Patents

Literature

37results about How to "Reduce the Cobb value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

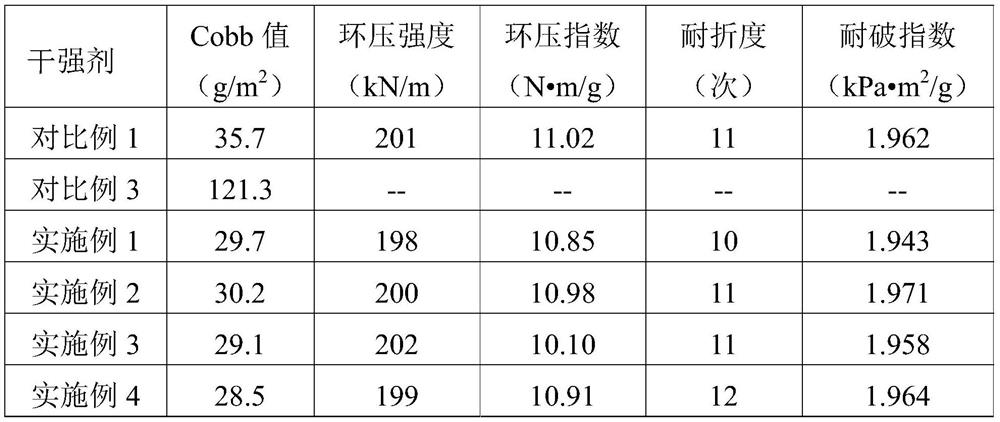

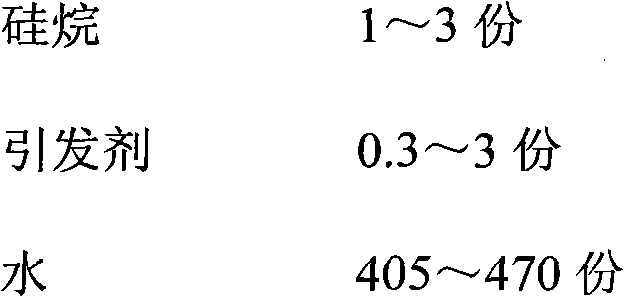

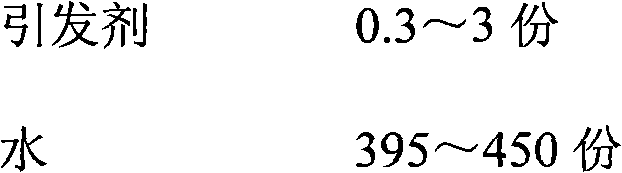

Preparing method of surface sizing agent for corrugated paper, product and application of surface sizing agent

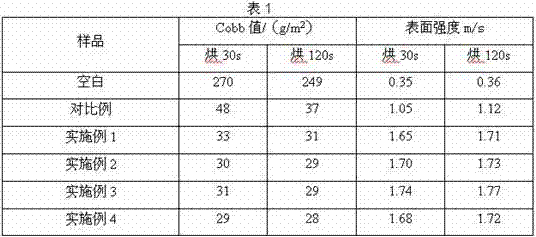

ActiveCN106368059AReduce the Cobb valueIncreased ring compressive strengthWater-repelling agents additionCoated paper substrateAcetic acidPulp and paper industry

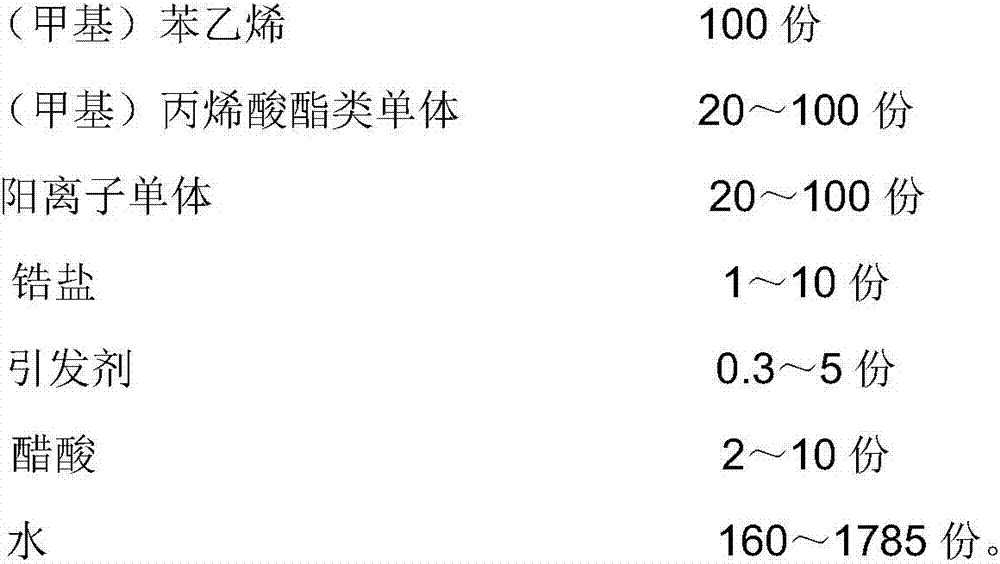

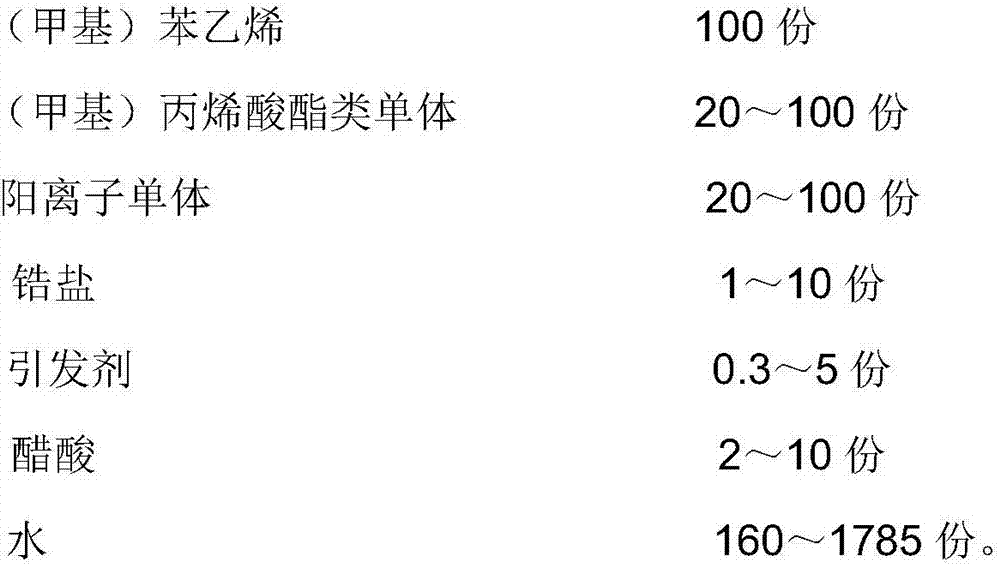

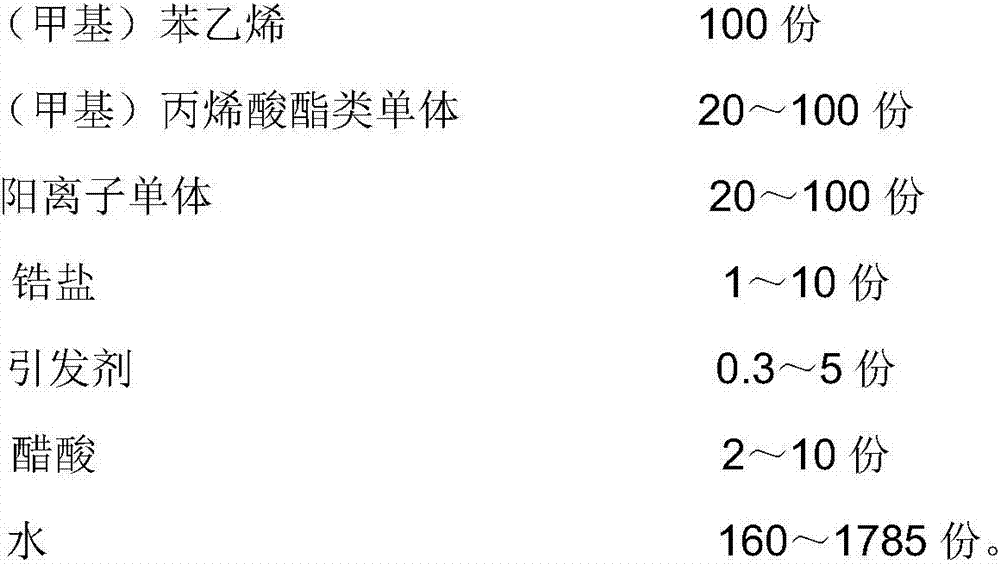

The invention provides a preparing method of a surface sizing agent for a corrugated paper, a product and an application of the surface sizing agent. The surface sizing agent for the corrugated paper is prepared by uniformly mixing a base stock of the surface sizing agent for the corrugated paper with a cationic additive. The preparing method for the base stock of the surface sizing agent for the corrugated paper comprises the steps of adding cationic monomer, siloxane, (metyl)acrylic monomer, (metyl)styrene, an initiator, acetic acid, and water into a reaction vessel, carrying out free radical polymerization reaction to obtain the base stock of the surface sizing agent for the corrugated paper. The preparing method for the cationic additive comprises the steps of adding alkylketene dimmer into an aqueous solution of cationic emulsifier, fully stirring the solution and carrying out emulsification and dispersion to obtain the cationic additive. The surface sizing agent for the corrugated paper obtained through the method can not only cure quickly, sharply improve ring crush compression resistance of the corrugated paper and sharply reduce a COBB value, but also has a very strong anti-dampness performance.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

