Modified guar surface sizing agent and its preparing method and application

A surface sizing agent, guar gum technology, applied in the direction of adding water repellent, can solve the problems of reduced use effect, high water-insoluble content, slow dissolution rate, etc., to achieve improved ring pressure index, good compatibility, high substitution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

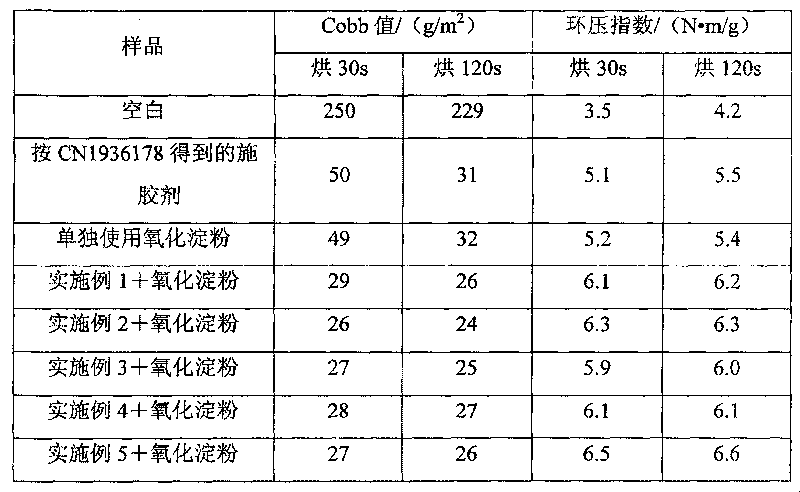

Examples

Embodiment 1

[0024] Add 50 grams of methanol to the reaction kettle at normal temperature, after dispersing 50 grams of guar collagen powder evenly, add 6 grams of sodium hydroxide solution with a weight concentration of 50%, raise the temperature to 20 ° C, then slowly add 3 grams of epichlorohydrin, continue Heat preservation reaction for 5 hours, then slowly add 2 grams of etherification additive ethylene oxide, heat up to 70 ° C, heat preservation reaction for 1 hour, cool down and discharge, use 12 grams of hydrochloric acid to neutralize the pH to 7, suction filter, dry and pulverize, Sealed packaging ready to use.

Embodiment 2

[0026] Add 150 grams of petroleum ether in the reaction kettle at normal temperature, after dispersing 70 grams of guar collagen powder evenly, add 15 grams of triethanolamine solution with a weight concentration of 50%, raise the temperature to 50 ° C, then slowly add 5 grams of phosphorous trichloride, keep warm React for 2 hours, then slowly add 5 grams of etherification additive propylene oxide, then raise the temperature to 35 ° C, keep the temperature for 3 hours, cool down and discharge, use 16 grams of acetic acid to neutralize the pH to 8, filter with suction, dry and pulverize, seal Packaged and ready to use.

Embodiment 3

[0028] Add 200 grams of acetone in the reaction kettle at normal temperature, after dispersing 80 grams of guar collagen powder evenly, add 20 grams of 50% diethylenetriamine solution by weight concentration, heat up to 80 ° C, then slowly add 8 grams of sodium tripolyphosphate, Insulate and react for 7 hours, then slowly add 8 grams of etherification additive butylene oxide, then raise the temperature to 45°C, heat for 5 hours, cool down and discharge, neutralize the pH with 10 grams of sulfuric acid to 7, filter with suction, dry and pulverize , sealed and packaged for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com