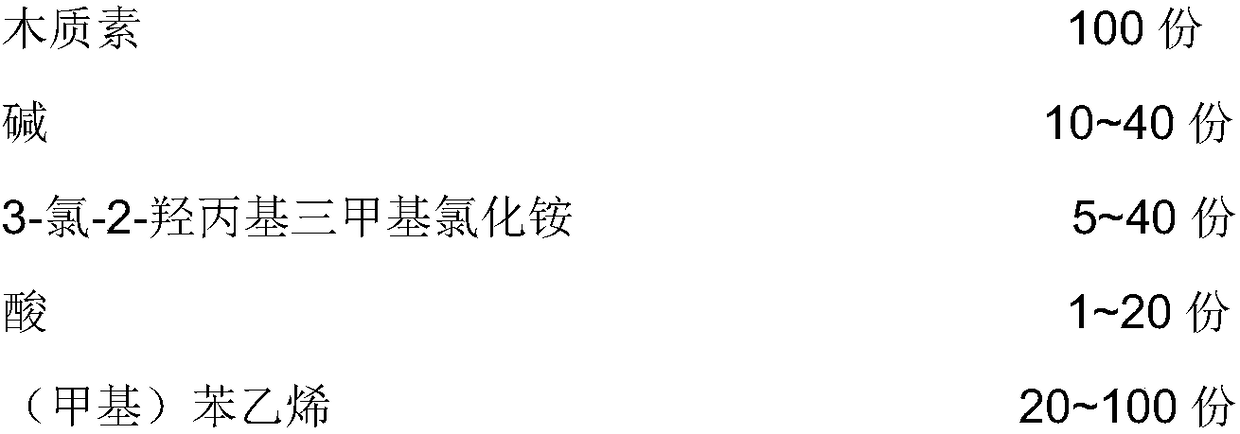

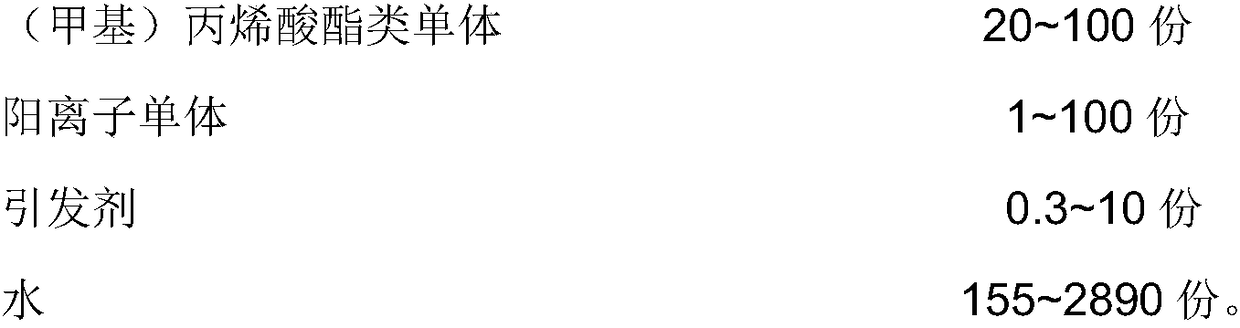

Method used

Image

Examples

Embodiment 1

[0033] Prepare lignin sizing agent according to the following steps ①:

[0034] Step A): Mix 20 grams of styrene, 20 grams of n-butyl acrylate, and 1 gram of N,N-dimethylaminoethyl acrylate, and set aside;

[0035] Step B): dissolving 0.3 gram of ammonium persulfate in 10 gram of deionized water, set aside;

[0036] Step C): Add 147.3 grams of deionized water, 10 grams of potassium hydroxide, and 100 grams of lignin into a four-necked flask with a condenser, a dropping device, a stirrer, and a thermometer, and heat up to 45° C. after completely dissolving. Add 5 grams of 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise, dropwise for 0.25 hours, continue to keep warm for 0.75 hours; heat up to 70°C, add 1g of hydrochloric acid; dropwise add step A) preparation at 70°C The obtained mixed monomer was added dropwise for 1 hour; at the same time, the aqueous initiator solution prepared in step B) was added dropwise for 1 hour; after the dropwise addition, the reaction w...

Embodiment 2

[0038] The lignin sizing agent was prepared according to the following steps ②:

[0039] Step A): Mix 100 grams of methyl styrene, 100 grams of isooctyl acrylate, and 100 grams of methacrylamidopropyl dimethylamine, and set aside;

[0040] Step B): Dissolving 10 grams of sodium persulfate in 100 grams of deionized water, set aside;

[0041] Step C): Add 2790 grams of deionized water, 40 grams of ammonium hydroxide, and 100 grams of lignin into a four-necked flask with a condenser, a dropping device, a stirrer, and a thermometer, and heat up to 55°C after completely dissolving. Add 40 grams of 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise, dropwise for 1 hour, continue to keep warm for 2 hours; heat up to 95°C, add 20g of dilute sulfuric acid; drop step A) at 95°C The prepared mixed monomer was added dropwise for 3 hours; at the same time, the aqueous initiator solution prepared in step B) was added dropwise for 3 hours; after the dropwise addition, the reaction ...

Embodiment 3

[0043] The lignin sizing agent was prepared according to the following steps ③:

[0044] Step A): Mix 60 grams of methyl styrene, 50 grams of ethyl methacrylate, and 50 grams of methacrylamidopropyl dimethylamine, and set aside;

[0045] Step B): dissolving 6 grams of hydrogen peroxide in 100 grams of deionized water, set aside;

[0046]Step C): Add 637.3 grams of deionized water, 20 grams of sodium hydroxide, and 100 grams of lignin into a four-necked flask with a condenser, a dropping device, a stirrer, and a thermometer, and heat up to 65° C. after completely dissolving. Add 20 grams of 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise, dropwise for 2 hours, and continue to keep warm for 1 hour; heat up to 85°C, add 10g of acetic acid; dropwise add step A) preparation at 85°C The obtained mixed monomer was added dropwise for 1.5 hours; at the same time, the aqueous initiator solution prepared in step B) was added dropwise for 1.5 hours; after the dropwise additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com