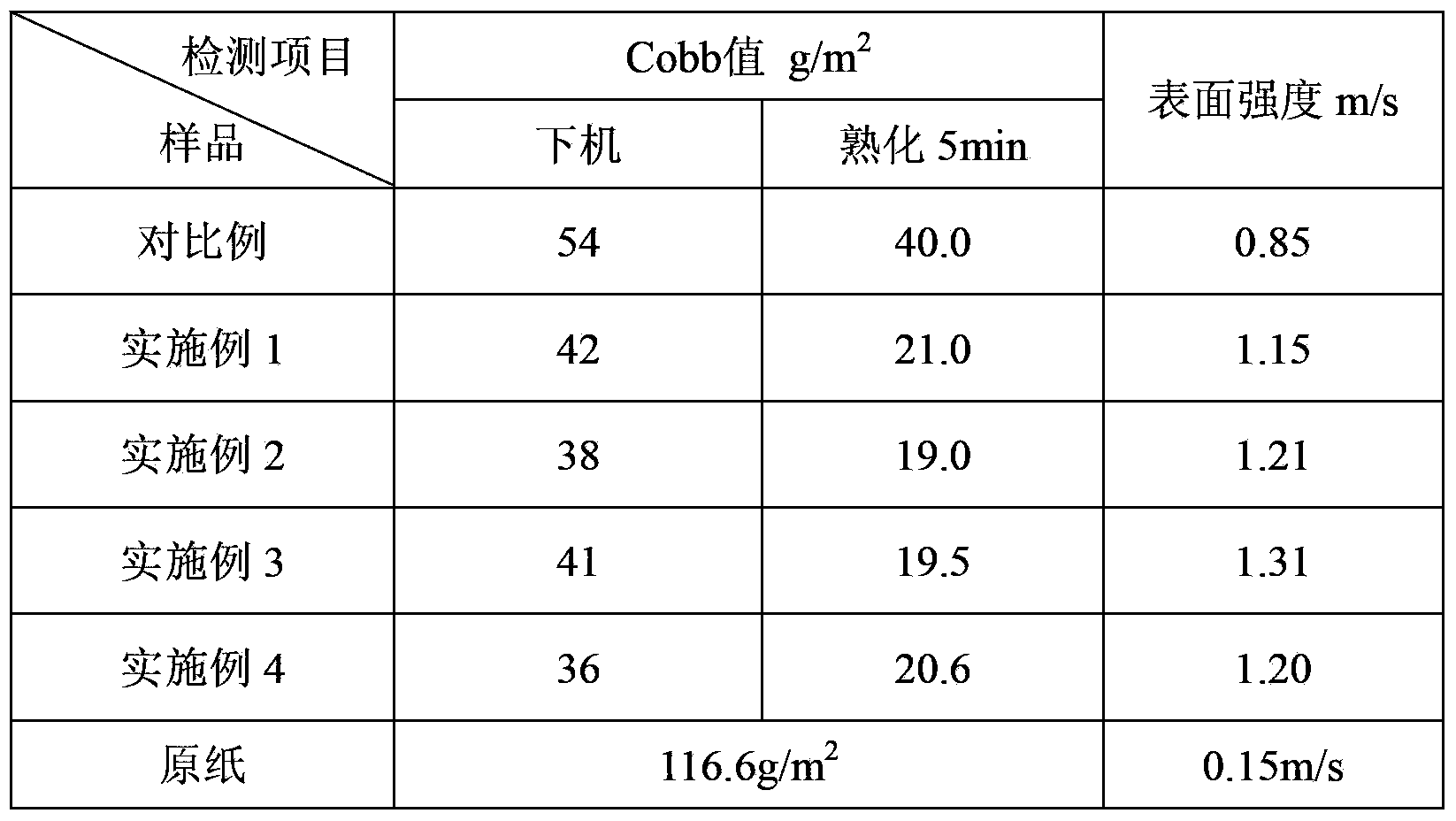

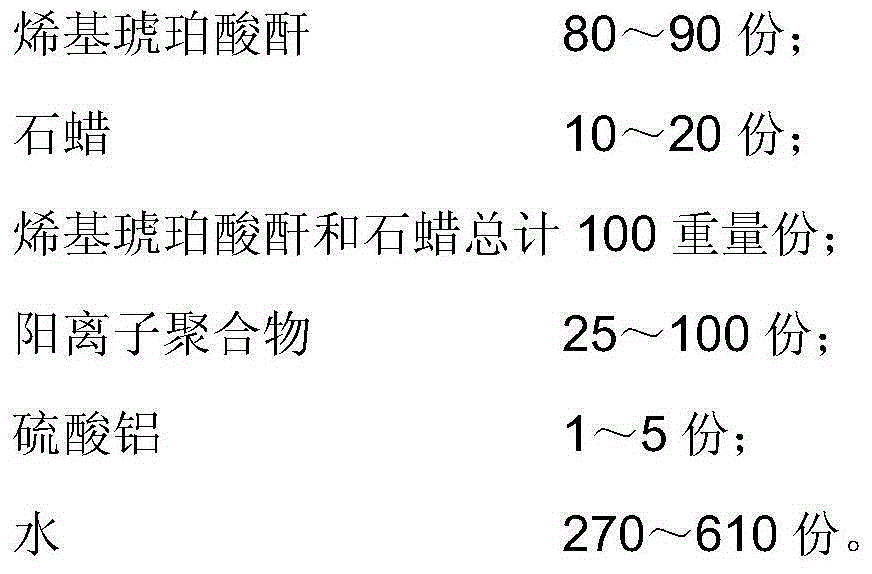

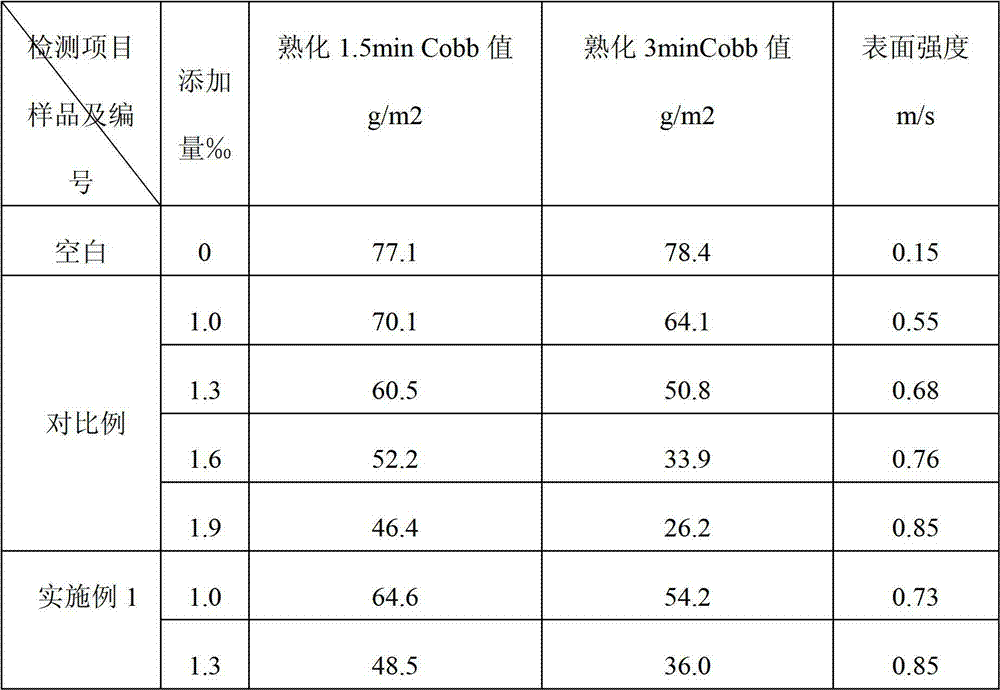

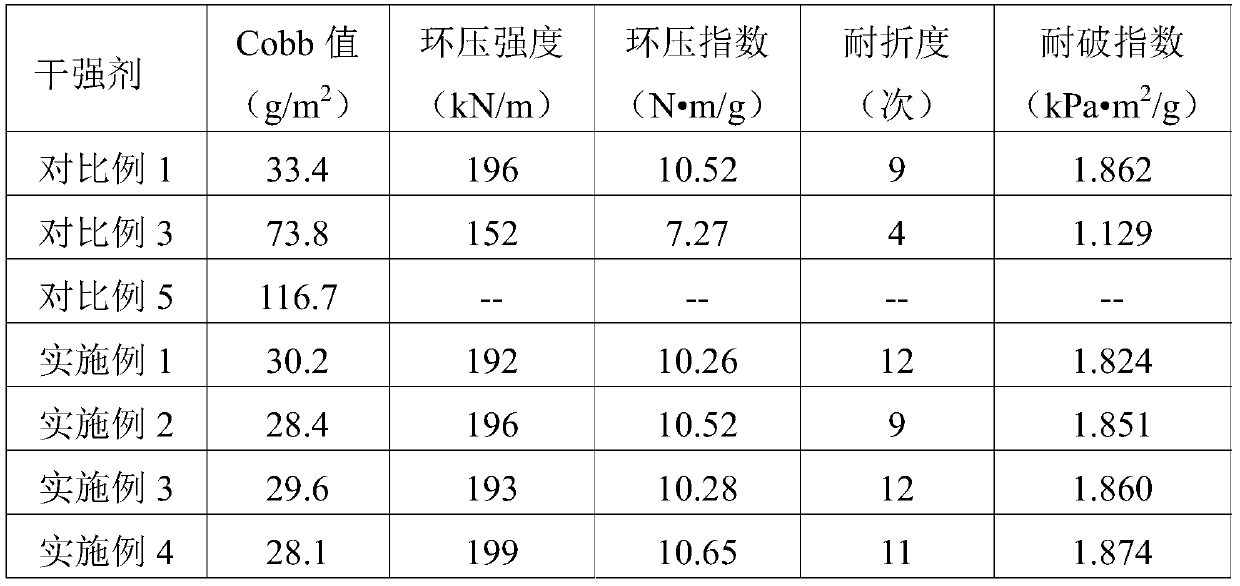

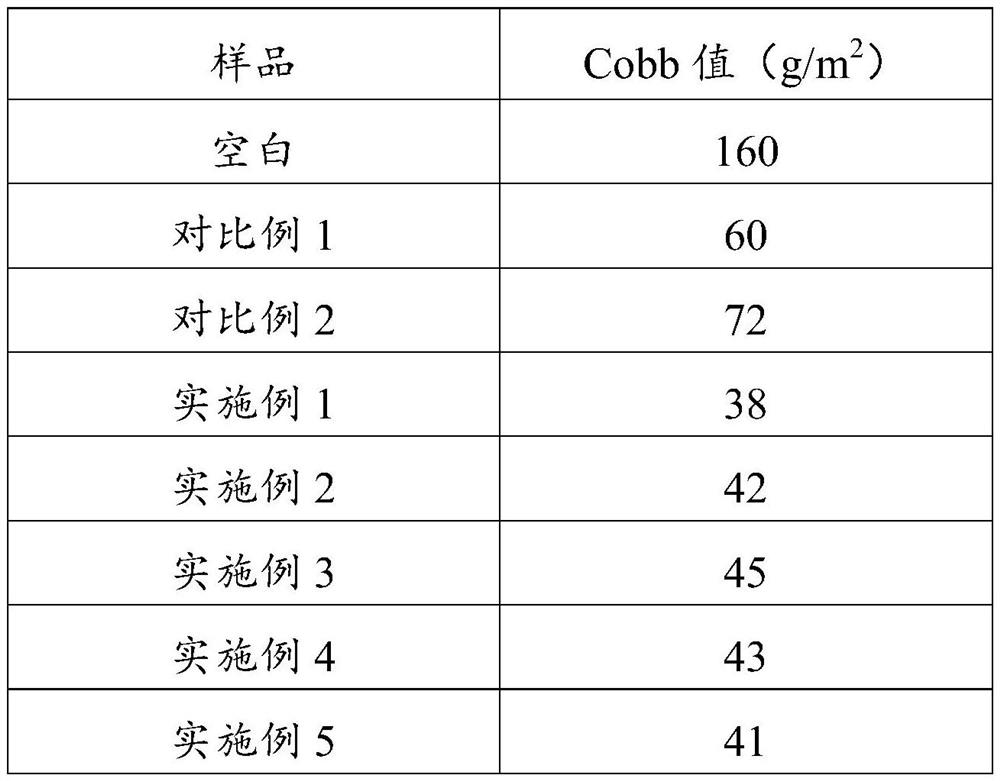

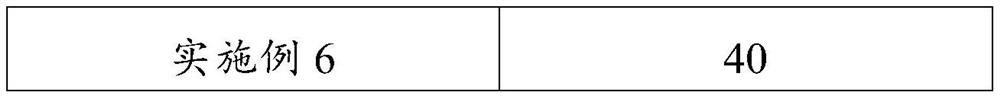

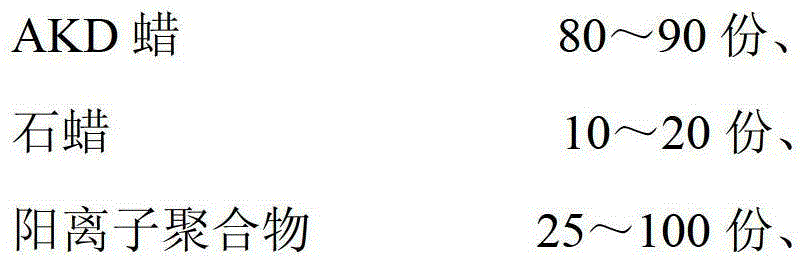

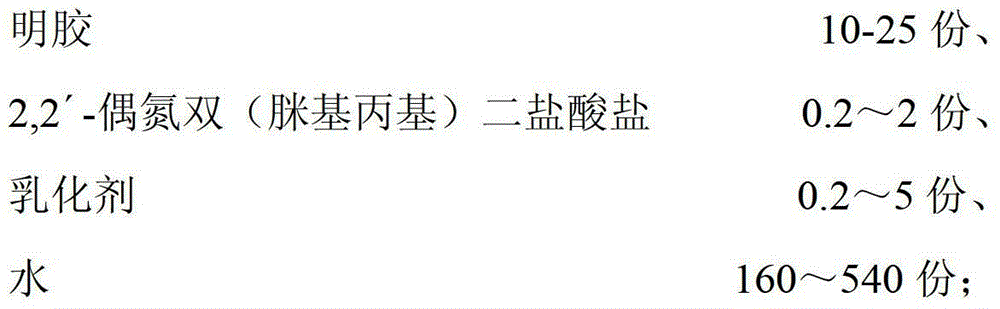

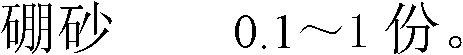

Surface sizing agent emulsion as well as preparation method and application thereof

ActiveCN103410050AImprove hydrophobicityImprove surface strengthWater-repelling agents additionNon-macromolecular organic additionParaffin waxSurface strength

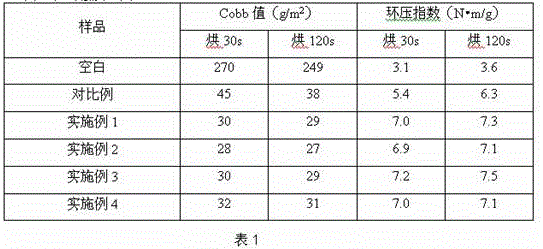

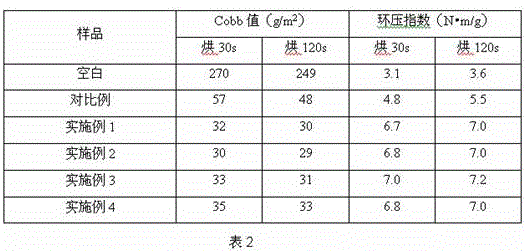

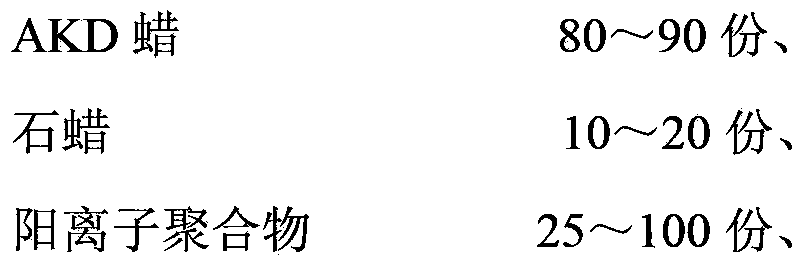

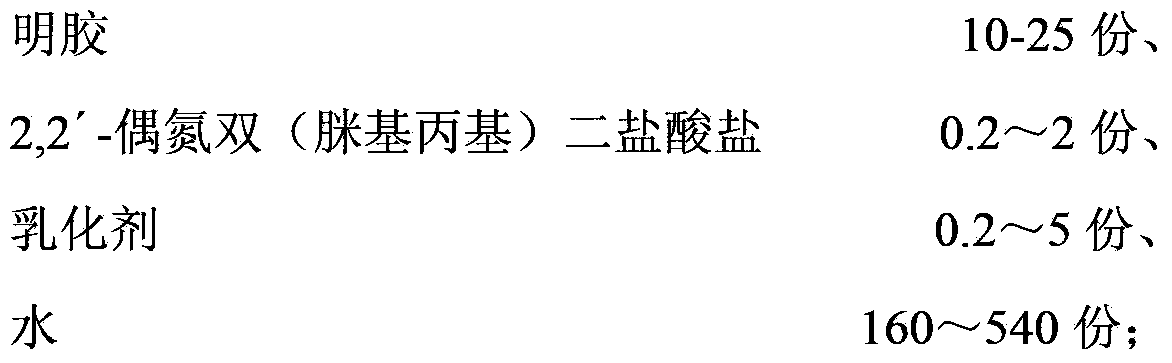

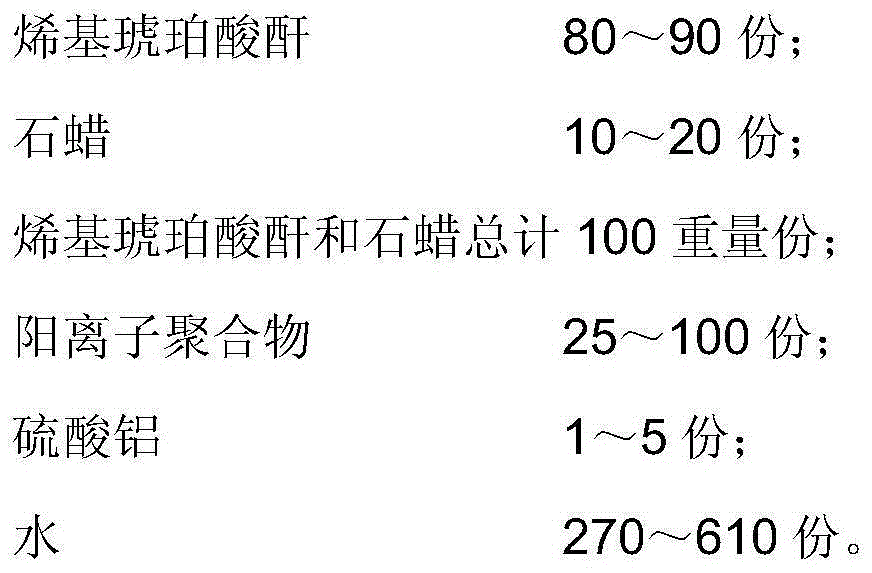

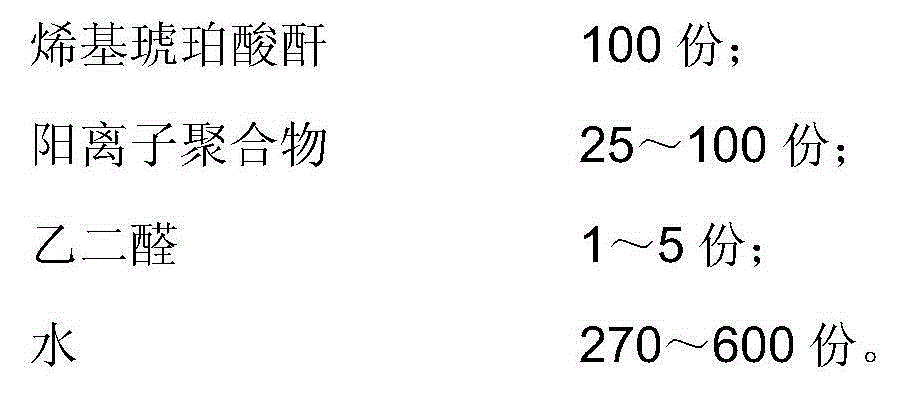

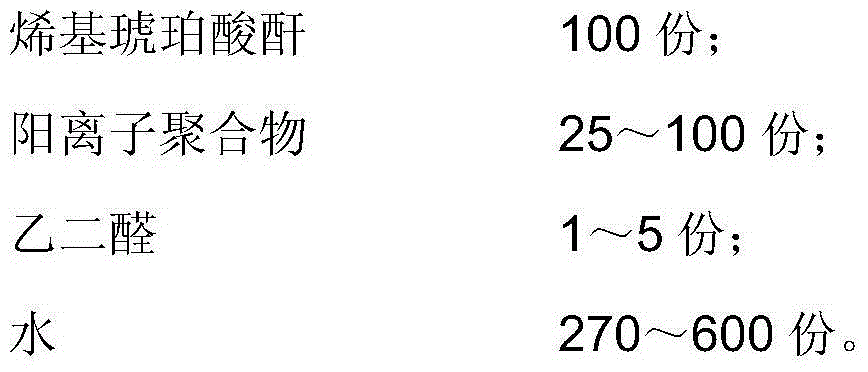

The invention provides a preparation method for a surface sizing agent emulsion. The preparation method comprises the following steps: mixing a cationic polymer with water; adding molten AKD (alkyl ketene dimer) wax and paraffin wax at 70-75 DEG C; and then homogenizing in a condition of 10-25 Mpa, cooling, and then adding glyoxal, so as to obtain the surface sizing agent emulsion, wherein the cationic polymer is an aqueous dispersoid copolymerized from a cationic monomer, a (methyl) acrylate monomer and (methyl) styrene, and prepared by taking gelatine as a dispersing agent, taking a cationic and non-ionic compound surfactant as an emulsifying agent, taking 2,2'-azo-bis (amidino-propyl) dihydrochloride as an initiator, and performing free radical emulsion polymerization on the mixed monomers; the surface sizing agent emulsion comprises the following components in parts by weight: 80-90 parts of the AKD wax, 10-20 parts of the paraffin wax, 25-100 parts of the cationic polymer, 1-5 parts of glyoxal, and 270-610 parts of water, wherein the total of the AKD wax and the paraffin wax is100 parts by weight. The surface sizing agent emulsion provided by the invention is capable of obviously improving the hydrophobicity of paper and improving the surface strength of the paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

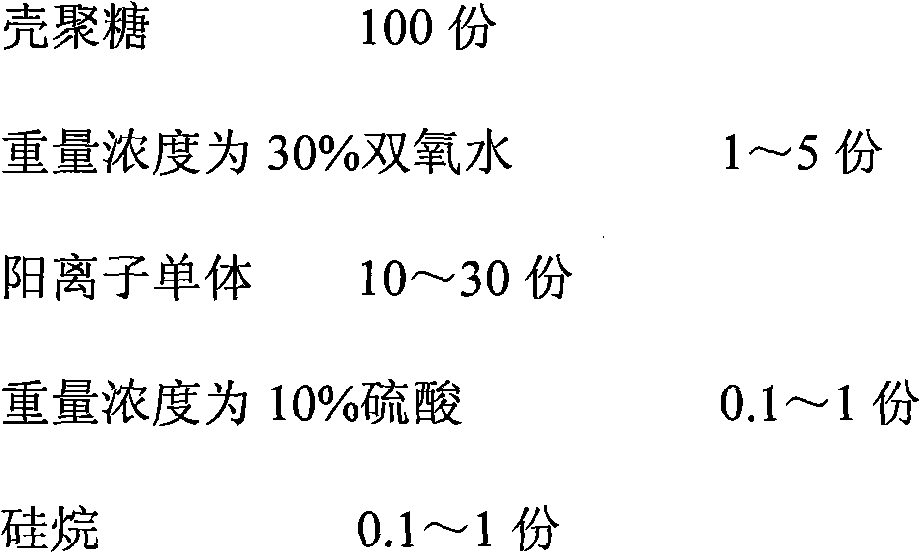

Surface sizing agent emulsion and preparation method for same

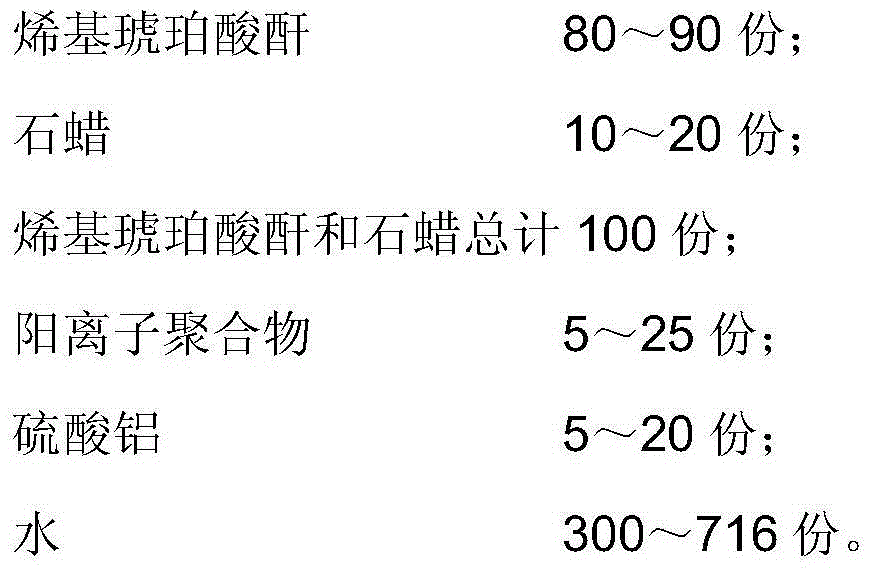

InactiveCN103410051AImprove hydrophobicityImprove surface strengthWater-repelling agents additionNon-macromolecular organic additionParaffin waxChemistry

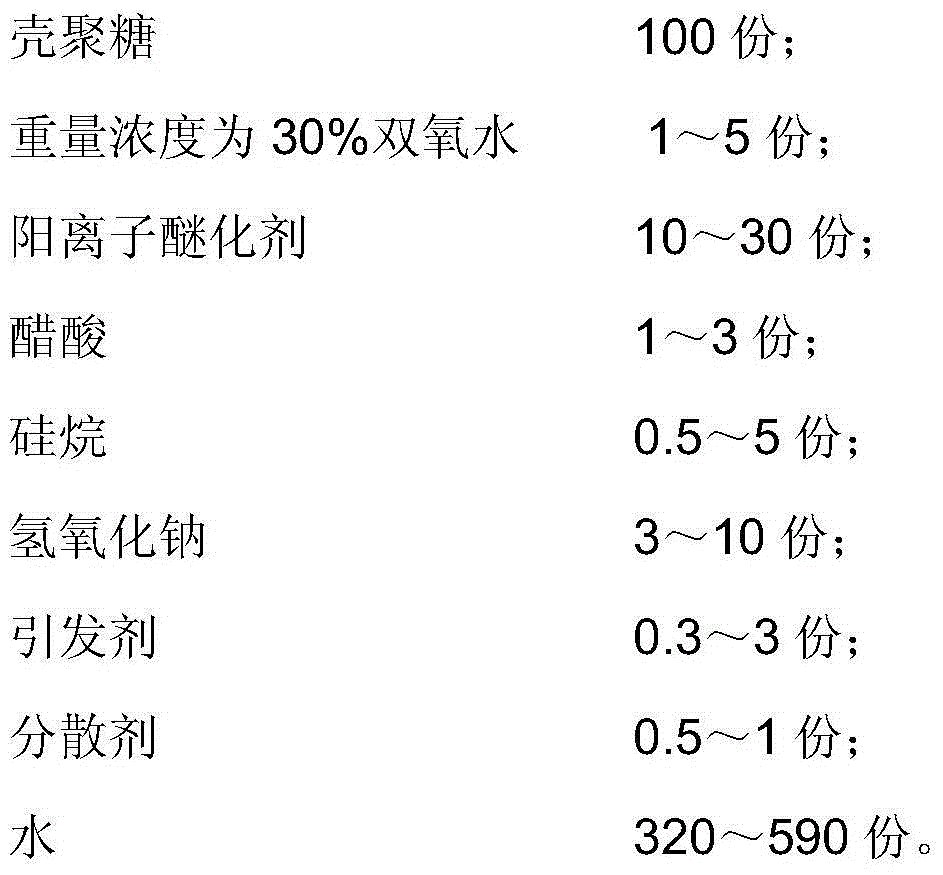

The invention provides a preparation method for a surface sizing agent emulsion. The preparation method comprises the following steps: mixing a cationic polymer with water; adding molten AKD (alkyl ketene dimer) wax and paraffin wax at 70-75 DEG C; and then homogenizing in a condition of 10-25 Mpa, cooling to a temperature below 40 DEG C, and adding glyoxal, so as to obtain the surface sizing agent emulsion, wherein the cationic polymer is prepared by reacting a cationic etherifying agent, chitosan, hydrogen peroxide, silane, acetic acid, sodium hydroxide and a dispersing agent under the action of an initiator; the surface sizing agent emulsion comprises the following components in parts by weight: 80-90 parts of the AKD wax, 10-20 parts of the paraffin wax, 25-100 parts of the cationic polymer, 1-5 parts of glyoxal, and 270-600 parts of water, wherein the total of the AKD wax and the paraffin wax is 100 parts by weight. The surface sizing agent emulsion provided by the invention is a high-performance and environment-friendly product capable of meeting application for papermaking coatings; the product is capable of obviously improving the hydrophobicity of paper, reducing the Cobb value, and improving the surface strength of the paper in case of being applied to surface sizing for the paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Novel surface sizing agent and preparation method thereof

ActiveCN106368062AIncreased ring compressive strengthReduce the Cobb valueWater-repelling agents additionPaper coatingAcetic acidGram

The invention discloses a novel surface sizing agent and a preparation method thereof. The preparation method comprises the following steps: 1, uniformly mixing methyl styrene, an acrylate monomer, a cationic monomer and an initiator to form a mixed monomer; 2, adding 10-20% of the mixed monomer obtained in the step 1 into a four-necked flask, heating to the temperature of 80-140 DEG C, reacting for 5-20 minutes, and dripping the residual mixed monomer; 3, adding acetic acid, and reacting at the temperature of 80-140 DEG C for 20-60 minutes; 4, adding preheated deionized water at the temperature of 80-140 DEG C, continuously reacting for 0.5-2 hours, adding siloxane for reacting 0.5-3 hours, cooling, and filtering, thereby obtaining the novel surface sizing agent. The novel surface sizing agent disclosed by the invention is capable of greatly reducing a Cobb value, promoting rapid curing, and greatly improving the ring crush compression resistance of corrugated paper and reducing gram weight of paper on the premise of maintaining invariable sizing agent amount.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

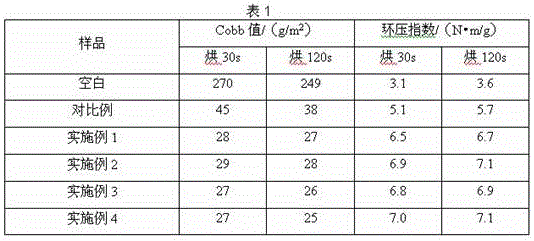

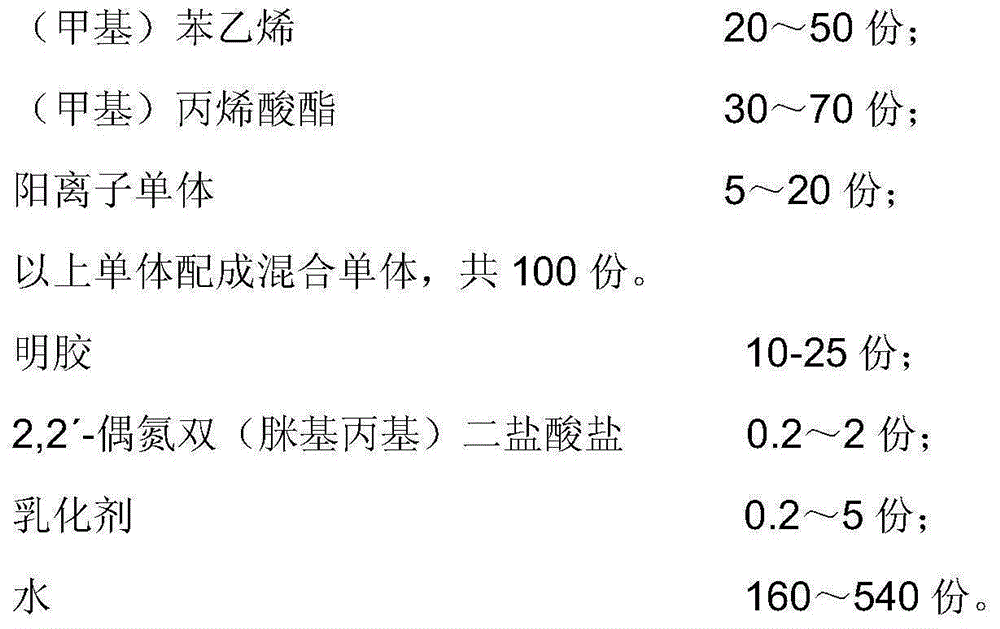

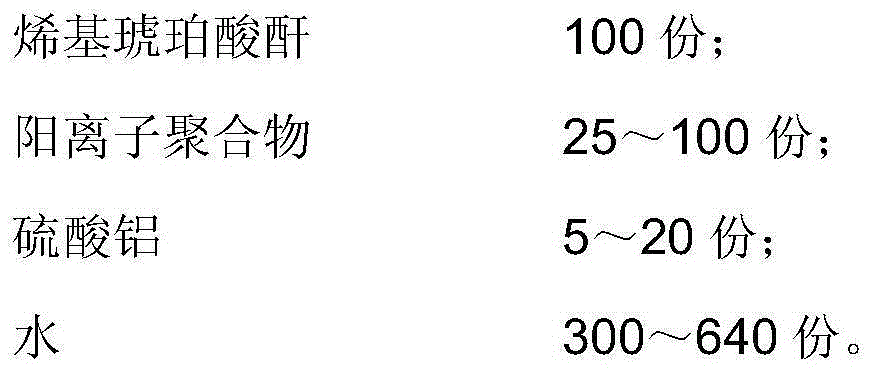

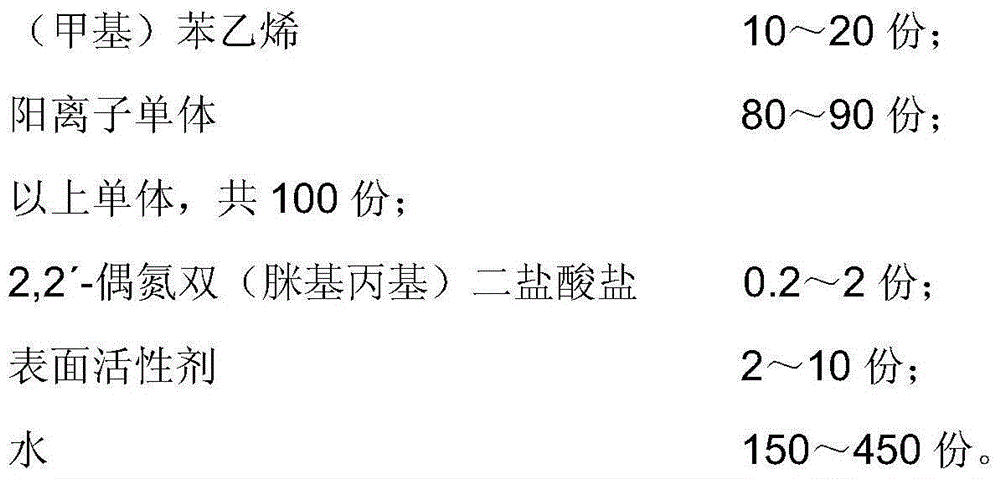

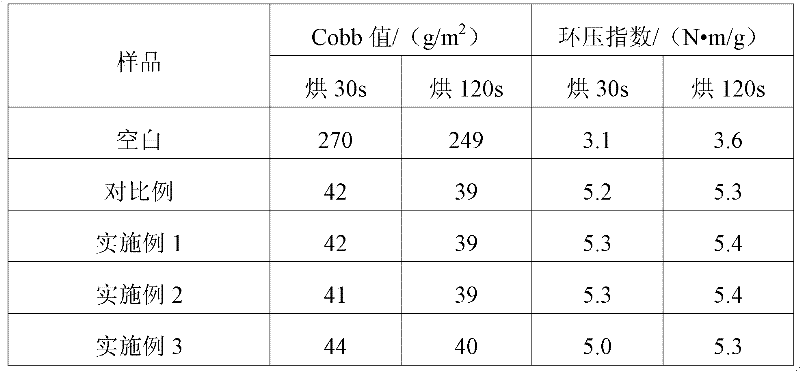

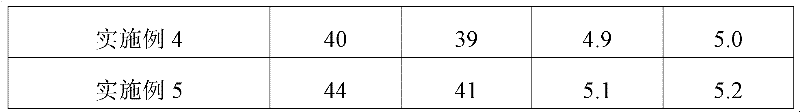

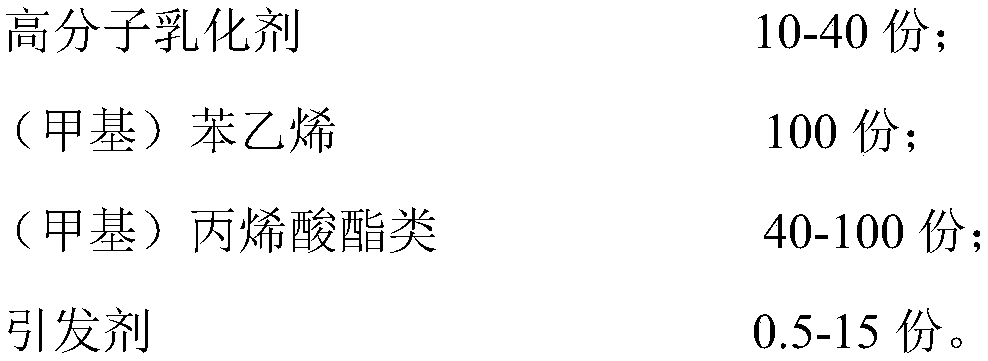

Surface sizing agent emulsion and its preparation method and use

InactiveCN106256954AImprove hydrophobicityImprove surface strengthWater-repelling agents additionPaper coatingEmulsionEmulsion polymerization

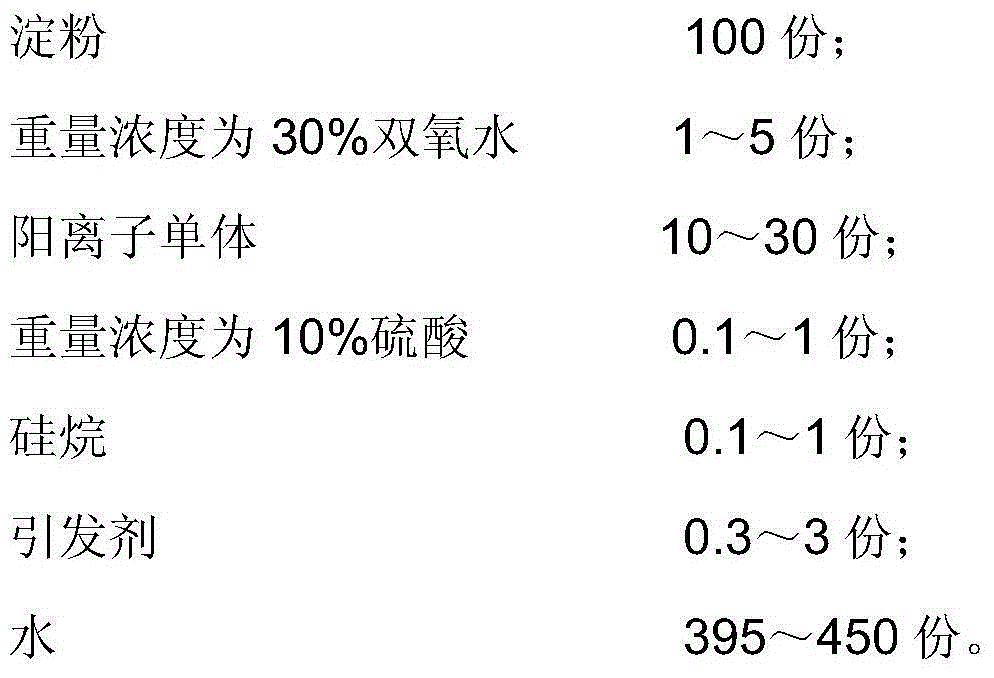

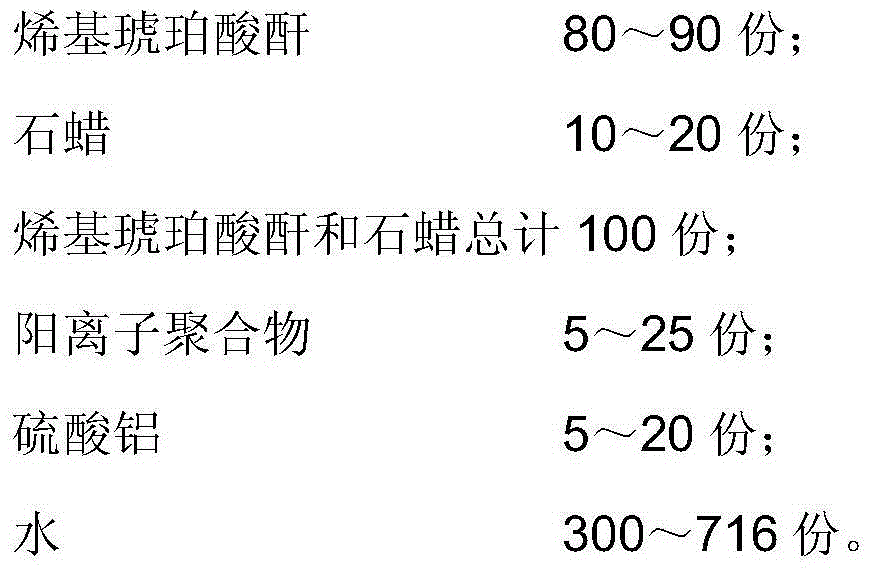

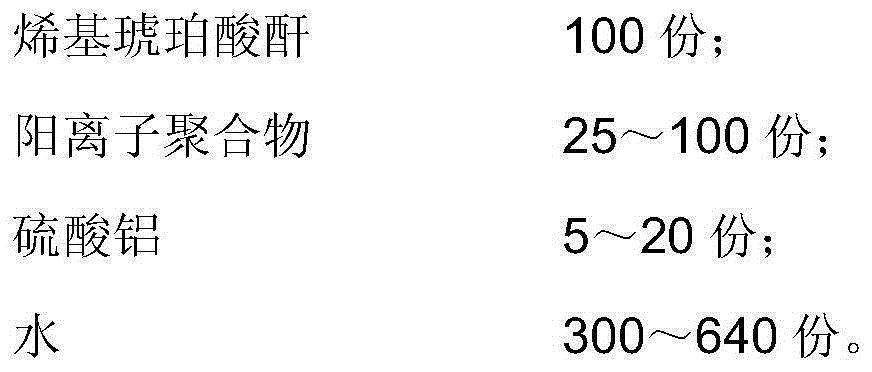

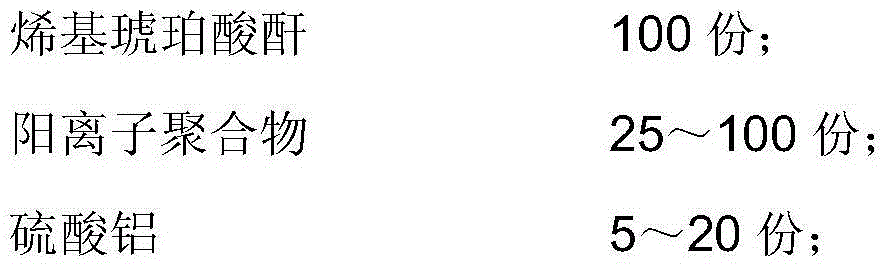

The invention discloses a surface sizing agent emulsion and its preparation method and use. The preparation method comprises mixing a cationic polymer and water, adding alkenyl succinic anhydride (ASA) and paraffin into the mixture, carrying out stirring homogenization and adding aluminum sulfate into the mixture to obtain the surface sizing agent emulsion. The cationic polymer is an aqueous dispersion prepared through copolymerization of a cationic monomer, a (methyl) acrylate monomer and (methyl) styrene. Gelatin as a dispersant, a cationic-nonionic composite surfactant as an emulsifier and 2, 2'-azobis(amidinopropyl)dihydrochloride as an initiator undergo a free radical emulsion polymerisation reaction to produce the surface sizing agent emulsion. The surface sizing agent emulsion is a high performance and eco-friendly product satisfying papermaking paint use requirements. The surface sizing agent emulsion is used for paper surface sizing, obviously improves paper hydrophobicity, reduces a Cobb value and improves paper surface strength.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Surface sizing agent emulsion and preparation method and application thereof

InactiveCN106320073AImprove hydrophobicityImprove surface strengthWater-repelling agents additionParaffin waxPolymer science

The invention discloses a surface sizing agent emulsion and a preparation method and application thereof. The preparation method comprises the following steps: mixing a cationic polymer with water, adding alkenyl succinic anhydride (ASA) and paraffin wax, evenly mixing, and adding aluminum sulfate to obtain the surface sizing agent emulsion, wherein the cationic polymer is prepared from a cationic monomer, starch, hydrogen peroxide, silane and sulfuric acid by reacting under the effect of an initiating agent. The surface sizing agent emulsion is a high performance and environmentally-friendly product meeting use of paper product coatings. The product is applied to coating surface sizing, can significantly improve the hydrophobicity of paper, reduces Cobb value, and improves paper surface strength.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

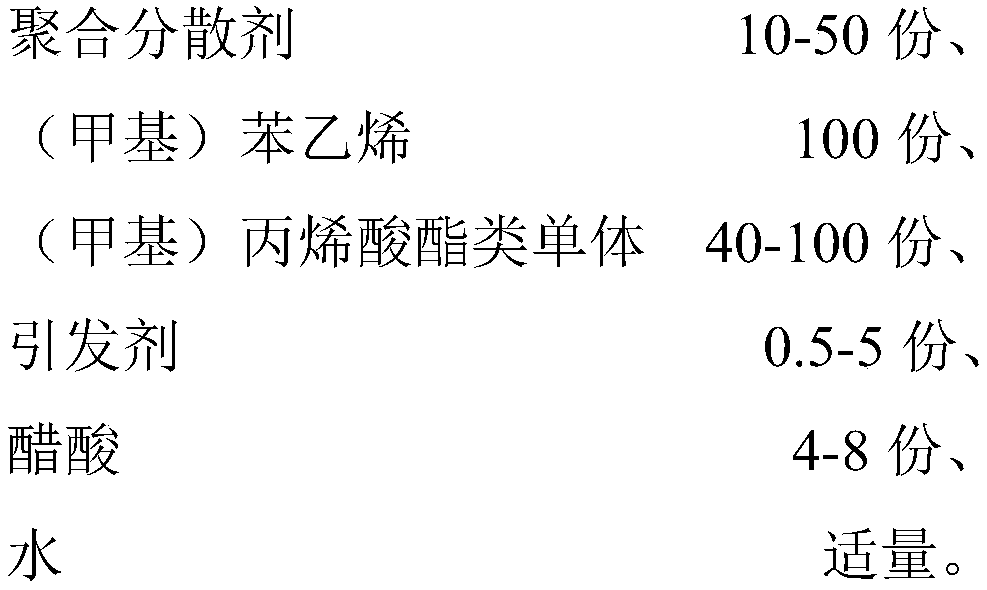

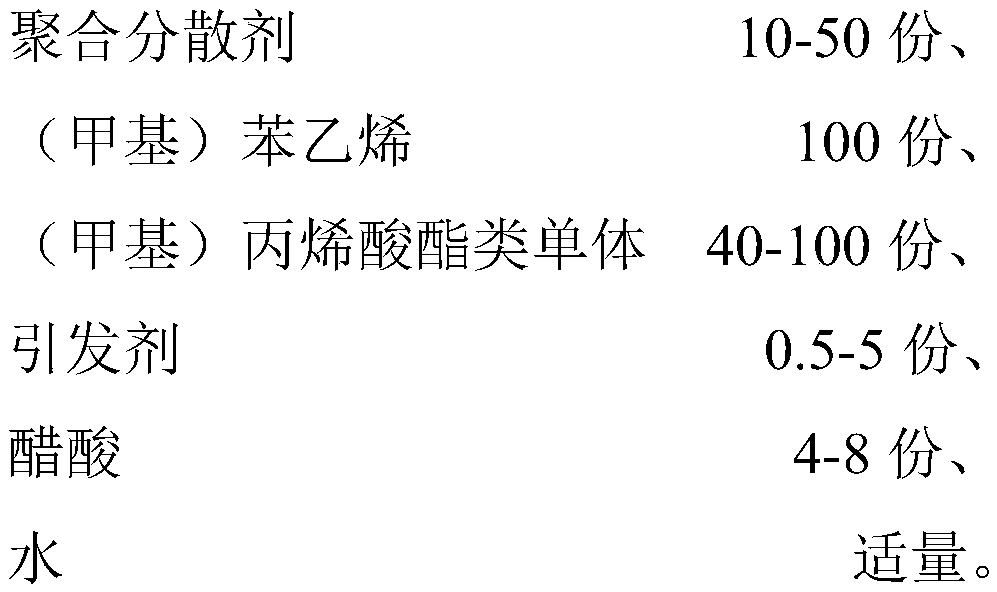

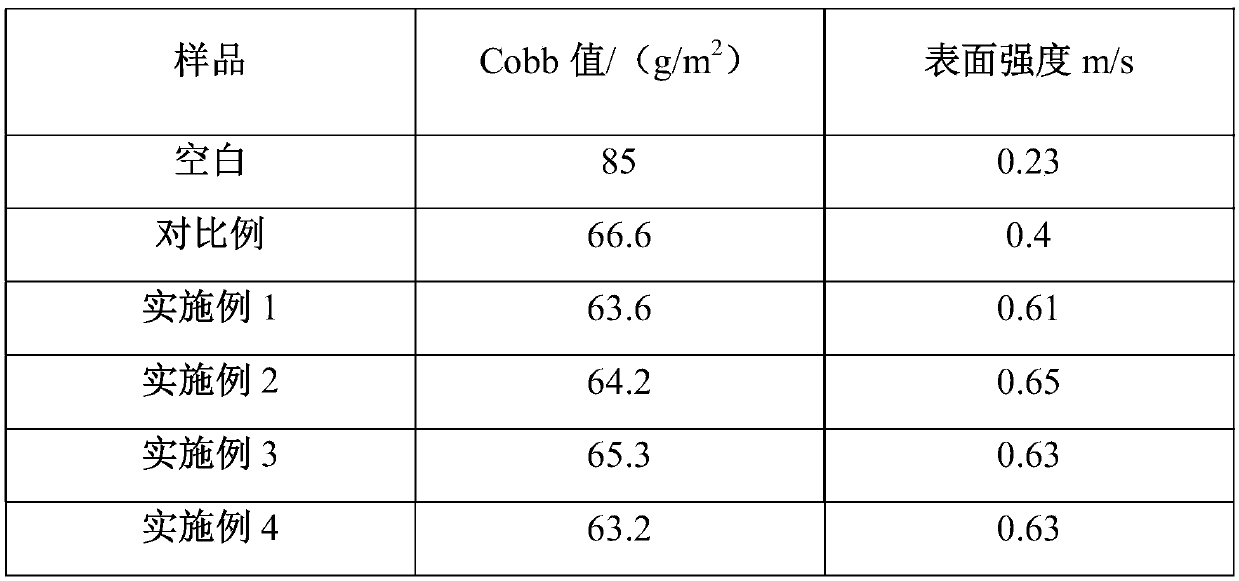

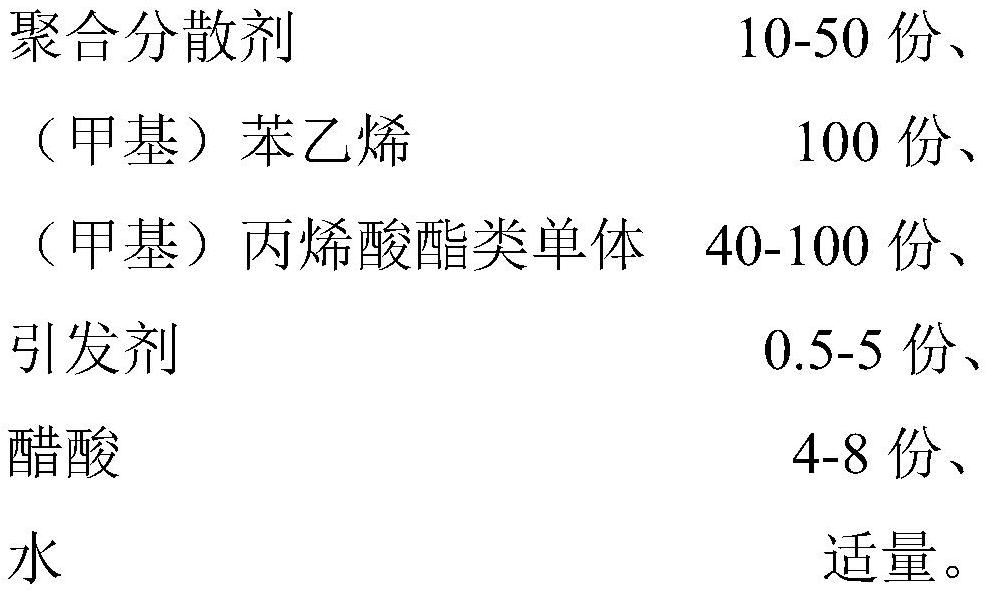

Polymeric dispersant and environment-friendly surface sizing agent prepared by utilizing the same

ActiveCN109537358AReduce the Cobb valueGood dispersionWater-repelling agents additionMaleic anhydrideEmulsion

A polymeric dispersant is disclosed. A preparation method of the polymeric dispersant includes mixing maleic anhydride and polyvinyl alcohol, heating the mixture until the mixture is molten, then performing polycondensation, cooling the product after the reaction is finished, adding chlorosulfonic acid, and preparing the polymeric dispersant after the reaction is finished. The invention also discloses an environment-friendly surface sizing agent. A preparation method of the surface sizing agent includes mixing the polymeric dispersant, acetic acid and water, adding an initiator, reacting the mixture, adding (methyl) styrene and (meth)acrylate type monomers, and sufficiently reacting the mixture to obtain the surface sizing agent. The surface sizing agent is a high-performance environmentally friendly product used for paper surface sizing, is used together with starch for surface sizing of base paper, and can significantly improve water tolerance of paper. The polymeric dispersant has good emulsifying performance so that a synthesized emulsion is low in monomer residue.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Sizing agent emulsion and preparation method for same

InactiveCN102864686AImprove hydrophobicityReduce the Cobb valueWater-repelling agents additionSurface strengthEmulsion

The invention provides sizing agent emulsion and a preparation method for the same. The preparation method includes steps of adding fused alkyl ketene dimmers into mixture of cationic polymers and water under the conditions that the temperature ranges from 70 DEG C to 75 DEG C and the stirring speed ranges from 8000rpm / min to 10000rpm / min; stirring; and homogenizing under the condition that the pressure ranges from 10MPa to 25MPa to obtain the sizing agent emulsion. The sizing agent emulsion is a high-performance and environment-friendly product for coatings for papermaking. The product is applied to internal sizing for paper, so that hydrophobicity of the paper can be obviously improved, a Cobb value is reduced, and the surface strength is enhanced.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Modified sizing starch, surface sizing liquid, preparation method of modified sizing starch, and application of surface sizing liquid

ActiveCN111364284AReduce dosageLow costWater-repelling agents additionPaper recyclingPtru catalystEngineering

The invention discloses a modified sizing starch, a surface sizing liquid, a preparation method of the modified sizing starch and an application of the surface sizing liquid. The preparation method ofthe modified sizing starch comprises the following steps: (1) sequentially mixing and gelatinizing a pulping waste liquid and starch to prepare a material A; (2) mixing the material A with a catalystand an aqueous hydrogen peroxide solution, and carrying out heat preservation to obtain a material B; (3) mixing the material B with a reducing agent to prepare the modified sizing starch. In the step (2), the catalyst is one or more of compounds containing Fe<2+>, Cr<2+>, V<2+>, Ti<3+>, Co<2+> and Cu<+>, the weight ratio of the dry weight of the pulping waste liquid to the aqueous hydrogen peroxide solution is 1:(0.04-1.6), and the mass fraction of the aqueous hydrogen peroxide solution is 24-35%. The prepared surface sizing liquid can effectively improve the water resistance of paper and reduce the Cobb value of the paper, the mechanical properties of the surface sizing solution are equivalent to those of an existing surface sizing liquid, and raw materials are degradable.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

Internal sizing agent emulsion and its preparation method and use

InactiveCN106256955AImprove hydrophobicityImprove surface strengthWater-repelling agents additionInorganic compound additionEnvironmental resistancePolymer science

The invention discloses an internal sizing agent emulsion and a preparation method thereof. The preparation method comprises mixing a cationic polymer and water, adding alkenyl succinic anhydride (ASA) into the mixture, carrying out stirring homogenization and adding aluminum sulfate into the mixture to obtain the internal sizing agent emulsion. The cationic polymer is an aqueous dispersion obtained through copolymerization of a cationic monomer and (methyl) styrene. The preparation method comprises that the mixed monomers undergo a free radical solution polymerization reaction in the presence of 2, 2'-azobis(amidinopropyl)dihydrochloride as an initiator so that a solution is obtained and a surfactant is added into the solution so that a desired cationic polymer is obtained. The internal sizing agent emulsion is high performance and eco-friendly product satisfying papermaking paint use requirements. The internal sizing agent emulsion can be used for paper internal sizing, obviously improve paper hydrophobicity, reduce a Cobb value and improve paper surface strength.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

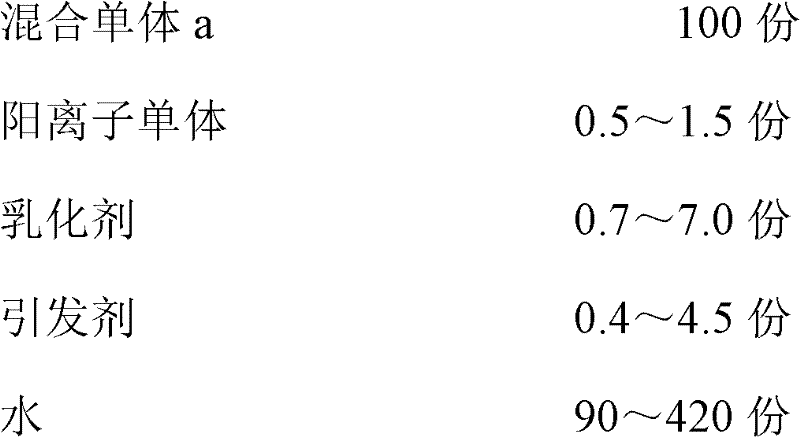

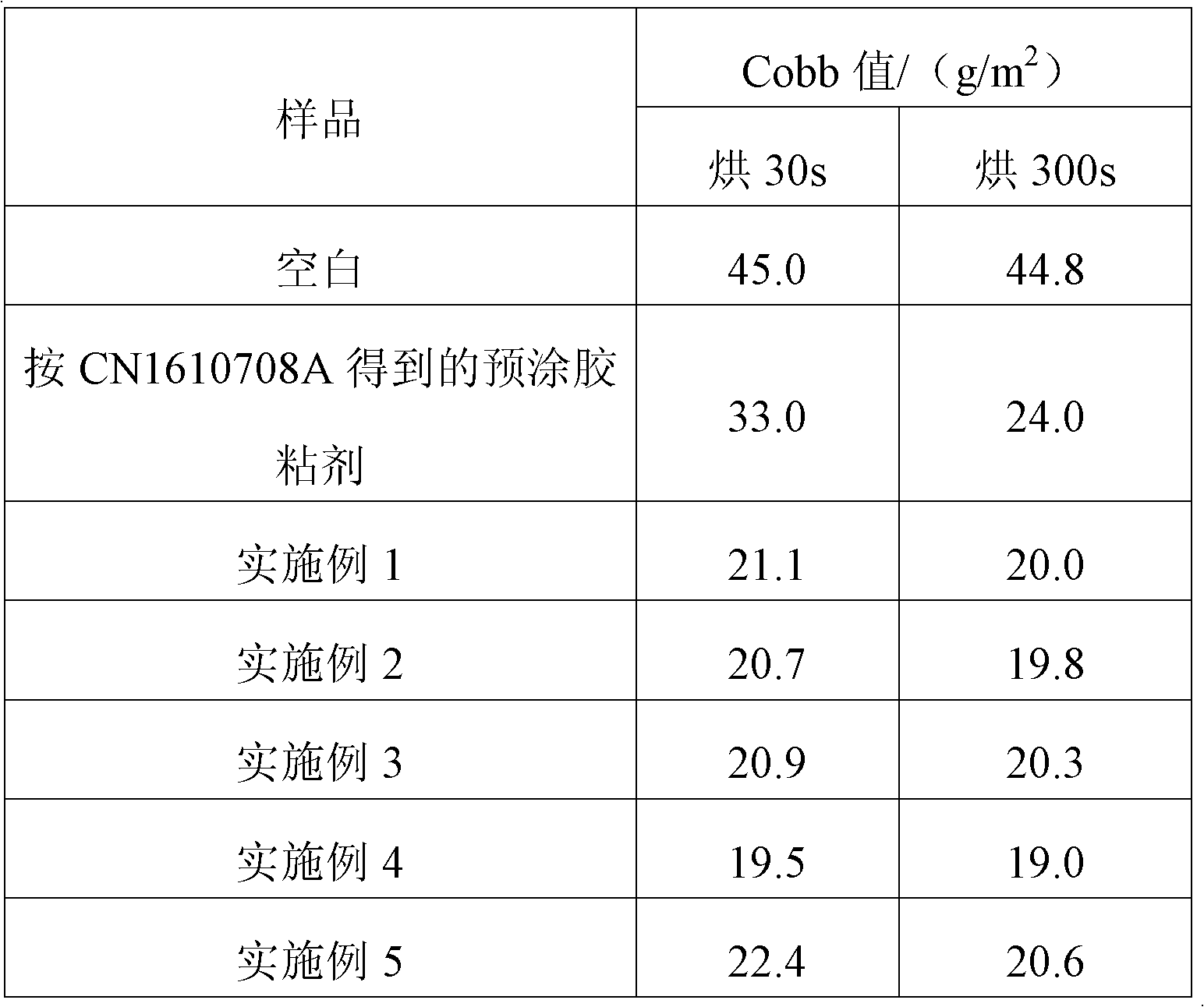

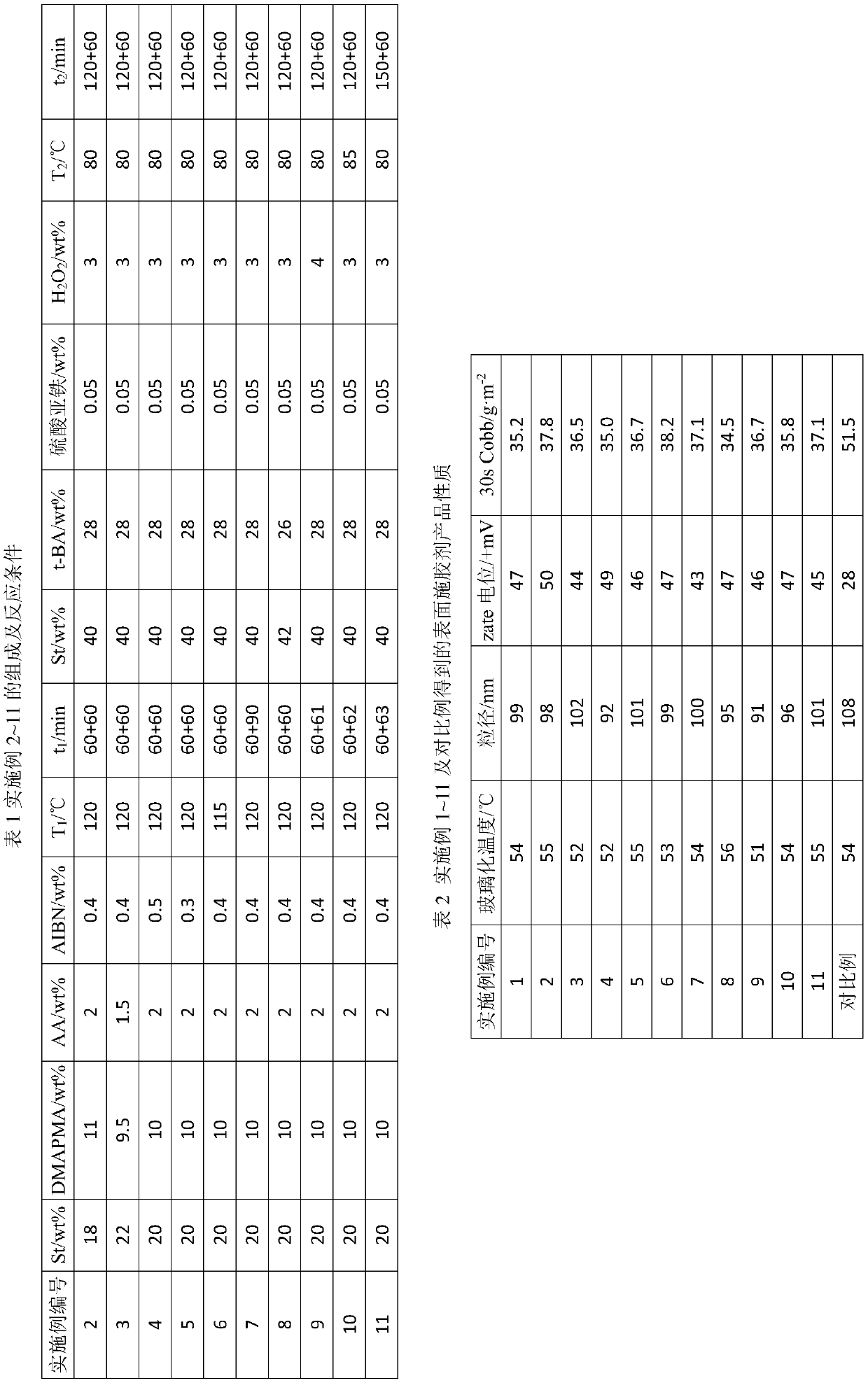

Cationic styrene-acrylic emulsion, preparation method and application thereof

InactiveCN102558415AGood water solubilityImprove surface strengthWater-repelling agents additionPaper coatingMethacrylateFiber

The invention discloses a cationic styrene-acrylic emulsion, and a preparation method and application of the cationic styrene-acrylic emulsion, wherein the preparation method comprises the steps of a) mixing methacrylate, methyl styrene and methacrylic acid to obtain a mixed monomer a; b) mixing an emulsifier, an initiator and water to obtain an emulsifier and initiator aqueous solution b; c) mixing a cationic monomer and water to obtain a cationic monomer aqueous solution c; d) adding the mixed monomer a to the emulsifier, the initiator and water and mixing to obtain a mixed monomer solution d; e) adding the mixed monomer a to the emulsifier, the initiator and water, allowing reaction, and then dropwise adding the mixed monomer solution d, the emulsifier and initiator aqueous solution b and the cationic monomer aqueous solution c, performing reaction; then using alkaline solution to neutralize the mixture till that pH is 7-10, and finally obtaining the product. The invention improves adsorption and retention of the emulsion on the fibers of paper surface, remarkably strengthens surface strength of the paper and notably reduces Cobb value of the coated duplex board with grey back.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

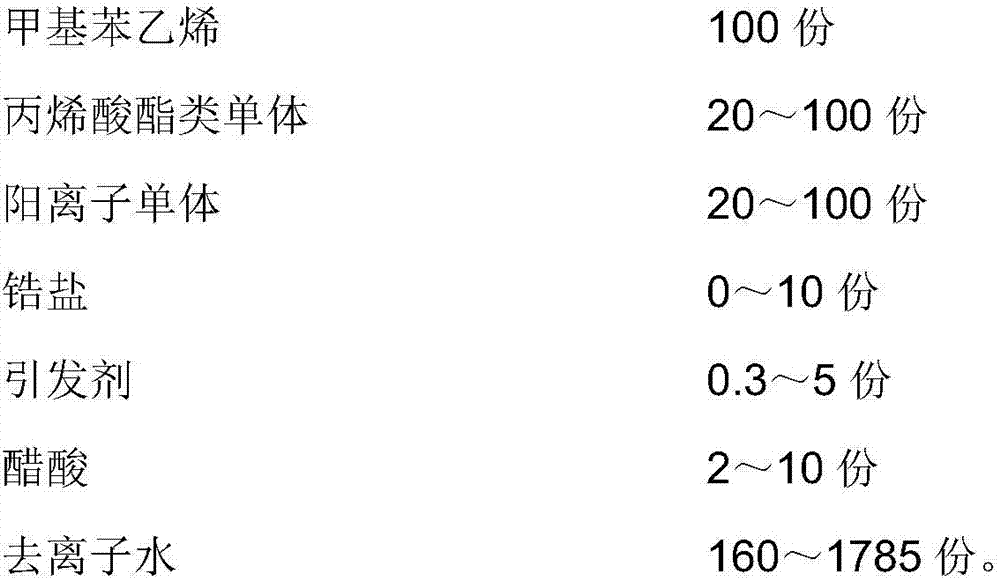

A kind of surface sizing agent and preparation method thereof

ActiveCN106223116BImprove surface strengthIncrease forceWater-repelling agents additionInorganic compound additionAcetic acidZircon

The invention discloses a preparation method of a surface sizing agent. The preparation method comprises the following steps that firstly, methyl styrene, acrylic monomers, cationic monomers and an initiating agent are mixed to be uniform to form a mixed monomer; secondly, 10% of the mixed monomer obtained in the first step is added into a four-opening flask, the temperature is raised to 80-140 DEG C, residual mixed monomer is added dropwise after a reaction is carried out for 5-20 minutes, and then the temperature of 80-140 DEG C is kept for 0.5-1.5 hours; thirdly, acetic acid is added, and at the temperature of 80-140 DEG C, a reaction is carried out for 20-60 minutes; fourthly, preheated deionized water with the temperature being 80-100 DEG C is added, a reaction continues to be carried out for 0.5-2 hours, and the mixture is cooled to 25-35 DEG C, zircon salt is added, the mixture is stirred to be uniform, filtering is carried out, and the surface sizing agent is obtained. According to the surface sizing agent, the Cobb value can be greatly reduced, the surface sizing agent can be quickly cured and is basically cured as soon as the surface sizing agent is loaded to a machine, and the surface strength of body paper can be greatly improved under the situation that the dosage of the sizing agent is not changed.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Cationic tert-carbonic acid styrene-acrylic emulsion and preparation method thereof

ActiveCN102718913AImprove surface strengthReduce the Cobb valueWater-repelling agents additionPaper coatingThermal insulationSurface strength

The invention discloses a cationic tert-carbonic acid styrene-acrylic emulsion and a preparation method thereof. The preparation method includes the following steps of a) mixing a (meth) acrylate, a (methyl) styrene and a vinyl ester of tertiary carbonic acid to obtain a mixed monomer; b) mixing an emulsifier, an initiator and water to obtain an aqueous solution A; c) mixing a cationic monomer and water to obtain an aqueous solution B; d) mixing the mixed monomer, the emulsifier, the initiator and water to obtain an aqueous solution C; e) adding the mixed monomer into the emulsifier, the initiator and the aqueous solution to be subjected to a reaction and then dropwise adding the aqueous solution C, the aqueous solution A and the aqueous solution B; and f) performing a thermal insulation and neutralizing until the potential of hydrogen (pH) is identical to 6 to 9 to obtain the cationic tert-carbonic acid styrene-acrylic emulsion. According to the cationic tert-carbonic acid styrene-acrylic emulsion and the preparation method thereof, the addition of aluminium sulfate is not required, the surface strength of paper can be remarkably improved, and the Cobb value of a white Manila board can be remarkably decreased.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

High-surface-strength paper surface sizing agent

InactiveCN110409217AReduce the Cobb valueImprove antibacterial propertiesWater-repelling agents additionFiberNon toxicity

The invention discloses a high-surface-strength paper surface sizing agent. Modified chitosan is taken as an effective component. The modified chitosan has very well film-forming property, and can beconnected with paper fiber through a hydrogen bond. The paper surface sizing agent is a high-performance and environment-friendly product which can meet using of paper surface sizing. Surface sizing is conducted on a raw paper by the product together with starch, the surface strength can be significantly improved, and the Cobb value of the paper is not lowered. At the same time, the chitosan has the advantages that non-toxicity is achieved, degradation is easy, the biocompatibility is good, film-forming is easy, and antibacterial property is very high.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

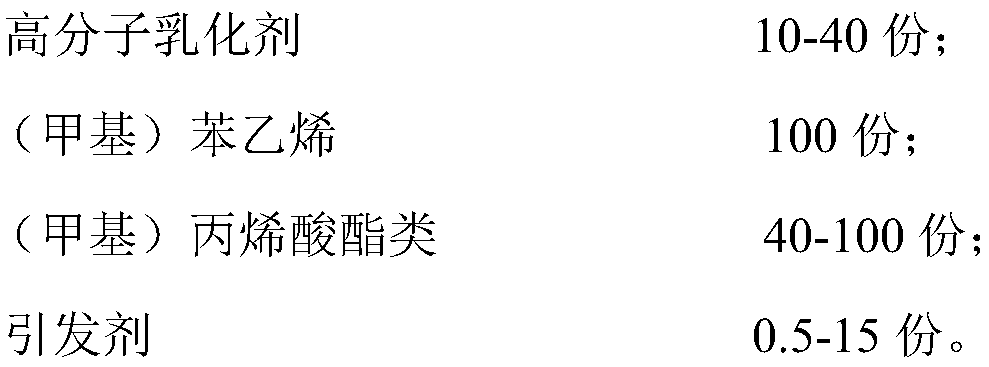

Preparation and application method of water-tolerant paper surface sizing agent

InactiveCN109577085AReduce the Cobb valueImprove water resistanceWater-repelling agents additionIonEmulsion

The invention discloses a preparation method of a water-tolerant paper surface sizing agent. The method comprises intensely mixing a part of high-polymer emulsifier, (methyl) styrene, (methyl) acrylate mixed monomers and deionized water to prepare an emulsion; heating the other part of the high-polymer emulsifier and water inside a container to 80-90 DEG C, then adding in initiator for reaction for 10-20 min, dropwise adding in the prepared emulsion for 1.5-3.0 hr for continuous reaction for 1.0-2.0 hr, and performing cooling and discharging. The invention also relates to the water-tolerant paper surface sizing agent prepared through the method and application of the prepared water-tolerant paper surface sizing agent. According to the preparation method of the water-tolerant paper surfacesizing agent, styrene acrylate emulsion is prepared by polymerizing soap-free emulsion and monomers are dropwise added through monomer emulsification, so that bonding between the styrene acrylate emulsion and the surface of paper can be enhanced. When the water-tolerant paper surface sizing agent is applied to the surface of the paper, the applied paper can have the advantage of high water tolerance; due to the fact that no micromolecular emulsifier is applied during polymerization, the water-tolerant paper surface sizing agent is an environment friendly product.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Internal sizing agent emulsion and preparation method and application of same

InactiveCN106320075AImprove hydrophobicityImprove surface strengthWater-repelling agents additionEnvironmental resistancePolymer science

The invention discloses an internal sizing agent emulsion. A preparation method comprises the steps of mixing cationic polymer with water, adding alkenyl succinic anhydride (ASA), stirring and homogenizing the materials, and adding aluminum sulfate to obtain the internal sizing agent emulsion. The cationic polymer is a aqueous dispersion of a cationic monomer, (methyl)styrene, and silane through copolymerization, the preparation method takes 2,2'-azo-bis (amidino-propyl) dihydrochloride as an initiator, uses the above mixing monomer for free radical solution polymerization to obtain the solution, a surfactant is added, and the cationic polymer is prepared. The internal sizing agent emulsion provided by the invention is high-performance and environment-friendly product capable of being used for the papermaking coating. The product is used for internal sizing of papers, and can obviously improve the hydrophobicity of the papers, reduce the Cobb value and increase the surface strength of the papers.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Surface sizing agent emulsion and preparation method and application thereof

InactiveCN106320074AImprove hydrophobicityImprove surface strengthWater-repelling agents additionEnvironmental resistanceSilanes

The invention discloses a surface sizing agent emulsion and a preparation method and an application thereof. The preparation method comprises the following steps: mixing a cationic polymer with water, adding alkenyl succinic anhydride (ASA), stirring and homogenizing, and then adding oxalaldehyde, to obtain the surface sizing agent emulsion; the cationic polymer is prepared by carrying out a reaction of a cationic etherifying agent, chitosan, hydrogen peroxide, silane, acetic acid, sodium hydroxide and a dispersing agent under the action of an initiator. The surface sizing agent emulsion is a high-performance and environmental-protection product which can meet papermaking coatings. The product is applied in paper surface sizing, can significantly improve the hydrophobicity of the paper, reduces Cobb value and improves the paper surface strength.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

A kind of preparation method of surface sizing agent for corrugated paper and its product and application

ActiveCN106368059BReduce the Cobb valueIncreased ring compressive strengthWater-repelling agents additionCoated paper substrateAcetic acidDimmer

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Starch emulsifier, preparation method thereof, and anionic AKD surface sizing agent prepared from emulsifier

ActiveCN111118951AGood compatibilityReduce the Cobb valueCoatings with pigmentsWater-repelling agents additionCompatibilizationMaterials science

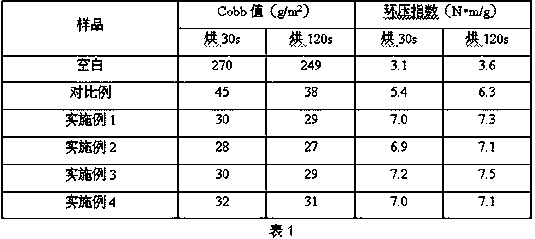

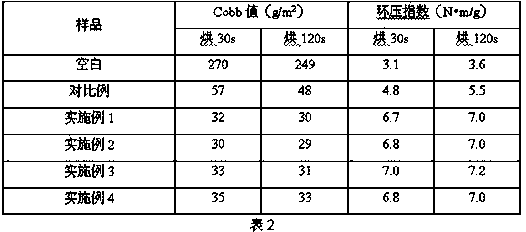

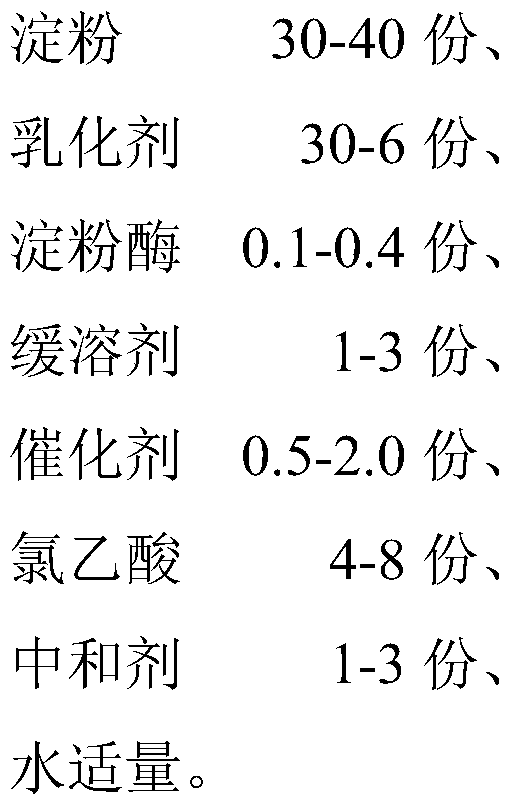

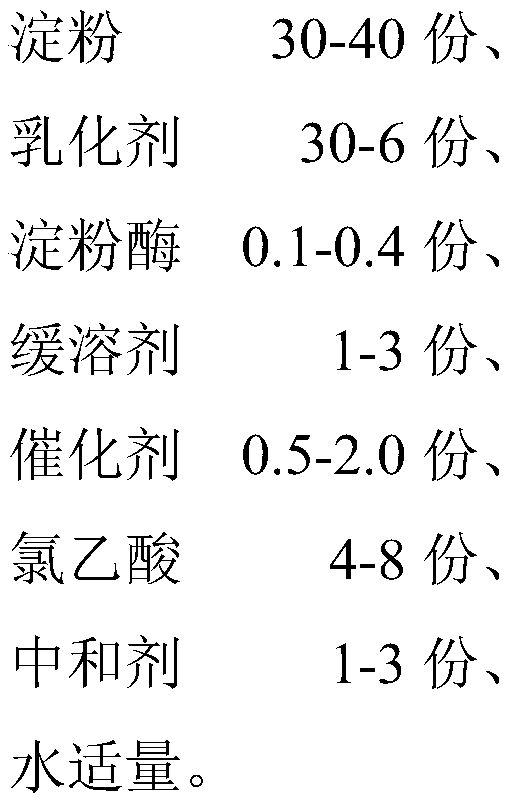

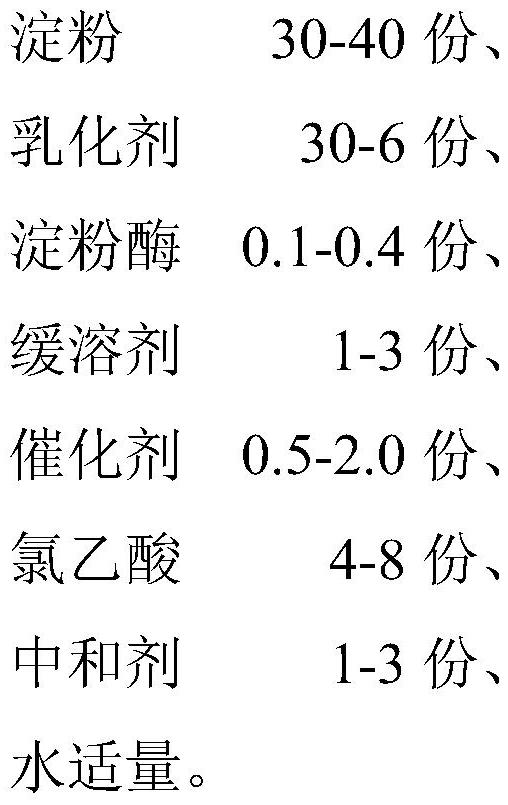

The invention discloses a starch emulsifier. The starch emulsifier comprises, by weight, 30-40 parts of starch, 30-6 parts of an emulsifier, 0.1-0.4 part of amylase, 1-3 parts of a slow solvent, 0.5-2.0 parts of a catalyst, 4-8 parts of chloroacetic acid, 1-3 parts of a neutralizer and water. A preparation method of the starch emulsifier comprises the following steps: mixing the starch, the emulsifier, amylase and water to obtain starch milk, heating, adding the slow solvent and the catalyst, adding chloroacetic acid, fully reacting, and regulating the pH value of the system by using the neutralizer to obtain the starch emulsifier. The invention also provides an anionic AKD surface sizing agent. The anionic AKD surface sizing agent is prepared by the following steps: mixing the starch emulsifier and water, heating, adding the AKD raw powder under high-speed stirring, adding the obtained mixture into a high-pressure homogenizer, and homogenizing, cooling and discharging the mixture. Theanionic AKD surface sizing agent has excellent compatibility with an anionic auxiliary agent, and can remarkably reduce the water absorption value, improve the surface strength of paper and effectively improves the printability.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Water-resistant surface sizing agent as well as preparation method and application thereof

PendingCN114163569AReduce the Cobb valueImprove bindingWater-repelling agents additionPaper sheetSizing

The invention provides a water-resistant surface sizing agent. A preparation method of the water-resistant surface sizing agent comprises the following steps: mixing oxidized starch and water, heating, adding caustic soda liquid, adjusting the pH value to 11 or above, continuously heating to 60-80 DEG C, and adding a cross-linking agent for reaction to prepare cross-linked oxidized starch; mixing the cross-linked oxidized starch with water, heating to 80-90 DEG C, and adding an initiator; dropwise adding (methyl) styrene and (methyl) acrylate monomers, reacting, cooling, and discharging to obtain the water-resistant surface sizing agent. A sizing solution obtained by compounding the water-resistant surface sizing agent and gelatinized oxidized starch is used for paper surface sizing, the water resistance of paper can be greatly improved, and the Cobb value of the paper is reduced.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

Surface sizing agent emulsion and its preparation method and application

ActiveCN103410050BImprove hydrophobicityImprove surface strengthWater-repelling agents additionNon-macromolecular organic additionParaffin waxPolymer science

The invention provides a preparation method for a surface sizing agent emulsion. The preparation method comprises the following steps: mixing a cationic polymer with water; adding molten AKD (alkyl ketene dimer) wax and paraffin wax at 70-75 DEG C; and then homogenizing in a condition of 10-25 Mpa, cooling, and then adding glyoxal, so as to obtain the surface sizing agent emulsion, wherein the cationic polymer is an aqueous dispersoid copolymerized from a cationic monomer, a (methyl) acrylate monomer and (methyl) styrene, and prepared by taking gelatine as a dispersing agent, taking a cationic and non-ionic compound surfactant as an emulsifying agent, taking 2,2'-azo-bis (amidino-propyl) dihydrochloride as an initiator, and performing free radical emulsion polymerization on the mixed monomers; the surface sizing agent emulsion comprises the following components in parts by weight: 80-90 parts of the AKD wax, 10-20 parts of the paraffin wax, 25-100 parts of the cationic polymer, 1-5 parts of glyoxal, and 270-610 parts of water, wherein the total of the AKD wax and the paraffin wax is100 parts by weight. The surface sizing agent emulsion provided by the invention is capable of obviously improving the hydrophobicity of paper and improving the surface strength of the paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

A kind of modified sizing starch, surface sizing liquid and its preparation method and application

ActiveCN111303307BReduce dosageLow costWater-repelling agents additionPaper recyclingPtru catalystChemical compound

The invention discloses a modified sizing starch, a surface sizing solution, a preparation method and application thereof. The preparation method of the modified sizing starch comprises the following steps: (1) under the condition that the pH is 3-6, mixing the pre-hydrolyzed solution and starch to obtain material A; (2) mixing material A, catalyst and peroxidized The hydrogen solution is mixed and kept warm to obtain material B; (3) material B is mixed with reducing agent to obtain modified sizing starch; in step (2), the catalyst is Fe-containing 2+ Compounds containing Cr 2+ compounds containing V 2+ Compounds containing Ti 3+ Compounds containing Co 2+ Compounds and Cu + one or more of the compounds. The raw material of the modified sizing starch in the present invention uses the pre-hydrolyzed solution to replace part of the starch, which reduces the cost; it does not need to enzymatically hydrolyze the starch, which saves workshop costs; the surface sizing solution in the present invention can effectively improve the water resistance of the paper, Lower the Cobb value of the paper.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

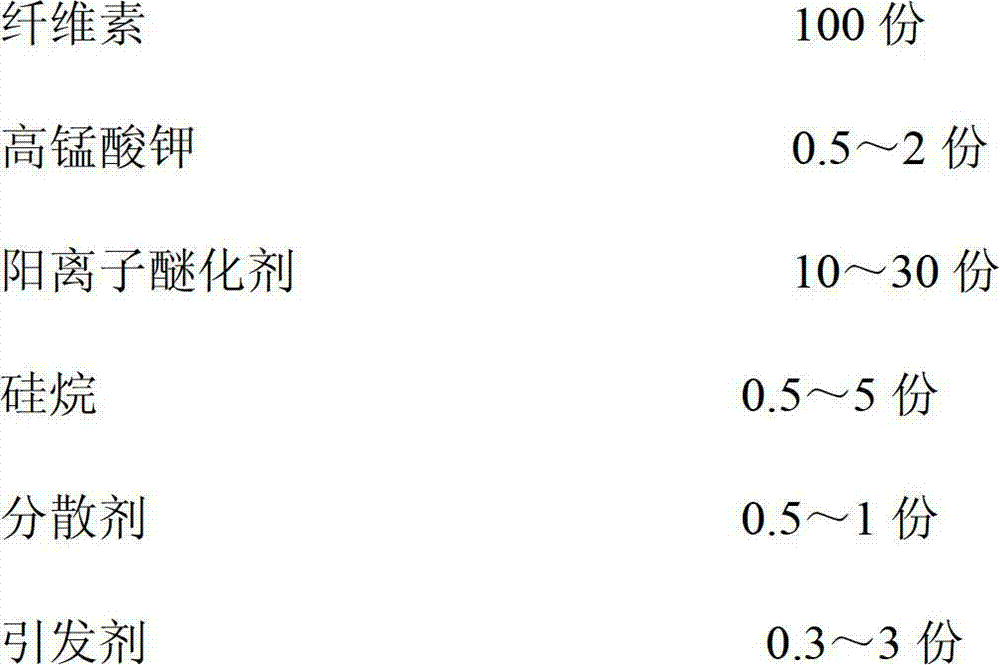

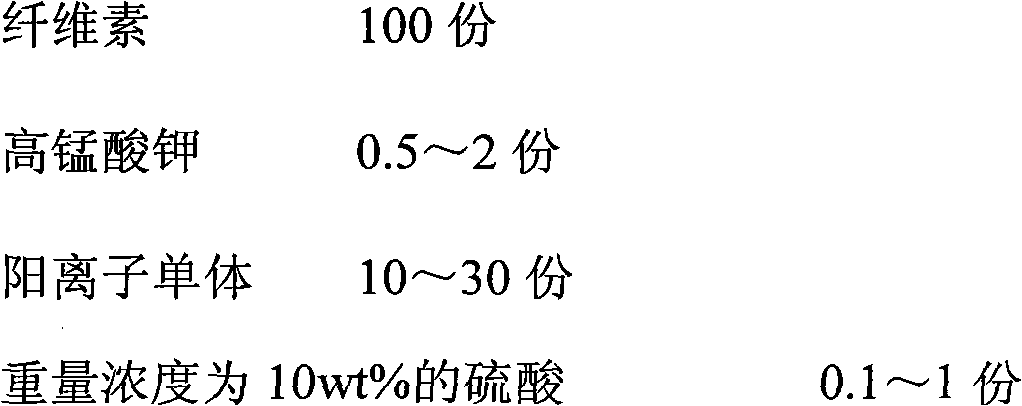

High-performance sizing agent emulsion and preparation method thereof

ActiveCN102220729BImprove hydrophobicityReduce the Cobb valueWater-repelling agents additionPaper/cardboardCelluloseEmulsion

The invention discloses high-performance sizing agent emulsion and a preparation method thereof. The preparation method comprises the following steps of: adding molten alkyl ketene dipolymer into a mixture of cationic polymer and water, stirring and homogenizing to obtain the sizing agent emulsion, wherein the cationic polymer is a product obtained by reacting a cationic monomer, cellulose, potassium hypermanganate, silane and sulfuric acid under the action of an initiator. The sizing agent emulsion is a high-performance and environment-friendly product for papermaking coatings. The product is applied to the internal sizing of paper, so that the hydrophobicity of the paper can be improved obviously, and a Cobb value can be reduced.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

Modified cationic latex and preparation method thereof

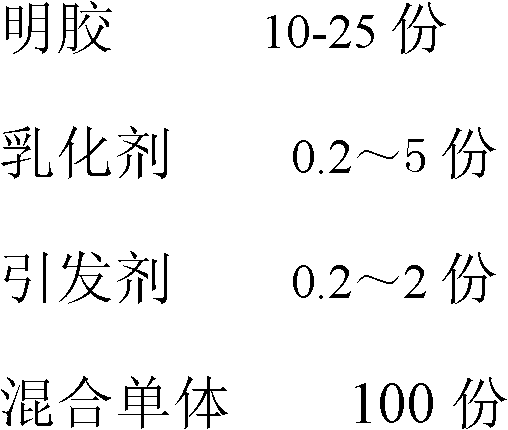

InactiveCN102505558AGood application effectReduce the Cobb valuePaper coatingCoatingsGramRoom temperature

The invention provides modified cationic latex and a preparation method and application thereof. The preparation method includes the following steps: mixing gelatin aqueous solution, emulsifier aqueous solution and initiator aqueous solution, then adding mixed monomers preferably through the manner of dripping for 1-3 hours, thermally insulating for 1-2 hours at 60-95 DEG C, cooling to room temperature, adding borax aqueous solution, and finally filtering. In this way, modified cationic latex can be obtained. According to the invention, the Cobb value can be remarkably reduced, latex can quickly cure almost after leaving the machine, so the gram weight of paper can be reduced; part or even 100% of waste paper is used to replace wood pulp, thus the sizing treatment process is simplified, the cost is reduced and the quality of the product is improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Efficient surface sizing agent for paper and preparation method and application of efficient surface sizing agent

ActiveCN110438838AHighly cationicGood strength performanceWater-repelling agents additionFiberPolymeric surface

The invention discloses an efficient surface sizing agent for paper and a preparation method and application of the efficient surface sizing agent. The surface sizing agent is prepared through two stages of pre-polymerization and polymerization, and the surface sizing agent is prepared from the following polymerization monomers in percentage by weight: 55-75% of a hard monomer, 15-35% of a soft monomer, 5-15% of a cationic monomer, and 2-6% of unsaturated carboxylic acid. The high-potential polymer surface sizing agent has the high cationic property, and thus can be combined with a large number of hydroxyls on the surfaces of fibers, and thus the high-potential polymer surface sizing agent has very good water resistance, film formation and thermoplastic properties. A film layer formed through the efficient surface sizing agent is dense and smooth, on the one hand, the water resistance of the paper can be improved, so that the Cobb value of the paper is decreased, and the anti-damping capability is improved; and on the other hand, good strength performance can be given to the paper. In addition, the smoothness of the paper can further be improved, foam and impurities in the sizing process are reduced, and production stability is improved.

Owner:广东诚铭化学品有限公司 +1

A kind of polymeric dispersant and environment-friendly surface sizing agent prepared by adopting the dispersant

ActiveCN109537358BReduce the Cobb valueMeet environmental protection requirementsWater-repelling agents additionMethacrylateMeth-

The invention discloses a polymeric dispersant. The preparation method comprises the following steps: mixing maleic anhydride and polyvinyl alcohol, heating to melting, and then performing a polycondensation reaction; after the reaction is completed, the temperature is lowered, and chlorosulfonic acid is added to obtain the reaction after the reaction is completed. the polymeric dispersant. The invention also discloses an environment-friendly surface sizing agent, the preparation method of which includes the following steps: mixing the above-mentioned polymeric dispersant, acetic acid and water, then adding an initiator to react; continuing to dropwise add (methyl)styrene, (methyl) base) acrylate monomer, and the surface sizing agent is obtained after sufficient reaction. The environment-friendly surface sizing agent of the invention is a high-performance and environment-friendly product that can meet the requirements of paper surface sizing. The product, together with starch, is used to surface sizing the base paper, which can significantly improve the water resistance of the paper. At the same time, the polymerized dispersant has good emulsifying performance, so the residual monomer of the synthesized emulsion is low.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

A kind of preparation method of cationic starch/nanocellulose-based water-resistant reinforced composite emulsion

ActiveCN108383944BQuality improvementRaise the gradeWater-repelling agents additionPaper coatingPolymer scienceEmulsion

The invention provides a preparation method of a cationic starch / nano cellulose based water-resistant reinforced composite emulsion. The method includes the steps of: starch oxidation, preparation ofa mixed monomer, preparation of an initiator and reaction. The reaction includes: introducing oxidized starch into a reaction kettle, heating the oxidized starch, then adding an initiator A and an initiator B simultaneously; are dripped at the same time; 0.5-2min after adding of the initiator, starting adding of the mixed monomer; at the end of the reaction, adding texanol ester alcohol dropwise,and then performing cooling, thus obtaining the starch / nano cellulose based high water-resistant reinforced composite emulsion. The composite emulsion prepared by the method provided by the inventionhas reinforcement and water resistance functions simultaneously, also has good water resistant effect and significant reinforcement effect, and can obviously improve the paper quality and grade.

Owner:SHOUGUANG MEILUN PAPER

High-performance sizing agent emulsion and preparation method and application thereof

ActiveCN102220728BImprove hydrophobicityReduce the Cobb valueWater-repelling agents additionEmulsionSilanes

The invention discloses a high-performance sizing agent emulsion and a preparation method and an application thereof, and the preparation method comprises the following steps: mixing a cationic polymer and water, adding a molten alkyl ketene dimmer, stirring for homogenization to obtain the high-performance sizing agent emulsion, wherein the cationic polymer is prepared by allowing a cationic monomer, chitosan, hydrogen peroxide, silane and sulfuric acid to react under the action of an initiator. The high-performance sizing agent emulsion of the invention is a high-performance environment-friendly product which meets requirements of papermaking coatings. The product is applicable to the internal sizing of paper, and can significantly improve the hydrophobicity of paper, and decrease the Cobb value.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

A kind of starch emulsifier, preparation method and anionic akd surface sizing agent prepared by using the emulsifier

ActiveCN111118951BImprove surface strengthGood compatibilityCoatings with pigmentsWater-repelling agents additionAmylasePtru catalyst

The invention discloses a starch emulsifier. The parts by weight of each component are as follows: 30-40 parts of starch, 30-6 parts of emulsifier, 0.1-0.4 parts of amylase, 1-3 parts of slow solvent, and 0.5-2.0 parts of catalyst , 4-8 parts of chloroacetic acid, 1-3 parts of neutralizer and water. The preparation method is to mix starch, emulsifier, amylase and water to obtain starch milk, raise the temperature, add slow solvent and catalyst, then add chloroacetic acid to fully react, adjust the pH value of the system with neutralizer, and obtain starch emulsifier. The present invention also provides an anionic AKD surface sizing agent, which is prepared by mixing starch emulsifier and water, heating up, adding AKD raw powder under high-speed stirring, and then adding it into a high-pressure homogenizer to homogeneously cool and discharge the material. . The anionic AKD surface sizing agent of the present invention can have excellent compatibility with anionic additives, and at the same time significantly reduce the water absorption value, increase the surface strength of paper, and effectively improve the printing suitability.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

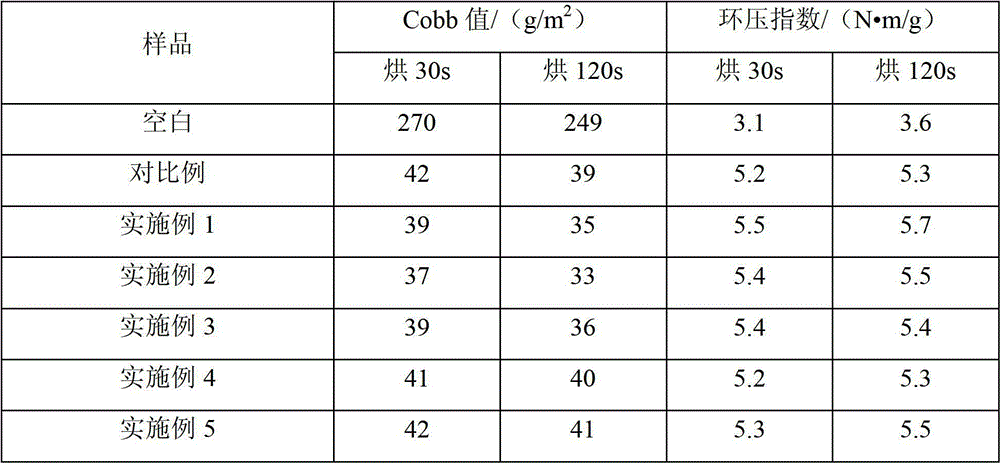

A kind of preparation method of surface sizing agent for corrugated paper and its product and application

ActiveCN106245431BReduce dosageLow cost of industrializationWater-repelling agents additionPaper/cardboardAcetic acidPulp and paper industry

The invention provides a surface sizing agent used for corrugated paper as well as a preparation method and application thereof. The surface sizing agent used for corrugated paper is prepared by uniformly mixing a base material of the surface sizing agent used for corrugated paper and a cationic additive, wherein a preparation method of the base material of the surface sizing agent used for corrugated paper comprises the following steps of: adding cationic monomers, zircon salts, acrylate (methacrylate) monomers, styrene (methyl styrene), initiators, acetic acid and water to a reaction vessel to carry out free radical polymerization reaction, thus generating the base material of the surface sizing agent used for corrugated paper; a preparation method of the cationic additive comprises the following steps of: adding an alkyl ketene dimer to a water solution of cationic emulsifiers and fully stirring the materials to carry out emulsion dispersion, thus obtaining the cationic additive. The surface sizing agent prepared by the method provided by the invention not only can conduce to substantially reducing the Cobb value and can be rapidly cured and be basically cured immediately after coming off a machine but also can achieve the effect of substantially improving the ring crush strength of the corrugated paper under the condition that the dosage of the sizing agent is invariable.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com